-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Welcome here - me is Singer-Idjit too because of your 29K58 - when a Chinese seller on Ebay or elsewhere offers new 29K parts then they are meant for the latest 29K´s like 29K71, 29K72, 29K73. That is because the Chinese have cloned these models and keep on making them but the earlier 29K´s in many cases are using different parts. 29K´s are by far not all the same. They share certain pars but especially the gear boxes have changed over the decades. You have at least 3 different sizes of gear box pinions and they are not interchangeable. The Chinese clone makers just do not know the earlier 29K models. They sell parts for machines they know / make but not for ancient machines. So can you blame them? Well - it depends I´d say. It´s like asking a modern Ford dealer for Parts for an F-150 from 1953. Some may know what you are talking but most likely they will have no parts for you. Since you are in Downunder MAFAR is probably a good parts source for you. https://marfar.com.au/

-

Pfaff 145 bobbin/hook troubleshooting

Constabulary replied to medion's topic in Leather Sewing Machines

I would guess some set screws on the hook driving gears are loose. I´d tilt back the machine and check what is doing on the in drive train when turning the hand wheel. -

I´m in the same boat. If you can afford the big machine go for it. Nothing wrong with that. Just wanted to share a different perspective.

-

I meant I could NOT justify... some folks say buy once cry once - maybe true if you have the money and you know you will have a good output. I have seen people buying f.i. a CB4500 and spent big money and soon figured its not the right hobby and sold the machine with a loss. If it is for a business then its a different story but still... Just my 2 cents.

-

Not sure how the tension release works in this state but when you buy the new tension unit you may need the tension release lever rod as well except it is present but I doubt. https://www.ronsew.com/lifting-lever-rod-267265-for-singer-212w/ looks like the upper thread guide + screw is missing too. https://www.ronsew.com/thread-guide-upper-267316-for-singer-211g-211w-211u-212g/ https://www.ronsew.com/screw-200582/ Maybe you should post some good large pictures from rear and front so we can figure if something else is missing

-

Don´t forget the good old Singer 45K or their modern clones like GA5-1 or CB2500. Also the Adler 5. These machines have been used for many decades before the triple feed machines became "en vogue". https://www.tolindsewmach.com/cb2500.html Sure, not as good as the triple feed machines like cb4500 and the like but they work. Depends a little bit how thick you want to sew and if you want to sell leather goods or if you just sew things now and then. I´m using a Singer 45 and for me they work. I could justify a $2000-$3000 machine. I restored my 45D91 ~8 yrs ago and still have it. I´m not selling leather goods but it works for me.

-

Why bother - I´d replace it. Just 2 screws you have to loosen but you may have to adjust the tension unit https://www.ronsew.com/tension-unit-complete-240446-240024-singer-111g-except-111g117-singer-111w-singer-211w-singer-211g-singer153w-singer-168/ https://www.ebay.com/itm/162714404863 https://www.ebay.com/itm/152426630012 or buy local from a sewing machine dealer.

-

Cobra class 26 thread tension knobs/adjustments

Constabulary replied to DieselTech's topic in Leather Sewing Machines

Sorry to say that but needle size matters!!!! Otherwise playing with the tension does not make much sense. If the 2nd picture shows the underside then I would guess your needle size is too small meaning the needle hole is not large enough so the thread knot cannot be pulled into the material. Thread tension is no science you don´t need markings you just have to understand how top and bottom tension plays together (mentioned in all proper sewing machine manuals) and again you have to use the right needle size. Even when a needle thread chart tells you what the "right needle" is in reality it can be slightly different. BTW the lower nut with the marking at 3 o clock has nothing to do with tension. The silver nut on the right (marking at 10 o clock) is just a light pre tension but the main tension unit is the nut with the marking at 1 o clock this is where you adjust the top thread tension in general. -

This is from a parts list for the 211A but for a different sub class. I downloaded it here https://www.universalsewing.com/parts-lists/singer Looks like there belongs and oil reservoir under the hook saddle but again, its a different subclass. I cannot find a parts list for your sub class but I would guess it is the same or very similar. I found it online at MARFAR in Downunder and it seems to be a plastic container. Singer prats number 281048. https://marfar.com.au/products/hook-saddle-oil-reservoir I´m sure you can get it from other dealers too I would try https://powersew.com/ But again - its from a different sub class so I would check with a dealer. On your machine the oil drip pan seems to be missing so it also could be that the oil drip pan had a reservoir as on sewing machines with an oil pump. Insert other media

-

Looks like a 206RB Model https://www.consew.com/view/consew-model-206rb-5

-

IIRC the Adler 4, 5, 104, 105 came ex factory set up for 328 / 214 needles. And I think most of the 204 & 205 also came with 328 / 214 needles. I think the triple feed (like 205-370) used the 794. @TinaD let us know what machine model you have.

-

Adler 205-370 feed dog and needle plate

Constabulary replied to Michiel's topic in Leather Sewing Machines

I would not say it is is impossible. When you go back in the history of these machines then it all started with the singer 45K, then later Adler 5, Adler 105 and the needle plates and feed do were interchangeable only difference I noticed is that the feed dog have different length oval screw hole. I´m using an Adler 5 needle plate and feed dog on my Singer 45D91 I only had to alter the feed dog hole a bit to make it work. Sure the machines 441 and 205 are later / more modern machines but Juki´s have a lot in common with the Singers and the 205 is the later version of the 105 so I would not say it is impossible but I have no direct comparison. Just my 2 cents... EDIT: 2 more cents: Since they are the manufacturer of this device I´m almost certain that they have tested this set before they claim that it works for other machines too. -

Sound like a very big needle size, I guess it is Metric size NM 280 / US size 28 . Can you post a picture or the model number of your Adler machine?

-

if you fear online tracking then use https://duckduckgo.com/

-

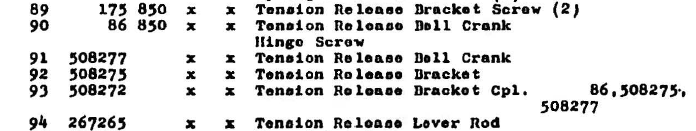

You have not found them? I just googled the part numbers / items description from the parts list. #94 - 267265 https://www.ronsew.com/lifting-lever-rod-267265-for-singer-212w/ #624 - 12361 https://www.ebay.com/itm/125637743697 #89 - Singer screw #175 https://www.sewingpartsonline.com/products/feed-fork-connection-screw-175 #90 - singer srew # 86 https://www.ebay.com/itm/265240279882 #93 - 508272 https://marfar.com.au/products/sin-508272-singer-link so the parts seem to be available - I would check with local industrial sewing machine dealers or with Toledo Industrial Sewing Machines https://www.tolindsewmach.com or maybe with Ralph´s Power Sewing https://powersew.com/parts I would guess an industrial sewing machine dealer can get most parts at once.

-

BTW - 12mm is pretty much the maximum this machine can sew - you may have reached it´s limits or you are close to it...

-

so the problem - I guess - is the foot cannot climb over the thick folded "bulge" right? There were feet (I say were cause they are barely available anymore) with a spring loaded foot sole this foot a easier climb over thick spots but there is no guarantee that it will work in your case. The only available foot for this kind of machine that may work comes from a Seiko SK-2 / Singer 132K. They also fit on Singer 45K and Adler 4 / 5 foot bar (machines w/o jump foot only) but the foot bar height may need some adjustment cause the Adler feet are a bit shorter than the Singer 45K feet. https://www.college-sewing.co.uk/170397661-presser-foot-seiko-singer-132k.html However you may need something something that "equals" the height difference too. In Germany we call it "Hebamme" (word has different meanings) and looks like this: https://schnittenliebe.com/shop/hoehenausgleich/ Check the pictures in the above linked offer so you will see what I mean. When talking about Adler 4 & 5 class machines and sewing over thick spots then the best would be a machine with jump foot (as mentioned above) on which you can adjust how high the foot lifts when sewing over thick spots. But I guess a new or different machine is no option for you, right?

-

Morning - sorry my bad. The Adler 5-6 is a machine w/o jump foot, I just checked my records and I was on the wrong track. The machine ex factory came with a roller foot! I mixed it up with the 5-8 which has a jump foot. The jump foot is a mechanism that enables the presser foot to feed the material along with the presser foot and it jumps back to its position when the feed dog descents at the end of the stitch cycle. The mechanism is not mechanically driven it works just with foot pressure and is pulled back to the front by spring. You can see it in this video at about minute 5:00 https://www.youtube.com/watch?v=QosP-IaqT_E How stick is the material (all layers together) you want to sew? Have you tried reducing the foot pressure?

-

This is what I´m using for resizing pictures: https://www.bricelam.net/ImageResizer/ super easy

-

Have you turned the jump foot mechanisms on or of? I guess you know what I mean. Due to the jump foot mechanism it would require removing parts from the foot bar to install a roller foot and make other adjustments as well - meaning the machine ex factory is not designed for mounting a roller foot. In what condition it the feed dog maybe the teeth are worn. Or maybe the feed dog is se too low.

-

I cannot see how good or bad the stitches are, pics are too small but when I sew NM 20 thread I´m using a larger needle size like NM 140.

-

BTW - this is how my singer 212 (double needle) look from the underside. Maybe it helps. Pic 2 show the junction point where bras tubes for the oil wicks come together a bit closer. How is it looking at your machine?

-

Have you checked in this Forum: https://www.naehmaschinentechnik-forum.de/

- 19 replies

-

- double needle holder

- needle type

-

(and 1 more)

Tagged with:

-

The subclass is not very common as it seems. I´d post post some pictures that may help finding answers.

-

Machine for sewing or generally? I`m a vintage machine guy and have a been bitten by the Singer bug but most likely it would be a Juki 341 or something in this class or a CB 3200 but I´d choose the 341 first I think.