jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

Hi Niles, I am with Bob here, unless imperative.... If you have to separate the machine you might be able to get a old chisel in there to help separate the head from the base, Maybe a little heat if you have taken the paint off? or maybe a few knocks with a soft faced hammer on the back corners of the base, not on the neck! It is a very delicate job Niles so take care, you could break the casting??? I have a 29k12 on a29k1 or 4 base, I had no choice because of the pinions used on the 29k12.

-

Good to hear you have solved the problem,

-

This is a photo i looked for and it is from here on leatherworker, i do not have this machine but one similar without the kick foot. was the 1st tension assembly moved for a specific reason??, I think it´s proper place is on the top left corner of the face plate?. And remember you have to go around the second tension pully 1 1/2 times.

-

Is this a new machine to you? or have you had it a while? I would say looking from the pictures that you need to go a little thicker with your thread for a 160 needle? T210, 207. Did you change anything and then it started to skip or have you been sewing with this setup and not having problems??

-

-

Can you send a picture of your machines thread path.

-

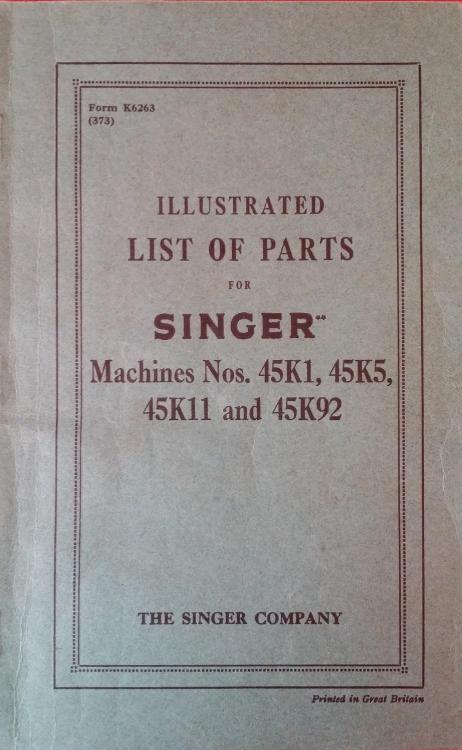

Hello, I`am not familiar with your model of machine but comparing it to a Singer 45k it looks basically the same, i think both of these shafts do not fully rotate, one is for your shuttle and the other for the feed dog, and for adjusting the timing you just need to move the needle bar up or down which is accessed from under the front head plate. So if i was you i would tighten the screws up and put the small shaft back on again and try moving your needle bar up or down for the timing and see if that helps. If this has just happened and everything was stitching good before then it might be the needle size, thread size, or changing from thin to thick leather, These are just possibilities you might want to look at before taking any parts off of your machine.

-

-

-

-

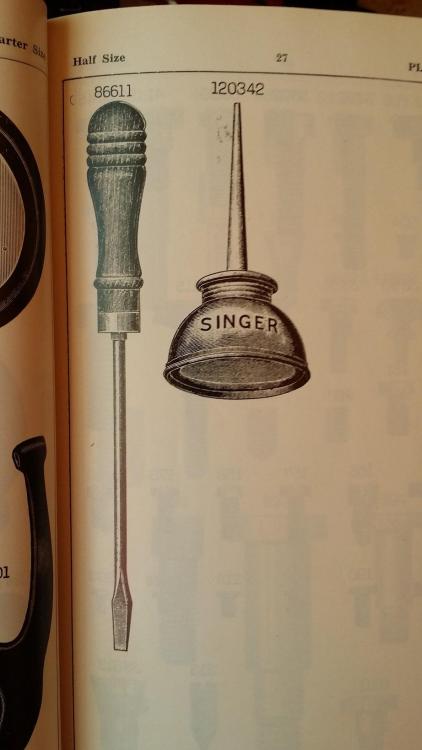

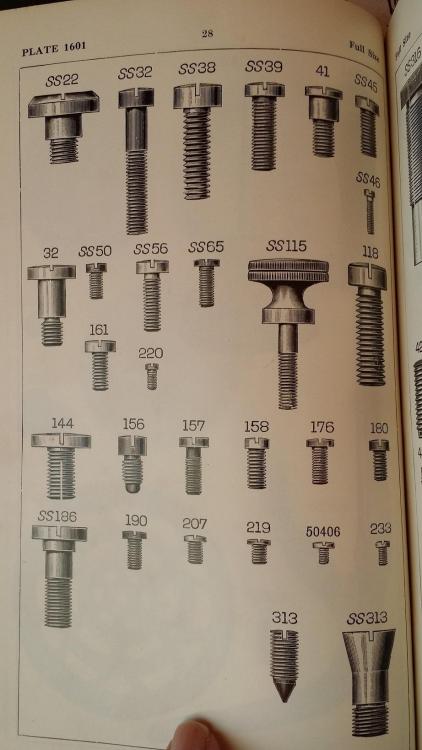

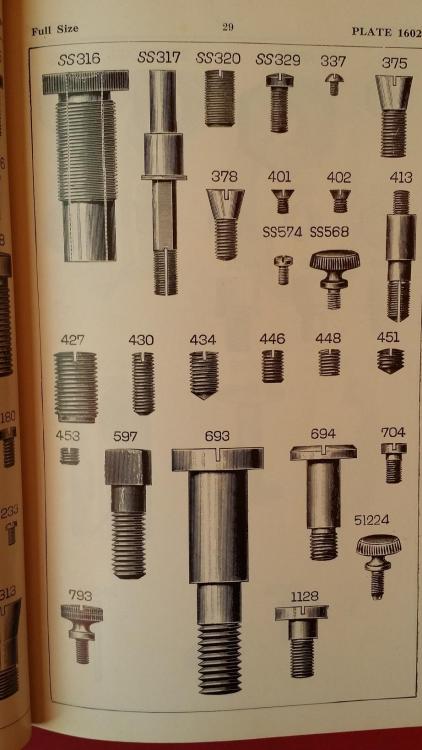

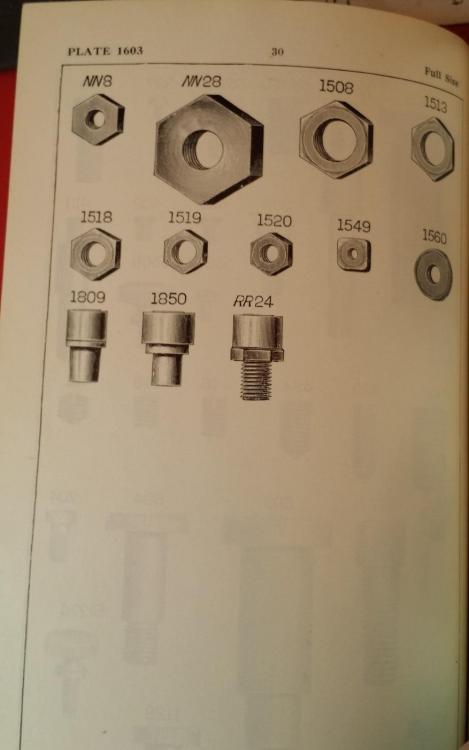

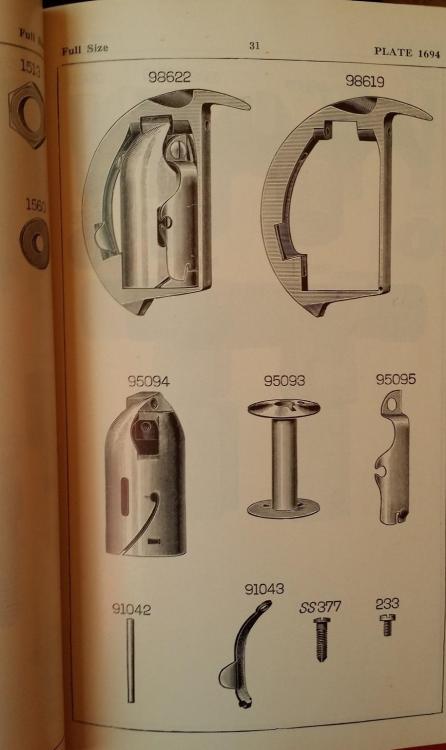

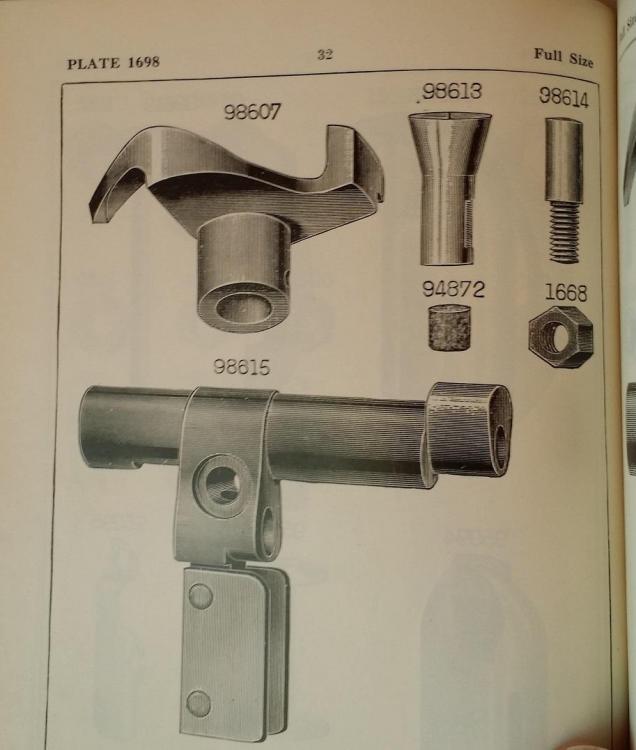

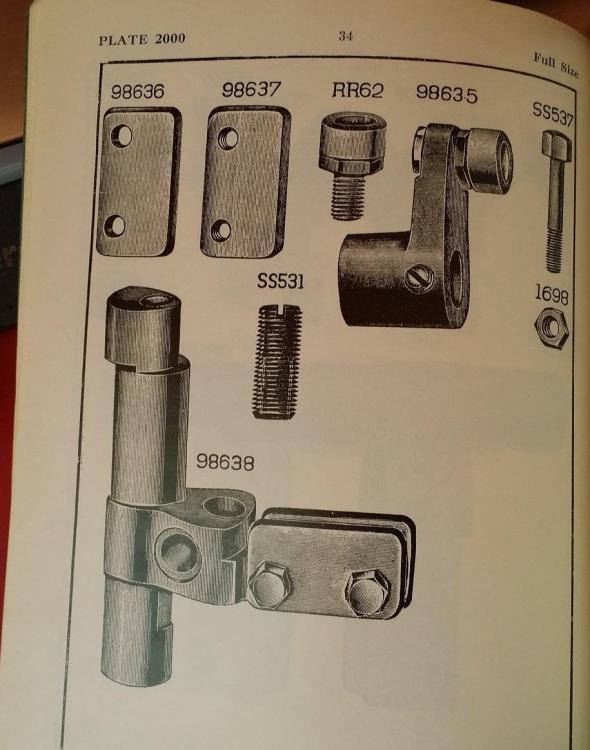

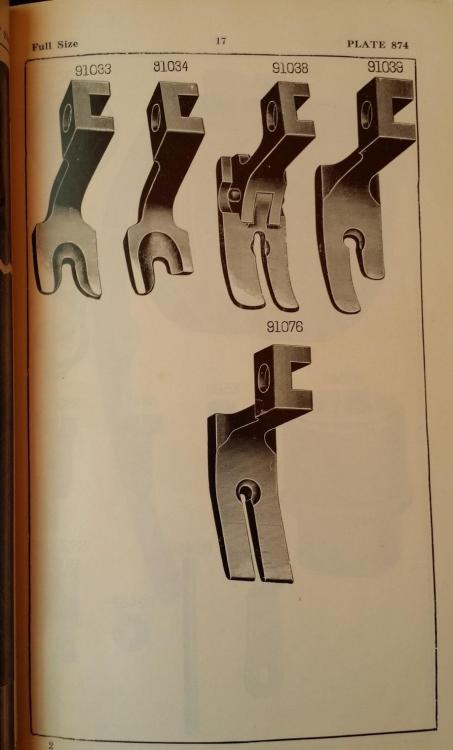

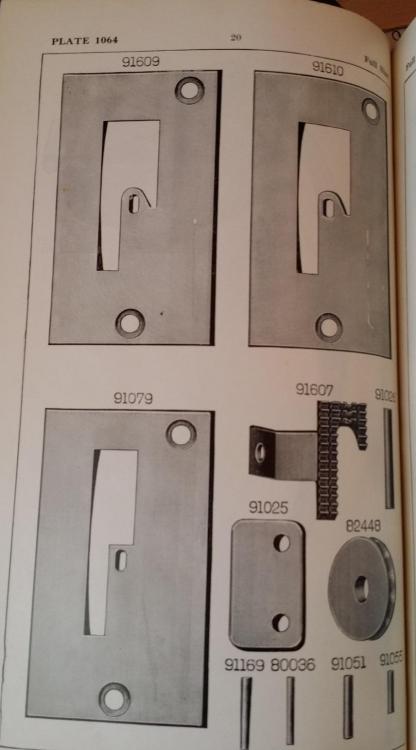

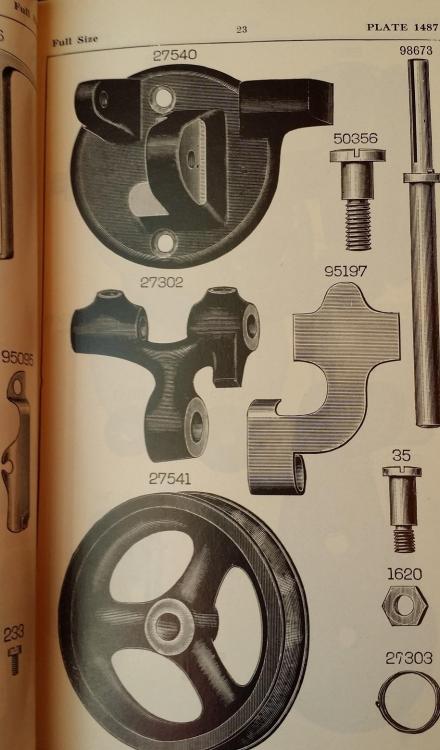

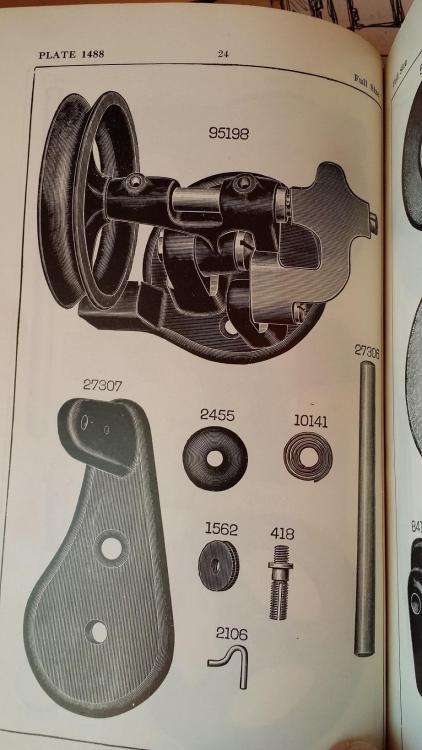

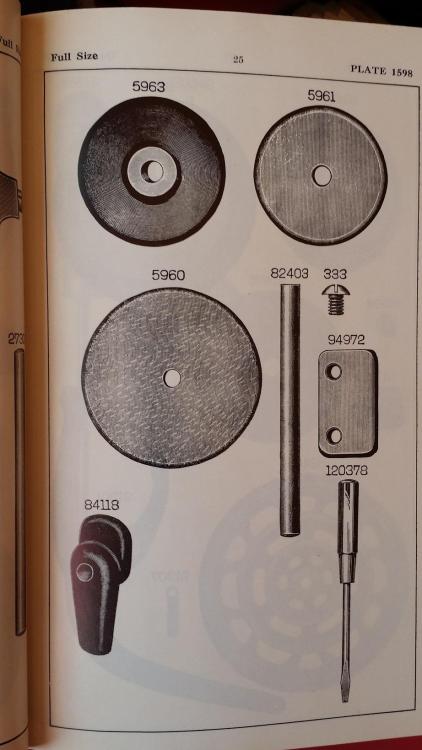

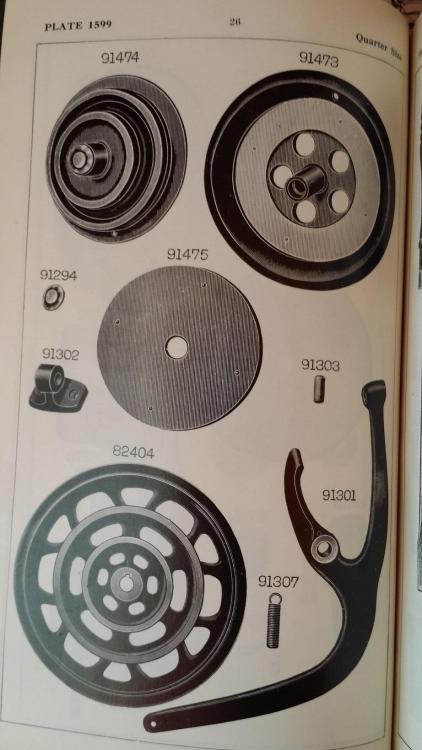

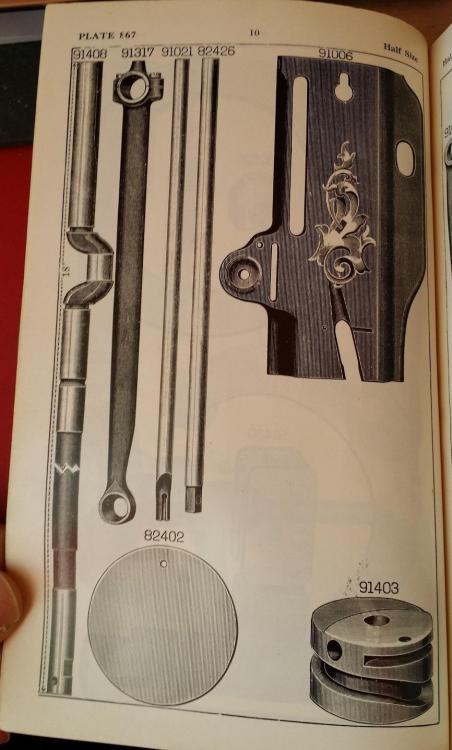

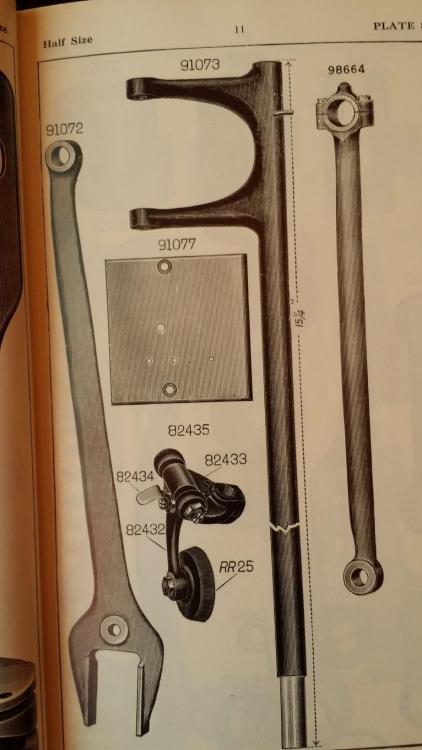

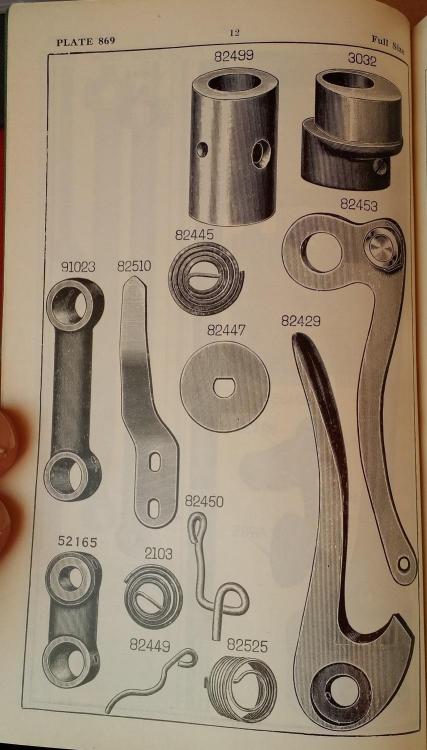

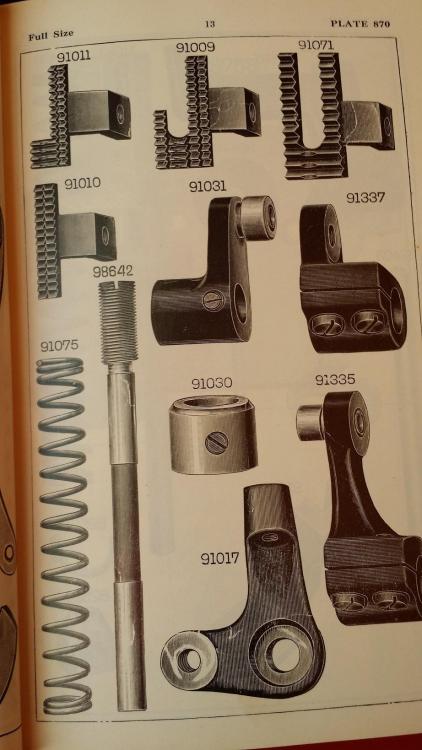

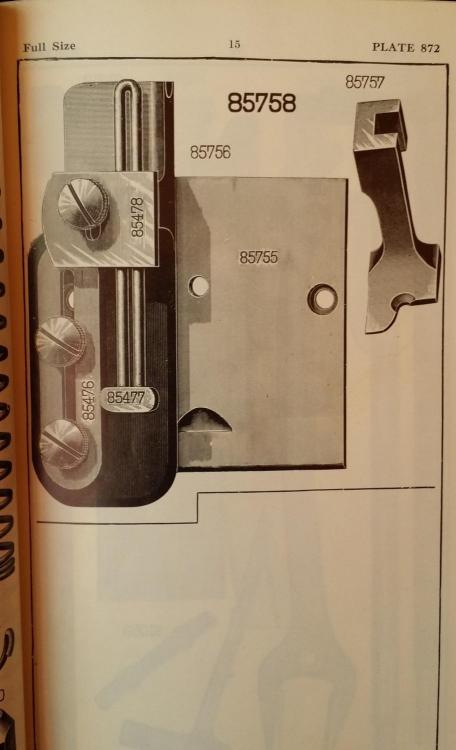

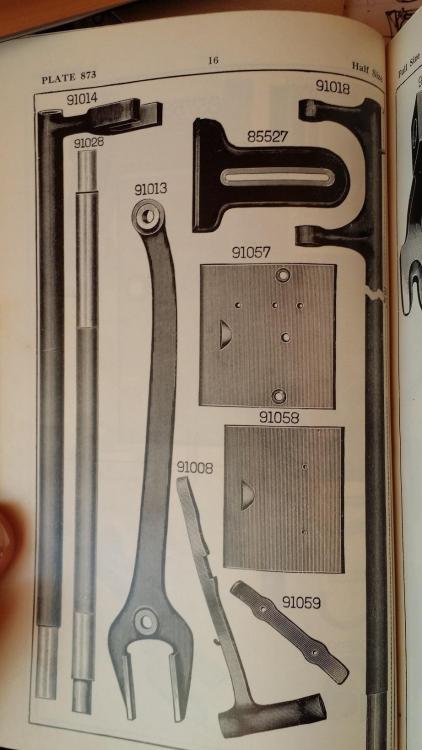

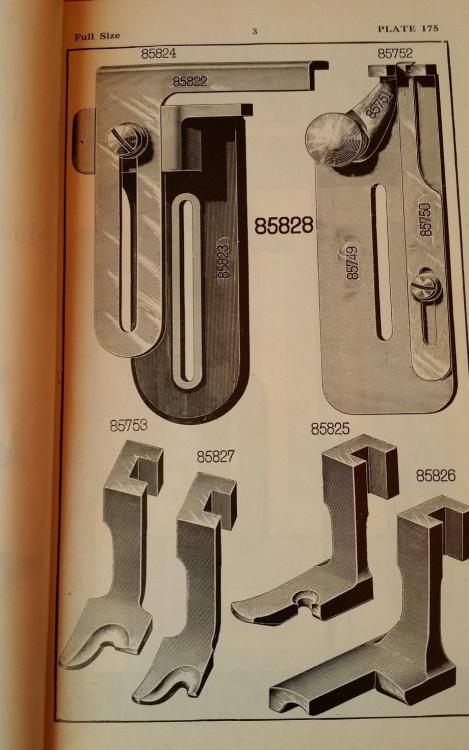

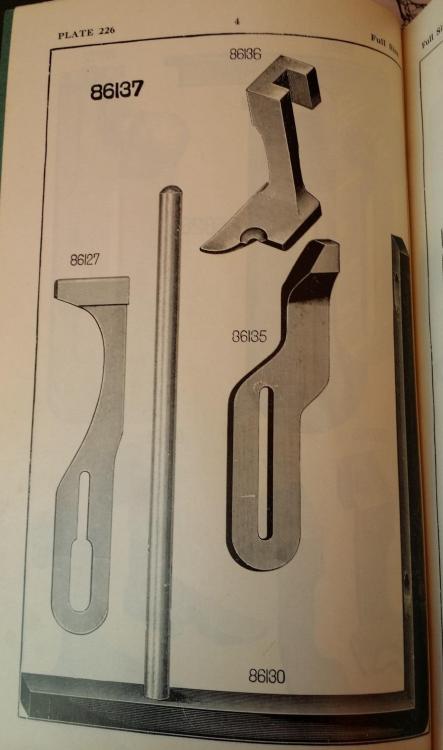

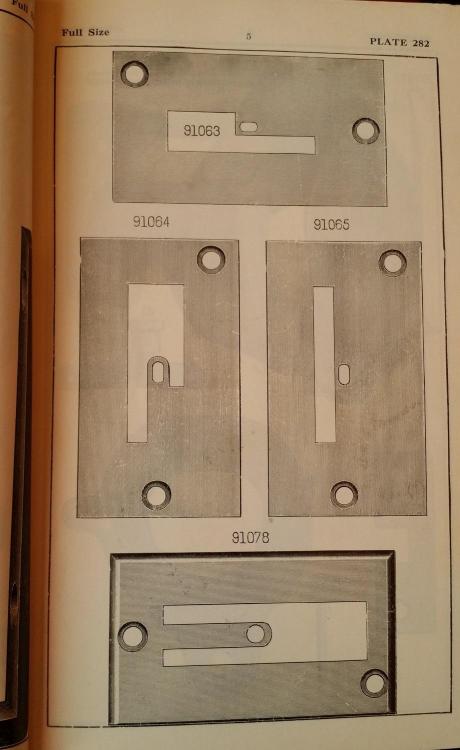

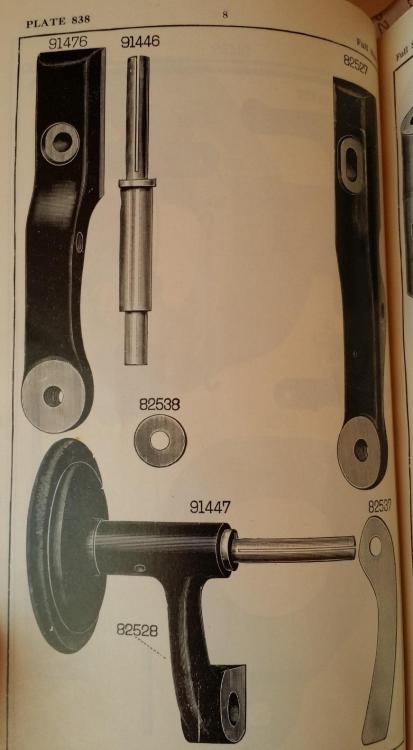

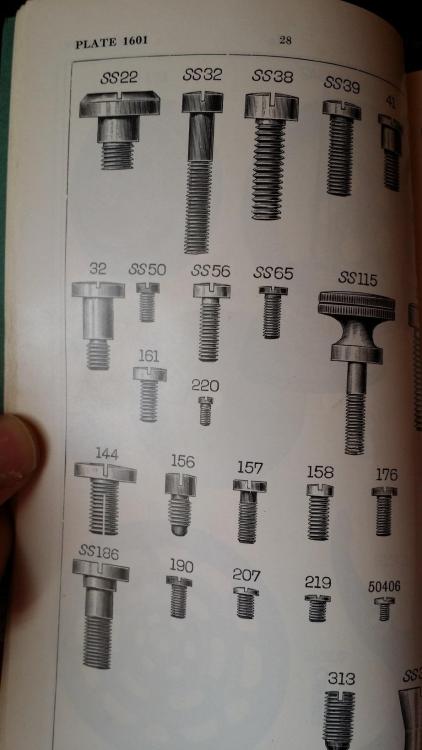

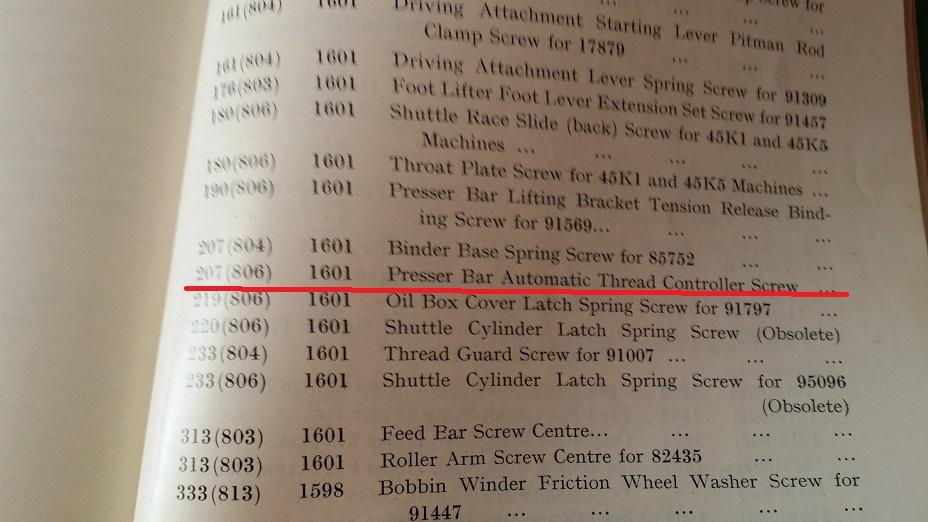

Here are the pictures you asked for Niles, they are not the best as the book is very tightly bound in the middle but you can see the pictures ok for reference.

-

Could you post a picture of the parts, there was a roller foot a couple of weeks ago on Ebay UK for about €25 but it looks like it has gone......

-

Help! Which machine for this stitch please?

jimi replied to johnnywalks's topic in How Do I Do That?

This is a up the arm feed not across the arm feed. -

Hi Niles, yes you just hook it on, then when the whole assembly is in place and the outer spring is resting on the controller, then just turn the whole assembly towards the machine and then tighten the grub screw when you think there is enough tension on the spring.

-

I think you might find it better starting off with cardboard or thick paper and fit things together first to see how they go together, otherwise you might end up making a lot of key fobs this lockdown??

-

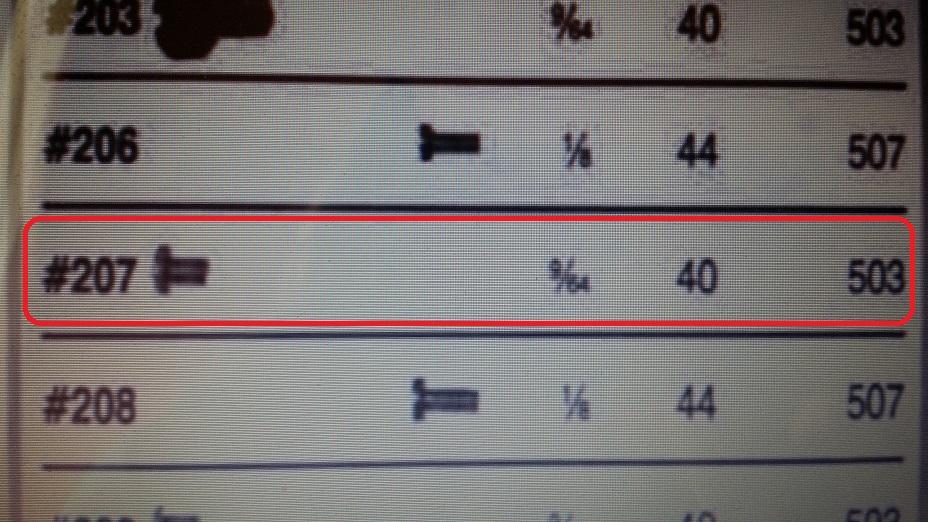

Sorry Niles, No small screw here in my tray. Part number is #207 page 28 plate 1601, look in numerical list of pats page 61. I did notice it is the same thread as the screw holding the top wire before going through the disks and also it is the same as the screw for holding the foot on, so if you find a spare one of these you will nee to cut them shorter. Hope this helps... Here is the thread pitch doodle, TPI is 40

-

Singer 45k - clutch motor or treadle sewing machine

jimi replied to Buster2008's topic in Leather Sewing Machines

Hi, could you post some pictures of your machine and parts if any that came with it. For uploading pictures look below, just drag or choose from a file on your pc. Right click, Edit, resize, pixels, then change the number ...say from 4880 to 850, that way you can upload a few more as the limit is 1.45 mb. If you want to see if you have a reply and your post is gone from the front page then just click on your icon top right and look at your activity, then you will find the posts you were active in. You can find some info here in this link.... -

They are chain stitch machines... check out this link.. https://www.singersewinginfo.co.uk/24/

-

Hi, If i was you i would try to get it unstuck? It might be easier than you think? Have you tried hammering very lightly while gripping the centre swivel??

-

Help! Which machine for this stitch please?

jimi replied to johnnywalks's topic in How Do I Do That?

-

Just an observation Soren?? I was looking at your pictures just now...... did you tape up the machined areas??

-

Hi Soren, Yes the paint looks Nice.. This leg was missing on a 45k92 i bought and the break was right in the middle of the threaded hole for the bottom bar, so i drilled 4 small holes then put some SS threaded rods in them and filled it with JB weld. The middle hole was plugged with wax to the approx diameter leaving enough for the other half of the thread to be made and then i made a casing from thin plastic sheets taped around the leg and filled it up with JB weld. then i used a tap to make the other half of the thread. JB weld sets like a rock!