-

Posts

7,800 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

I'm here to tell ya that some of the current crop of straight stitch and needle feed garment sewing machines can sew at 5500 stitches per minute! They have forced oil pumps sitting in an oil pan that has a gasket. Scary shit the first time you see them in action. Definitely not for crafters.

-

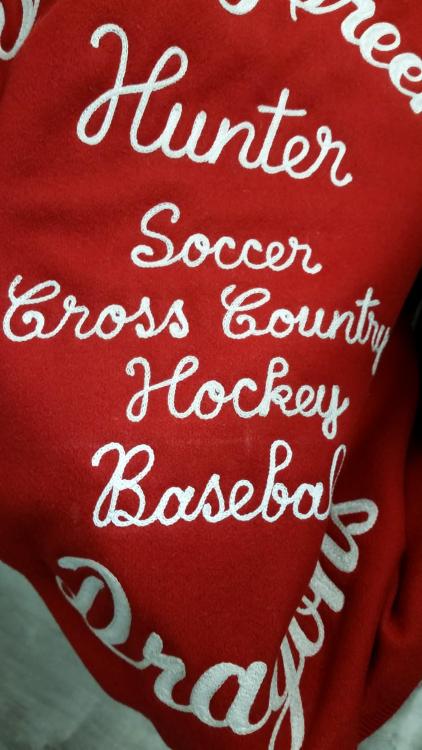

I used to have a Juki LU-563 (no longer made) that I used with 1 1/4" bias tape through a custom built double folder. The modern equivalent would be the Juki DNU-1508NS. One of my customers does freehand embroidery with a Consew 104 chainstitch machine. It produces a fabulous result on jackets and vests because the chain sits on top of the material. It can also produce a hooked rug effect on patches and jackets. There is a learning curve, but it may be worth your time looking around for a used 104. Check out the jacket that was embroidered by a Consew 104.

-

Are you searching for a leather sewing machine or a garment sewing machine? So far, your posts and photos have garment machines in them. This is an advanced garment sewing machine. It is for sewing cloth, garments and draperies at unbelievably high speeds. This is an upholstery, wallets and chaps sewing machine for medium temper leather, motorcycle seats, phone pouches, vinyl, denim and heavy outdoor fabrics up to 3/8 inch compressed thickness. A servo motor allows for precision speed control. This is a heavy leather sewing machine for thick belts, holsters, sheathes, gun-belts, weight belts, saddles and harness. It sews from about 6 ounces to over 64 ounces with very heavy thread. It has both a servo motor and a 3:1 speed reducer that penetrates the toughest stacks of leather at turtle crossing the road speeds. I can sew as slowly as one stitch every 5 or 6 seconds on mine. All of the above are lockstitch sewing machines. You have been asking us about chainstitch machines that are not suitable for jobs where the back side is visible and must not allow the thread to unravel if the chain is broken. You should define what you are wanting to sew and add it to your profile. This will help our members give you more meaningful answers. With a few exceptions, most of us on this forum are not versed in high speed garment construction machines.

-

That's a strange looking vacuum cleaner!

-

Yes, your motor has a cork brake. Give it a little pedal to disengage the brake when you hand wheel. This is a learning curve experience. There may even be a means of adjusting slack motion between full braking and the release point. Otherwise, the brake may have to come off, or be ground/sanded down.

-

No, I don't.

-

That Adler is made to sew moccasins and moc style shoes. That is what the -MO indicates. You will have trouble sewing regular leather with that setup.

-

The Consew 206RB series are clones/improvements of the Singer 111w155. They take the same smooth feet as all other 111 clones. Why not buy smooth bottom feet instead of destroying the ones you got with the machine? These inside and outside feet are sold in pairs by virtually every industrial sewing machine dealer in the known World. Here is just one of many styles of presser feet used in a Consew 206RB or Singer 111w155.

-

All your sewing machines are belong to us!

-

Singer 331lx918 ... Real walking foot .. pics

Wizcrafts replied to Ro9beam2002's topic in Leather Sewing Machines

I have one spring foot Singer in my shop: a Singer 42-5. It works fine without any teeth or positive top feed. But, the teeth on the feed dog are huge! -

Singer 331lx918 ... Real walking foot .. pics

Wizcrafts replied to Ro9beam2002's topic in Leather Sewing Machines

That machine has obviously been custom built (maybe by Singer Co.?) into a dual feed walking foot machine. The shaft on the back of the bed is part of the driven outside foot. A close-up of the foot area will show better details. At best it will be a top/bottom feed walking foot. The needle would remain static, along with the inside foot. The outside foot would be pulling the work back instead of just following the material. -

Overwhelmed by leather Sewing machines

Wizcrafts replied to Starwind0's topic in Leather Sewing Machines

You will find a very well stocked and knowledgeable industrial sewing machine dealer up in Arlington, Texas; Solar Leather Machines. There is another industrial sewing machine dealer in Conroe, Tx, Campbell-Randall Co. -

The Cowboy line includes both Juki and Adler clones. The Juki clone feet will not fit an Adler. But, their Adler 205 clone feet may possibly fit your machine. It is worth your time to inquire at either Toledo Industrial Sewing Machines or Solar Leather Sewing Machines

-

That was my bad. The Singer 111 uses a G bobbin, not L. For some reason I keep cornfusing those pesky little bobbins. Must be getting old.

-

Singer Machine With Table and Motor

Wizcrafts replied to Sheilajeanne's topic in Leather Sewing Machines

You can sew through a vest with just about any sewing machine that's powerful enough to punch holes and pull up the bobbin thread. But, what about sewing patches over pockets? Whatcha gonna do? That takes a universal feed patcher. -

Let me answer with a specific link to a suitable machine for sewing wallets and other items not exceeding 3/8 inch thickness. There are more souped up machines, like this machine's big brother, the Consew 206RB-5 - which has a safety clutch mechanism that protects the rotating "hook" from physical damage, or being thrown completely out of time from thread jams. Since even seasoned pros can accidentally jam the hook, I recommend buying a machine that has this extra protection built in. Later on, when your business picks up and people want you to make custom holsters, look into getting a holster and harness stitching machine.

-

Chinese cobble machine breaking the thread.

Wizcrafts replied to climent's topic in Leather Sewing Machines

Check the needle and the hook for burrs. Wrapping the thread around the sharp toothed foot is asking for broken thread! -

Ads for machines for sale go in the Marketplace section. I am moving the topic. Photos should be posted along with the payment and shipping terms and options.

-

I recently learned that and should have clarified my statement. I repent in dust and ashes! I was thinking about the motors sold by some eBay and Amazon general purpose industrial sewing machine dealers who don't specialize in precision slow speed leather sewing machines. In fact, there is a recent topic about a new member who bought a Family Sew motor online that had a 70mm pulley and all the trouble he is going through trying to refit it with a smaller pulley.

-

Here is a needle\thread chart that explains the correlation between sizes.

- 31 replies

-

- leather stitching machine

- cowboy outlaw

- (and 6 more)

-

Any common brand name triple feed walking foot machine will sew wallets. This is typically a flat bed machine like those seen in upholstery shops. They are built to properly handle bonded (nylon|polyester) thread sizes 69 through 138. Some ise the Singer standard L style bobbins like those used in the old Singer 111w series of the 1950s. Newer machines use a 1.5x "M" bobbin. Juki walking foot machines often have a 2x capacity "U" bobbin. Old Singer industrial sewing machines usually don't have a reverse lever. Most newer machines have a push down reverse, or a single stitch lever that controls both directions. Triple feed walking foot machines usually have smooth bottom feet to avoid marking veg-tan leather (there are all manner of accessory feet). Avoid dual, top and bottom feed walking foot machines as they have aggressive teeth on the feet to drag the material through the machine. They are intended for sewing chrome tan leather, awnings, tarps, drapes and vinyl. Read my sticky article about the type of sewing machine you need to sew leather. While the machine head is less important, the same can't be said for the motor. All upholstery shops use clutch motors for their speed and torque out of the gate. Most newbies to sewing leather projects want slow speed for ease of use and precision on short runs. While any skilled upholsterer can feather the clutch to slow down, it is not so easy for leather crafters who frequent this forum. So, we tend to buy servo motors and sometimes speed reducers to gain slow speed torque and ease of control. While there are a number of servo motors on the market, many of us, including me, use this Family Sew FS-550s, which is sold with a non-stock 2 inch pulley by Toledo Industrial Sewing Machines. Other industrial sewing machine dealers usually sell the motor with a 70mm pulley which runs faster and is harder to slow down without adding a reducer.

-

Singer Machine With Table and Motor

Wizcrafts replied to Sheilajeanne's topic in Leather Sewing Machines

A patcher is also a perfect machine for repairing purse straps and tabs, as well as their zippers. For the small price the seller is asking, as long as it is in good sewing condition, it is a very good deal and will do work no other type of machine can do. I would try it before buying it. -

The inside foot must make contact with the feed dog in order to have the feet alternate up and down. By any oddball chance, could your foot lift chain, or the hand lifter lever be holding the feet up too high? This is the "big bolt" I was referring to (I am not in my shop). It controls the vertical position of the inside foot.

-

Singer Machine With Table and Motor

Wizcrafts replied to Sheilajeanne's topic in Leather Sewing Machines

I use patchers to sew embroidered patches onto bikers' vests and jackets. They are the only machines, aside from freehand embroidery machines, that can sew patches over pockets, or between the leather and the lining. I make about 25% of my leather shop income sewing patches. Once the word gets out that you can sew patches, motorcycle clubs and individual riders will come to you. I even sew patches on for an embroidery shop that makes patches but can't sew them on! If you are or want to be in the leather business, get a patcher.