-

Posts

7,804 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

The holster plate serves one purpose. It raises the leather above the end of the machine and the shuttle cover so that lower shapes can pass by close to the stitch line. Some holsters are sewn pre-shaped, or have belt loops on the back, or other hardware that would get hung up on the standard low throat plate. The holster plate is also useful for sewing dog collars and horse tack so that hardware can slide by close to the left side of the feet. I usually use a right toe foot in these instances.

-

There are different configurations of presser feet to handle particular jobs better than the standard double or split single foot. If you need to sew very close to the right edge, use a left toe foot. If you need to sew close to a raised surface on the left, use a right toe foot. Zippers are usually sewn with a left toe foot that misses the teeth on the right. Edge guide feet eliminate the need to fit a moving edge guide. They come in several spacings from 1/8 through 3/8 inches from the spring. Most have the spring on the right but some are on the left. Piping feet are sold in sets of matching curvature on the inside and outside foot (walking foot machines). They let you sew extremely close to the piping inside the raised material on the left. There are also double sided piping feet that sew two pipes at the same time. This is just a sample of what is available. Necessity is the mother of invention (Help, I'm A Rock!). As new needs are encountered by the sewists, manufacturers fill those needs.

-

Left Stand Singer 45K Variant → Singer 145K1

Wizcrafts replied to Constabulary's topic in Leather Sewing Machines

Translation: Excellent work and an impressive restored relic well done this machine would appreciate it -

The post may have been to a members only group, or from a person who only shares with their friends. "This content isn't available right now" "When this happens, it's usually because the owner only shared it with a small group of people, changed who can see it or it's been deleted."

-

CB4500 in-line presser foot problem

Wizcrafts replied to voidsurfer's topic in Leather Sewing Machines

That drawing is correct. That is the curved slot that determines the lift by the position of the crankshaft you arrowed. You should zero the position of the feet first, as I described. Then adjust the amount of lift if any change is needed. -

CB4500 in-line presser foot problem

Wizcrafts replied to voidsurfer's topic in Leather Sewing Machines

Loosen the big bolt on the rear-left of the head, where the crankshaft goes into the head. Handwheel (verb) until the tip of the needle just reaches the top plane of the throat plate. Now pull on the inside foot until it meets the throat plate and lock the big bolt in in that position. This is the ideal setting for the alternation of the feet. The actual lift is controlled by the vertical position of the crank in a curved slot, coming out of the body on the other side of the housing that the big bolt crank connects to. The farther the movable arm is from the axle, the higher the lift. -

She's a keeper! Congrats!

-

Cobra class 26 bobbin loading issue

Wizcrafts replied to AdamDavis's topic in Leather Sewing Machines

Make sure you are threading the top thread through the top guide post, then around the top tension disks, around the check spring, up to the takeup lever, then down through the guides to the needle. Make sure the thread stays in the top tension disks and that they don't separate as you sew. The disks should only open when you raise the feet manually with the hand/foot/knee lifter. Make sure you are using the correct needle System. You machine prefers System 135x16 (leather point) and 135x17 (round point). Make sure the needle is all the way up in the hole in the needle bar. Make dead sure the rib side faces due left and the cutout scarf over the eye faces due right! Hole back the starting threads! If the material covers the bobbin thread, hold the top thread under the presser foot for a couple stitches, so it catches and doesn't jam in the shuttle. Insert the bobbin so it unloads opposite the direction of rotation of the shuttle. -

Is there any chance you can convert that file into .jpg format and re-upload it? Windows users cannot view the .heic file format without a purchasing a special commercial decoder.

-

From what I've seen all of the portable walking foot machines have dual feed, not triple feed. This means that the outside foot moves in sync with the feed dog while the needle and inside foot just move up and down. A triple feed system has the needle, inside foot and feed dog moving in sync while the outside foot just moves up and down. When it comes to zig zag walking foot machines, the portable walkers are more likely to offer zig zag than full size industrial machines. The Singer 20 series are bottom feed only. If you do find an industrial walking foot machine with zig zag, it won't be cheap. The Sailrite and its clones max out at 1/4 inch of material sewn. The feet lift higher only to insert and remove the work. Since you have an industrial sewing machine table, measure the opening. Many Singer and clone machines fit into a 7 x 17 inch opening. But, the oil pan, if any, may or may not have the proper cutout for a knee lifter that pushes under the machine. This won't matter if the machine has a pull down crank along the back that is activated via a chain with a hole in the table.

-

For small size thread the check spring travel is also important. If the spring holds onto the thread too long the loop might dissolve before pickoff time. The bottom stopper can be raised to stop the spring earlier. This adds more slack that might help the loop. Another thing is thread twist. If the thread is twisty it might turn away from the hook. You can offset clockwise twist by wrapping the top thread counterclockwise through two holes in the top thread post. I use the top and bottom holes to do this.

-

Define your workload. That will help with machine recommendations. I can tell you that the only current portable walking foot machine that is comparable to the Thompson is the Sailrite. The others are made of lesser materials and may not hold up if you sew leather, or thick seams, or hard canvas or ballistic materials. The Singer 20U is a light duty machine. So is the older Singer 107. What, pray tell, do you plan to sew?

-

It uses System 135x16 leather point or 135x17 round/cloth point needles. I try to buy titanium coated needles because I sew through leather tape a lot and the titanium resists gumming up. Should you need to floor it, titanium needles don't heat up as much. I would stock up on needles in sizes 110 through 160, covering thread sizes T70 thru T135. Get packs of leather and round points. Gross Beckert are very good, especially the Gebedur series. Schmetz are also up there. Orange are less expensive, but I use them a lot in titanium coated needles.

-

The first machine you linked to is a Singer 211G155 or 156 (can't see the front view). I have a 211G156 and use it occasionally where slow speed isn't important. It lacks the slow speed punching power of the 111 series. Otherwise, it's not a bad option. The bobbins are G size, like the 111. Same needles too. I get 5 stitches per inch in both directions.

-

I time my CB4500 with the stitch lever in the zero motion position. This is the recommended position for timing 441 type machines. There is another factor that comes into play when using thin needles and thread with thin leather on a 441 clone. This factor is the check spring. Normally, one sets and forgets the check spring (or never changes it from how it was setup by the dealer). This usually works out for the best when you use thread sizes 207 and larger. It gets a tad iffy with #138 thread and can be disastrous with #92 or smaller thread. This is because the standard setup has a lot of tension on the check spring to control heavy thread during the take-up lever's downstroke. This heavy tension completely overpowers thin thread and can cause the loop to dissolve before pick off time. I would back off the check spring tension until it just drops all the way down to the bottom stopper The stopper itself should stop the downward motion when the spring is horizontal. It may have been set a little lower for heavy thread.

-

You probably won't be happy with a binder machine because the feed dog just moves forward and backward, never dropping down. This forward and backward motion could interfere with your stitch length consistency and corners. Some people can tolerate this 2 way motion, others find it problematic. OTOH, if you are looking for a machine to apply edge binding through a folder attachment, this is a great machine for that purpose. Instead of trying and failing with used machines, write down your requirements, then search for a new machine that meets those specs. Buy once, cry once! Example worksheet Triple feed walking foot, or dual top/bottom feed, or other type of feed?? Cylinder arm or flat bed? (Some cylinder arm machines have accessory flat table attachments) Minimum and maximum thread size? (This dictates the corresponding needle range) Minimum and maximum thickness to sew? (You will be able to lift the foot/feet higher to insert and remove the material and release the thread tension) Safety clutch in case you jam the shuttle? (A safety clutch disengages the drive to the hook to keep it in time instead of possibly getting knocked out by thread jams) Reverse lever? If so, do the forward and backward stitches match? Maximum stitch length you want to use. This may be limited by the reverse mechanism. Foot or knee lifter? If a cylinder arm, flat table on a steel K or H legs frame, or shorty table on a pedestal stand? Clutch or servo motor? Speed reducer? Warranty and dealer service, or self service? Maximum amount to spend on a cash sale? Maximum monthly amount if it can be financed? Once you drill down and find a couple machines matching your desired specs, talk to dealers and see if you can try one out. Bring your leather, or other material. Pick a machine that you feel comfortable using, whether sitting or standing. Don't be afraid to buy a major brand, like a Juki, or Seiko, or a new Adler. I had a chance to sit down and play with an Adler 869 and it blew me away. Unfortunately, I didn't have the kind of money to buy it.

-

I think you guys need to buy the narrow throat plate/feed dog from @RockyAussie

-

Search for a Singer 111w155. It is a compound feed walking foot machine that can sew up to 9 or 10mm (20-24 ounces) if properly setup. It uses a medium size G style bobbin and should be limited to Tex 135 and smaller thread. It takes the common System 135x16 (leather) and 135x17 (cloth) needles. They are workhorse machines that keep on going and going. Check with local upholstery shops to see if they have one they will let go of.

-

Yes, the 132k6 has an early foot walking foot design: a spring loaded follow foot that moves as the feed dog pushes the material on the bottom. The inside foot acts as a needle guide and moves up and down as the outside foot moves back with the material. They were originally meant to sew 1/2 inch thick cotton or canvas buffing wheels using a special spiraling attachment. Despite the massive case and huge bobbin, it is not a leather sewing machine. I learned that the hard way.

-

Apparently, some of the 132k10s have roller presser wheels. See this page for an example. It will definitely improve the feeding vs a flat foot. I used to have a 132k6 and it had trouble sewing 1/4 inch of veg tan with #346 thread using a #26 needle. It did a better job on cloth and webbing. But, I was inexperienced at that time and I didn't know about #277 thread, or if anybody sold it. My solution was to sell it and buy a more capable leather stitcher.

-

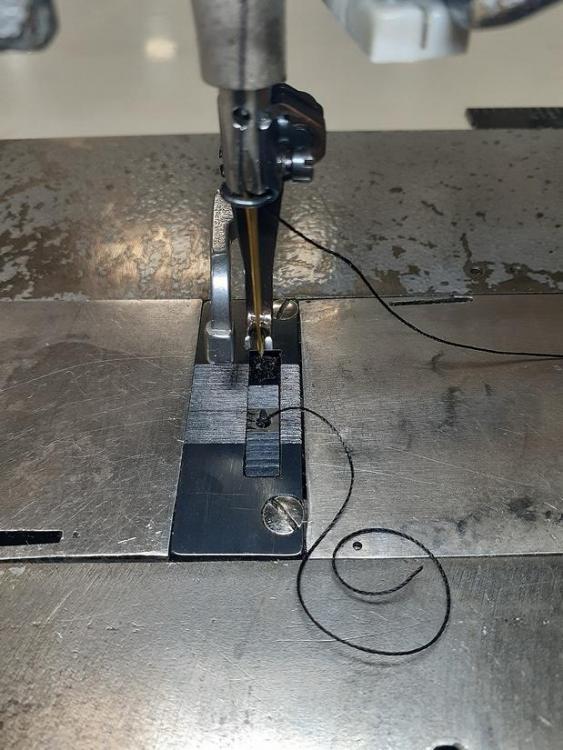

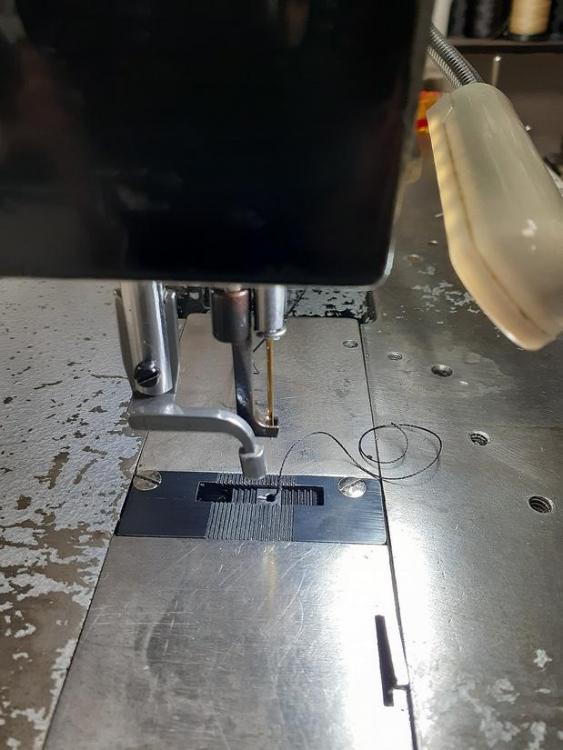

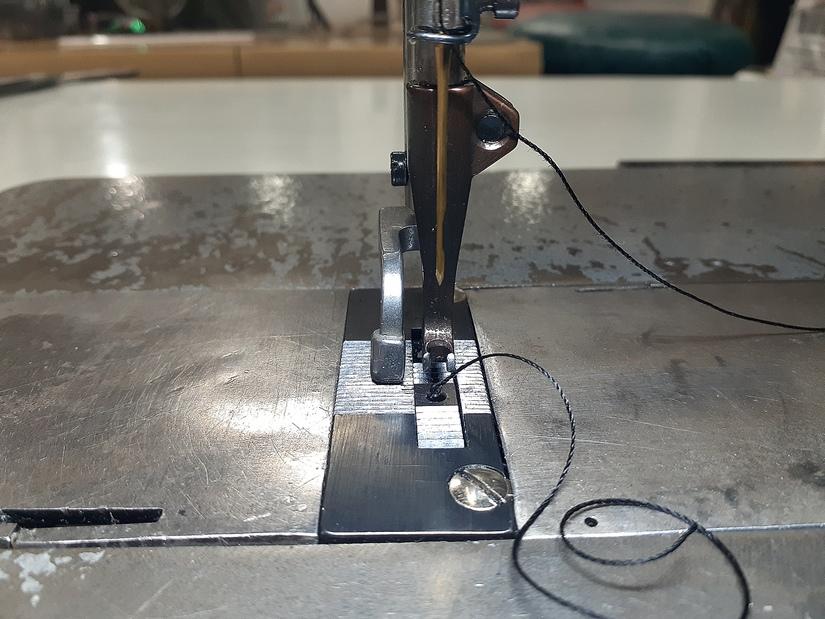

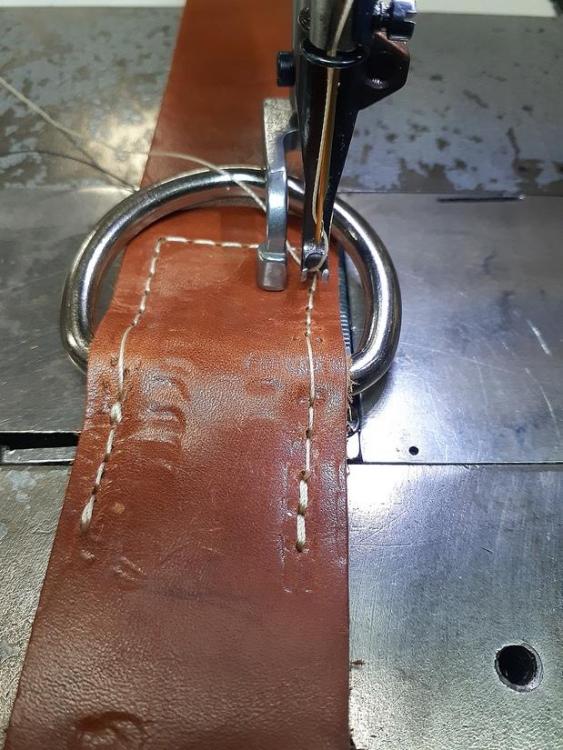

I didn't have much time to play with the buckle foot, but it leaves a deep round foot impression in bridle leather. I tested it sewing on a large steel dee ring. It does get over the back bar with ease. I wouldn't recommend it for bridle or moist veg tan. Maybe bison or chap would hide the marks better. However, the foot is about 1/4 inch from the needle. There is a gap of 1/8 inch on the left of the inside foot. It could have been closer in my opinion. Or, a wider inside foot supplied.

-

I just got a buckle jumping foot from KP last week (it took a month on a slow boat from China). I haven't tried using it yet, but will when I go to my shop. I'm not sure what it is made to accomplish. I'll have to figure that out. I think it might be designed to sew before and after inline buckles or Dees. I can tell you it looks well made and included a narrow inside foot. I'm dubious about the claim it is for sewing zippers. I use a left toe, or narrow double toe foot for those.

-

Consew 206RB-5 Table Cut-Out Pattern

Wizcrafts replied to DavidBraley's topic in Leather Sewing Machines

I am curious. Why did you make that poor decision? You can still buy a knocked down table that is setup for your make and model. It will save a lot of time, mess and probably money too. Most tables include a proper machine cutout with countersunk supports at the four corners, a slot for the belt, a K or H legs steel frame, a motor, a switch box and wiring, a proper length v-belt, a floor pedal and linkage for the motor, either a knee lifter assembly or foot lifter and chain with a cutout in the table, a bobbin winder, a drawer, an oil drip pan with a cutout for a knee lifter (or a fitted and gasketed oil pan for oil pump equipped machines), a thread stand, a tilt back peg and a flex lamp. -

Consew 206RB-5 Table Cut-Out Pattern

Wizcrafts replied to DavidBraley's topic in Leather Sewing Machines

That is because the owner died in March of 2021. The website is still registered until 2023, but all pages now render a 403 Forbidden response. All content has been removed or is concealed.