-

Posts

1,369 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by plinkercases

-

Working Chaps (Bison)

plinkercases replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

My waist (waste?) was 32 for a long time... at the belt line but surprising getting larger north of the equator... the numbers are getting closer together now but not due to any reductions. Roland all the holes make sense now that its for a larger fella. I am sure the whole set will age very well. I love seeing the photos of the vintage chaps that have seen real use but held up and weather with real character.- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

EMS Radio strap

plinkercases replied to Horsewhishper's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thats a nive piece of work. All I cam suggests it "blocking" your keepers by dampening then amd sliding them over a piece of wood the same dimensions as the strap width and number of layers of strap and then tapping them square around. Looks sharp, less likely to get cuaght and give more contact area. When i was doing a fair bit of strap work I made a variety of sizes of loop sticks for this purpose. -

tri-weave padded rifle sling

plinkercases replied to plinkercases's topic in Gun Holsters, Rifle Slings and Knife Sheathes

And thanks all for the compliments... seeing some of the older work makes we fell even more push to get some bench time. -

tri-weave padded rifle sling

plinkercases replied to plinkercases's topic in Gun Holsters, Rifle Slings and Knife Sheathes

its really called tri and tri again weave...... -

tri-weave padded rifle sling

plinkercases replied to plinkercases's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I cut it so I wasn't stitching through it and with a soft suede over it was very comfortable. -

Pancake knife sheath

plinkercases replied to mick86's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice rework of an already good design. -

Juki 1341 experience? pros cons?

plinkercases replied to plinkercases's topic in Leather Sewing Machines

I ordered a techsew servo to out on my my 335... are your issues with the servo itself or the head? My 1245 is comig with a Kobe servo like Chris sells. -

Juki 1341 experience? pros cons?

plinkercases replied to plinkercases's topic in Leather Sewing Machines

Agreed super guy and service. -

Juki 1341 experience? pros cons?

plinkercases replied to plinkercases's topic in Leather Sewing Machines

Hi HardenGoods I actually ended up with a Pfaff 335 as my first cylinder arm. -

Working Chaps (Bison)

plinkercases replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

Excellent work and you left your friend a few holes to grow into ! I would agree the back belt could be tanned so to speak but it will weather and blend in in no time.- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Made for a 22LR mares leg and I modified an old Daisy Red Ryder to match the form factor to build around. Oak leave pattern throughout the belt.

-

Surprisingly comfortable as it turns out but hard to take a good photo off. I have some old leather as I work slow and fro this I forgot to do a light NFO treatment so I assume that's why some of the wrinkling occurred.

-

Pancake knife sheath

plinkercases replied to mick86's topic in Gun Holsters, Rifle Slings and Knife Sheathes

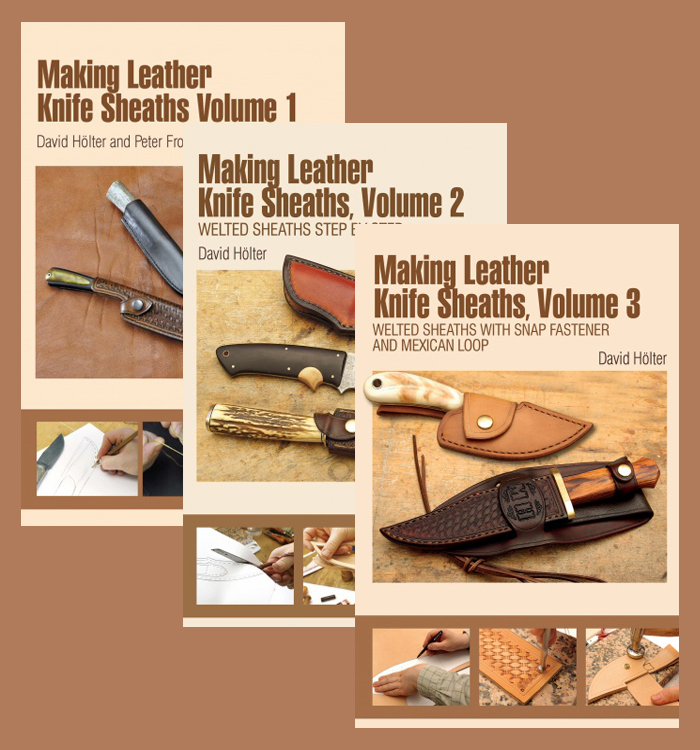

These are good books if you are a blade and sheath maker. Internet is great but its nice sometimes to have a book on the bench as you work through something. -

Pancake knife sheath

plinkercases replied to mick86's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If it is a good sharp blade it will eventually cut your threads again unfortunately unless you built the second version with a welt. blades have even cut out of the sheath when there is not welting in the design and that is a danger to the carrier more than a concern for a ruined sheath. That said that is a very cool looking design all round. -

In this case essentially he wanted mote leather and opening than needed for the XDm so he could shove a longer pistol in there... not necessarily that he didnt want it close. For an IWB I believe a little longer and open toe is more comfortable specially with the square stibby poly guns... OWB I think its a matter of style/design and function... i dont think a feild holster should have an open toe for instance. Just me. That might be a good question for a nrw thread and hear from some of the other more experienced makets.

-

Pfaff 1245 or Adler 067-GK373

plinkercases replied to plinkercases's topic in Leather Sewing Machines

Pfaff with a new servo and table!!!! Very excited and now must stop looking at machines and spent more time using them more!!! Stand by for pics of the machine shop revised to hold all 3 machines now... pfaff 335, 1245 and Singer 96k. Next an hopefully last will come a bih 441 clone but for now its the stitching horse for thicker pieces. -

Attention! Congratulations Caitlin

plinkercases replied to RKCrowe's topic in Leatherwork Conversation

Wow congratulations Caitlin! Just keep dreaming and doing!

.jpg.77fb3c3c0c5dd835f4c365dc57f660be.jpg)

.jpg.f703cd4d5ac93995cfe18227d264a4d9.jpg)

.jpg.9c3543e10e0a0420994fca0ab6742b16.jpg)