brmax

Members-

Posts

1,027 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by brmax

-

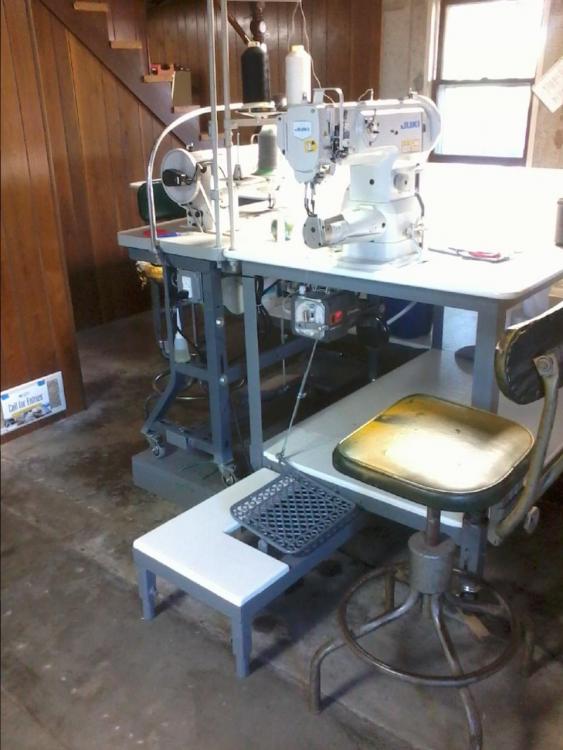

I work with canvas projects and maybe an 1/8" over seams so not a comparison with the sheaths and leather gear projects. At this time I haven't a lot of time on it, and honestly set it up for canvas exclusively, it is quite the machine and I am here to first help in your search but would like to hit myself in the head if you can get a new one for 1900. Canadian/1450.US they can run twice that amount. In my opinion I see you work with more holsters so recommend something with heavier thread, this in my small opinion is best suited to the lighter work on your site, and nice site by the way. If you decide this, please look with some others here on that particular, but in any account it will stitch all day long forever the stuff I do.

-

That's a pretty nice price so I would consider it for that money, though It would be great if some 1341 operators chime in that have stitched a lot of thick stuff and for sure if they put some layers of leather or any gear like 2 x 11oz on that particular machine. At the moment I'm showing .344" on my calculator of 11/64 x 2 but its a new one. My 1341 will stick with the lighter stuff for a bit, as I haven't tried it on any heavy duty, and would most likely push that project under a bigger foot machine unless it needs or request a small cylinder arm, I'm mean 2 layers of that may need bigger thread securing that. But again great price for a Juki. Good day there Floyd

-

Must be hump day again, sewing along on a canvas repair earlier, ran out of bobbin thread and none loaded I even get up and look in my stash, nope! well I commenced to wind 4 and so finished and loaded one up. Started stitching gnnnnhh hh Bling! bobbin case hit the foot, hits the floor, takes a run clear under the table only when 28" canvas wants to slide off the other side, omg I suppose that gremlin unlatched the bobbin, because I know I latched it (roll eyes) anyhoo cleared that gob a birds nest and rocked on! Tomorrows another day my friend Floyd

-

Sidona to stay inline with your project description the machines really cannot be compared in price completing your capability needs, so being me, hope this helps. The CB4500 compares in work capability with GA2688-1 and this is for a 16" cylinder arm and these are a XHD class machine this also is available in other brands talked about on here as you may know. If at all considering a short arm version machine then to be fair all other Highlead cylinder machines to my knowledge are all in the thread size 138 and lighter as the GC2268 this has a comparison from several companies, keeping the thread size restrictions in mind as this is most important. I'm trying to keep in mind if thread size wont run in the bobbin I'm not saying it. To bump the XHD class machines we can change thread colors to tone down the looks if needed but its a serious choice that cannot be changed with smaller thread size in short order. If leather 1/4 thick sewing 50% of the time then a reducer should be standard purchased item in my op. have a great day Floyd

-

Probably don't want a positioner with these extra heavy machines, as they are generally setup with a reducing pulley, drive system. With this system your foot controlled speed of the needle and its position is relatively easy. I think the machine frames are about the same size with their capabilities as both resemble each other and so the, accessories and ability to access support is a key point. The site here has a lot of great stitchers and some with extensive knowledge of many machines so a question can be addressed pretty quick on your selection. This is not a one brand place here for sure and there are so many machines finds in one month its difficult to not like them all for one reason or another. As mentioned the thread size you select is another key point, this may lead you to a style you want or not in projects. Another point and this could use clarification, is the machine head looked over and tweaked or tuned "before" its at your business doorstep and at what level is this carried out. other than that, the pros cans chime in, also their are companies in the upper heading and other members that are equipment dealers so welcome here and enjoy. Floyd

-

The problem I was running up against led me to looking at each machine " I thought they were the same" but anyway just taking a look at the thread path, surprised they worked but different and why I thought they were the same was my head down moment! wha? So I rethreaded through the guide post on them the "same" and did a recheck, re-sight and decided to change needles from a 18 to 19 running 92. Working through these changes were the biggest part I believe. The option to use all the guide holes for thread in the piece above the winder is a choice one has to make, and the route described is experimental. I will admit keeping things the same on these is great by me most all the time, but here on the 08nh, I run thread one loop through the upper thread guide between post and tensioner in this change. This model is a bit difficult so I guess it gets its due, They made it to be a bad az and so here this round I'm standing. After reading Bobs post I looked at the check springs here and they are positioned the same headed to 9:00, as to any measure of them I haven't experimented getting any figures, that really maybe the difference one could measure, also here these are oem springs. What kicks this to a thread path I think is (it looks as mine did) not every stitch, like a hook issue might be. So right now I'm in the area of watching mine and listening here as the others offer up some great tips and checks as they have already, I appreciate the help, and good luck Jim Floyd

-

I seen someone on a video demonstrating some auto upholstery stuff and picked up on this tip, and myself think its great and have about made it a habit; When finished with the sew / seam and presser foot is down and lever is up, I pull thread just below the lever, this making some thread slack for easy pulling material away for a thread cut. I am not sure what I did but its working, I have to admit I don't have Juki bobbins and did get some from online supply. Its very possible and will add I did get the caliper out long ago when purchased way way back as something was a bit different in the rewind stem with these bobbins and so a tweak of that split stem was remembered so that's noted. I would like to try some pre wounds but again its working at this time and in the center of the materials. So will keep an eye out for factory bobbins for sure. The thread tension as you mention sounds familiar, and its not like you can measure with a tool as easy as the side loaders. Would be curious to hear a standard method of bobbin tension measure, other than a bag sewn and weighted? or if that a measure amount. Floyd

-

Totally understand the frustration, and wish I had a clear answer rather than having had some of the same. Something I found tough how to describe is the consistent stitch issue, so will say I have found the very same in my general settings to show every 8 stitches this part was consistent, but showing up as a loop on the top fwiw. I ran through some troubleshooting and I'm sure missed many things, what I had done before on all my machines was going through and by the book setting specs to the manual each step, but knowing that I don't but some pros understand a tweak here and there "and what it does". I did follow up with making the hook/needle guard have slight pressure in its rotation against the needle on my 08 but inline on my 212 hooks. This issue I had pretty much eliminated finally with more tension on upper adjustment. The best problem solving here is going to be from the pros on the site here, and I surely welcome the help in this specific issue. I wondered many times that it maybe myself operating and the movement of material during the stitch line/seam. This is also with a 1508NH I'm referring to and also as you mention same material runs fine through a 212, or 1341 so there's a catch in its getalong I haven't yet tuned! So I'm interested in some thoughts here from the experts as it is weird because my stitches were perfect also except pretty darn near 8-10'th then a top loop. Now with more top tension I'm rolling on fine now, but its not a clear answer for myself and so I'm in line for hearing answers to your question also. its Good that its Friday Floyd

-

Dürkopp Adler 869 180122 M Type Cylinder-Arm Machine

brmax replied to Anna1980's topic in Leather Sewing Machines

Anna, good day I think they are designed very well for the materials in the general specification range. Where I might look a bit further is if and how much you may sew thicker weight materials. In some leather weights over 4oz I think its a good idea, and at this level of purchase to consider a reduction pulley installed for more power. This typical power setup for leather work could not be used on the direct drive, so in my personal opinion no direct for leather. So a few more choices for your project decisions : ) Floyd -

earthling, good day! get 2 "exact" length strips 18" long of decent textile whatever: example- canvas lift the foot put a piece under, the feet, needle up, now pull the piece of the material by hand to judge the required pull ( it should pull through a bit to judge) now remove needle, secure the screw Lift the feet, take both pieces one on top of the other exact in length and of same material. With these put them under feet let feet down. With power on run material as if sewing a line, when at the end "are the ends going to be even" ? The pressure knob above will clearly have an effect on this by applying more or less tension, you want the material even. that's all I got, after that your gonna have to go bark with the big dogs because I'm stayin on the porch with an umbrella drink Floyd

-

You found the right machine, as there is a lot of nostalgia and a cool factor fixing some of these machines and seeing what they can do for us. Just keep stitchin, if it works for the projects you want great if not just change projects. good day Floyd

-

I think what spurred the interest maybe a year ago I guess was a more experienced comment something like, that it would good if one could have the 441 shuttle system and the 205 top system, I think that's it? may have been reversed. No doubt another interesting machine discussion. I just now? ( I need a sign ) checked out some old post on the cb205 here on the site, and recently this year remember seeing some workup videos Neel's did running through one of these machines. Floyd

-

Its great to hear some others interest, I have had the part no. printed on a paper tacked to the wall for 6 months at least. 7205 - Cylinder arm machine AE: leather saddle and harness BF: upholstery and the top stitching of such I haven't searched here, just the company site ages ago. good day there Floyd

-

Help! Reverse stitch too long or forward too short??

brmax replied to kwalk20's topic in Leather Sewing Machines

If I'm not mistaken this is adjusted from the top and under that plate on the right. It maybe at some point together like the photo there and say at a certain stitch setting? when adjusting. None the less it can be moved to correction either way, I would say for myself the best method has been to run through all checks in sequence. I believe towards back lengthens reverse and then forward for the opposite. keep us posted and good day Floyd- 11 replies

-

- reverse

- reverse stitch

-

(and 1 more)

Tagged with:

-

Curious is it with an oil pump or have the places on the top for daily oil. I did find a pic from an earlier post you made, sorry. It looks like a newer juki casting maybe 87series. The Juki manuals have like 5 languages in them and drive me nuts, I wished for just one! mine. Another pic or two of the needle end would be cool. Good day Floyd

-

Do you have some pics or a link I cannot find it anywhere, Cowboy, Hightex. What is it similar to in your opinion Thanks

-

Well its good that you solved that, I have recently thought some bobbins also seem to give a bad issue. They were new but slightly off size bigger but listed to work? I know better now. Give it another try with some fabric or other material while holding the thread tails for the first few stitches. A lot of the flat bed machines require that method as they will pull that easier thread, and make a bad day quick. The lever or latch seems to have a bit more clearance than needed still as its looks to be opening to early, like that part may need some looking into more extensive in the timing. It is good to see it by manually turning the hand wheel as it seems in the video. They are tough adjusting sometimes for sure. I think using some fabric or material as in that video test situation will hold the thread somewhat. Good day Floyd

-

Where to buy a quality machine with a Efka servo?

brmax replied to ruinbliss's topic in Leather Sewing Machines

It worked here, after I signed in The classifieds here on the board are some good places to look for machinery also, just no one within 700 miles of me has used items : ( at the time I'm lookin. You will need a reducer so a decent servo is needed, I wish for an efka but not so much need of that production setup imo. have a good day Floyd The internet explorer pops up asking me if open or download I just hit the open, but I still like the ole ie -

I think and most here do as well the Company, seller and buyer is first to contact on operations of equipment and an easier transfer of manuals and or their available technical support recommended. With that, there is like 69,000members so there is a lot of help on one day or another by many contributors happy to share a thought or some of their experience. Good day there Floyd

-

Sorry! Its called a Bob part, Some Singer manuals call it a hook latch lever, some Juki manuals call it a inner hook guide. The hook is pretty tough as far as bending so probably not affected, it looks normal from here but the thread sure is locked in that basket by the screw it looks like, so order a few extra screws with that part in red. Bummin here dude hope ya get it fixed up soon Floyd

-

Any idea which Seiko this machine is?

brmax replied to sparky20006's topic in Leather Sewing Machines

It would require a different Hook assembly and is what carries the bobbin case and then this carries the bobbin. So not with out $$ and some extensive tech work if the L size bobbin Hook setup "could?" be used as other clearance is needed. A good decision can be answered and maybe ask with what you are making and is the stitch seam a certain length with such n such thread size worth it or more importantly needed. Going on just the machine that has this G bobbin setup a 138 thread size is normally max in that bobbin and probably better with a smaller actually like 92 and below. I will say some techs on here can build it to do some amazing things but is this job in need of that mod. Ninety two thread can go a pretty good distance, I would really like to see a laymen chart of distance and know many have made a few, if nothing else than penciled on a wall. Good day there Floyd -

Good morning! What size thread is running in the bobbin in this photo, I ask kindly with this other question also; is the needle that close to the left side when presser foot is down. I think its a bit to close rubbing the side in my view and may well be the photo angle so a further look later. On to the gap about .004" to .018" inch is the range and generally .011" is ok for 92 thread and its roughly 3 sheets of plain copy paper folded. This spec may be fine tuned by some pros here on the site more specific to a textile, oz type of leather etc. Now importantly is the proper time the clearence setting is made; turning the h wheel towards you bringing the hook guide/lever to its back position and or far right position. Turn the bobbin case reverse or counter clockwise these two parts make the gap and so adjust accordingly eliminating slack. With this all set correctly the tab on the bobbin case, that fits in that slot mentioned on bottom of needle plate cover has a slight but close contact on the operator side and thus reducing some extra lyrics of the machine. I think the opening amount is among other things used to make tension regulated, and in that only needs the gap of thread size capable in design with machine and other setting specs. Some are the bobbin case thread capability and spring design, then the bottom of the feed plate where it covers the tab of the bobbin case this clearance also has a certain drag/tension in forming that perfect loop and locking the stitch, quite the design. Good day Floyd

-

It may be easier to use a servo style motor unless a regular supply of thick leather is always going to be sewn. If the latter probably a reducer setup is the route you want to head toward really, as it would be better by far than a 2" larger big pulley. Floyd

-

Hey Jackmitch whats the motor look like, or any buttons and digital light stuff. Sure just sew, and skip the knob turning. Knowing the motor style you have and if it is going to run the slow speed for some leather stuff really is needed. Nice machine there, and have a good day. Later Floyd

-

Is this maybe a different thread than what you used before or in testing. It makes me think the bobbin should be put back as was, ? saying because viewing the top line of thread is better. With that I am considering the top tension should be looked at instead, and the take up spring also, just a good look see if something is clearly loose. its a start imo Floyd