jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

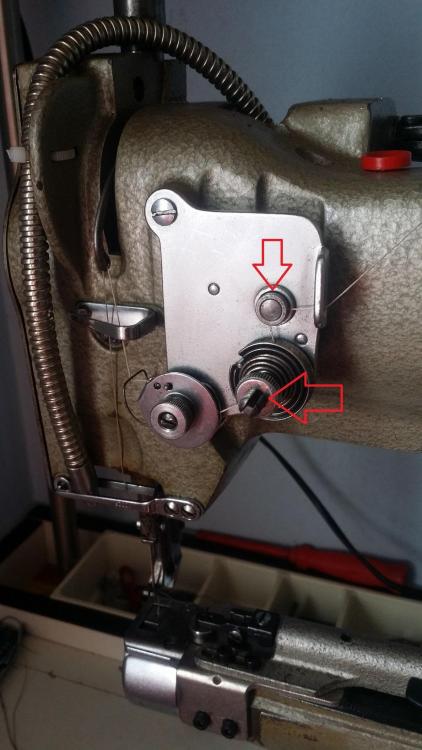

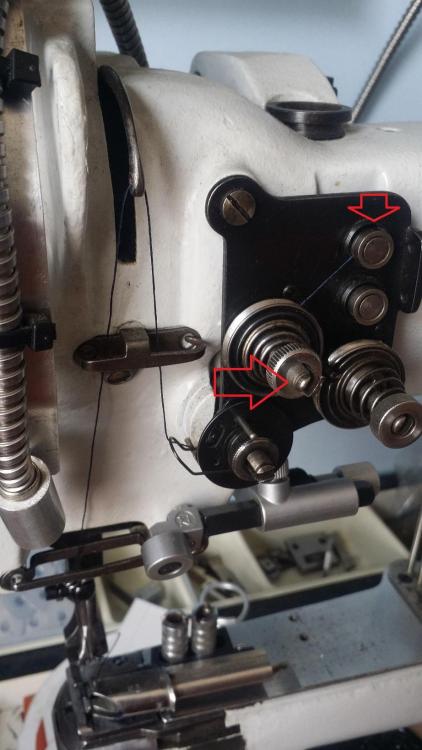

In your picture the thread is not going through the first pin? it looks to be going around the outside, (see picture) also it looks like you have little tension compared to my machines??(see picture) can you send a picture of your tension unit from the side also?

-

Is the tension release pin working when you lift the foot up? If the thread is sticking then take off the disks and see what is causing it to stick?

-

Hey Matt, you will be a 3d nerd in no time nice one, I am sure you will have fun making things for your projects and whatever. I was thinking of jumping to a Elegoo type also for doing the Reel to Reel plugs as i am looking for a better finish but in the end i am still with the filament. So i will be listening to hear how it goes with yours. What i did read about is seemingly the LCD chucks a duckie every XXXX hours and you have to change them??? not sure if this is true or not?? I am almost sure you will be doing some custom stamps?? as 8dsf said the detail is much better.

-

I would pull out the thread and start again, if it is still the same then start to increase the top tension little by little? The only thing i can think of just now is the top tension is too slack??

-

can you send a picture of the thread path from the start to finish?

-

-

Hi and welcome, did you change anything or did it just start to not sew??

-

Thanks for the picture Folker....I think at least it has been out of the crate before as i am almost sure they used two pieces of wood to secure the machine in the crate, you can see the holes where they went ( you can see how they put them in in the film "The Birth of a Sewing Machine") I could be wrong but it looks like one seems to be packed by, probably a person with the Nº33 on Sept 1950 and the other by Nº 32 on Aug 1955?? EF- 902629 907628 95k 5000 July 17 1950 EK- 516453 521452 31K 5000 May 24 1955 these two were in France

-

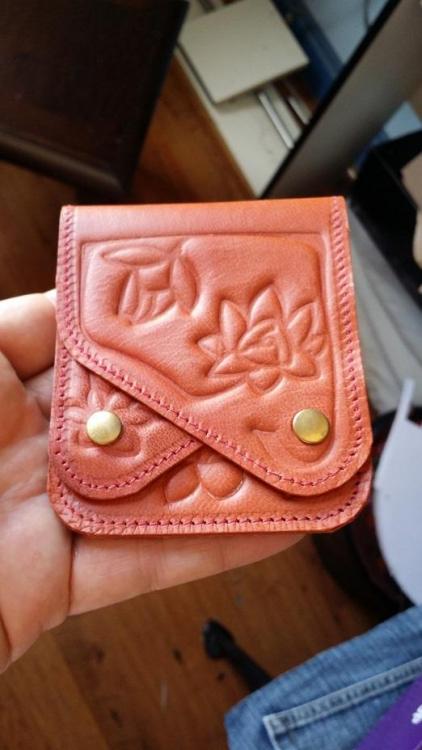

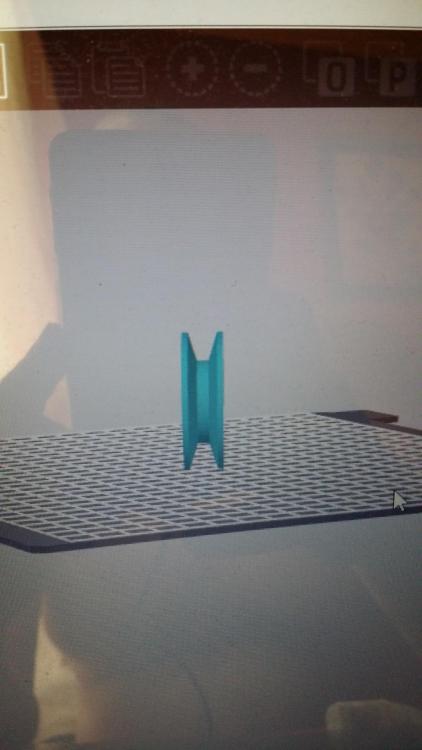

That took 1h54 i think it was to do? The first one there in my hand is still working no problems, i just printed the other one to make sure i was not sending a dud file for 8dsf. I don´t remember changing any flow settings, and last time the cube was 20x20x20.1 or 2.

-

Hi 8dsf, i printed the 50mm one yesterday with support to see how it was, and the support came off good and the pulley just slipped on no problems??? Cannot understand why it was so tight?? i printed this at 2.5 layer height, PETG, no bed heat and standing upright...

-

I think they call it fudging, there are also wheels that do this.

-

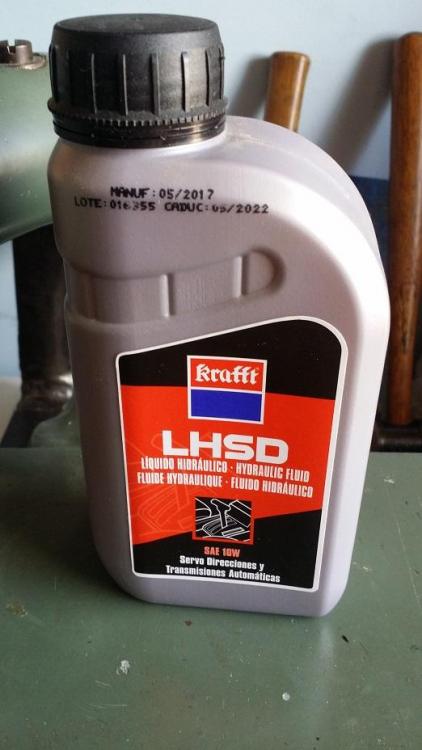

I cannot remember seeing any reference to the type of oil in the manual?? I am sure if you asked Fortuna they would tell you what they use in their machines. For oiling points i use normal sewing machine oil and for the box, hydraulic fluid....the stuff stinks! just as well it is sealed in the box. Until now i have had no problems using this, you normally see people stuffing it with grease.

- 72 replies

-

- fortuna

- leather machine

-

(and 2 more)

Tagged with:

-

Ok wiz, I will stick my next stl there.

-

Just realized i put up the smaller pully oohhps! This is the one that works with the jack servo 50mmpulley.stl

-

Hi There, and welcome, I hope your restoration comes along ok, this maybe sounds stupid, but before restoring a machine which you came by, disassembled!, i would have personally fitted it together before restoration to see if 1- there are any parts missing and 2- if there is excessive wear on the main shaft or bushings etc? I hope i am wrong but a disassembled machine says to me a possible spares machine?? I am sure you will feel satisfied whatever the outcome, the best part of restoring is seeing something useless going to useful. Good luck Sainte.

- 72 replies

-

- fortuna

- leather machine

-

(and 2 more)

Tagged with:

-

Thanks dikman, i do the printing and the cutting and sanding of the pins, the whiz kid does the electronics and programming. There is also another type for the din 8, you can´t imagine how good it is to get a vintage reel to reel working with a remote control instead of a 3m cable like back in the late 70´s Not personally john, but i think you might end up buying a servo motor, and even with a servo i had to slow that down. Yeah, those boxes look great finished Brian, you could maybe use bigger layers as everything is hidden afterwards? have you tried 0.6 or something similar? might be a lot quicker? what temperature do you use for the bed? with the petg i use 60-65 and sometimes an edge will curl up off the bed on the tronxy bed sheet some work with no heat, but not wide prints, they seem to need always a bit of temperature.

-

Thanks Brian, I thought about that on the last print but going over it again and applying the tapered face was tricky as some areas would not OBEY! that´s just me not controlling good the Autocad. But i will try it on the next one for sure but this time from the beginning. That print looks great Brian, 0.1 from here.....I see you have gone to the bowden on this one? That´s a biggie...Any bigger and you will be able to print a new work Shed! These are some plugs that i do for vintage Akai decks...gives you Remote control..

-

Never thought i would get hold of one of these things but....too cheap to see it go to the scrap! This machine was missing a few parts when it came and one was the foot and the clamp for the foot, I printed one up and put a rubber ring on the bottom ( like the originals) to see if it would at least let me see if it was worth looking for parts or not?? It worked! And the needle plate has a printed screw holding it on, this way you can evaluate before spending money on parts for a dud machine? It has its limits, its plastic in the end. And the spool holder on top has a toothed gear on the bottom. it is just for turning with the handle direction. I had an Old pair of jeans lying around and thought i would see how it goes/sews?? Yeah Yeah i know....sticky fingers Hahaha.... and the wifes kindle stand!

-

Ha ha... I think that pulley will work no problems Matt, your dangleberries will be fine I am still using the one i printed in two halfs and no problems with it, just a little creeky the past couple of days?? maybe the belt is dry?? Anyway here is the print altogether if you want it 8dsf. 40mmpulley2.stl I did not have too much luck with the support material coming off on earlier prints so that is why i done it in two halfs, but i am a noob at this... I think you would like it Matt, Here are a few things i have done so far..... this plate was modified by someone so it takes 2 singer thumbscrews which is not too good as they are too close together, I really need to find the pfaff thumbscrew and the small metal plate with the finger to bolck the other hole. It was very usefull until the pfaff guide came along, but it still needs that pfaff thumbscrew and finger. this is a holder for some printers blocks, it fits on the hand press.

-

-

Hi Soren, Looks like this might be another "long wait part" to find?? One solution would be going to a sheet metal worker with the one from your wifes machine and get them to make another the same? Or make one from thin plywood and paint it Machine green?? If you wanted the rounded corners then you would need a square post on each corner to later plane round. Good luck on your hunt.

-

Could you post some pictures of the machines??

-

You should have the Smithsonian website Bookmarked! And thanks to the Smithsonian website Once again!

- 8 replies

-

- sewing machine

- restoration

-

(and 4 more)

Tagged with:

-

Hi There, The list of 16k machines made at Clydebank can be found here. https://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/NMAHTEX/2753/index.htm The part with the pin looks like it was for letting the flywheel run without engaging the feet, normally for winding the bobbin. you seem to be missing the bobbin winder? I would take out the part that is left inside and try to put another shaft on it maybe threaded? The small clip on the plate looks like it could be just for holding the thread tight before starting sewing, And i think the only solution for the foot is to machine another??

- 8 replies

-

- sewing machine

- restoration

-

(and 4 more)

Tagged with:

-

Lw member Constabulary has restored a 16kSV also, he might be able to tell you where to find some parts? Needle size should be 2047-01.

- 8 replies

-

- sewing machine

- restoration

-

(and 4 more)

Tagged with:

.jpg.2bad331e8925eb1682f9b02998584c21.jpg)