-

Posts

5,757 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Pfaff 335 H2 complete rebuild thread

Constabulary replied to Woehlk's topic in Leather Sewing Machines

That definitely looks super cool! -

definitely and it is no Singer!

-

There for sure is always a pleasure in using quality tools but for me (I do just basic leather work) the 5 in 1 thingy you get everywhere fro 5-15 bucks works fairly good. Got mine from Ebay for maybe 5 or 6 bucks a while ago You can´t go wrong with it at this price - even if it turns out "not so good". I just sharpened / polished the edgers and grover with jewelers rouge and I´m pleased so far. https://www.ebay.com/itm/354015291037

-

access denied 403 could mean Geo Blocking - where do you come from? Machine is still available. 200Km away from me But not what I need.

-

feed stone too low or presser foot to high I´d say. Do you have a manual for your skiver

-

Can´t really help but in case you find a neoprene / rubber timing belt with he right width tooth measures and tooth distance from another Singer machine you can try splicing the belt / making one out of two. LW member @Thomo did this with a 307G2 timing belt which is obsolete too. Just an idea - check this:

-

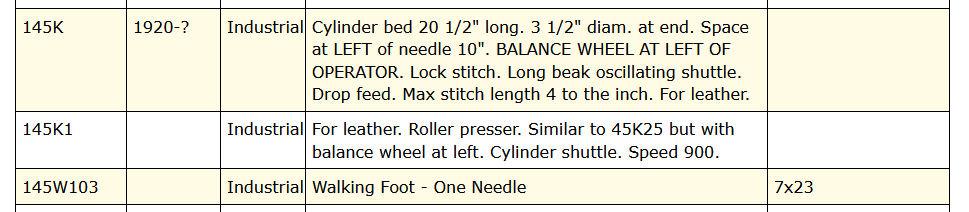

Its a rare machine (needle feed + drop feed but no alternating feet as on the Pfaff 345)! The feet of the Pfaff 141 should work but they are rare too, also Pfaff 141 / 145 bobbins should work. But better check the measures. https://www.college-sewing.co.uk/10079-steel-bobbin-pfaff-145-146-seki.html I would check with College Sewing, they seem to have OEM Pfaff parts as well as generic parts,. maybe they can get you some 141 / 341 feet.

-

Left Stand Singer 45K Variant → Singer 145K1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Parts and paint stripped - almost. Electrolysis did a good job again! Next is cleaning the parts. Most are just dirty and oily, just some rusted but so far not badly I´d say. Fortunately nothing broke! Just some smaller missing parts but I think most can be replaced with regular 45K bits. -

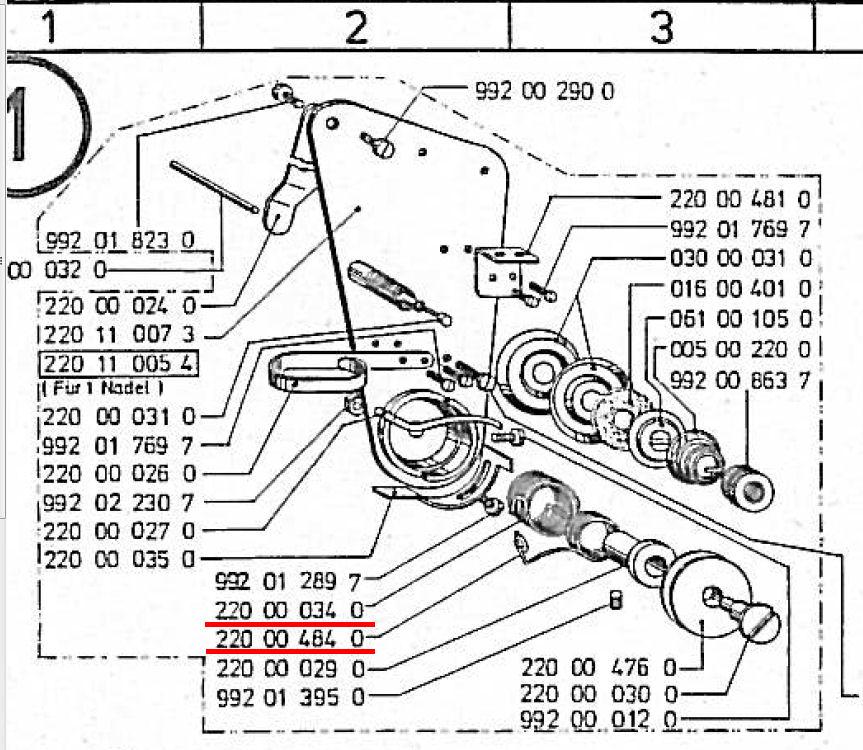

Neither nor - I have a Singer 145K (left stand cylinder arm Singer 45K variant) I´m working on and the tension unit is missing the 2 springs or better some one put an odd DIY spring in it. The regular 45K springs do not work cause they are wound differently. The springs that came to my mind were the Adler 220 springs cause when I look at the tension unit and consider how the spring works they appears to be correctly wound for my 145K. Meanwhile I learned the Singer 144 spring is one piece and the Adler 220 is two piece - like the 45K springs. So my assumption it the Adler 220 springs could work - hopefully - and they are easier available for me. So question is do they fit size wise.

-

fur sewing machine Fur sewing machine information.

Constabulary replied to Sammetje999's topic in Leather Sewing Machines

Looking forward to see pictures of your machine and to see screws you have turned. Always good when people share their experiences!- 16 replies

-

- fur sewing

- help

-

(and 3 more)

Tagged with:

-

Basically the same machine (both based on Singer 111) but w/o having seen them / tested them / knowing details like motor and accessories I´d choose the one with reverse or if both have reverse I personally would choose the JUKI.

-

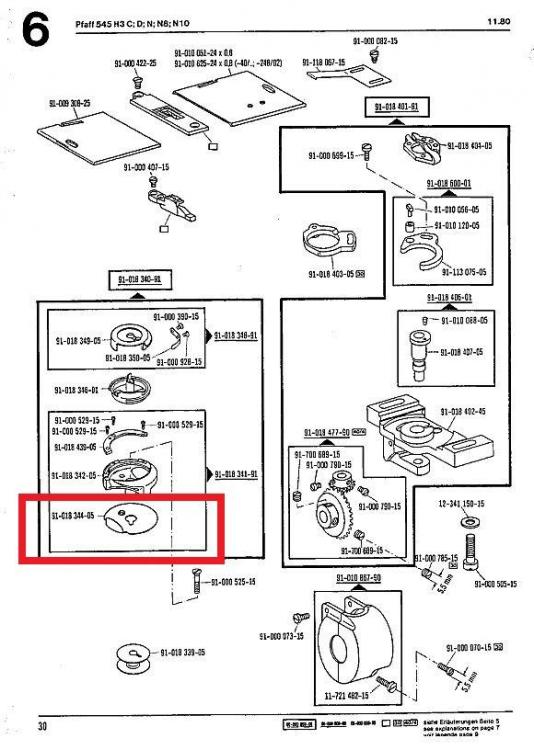

Saving some old cast iron again... Just recently I found a Singer cylinder arm machine that appeared to be a left stand 45K. The picture from the classified ad is the one below and no further information were given. So my rusted cast iron heart decided to pic it up. It was located near Cuxhaven up at the north sea. Gas prices hurt but it also hurts to see this thing in it´s current condition and probably end up at a scrap yard or as a "boat anchor" or garden decoration. So I figured it is a Singer 145K1 (name plate is present). Regarding its serial number the machine was built in 1939 and only 50 (fifty) of them were made at that time. While crawling through the ISMACS serial number lists I figured only 220 of them were made between 1919 and 1949 (regarding their lists). So this really is a rare bird! I will inspect the machine and I hope not too many parts are bad or missing - we will see.... The stand is a DIY stand obviously, not sure what to do with it. This thingy will keep me busy and my fingers dirty for a while, I think. Note for Jimi: it will be black again - not silver.

-

Help in identifying this skiver please

Constabulary replied to BrissyTrimmer's topic in Leather Machinery

I once restored a Textima skiver for a LW member here and the "dog bone" was missing too . I cut a "801 bone" in the middle and put a piece of tube between the 2 parts - worked w/o problems. This was the one: -

then add sewing machine to your needle bar search and you for sure will have more proper results

-

to start with when the hook is not picking up the top thread f.i. when needle bar is too high when the needle hit a hart spot (needle plate...) and the NB has been pushed up and so forth...

-

Even when you have a driver license it does not mean you are a good car driver. Same with sewing machines - you may have read the manual (really do that! Even print it and have it next to your machine) and watched a lot of videos and still things go wrong.... There is always learning curve.... One day when you have fixed enough sewing machine issues you will solve these tiny issues in a heart beat without thinking much. But even then, there will be always something new left and right of what the manual says.... Thats where experience jumps into the sewing machine game.

-

Help in identifying this skiver please

Constabulary replied to BrissyTrimmer's topic in Leather Machinery

I hope I get this thing done - one day - maybe... Back then (actually 2017 as I figured) I ordered a few parts in Poland for the nowadays 801 skiver (they all seem to be the same) and the parts worked for my skiver. You may have a source in Australia too - maybe MARFAR or you check ALI Express or Ebay for 801 skiver parts You can download a manual and parts list for the modern 801 skiver here - you for sure find a lot similarities. https://www.shoesystemsplus.com/Supreme-TK-801-Leather-Skiver_c_93.html -

@David Bruce

-

Help in identifying this skiver please

Constabulary replied to BrissyTrimmer's topic in Leather Machinery

finally.... here is mine. I restored it a few years ago (2 or 3 or so) but never really finished it , still missing some pulleys. Has collected quite some dust meanwhile. Looks very similar - Mine is a Model W (what ever that means) -

Broken Adler 67 hook cover ring - Compatible parts?

Constabulary replied to andru's topic in Leather Sewing Machines

And college sewing do not have it? I can look in my bins maybe I have one. But I´m in Germany. EDIT: Answered it myself - out of stock https://www.college-sewing.co.uk/068150910-hook-gib-adler-genuine.html EDIT II: I don´t have it - sorry -

I honestly never expected that this thing will ever sew again! Congratulations! Assuming needle too far away from hook of needle bar set too high.

-

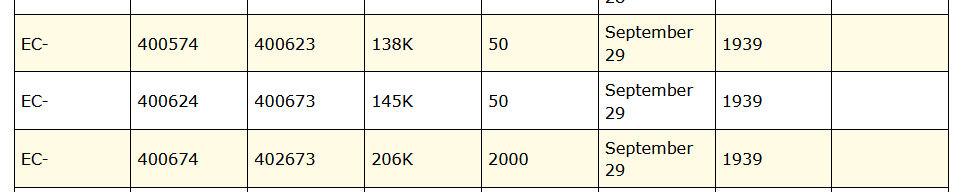

Help - Need a part # for my Pfaff 545-H4

Constabulary replied to suzelle's topic in Leather Sewing Machines

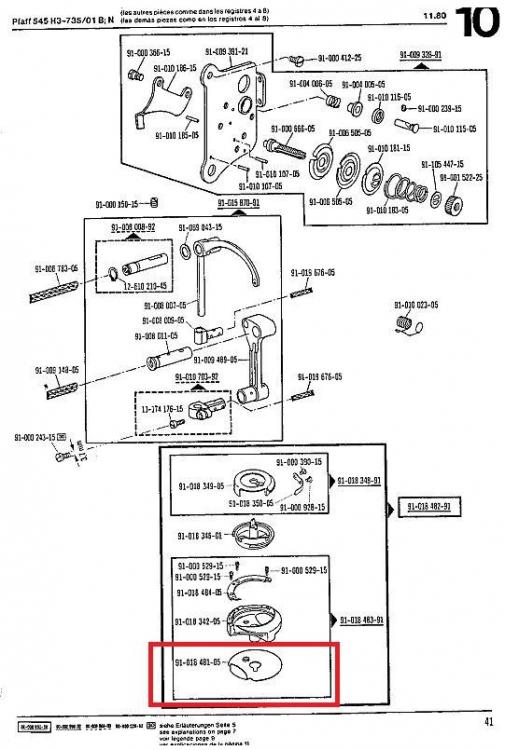

hm - sorry - I probably mixed up something. But further down in the parts list you find the needle guard 91-018-481-05 also listed for the 545. So it may depend on what hook gib you have - Hook gib seems to be the different and maybe therefore the needle guard is different too. -

Doberdan (or was it dobro dan) Just curious - directly from Serbia or Srpska?

-

Cobra 26 presser/walking foot marking up leather

Constabulary replied to AtomicLeathers's topic in Leather Sewing Machines

then you either try to find a lighter spring or cut down the existing spring