jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

Maybe try there website page, or as Arturomex said Campbell-Randall sells feet in the USA. Fratelli Alberti also sells feet for their FAV machines. Fortuna will probably sell them also.

-

Do you hold the two threads when doing the first 2 or 3 stitches?? If not, you should.

-

Here is a video showing a Nippy (bottom) skiver and some of the different options, I think you would be hard pressed to find something similar showing the options for a top and bottom skiver, but i could be wrong??

-

I was thinking of a more specific reason?? and there was

-

OK, so you are using this on holsters, now i understand. Yes good idea, as that would scrape the metal on the gun and mark it. Thanks for clarifying

-

Just curios hildebrand, why would you use the plastic cap on the back of the snap??

-

What part is that???

-

European Aristocrat's Leather Cartridge Belt.

jimi replied to goldfever79's topic in Leather History

Thanks very much for sharing goldfever79, that is not something we see every day. -

Hi, I am no expert but that looks like the paint has bubbled with the heat from the shave, or it is possibly water ?? Also why did you soak the leather all night??

-

Hola, se habla inglés en el foro. por eso nadie te contesta a lo mejor?? Usas el traductor si no sabes inglés.Mandame tu email y te mando una copia, es demasiado grande para subir aquí en PDF. Send me your email and i can send you a copy. If you use the search option you will find info on the 335 in various posts that might help you.

-

Hi Spyros, My son has a soldering iron just like that he got from Aliexpress, looks like someone has rigged it up with some tips from the same site. I have one like the tip in the handle but it looks like the guy who put it together probably put a thread or something on it and adapted it to the wooden handle, mines just slips in and tighten with a screw. Possibly the unit has been dumbed down, as for leather you would need it to be around 80º and up i think?? the soldering rigs go from 150º-450º or something like that. I agree Regad is OTT for what it is. Have fun...jimi

-

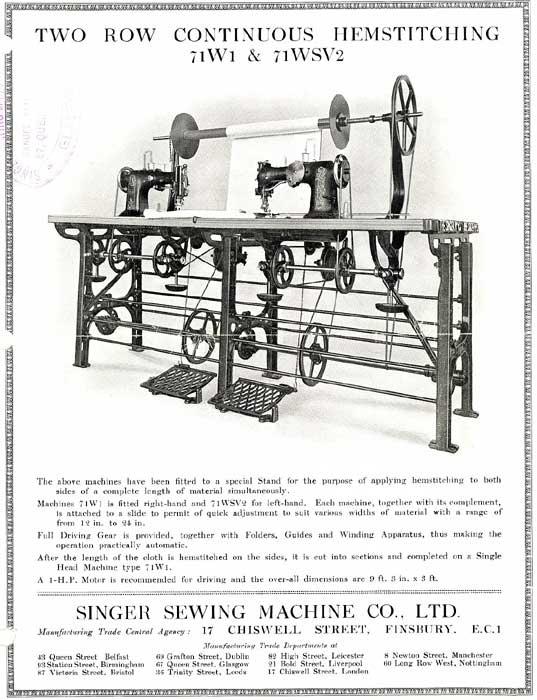

Here is the needle chart for the class 51 machines. Páginas desde Singer 51w.pdf

-

Yes no problem, PM me your email and i will send it, Jimi.

-

Thats looking great sainte, it looks earthquake proof!

- 72 replies

-

- fortuna

- leather machine

-

(and 2 more)

Tagged with:

-

Do you have a 3D printer?? if so you could print one of those bath and wheel type applicators??

-

-

I personally do not see anything wrong with the foot going backwards and forwards?? when the needle and the front foot lifts, and goes forward, the back foot holds your work down?? then when the back foot lifts, your work is carried along with the needle, the front foot and the feed dog. Also the feed dog is usually smooth so no marks on your leather unless you do not protect the feet with a thin piece of leather glued on or something similar.

-

Thanks Brian, Correct, I see you have a hawk eye!!....I could not find any screws and if i did with postage it was a joke so i taped them to M4 and got rid of mi headache. That looks like a job for your 29k with a very steady hand!! Maybe a foot with a guide??? So i take it there is no way to do that opened out and flat?? Thanks, Well when you convert it back you know you have a mini table waiting

-

-

I think the problem Bert is that i took the pictures with the phone instead of using the scanner I will give them a scan and see how it turns out.

-

Thanks Tom, Looks like i need to do some better shots in the future

-

-

Explorer works.

-

This will fit on your bed plate Matt S

-

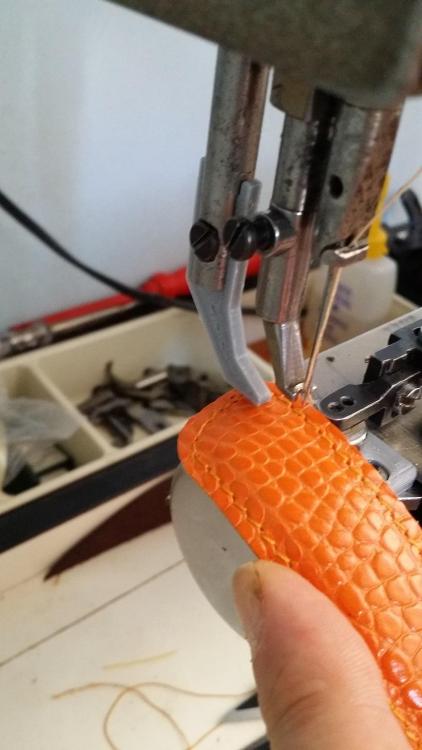

Here is another Pfaff 335 option, I have been trying to do doing some bracelets and found I needed a shorter needle plate to the left, and a inline foot because the bracelets have a hidden cap and post so when sewing, the female part underneath hits the side and angles the work, easiest solution is make the bracelet wider than 25mm, but I wanted to do a 25mm and see at the same time if this will work instead of ordering a cheap copy and grinding it down ( by the way, the last cheap copy did not even fit properly!!). this could get you out of a pickle.... This is 4mm from the needle hole as opposed to the 8mm before. The inline foot hole needed to be cleaned up with a 4.5mm drill bit for it to fit perfectly Pfaff needle plate button.stl Pfaff inline foot.stl