-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LeatherLegion

-

How hard would be to replace one of those take-up arms and where would i find one ? I tried to move the machine and i dropped it. The thread tension unit needs to be replaced too but i just bought one on ebay. Any help will be appreciate it Thank you ! Ed

-

Wax thread might clog up your needle

-

That's a Ranchero Buckle Blank sold by Tandy ...just visit their web-site

-

-

I tried them few weeks ago and they to the same job as most of the irons out there...punch slanted holes equally distanced from each other ...i don't think the price is justified I also used Wuta(owned the older model) , Kevin Lee and Beagle . I own 3 Beagle sets and i am extremely happy. I like the classic design , the size/weight , the very small hole and the price tag. I would like to get my hands on Crimson Hide's irons , even though the hole is a bit larger that i would want and the angle is not as steep as the other ones

-

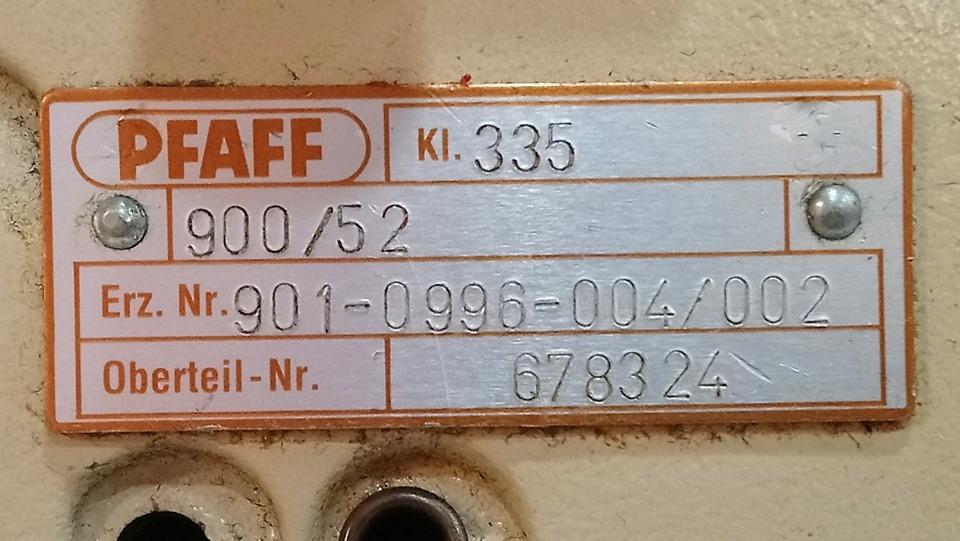

I couldn't pass the opportunity on buying a Pfaff 335 ...i didn't need it but the price was right . Here is a picture of the front plate. What can i learn from it.? I know there are some variances ...H1, H2 , PH1, PH2. I will need to get som e needles eventually and some bobbins.. Any help will be appreciated Thanks Ed

-

Look these guys up https://thread.blackcrowngarage.com/

-

I hammer down my stitches not only to flatten them but to close the holes a bit too

-

Tandy Craftool Pro Stamps Discontinued

LeatherLegion replied to Zonker1972's topic in Figure Carving

In the light of Tandy's new pricing strategy, i am pretty much sure ,if they gonna come up with a replacement for their Craftool Pro Stamps, everybody will be impressed...hopefully in a good way. -

To me is the distance between the stitching prongs i am using for that particular project, most of the time...so instead of using the dividers for my stitching line i am using my 2 prong pricking irons

-

Beagle irons

- 13 replies

-

- amyroke

- crimsonhides

- (and 8 more)

-

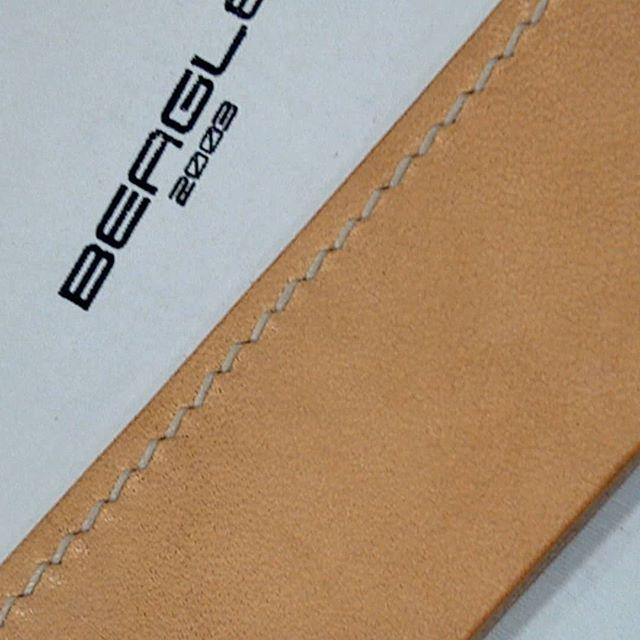

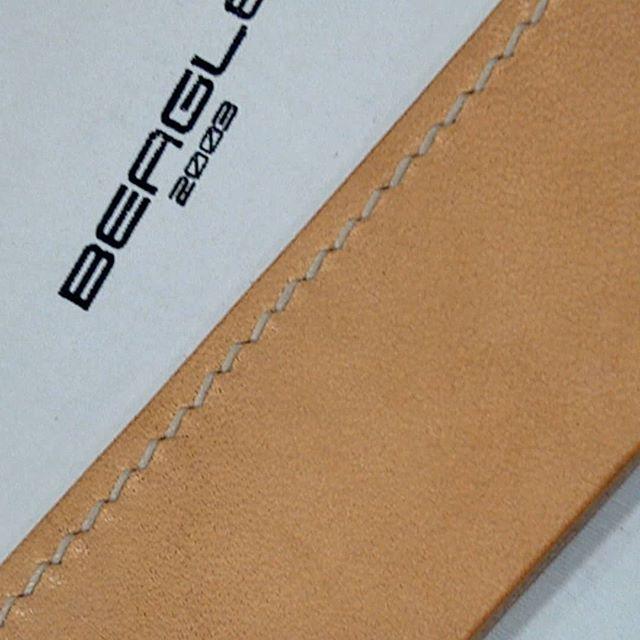

I have the Beagle irons in 3mm, 3.35mm and the 3.85mm .I don't think i can ask more from a set of stitching irons...great price , beautiful elegant design, very well made and probably the smallest hole made by any stitching iron out there. Pictured below are the 3mm using #92 thread (.337mm)

- 13 replies

-

- amyroke

- crimsonhides

- (and 8 more)

-

Makers stamps, who’s the best?

LeatherLegion replied to paulamoose's topic in Leatherwork Conversation

I have few made by LW Leather too , all under $30 and i am very happy with them. I guess his CNC is as good as everybody's else out there -

The Sailrite will stitch closer to edge without worrying about the leather dropping in the feed dogs slot every time the feed dogs are going down.

-

Look up this guys for a wide variety of colors in any weight https://thread.blackcrowngarage.com/

-

Tandy Pricing Structure Change

LeatherLegion replied to NVLeatherWorx's topic in Leatherwork Conversation

This new pricing structure has been in effect in Canada since the beginning of April. Some of the items ,including hand tools are priced even lower than Ebay or Amazon.Affordability combined with the great store experience, makes Tandy the one stop shop , that beginners or advanced leather workers will appreciate even more. -

1.5 amps motor on a walking foot

LeatherLegion replied to LeatherLegion's topic in Leather Sewing Machines

I might end up bolting the servo motor under my work bench and mount the machine only when i need to use it. I can probably cover the cut-out for the belt with the cutting mat when the machine is not being used . Thanks for your input guys -

1.5 amps motor on a walking foot

LeatherLegion replied to LeatherLegion's topic in Leather Sewing Machines

I guess replacing the flywheel with a larger one will help, without the help of an idler wheel? Will that also slow it down a bit too? Thank you . -

Would a 1.5amp motor be able to "move" a Nakajima 341 successfully ? I have a servo motor for that machine but having one of those small motors attached to it might save a lot of space as i don't have room for another full size table in my basement. I am planning on using this machine only for up to 6-8oz ..mostly wallets or light bags. Any other suggestion? Any input would be a appreciated Thank you ! Ed

-

Aren't this the same chisels sold on eBay for $10 for a set of 1,2,4 and 6 prongs?. I have the 3mm and the 4mm. . The 3mm makes very small holes , the other ones , not so small . They are not bad for up to 8oz. Can't go wrong for the price ... they will make diamond shapes holes , 3 ,4,5 or 6mm apart , so if that's what you want you will be happy. . If you are looking for a particular angle pitch , super steel, nice presentation packaging and so forth , then you might have to spend a "little bit" more . A 10 prong will cost you around $11

-

Here is a review ( not mine) on YouTube. At one point they are compared side by side to Amy Roke irons . https://www.youtube.com/watch?v=fzm8A61ZFxM

-

I am waiting on him to release a watch strap punch too. Apparently he is gonna come up with other tools in the near future. Philip Jury will post a YouTube review of those irons ...waiting on that too. Meanwhile i ended up buying a Beagle set in 3mm...front and back side pictured bellow. I used #92 sewing machine thread

-

That's one thing i like ( beside the beautiful design) about the 4Z irons : square tops , regular Allen key (or flat screwdriver) for easy change, including the ability of turning the teeth for an inverse stitch. It looks like they use a 440c stainless that's also used in knife blades, surgical instruments , chisels , ball bearings and so on. But then again , you can't them with 20 teeth like KS

-

I was just looking again on their website for the steel they are using and i found this . I assume it's because the tooth angle has to be set properly too. "Due to technical constraints, it is only possible to replace to replace the blade at head office and you are responsible for roundtrip shipping costs." I just wished it could have been done "at home" and even have few extra teeth included in that price just in case . It looks like i was wrong , the nice wooden box comes only with the $560 titanium gold set . Regardless, still a good value

-

Also you get a nice looking wood box...great presentation . It looks like a lot of leather workers love their KSblades tools and at $180 ( or $360 is you want the inverse set too ) still seems like a good deal. The titanium gold looks stunning. What is the steel used for the prongs? I couldn't find any details on their website. I wonder if anybody had to change any of the prongs yet and how easy is it ?

.thumb.jpg.839f147497785d2d58732bbd82361aa1.jpg)