jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

They still sell the top and bottom feed machines today, i think consew has one and the chinese copy´s also. I think they were mainly for heavy duty work, thick leathers and rubber.

- 72 replies

-

- fortuna

- leather machine

-

(and 2 more)

Tagged with:

-

Yes, the hole is in the same position

-

That seems to be going along great sainte, Nice work, i see now it is a top and bottom feed.

- 72 replies

-

- fortuna

- leather machine

-

(and 2 more)

Tagged with:

-

-

Needles to old Claes & Flentje mod. Militaria or Sattler No. VIII

jimi replied to Oluffen's topic in Leather Sewing Machines

Sorry johan, i do not know what version it is -

Needles to old Claes & Flentje mod. Militaria or Sattler No. VIII

jimi replied to Oluffen's topic in Leather Sewing Machines

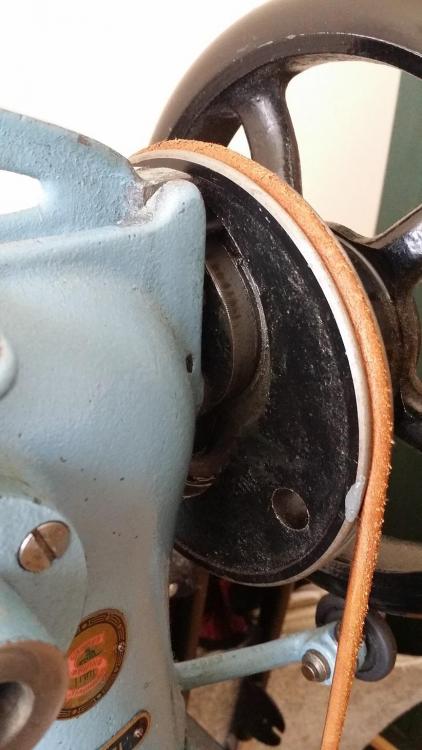

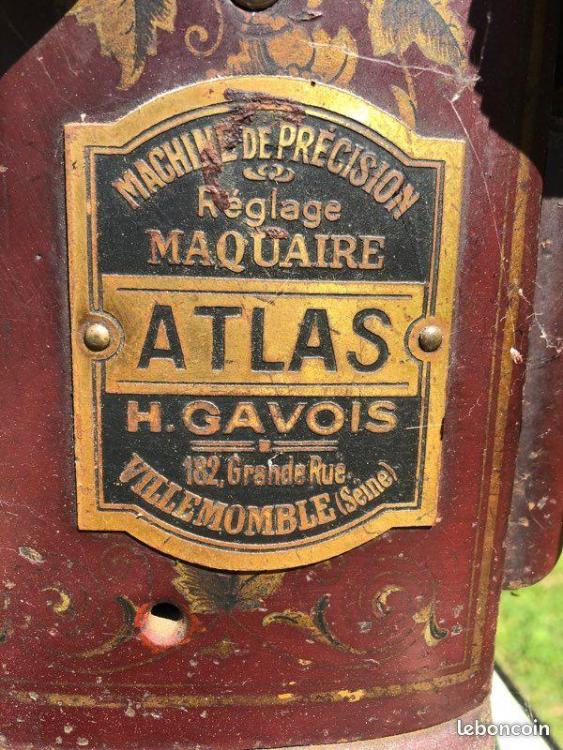

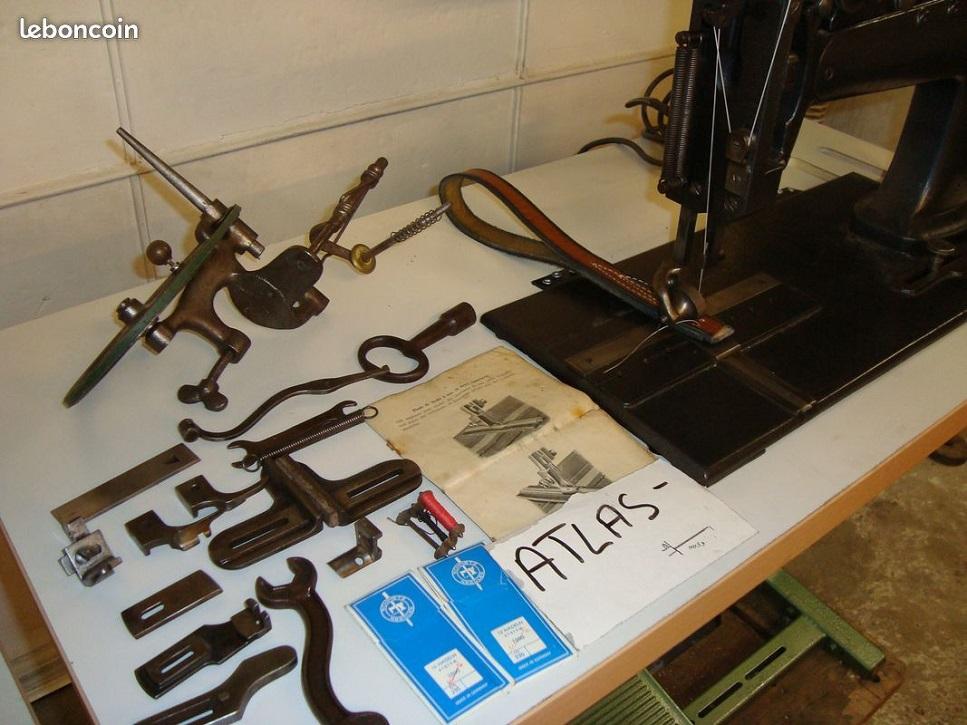

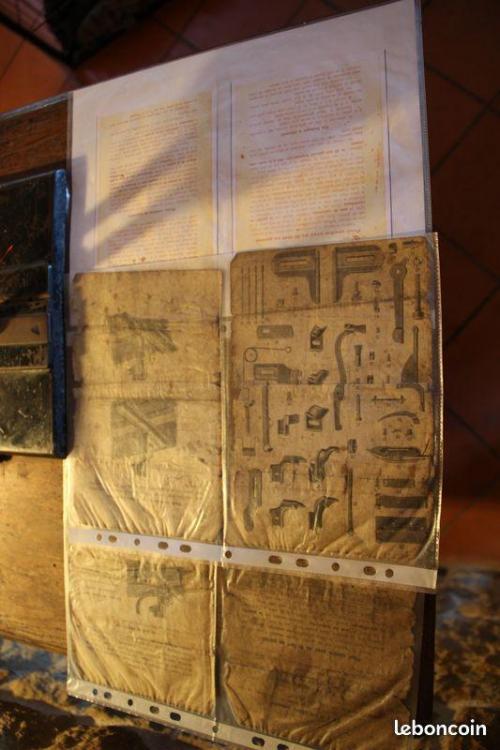

Atlas had the same type of machine, here are some pictures i have just found on the net. This red machine seems to be selling for 50€ so if you need spares you can look it up, The name of the site is on the picture. There is a black machine with white thread which might help you threading it up correctly. -

oohps i thought it was the other machine

-

I iam imagining your machine is the same as the Singer 45k so If you want your foot to come down on the needle plate when you lower the bar down you need to take of the face plate, lower the bar then loosen the screw/s on the bar where the spring rests, then once resting on the plate tighten again. Make sure you don´t tighten it up again with you foot squint otherwise your needle will hit it.

-

Welcome to the forum and what are the issues? (Pictures are the best way to go, that way someone might be able to spot the problem)

-

Sorry buddy i see you got no response yet? We don´t have that type of press over this side of the pond so i can´t help you out. The most common presses over here are the old Daudé/Vulcan type, the T4 and the waldes which all have screw in threads for the top die. Maybe someone from over your side with a similar press will chime in? good luck.

-

SL 71 patcher problem bending bobbins

jimi replied to localleather's topic in Leather Sewing Machines

Maybe a good idea would be to send a few pictures of the machine threaded? -

Thanks Brian, Looks like you got some funky lollipop yellow 335´s in you shop now

-

-

Attaché test piece based on Philip Jury's course

jimi replied to scrapyarddog's topic in Satchels, Luggage and Briefcases

Excellent looking briefcase, well done, the kind you see filled with wads o cash So i take it it is mitre/box stitched?? -

Yes the yellow part pushes the pin, , you might be able to get parts to fit from other 335 type machines?? Or ask here on the forum, someone might have a spare to sell.Good luck finding parts.

-

-

Hi there, there are 4 sizes,Check out the chart. https://www.custompartnet.com/tap-size-chart

-

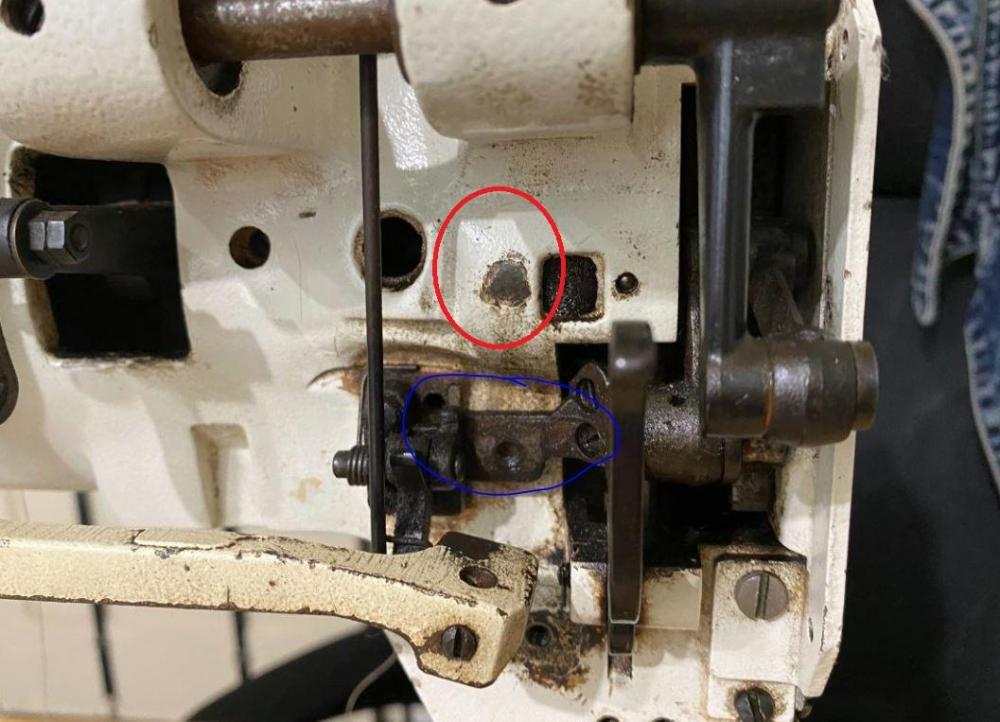

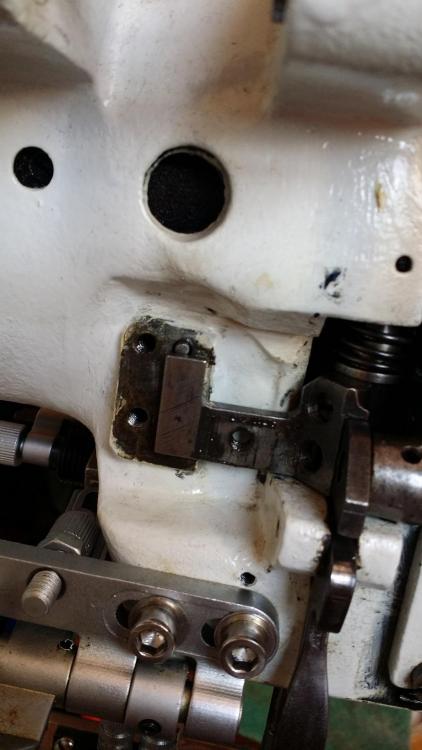

No i have not changed them over but i think they would probably fit, your machine is newer than my Black/white one as it has the square window for oiling, also it is possible they changed the lifting mechanism on your machine as there are two colours of white on the arms and there is a wear spot where the lifting device was before, (see red circle in the picture) The parts in your picture above are the parts you would probably need to convert it back and also the lifting arm.

-

Welcome and That looks like a tin opener FOR YA BEANS!...... Not a clue

-

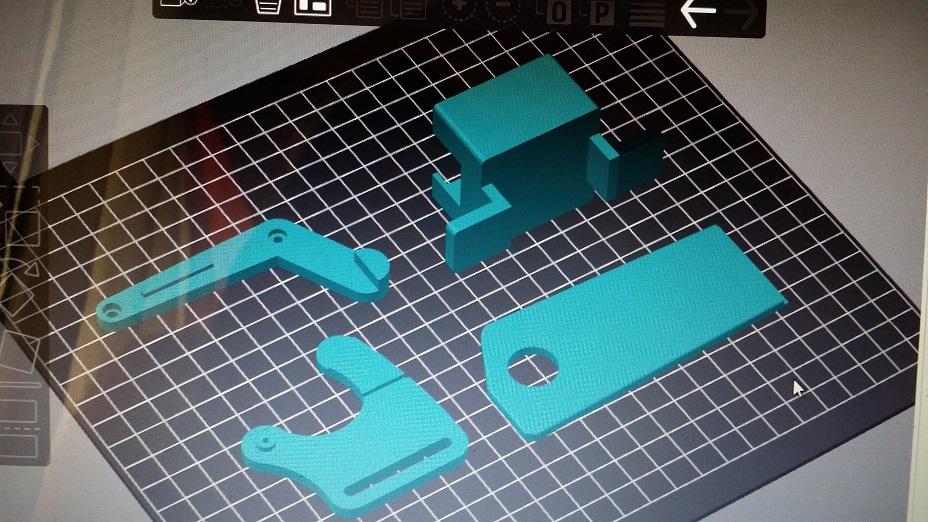

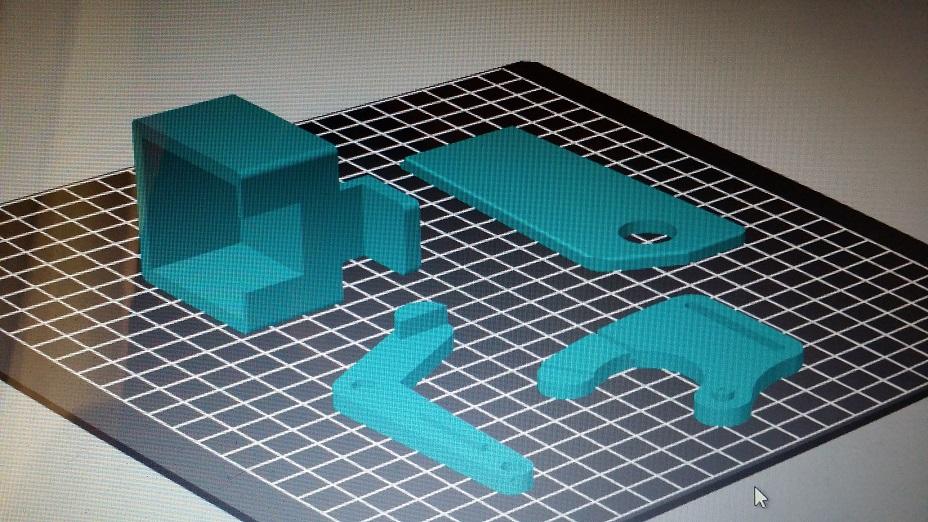

Hi guys, good idea Brian, these files are for a small guide i have been using while waiting on a decent pfaff one to turn up, it is used on the small plate that is screwed on the side of the arm and was very useful. I don´t know if you can use it on other machines? It swings in and out letting you turn etc. The other is the oil box that goes underneath as mine was missing, you will just need to drill the holes. The other one is the small arm plate that goes with the accessory plate with a lip to rest it on. You could just cut it off if not needed. Pfaff guide 3.stl Pfaff guide arm2.stl Pfaff oil box1.stl 335pl.stl

-

-

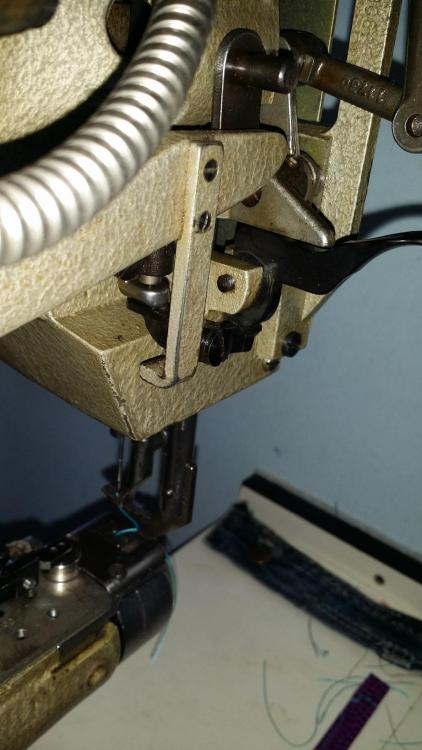

Hi There, here are some pictures i hope that will clarify. In the post there is a picture of a PDF with the parts, they are the same as the ones on the green 335, on the Black/white one they are different. It looks like the part that is connected to your lifting bar may need the parts the same as the ones on the green 335?? On the Black/White one the lifting bracket on the foot bar is higher?

-

-

I think the parts were maybe changed or this is not a pfaff tension assembly, anyway the first post where the thread passes on the assembly is not the same? you have the thread outside on the pin instead of inside the small ring?? See 1st red arrow in the pictures.

-

Hi, first of all I am no expert... I would use some saddle soap to clean/revitalize a little the leather and see how it looks from there??