jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

-

Possibly a little heat like you said could do the trick??. By the looks of the old paint, flat head screw at the end of the shaft and the brass arm i would think you have possibly the very old model Fortuna?? that looks like a 34mm wheel also?

-

Hi There and welcome, I think you only need to tap lightly on the back of the knife to free it, as for the screw for the feed wheel you might need some WD40 and then try again. It is tightened with an Allen key, is that right??

-

When the small strip of lining is getting glued before stitching i usually bend the wallet backwards then snip it, that way it is a little longer on the inside allowing for bulk afterwards. (just in case)

-

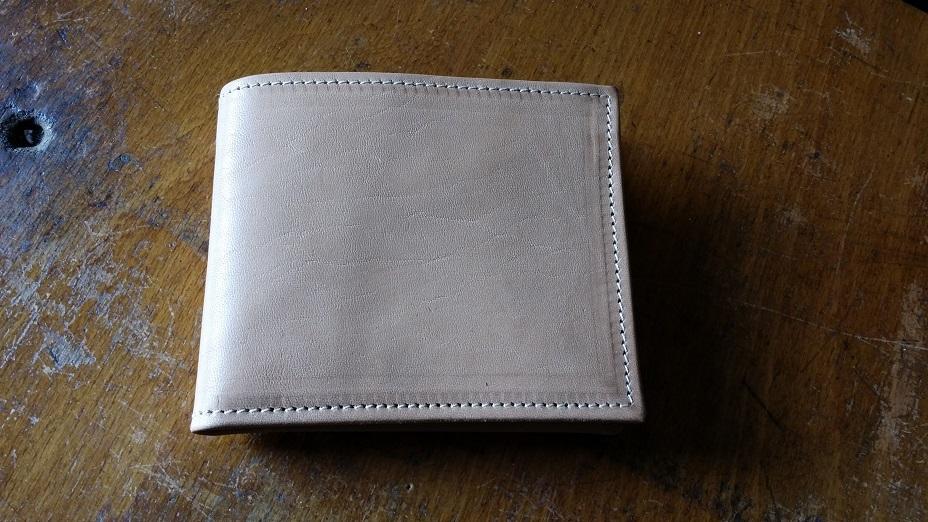

Thank you, yes this is what they look like after a few months-1yr. they are made from Veg tan horse leather. So yes we can have a wallet lay flat, why not guys....

-

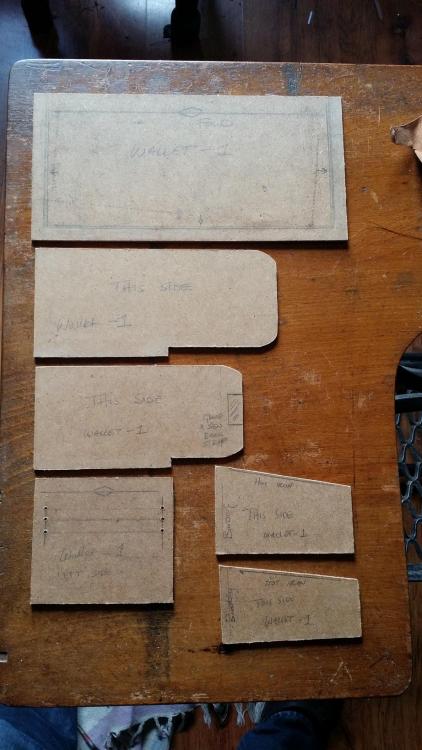

This is the parts for the wallet excluding the lining for the pockets etc.. the lining i use is thin and has a pvc or something like coating on one side.you could also line the note pocket. the white cardboard resembles a small piece of lining cut,glued and sewn on which later joins over on the right hand side inside the hidden pocket and sewn together with the right side when the edge is folded, whether it be the symmetrical type or not. (you can see this small tab in one of the pictures inside the pocket)

-

Hello Danne, I do some wallets also and to tell you the truth i have not made any the way you are talking about. there is another way which i got from wallet i was given when i was 16 yrs old (i am now 52) it has long fallen apart because i packed it too much Lol.... and have found it to be a nice way to do it. here are some pictures.

-

Here is the User manual for the 21w, you just need to download it. I suppose you mean threading pattern or how to thread the machine?? https://www.manualslib.com/manual/364478/Singer-21w.html?page=1#manual

-

I agree with mike... but i always clean first with warm water and natural soap. then you can see if you need to go any further.

-

Ultimate thread stand.....where to get?

jimi replied to Hockeymender's topic in Leather Sewing Machines

I think they might be holes for the thread to come through? -

Ultimate thread stand.....where to get?

jimi replied to Hockeymender's topic in Leather Sewing Machines

I have something similar that i made from some aluminium rod and a few stationary type trays i had for years lying around in a bag. the top of the rod has a saw cut, then splayed opened slightly to stop it from falling through. -

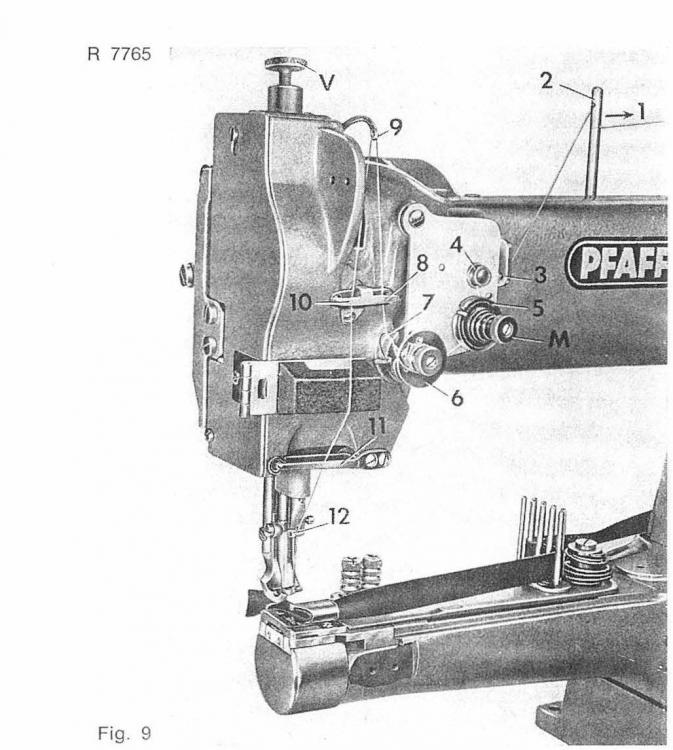

Hi There, i have it in pdf so Pm your email and i will send it, otherwise you could look here in the search box and put Pfaff 335 and i am sure you will find the threads talking about the manual and parts for the old casting. That looks like it was from a factory and had a hard life?? If things are tight with your needle you might need another feed dog with a bigger hole. If you have a needle positioner on your machine then it might not work with a speed reducer, at least that is what i have heard??

-

Here is a link for another thread on skivers which has a manual for download in PDF I think your blade for normal leather is 0.3-0.4 from the foot, thick leather 0.5 and thin like goat 0.2. I have mine set at about 0.2-0.3 for 1-1.4 mm thick Horse leather and works fine. If you have a roller foot on then settings will change, according to the manual, depending on the roller used and also the thickness of the leather.I have the distance between the stone feed and the knife at 0.1 mm,The blade has to be very sharp. Also if you are bevel skiving then the traction spring (which is on the front facing you) should be less than the traction spring for lifting and lowering (to the back left hand side) allowing the feed wheel to tilt, if you are parallel skiving then the other should be tighter allowing it to lift parallel to the knife. If it is any help i have a servo fitted at the moment on the skiver and it runs at number 10 which is i think is about 1100-1200 Rpm. this is spinning all the time and the feed wheel is actuated by a clutch. It looks to me like possibly your knife is not sharp, also because you said you turn the knob and no cut? You might need to clean the feed stone if it is clogged up with dirt.I use a soft wire brush.The thickness of the cut is done by adjusting your foot in height, the angle of the cut by tilting the foot and the width by moving the guide forwards or backwards. If you are looking to do the same as in the picture then for the edge you can use a normal foot and adjust the skiving width if the foot is wider but for those skives on the inside of the holes in the middle of the cover you will need a foot with the portion that skives on the tip of the foot only. hope this helps.

-

I think in French it is called Coupes-lacets.

-

Could be this one but not 100% sure. it is UNS. Best way is to get hold of a thread guage. https://www.ebay.com/itm/Lots-1pc-HSS-Machine-1-4-24-UNS-Plug-Tap-and-1pc-1-4-24-UNS-Die-Threading-Tool-/162544431108

-

Hi bikermutt, I have used the edge paint on a couple of projects on oiled calf and saw no problems with it. The paint was Giardini.

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

It is possibly 1/4-24 then.

-

You could try the clone type machines GA5-1 https://www.ebay.com/itm/New-GA5-1-GA5-1R-Roller-Foot-Cowboy-CB2500-Techsew-3650HD-/321787316620 or this one which is more like the original ones.https://www.ebay.ie/itm/221448164280 or you could try and find an original Singer one, (which are hard to find) or one from an Adler,Seiko,Claes or Hurtu who all had similar models to the 45k25 or flatbed 45k1.

-

Thread stuck to bobbin when pull out the work

jimi replied to Orrrmygod's topic in Leather Sewing Machines

-

Thread stuck to bobbin when pull out the work

jimi replied to Orrrmygod's topic in Leather Sewing Machines

That is why i put up the pictures -

-

Thread stuck to bobbin when pull out the work

jimi replied to Orrrmygod's topic in Leather Sewing Machines

These pictures are to show the way the machine is correctly threaded according to the pfaff manual. The thread does not go around the pin in the illustration. I would go for what wiz suggested. -

Ok, thanks Stor.

-

Thanks Stor, that looks good and slow. I have had this on my list for a while now also, maybe get around to doing it one day. the jack is also a little too fast for me.

-

Hi Stor, yes could you post a video of the speed

.thumb.jpg.3aaadc8edbeb3e20461fd513eb1b4bd0.jpg)