All Activity

- Past hour

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

My new burner!!! works well the first pic is at 1 psi the third is at 10 How hot is yellow hot? really hot about 2000 F. I could only go about 12 psi before the flue wasnt large enough. i can get it hotter lol And yea the welding sucks -

Leather work helps me to avoid all my bad thoughts in my head(

- Today

-

I normally say that I work with leather, it is also the term that I would use in Danish. To me leatherworker means that it is your "line of work" I mean what you do for a living. Leathercrafter (to me) sounds more like a hobbyist. But I guess it all depends on where you live in the world 🙂

-

According to Google... Factor Leatherworker Leathercrafter General view This is a broad term for anyone who works with leather professionally. It encompasses specialists like saddle-makers, cobblers, and artisans for fashion companies. In some contexts, particularly in the US, "crafter" can imply a hobbyist who works for enjoyment rather than profit. However, "craftsman" is widely recognized as indicating a high level of skill or artistry. Business vs. hobby The term "leatherworker" is often associated with the business or professional aspects of the trade, where profit is a key driver. The term "leathercrafter" can suggest an individual who is creating items for personal enjoyment. Scope of work A leatherworker might specialize in a single area, such as repairing shoes, or assemble pre-cut leather into finished products. A leathercrafter is more often associated with the process of making a product from scratch—including cutting, patterning, and finishing the leather. Level of artistry While many leatherworkers are highly skilled artisans, the term itself does not always carry the same emphasis on artistry as "craftsman" or "crafter". Many associate the term "craft" with the skill and artistry required to create a unique item. A person with this mindset may use "crafter" or the more formal "craftsman" to emphasize their dedication and skill.

-

If I can make a suggestion mate, you'll find it easier if you turn things around and find a way to slot in the various shapes at the end of the ram. On the receiving end, say you want a right angle you could weld two bits of sharp stuff so the internal angle is around say 85 degrees (guessing) to allow for spring back. I'll try to do a short vid.

-

The non-medical variant is simply called a (foldable) workshop crane. It comes in various configurations but it usually has two wheeled legs that go under or to the sides of the load and an arm (sometimes telescopic) that can be moved up or down hydrolically, pneumatically or with a screw drive. Max carrying weight goes up to two or three metric tons, depending on the model. My mechanic has one in his garage to lift engines out of cars.

-

These leather WWII aviation patches are really impressive. The craftsmanship and attention to detail make each patch feel authentic and full of character. I especially love how the stitching and design capture the historical look of the squadrons. It’s amazing how a small leather patch can add so much personality to a collection or display.

-

First bending bit, this was whipped up to see if I could actually bend anything in this contraption. As you can see it sort of works. Being angle iron the inside is radiused so I cant get a right angle bend, I'll have to file it to square up the inside. I also need to reinforce the underside where the 1/2" rod goes through to make sure it stays upright against the pushing force. Now to make more jig/tools of various shapes, I need one that is like a knife edge so I can get sharp bends, this may need to be made from something that can be hardened. One problem, which I half expected, is that pushing down on the handle causes the other end to rise so the whole thing needs to be clamped down

-

Leatherwork (verb) is the process through which one creates leathercraft (noun).

-

Thanks Wiz. I’ll read up on the p-1206rb

-

I use Leather Work to describe what I do. To me it is easier for the average Joe to sorta kinda have a idea of what my hobby is about. To me a "crafter" would be more like "master" as in a master electrician / plumber / tailor etc. having far better skills and knowledge then myself. kgg

-

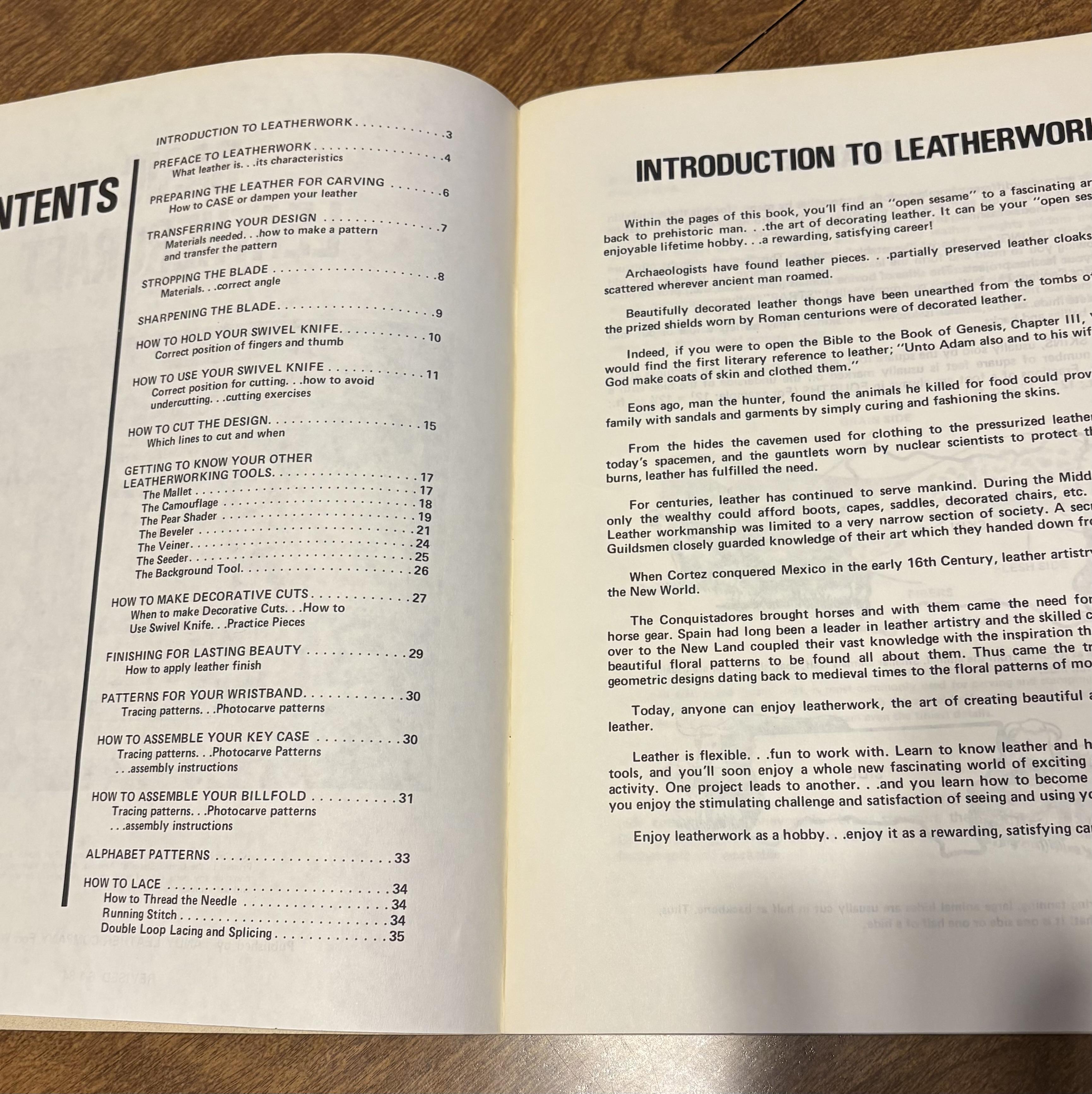

Is that the Tandy/Stohlman and others book? If it is my version says Leatherwork on the cover

-

The first place I landed when I took up the hobby was some "leathercrafter" kind of website, so that tends to be my terminology.

-

Where to get swivel for a holster

fredk replied to Randy Cornelius's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thats a clever idea May I add; just an idea, punch a hole larger than needed and fit a sail eyelet for the C/S to bear on rather than the leather -

Sewing machine stitches slanted-CB4500

RockyAussie replied to Crest's topic in Leather Sewing Machines

If the part you are sewing tappers thinner toward the edge it will often want to feed out away from that edge depending on what feet you are running as well. -

All my first books were titled Leatherwork or Leather Work So I mostly use that word or those words Some ppl on here are shure Leather Crafters, which is far above my mere status as a simple stumbler

-

I use them interchangeably in writing and speaking but I'm sure there is a correct answer. Often when people ask me what I do in my free time, I say leathercraft, and they say, "What's that?" Oh... that means that I make things out of leather. Then they get it. I get similar reactions when I say, ham radio. : ) In which case I say... oh, you wouldn't understand. It's kind of like being on a forum.

-

Kelli DeShazo joined the community

-

The scale will be any metal beyond the blade forming the basis of a grip. Contact glue the 3-4mm leather on to this, either side. Skive and shape the leather to make a firm grip. Tuck one end of the thonging betwixt the leather and the scale. turn it right angle to wrap the grip. Apply weatherproof PVA to the leather on the grip as you wind the thong around tightly. The PVA will give you a little working time and pull apart if the thong is not tight and needs to be done again. If you want, coat with thinned w/p PVA after its finished. If you don't have or cannot get weatherproof PVA you can make it by adding 'Mop N' Glo' (or similar) to ordinary PVA. About 10%. But it also thins it

-

Fred W joined the community

-

As far as I can tell the knife is one piece with no scales, just the bare metal handle part wrapped with paracord. If I understand you, I should use the 3-4mm leather pieces as scales then wrap with lace, then apply the PVA glue over the wrap. Thanks for replying

-

For many of us, this was the first leather instruction book we saw. Note the title. When you open it, it’s about “leatherwork”. What do you call it, and why?

-

Many beginners think laser engraving is difficult because it involves complex software and a wide variety of materials. In reality, the core principle is simple: a focused laser beam etches or cuts material according to preset parameters. Compared to CNC milling, which requires mastering toolpaths and cutting forces, or 3D printing, which depends on layer adhesion and print speed, laser engraver is much easier to get started with. Tools Make Learning Easy Popular control software like LightBurn, RDWorks, and EZCAD provides preset settings for common materials such as wood, leather, acrylic, and metals. LightBurn, in particular, is widely favored for its versatility, affordability, and ease of use. For design, free tools like Adobe Illustrator or Inkscape are available. Beginners can also find numerous tutorials on YouTube, making it easy to quickly learn how to operate a laser engraver. Quick Start for Beginners With just a few hours of practice, beginners can complete their first laser engraving project. Mini laser engraver is an ideal choice for newcomers, they usually offer simple parameter settings, can connect directly to a phone, and are generally low-cost, making them a practical option for anyone starting out.

-

JZC joined the community

-

Bobbin thread tension and thread color

eblanche replied to Gymnast's topic in Leather Sewing Machines

Would you kindly inquire with Amann about your results, if you have a contact? Curious if they may have a response on this, whether it be normal or unnormal. Thank you for providing these results! - Yesterday

-

That machine looks very similar to the Consew P-1206RB. It could be the forerunner of the 1206. Maybe the specs on the page will apply to your machine.

-

Agreed LOL Yes, that is true

.thumb.jpg.df03483a8f149b5c3635266f3ce9bbac.jpg)