-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

Filson Factory Auction Dozens of 211W151 Starting at $20

dikman replied to JJN's topic in Leather Sewing Machines

Not really a problem, if you get one at a good price then replacing the motor with a servo still means you've got a (better) machine at a good price. -

Nice job with the stand, looks good.

-

Are sewing machines worth the money

dikman replied to Horsewhishper's topic in Leather Sewing Machines

Are they worth the money? Yes and no. If you're in business or have a ready market as a hobbyist then yes, the right sewing machines will make life much easier. If, however, you just dabble in leatherwork (as many of us do) then it's doubtful you will ever recover the cost of, for example, a CB4500. Of course some of us just enjoy having the machines for what they are and accept that it won't pay for itself. As bikermutt said, however, one machine won't "do it all". If you buy a CB4500 (or its equivalent) you'll find that you'll need a smaller machine for lighter materials. By all means if you can afford it go for it, just don't expect it to do everything. -

Most likelly my last one

dikman replied to katsass's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I don't know you, although I have seen your name mentioned in dispatches, so to speak . Even though you may not be able to make stuff like you used to I'm sure that many here would appreciate your continued input as you obviously have a wealth of knowledge and experience that it would be a shame to waste. -

Nice looking job there, sarge. the walnut and black (satin finish?) go well together. Just be careful not to scratch it when you use it .

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

If it was me I'd already be half-way there .

-

Wiz, that Singer 168G101 sounds really interesting.

-

Always nice getting a new toy.

-

If you search here for "burnishing" you'll find information on what others are using for burnishing, some have fitted (or made) burnishing attachments onto bench grinders. They might be a little fast but they work ok. Yours looks to me like its burning the edge of the leather, I get the same thing when sanding on a belt grinder if I'm not careful. You've probably clogged the grinding wheel with leather so it's rubbing leather against leather at high speed and burning it. You could try using some beeswax on the leather when burnishing. The good thing about a proper burnishing attachment is the grooves will also round off the edges a bit.

-

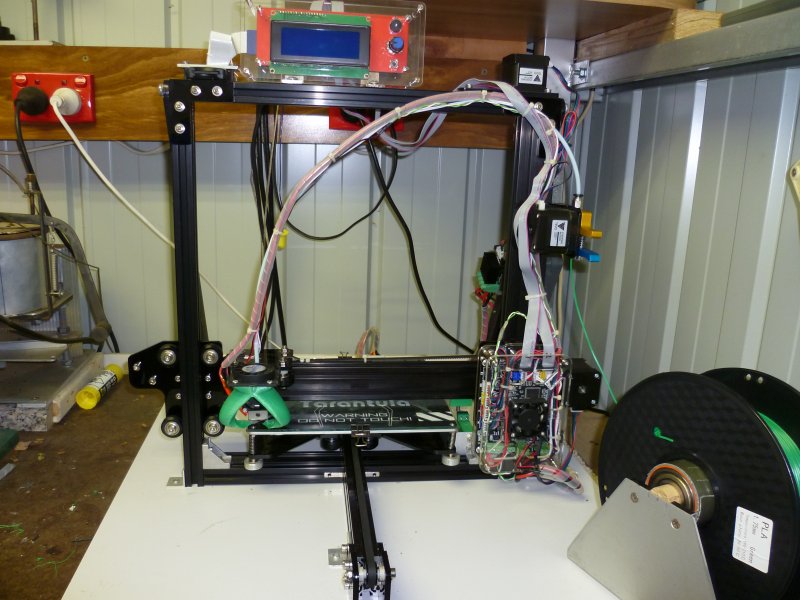

Here's my effort. It's a Tevo Tarantula kit (which is why it doesn't look neat and tidy as it's very difficult to run all those cables in a tidy fashion!). There are many kits available and a lot of them use perspex/acrylic for the framing pieces (which apparently works quite well) but I bought the Tevo because it uses extruded aluminium section for its framing. Rigidity is the key to using 3D printers, so mine is screwed to a baseboard, which also lets me move it around, and I fitted additional diagonal braces at the rear from the top to the back of the board. It's now very rigid. I've done a few mods, all the power normally goes through the main board (in front) including the heated bed, so I attached a box to one of the diagonals to use as a power distribution and bought a MOSFET unit to feed the heated bed (it removes that heavy current drain away from the main board). The Z axis was fitted with a universal joint, rather than the springy thing that was supplied, and I printed a gimbal joint, this allows for any slight mis-alignment in the shaft and removes any possibility of Z banding. I have a kit on the way to fit a second Z drive unit on the other end as there is a very small amount of vertical play in the bar carrying the nozzle assembly so this will make sure it can't shift. I may make a decent housing one day for the control board on top, but it's not a priority as it works well as it is.

-

Cylinder Bed Needle Feed Nakajima 321L on CL Seattle

dikman replied to JJN's topic in Leather Sewing Machines

If something like that came up near me at the very least I'd grab the servo. -

Rustic, could you post a link to this $50 binder? I'm very curious to see what you're talking about. Your suggestion that a heavy binder could be made for $50 made me laugh. Even if Amazon offered the Cowboy binder for sale I doubt it would be much, if any, cheaper. For that to happen it has to be mass produced, but the market simply isn't there as it's too specialised a piece of gear.

-

I thought it might be an idea to have somewhere that those of us who own a 3D printer of some sort can show a photo or two of it and maybe brief details - make etc and anything relevant? One or two people have expressed an interest in them and it might be of some help to them. I'll post a photo of mine tomorrow, the bed is off at the moment while I make better adjusting nuts.

-

Zipper installation multipurpose guide

dikman replied to RockyAussie's topic in 3D Printers and Lasers

That pile looks like something for a model railway. Thanks for providing the file, what is the nominal slot width in your version? -

You have two options if you want to make "Western" gear - hand stitching or a heavy duty machine. The most common machine used is a 441-class, e.g. Cowboy CB4500 etc.

-

The big advantage (for me) in using an electric machine is I can use two hands to hold/manipulate the material. Not having three hands (!) I've found using a machine manually has limitations. And Constabulary is right, a servo is great, a servo with a small pulley is greater and a servo with a small pulley and a speed reducer is the greatest! (Or a servo, small pulley and large handwheel). If a Tippman/Outlaw came along at a bargain price I'd have it, but if I have to pay full price I'd rather put more money in and buy a CB3200/4500, far more useful in my opinion.

-

Cost is nearly always a factor, but if you have a market for your products then the initial outlay will be money well spent. If you're purely a hobbyist, as many on here are, then it can be hard to justify the expenditure. If all you're going to make is pancake-type concealed holsters then a CB3200 would be a great machine, but if you intend doing Western-style holsters then you'll really need a CB4500, anything smaller is not going to be suitable.

-

Juki Machine Identification and Tips for Buying Used

dikman replied to Askal's topic in Leather Sewing Machines

As long as the frame isn't damaged it could be a good buy, tell them it's an unknown quantity because they can't tell you if it's working and the table looks pretty knocked around. Turn the handwheel and make sure that the needle bar/feet move up and down with no binding and there's no funny noises. If you get it at a good price but it proves to have a problem you can always sell it for spares. -

Do a google search on Juki 227, it will show quite clearly that the seller doesn't know what he's talking about!

-

Singer Age by Serial Numbers Slide Chart

dikman replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

Yep, and no records have been found for the W machines. It seems when the factory was demolished the records went with it? -

Thanks for that, Alexander, it makes for an interesting story.

-

That is a very old motor and clutch!

-

New to industrial sewing machines Juki LU-562

dikman replied to jshep's topic in Leather Sewing Machines

Sorry, I just assumed that anyone using a forum knew what a "sticky" was. My bad. Thanks Wiz. Wiz answered your question with his first post. The maximum size you will be able to use reliably is #138 thread. It doesn't look too bad on a dress belt, but on gunbelts it can look a bit "small", likewise on a sheath. 3/8", by the way, is the maximum you can fit under the feet and still sew. -

Well, that explains the missing bits - if the crate was open then anything that was loose and not too heavy has probably been "appropriated". As Don said check the casing/frame very carefully, if it looks ok then you may be onto a good thing (even better if you can beat him down a bit).

-

Ahh, holsters, if your friend wants to sew holsters with a machine then he's looking at a heavy-duty machine. A minimum is a 441-class. Don't even think of anything less.