-

Posts

5,966 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by fredk

-

What did the old shoe and boot makers use to waterproof them

fredk replied to chrisash's topic in How Do I Do That?

They also used shellac varnish. I believe shellac is still used on the boots of the Household Cavalry, the long ones worn for official duties -

A nice thing to solve the problem. Did you prep your leather before dyeing? I give mine a wipe over with a clean rag dampened with cellulose (aka lacquer) thinners to remove any surface contamination. Even some grease from your fingers can leave contamination which will prevent dye penetrating properly

-

Most excellent The kid wot rides that will need a leather jacket and cap. ala Marlon Brando in 'The Wild One'

-

I bought a brass one from a Chinese seller on ebay

-

Can I make a molded hat visor rain-resistant?

fredk replied to DanDSilva's topic in How Do I Do That?

Seal the dye with several coats of diluted Resolene. Then apply several coats of Snow Proof paste. Even apply some soft bees wax and buff it in. Then it will be rain-shower resistant, but not totally rain proof, it will never be that -

Found square head Chicago screws https://www.ebay.co.uk/itm/Solid-Brass-Square-Head-Binding-Stud-Leather-Belt-Bag-Chicago-Screw-Nail-Rivet/152694517062?hash=item238d4d6d46:m:mjGLK7T9Mvki-qyv6zAuvxw

-

double; I know you can't cut the edges and retain the integrity of the rivet head. Cutting off one part of the edge is one way I use to remove them. The Chicago screws is the way I think. You can buy square ones from Chinese sellers on ebay

-

A; when someone goes to lawyer and says 'I have copyright on this' the lawyer takes his/her word for it and does not investigate if they have. They act on the word of their client B. Its very, very expensive to take a court case. In N.I. a copyright case is a civil action and the complainant has to lodge a minimum of £10, 000 ~ in cash, with the court before proceeding C. I've had threats by lawyer letter over copyright ownership (I never infringe anyone's proper copyrights). I have just written a letter back to the lawyer; telling them 'no they don't have copyright' give an example or two, and tell them to prove it in court. Thats the last I've heard from them. An eg; when I had a wooden toy company it was called 'Tyrone Toys'. Shortly after I started it I got a lawyers letter saying I infringed his clients copyright, his company name was 'County Tyrone Toys'. The letter told me the date from when the client had used the name, which predated the first of my toys going on sale. I sent back to the lawyer a newspaper advert and the company registration papers for my 'Tyrone Toys' which both predated his clients claim and told him' see you in court'. btw the other toy company changed to 'Wooden Toys of Co.Tyrone'

-

Big cheat; get the Tandy Craftaids. They have them all drawn out. Also Tandy have a 'library' where you can buy older designs. Prices are from $0.00 upwards. These come to you as PDF files. With these you can resize and squeeze or expand in your computer to suit your item, then print out, trace over on your item then go to work on it. It suits me cos I'm no artist Floral design craftaid example; https://www.tandyleather.eu/en/product/floral-keycase-belt-craftaid from the 'library'; https://www.leathercraftlibrary.com/p-1743-sheridan-floral-corner-and-belt-pattern-by-jim-linnell.aspx https://www.leathercraftlibrary.com/p-1739-2681-floral-belt-craftaid-tracing.aspx

-

Try searching outside of leather work items. Model railway boiler rivets; https://www.ebay.co.uk/itm/1-16-x-5-8-brass-rivets-round-head-snap-head/232802078698?hash=item363415cfea:m:mWtAA9QFjYHGGtJWdcewASg

-

Rune bags & some questions.

fredk replied to mick86's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I dug through my tools and found the screwdriver interlacing markers. One makes a square edged lace the other makes a slightly wider round top lace; Just a rough drag thru some leather. I don't know if you can make it out the round top shape is to the top of the picture. Proper back-grounding would tidy the lines as well. And finally; if you're not totally set on using wood for your rune beads ~~ I use 'granite' polymer clay. Polymer clay is also known as FIMO and Sculpey. I use the Tandy Rune letters to impress the letter then I fill the grove with liquid polymer clay mixed with gold paint and gold glitter. The two top beads are FIMO straight from the packet, for the two lower I added white polymer clay to lighten them a bit. I make these for games as well as for necklace beads. They have been mistaken for real granite pebbles. A block of polymer clay is 2 ounces (58g) and I get between 14 and 18 beads from a block -

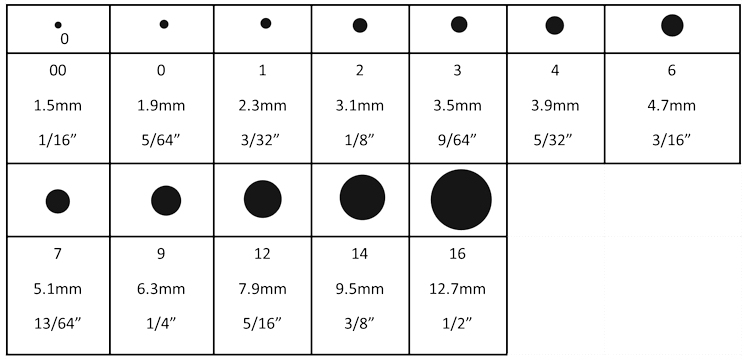

This is a chart from one punch maker. Its not perfect, it doesn't cover all the sizes ~~ and ...... I find that different makers have slightly different sizes for the numbers. Eg, Tandy's #3 is 1/8" = 3.17mm, the #2 above, the #3 above = Tandy's #4 and the above #4 = Tandy's #5 You might need to draw up your own chart

-

Rune bags & some questions.

fredk replied to mick86's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

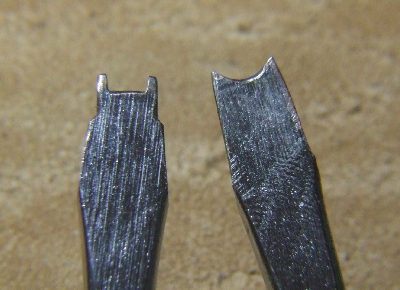

Also; cut the piece bigger than you need. Allow for the stretch, and then you can cut your required shape out, around your worked area when its completed btw; for doing fine interlacing patterns I ground the blade of a stubby flat screwdriver. I ground out the middle of the blade to leave two points. I actually made two, slightly different. Then I use this to draw over the wet leather, leaving two tracks. It means my ribbon width is always constant. I've not used them for several (many) years -

Rune bags & some questions.

fredk replied to mick86's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

For background you do need a range of tools, from very small to the largest which your design can take. One of the common backgrounders is the simple cross-hatch as on Tandy A104 https://www.tandyleather.eu/en/product/a104-craftool-background-stamp Although this is very small, it might not be small enough. You can buy these tool very cheaply. Use a dremel type tool, or just a file to shape a backgounder to size and shape that you need For interlacing; the most important aspect imho is to have the widths of the ribbon the same size throughout. Modern drawings of interlacing are all nice and regular, but the ancients didn't have it that way; so for a 'rustic' / 'ancient' look the design can be a bit uneven As with all design stamping, but Celtic interlacing patterns especially, work slowly and carefully, taking breaks from it every-so-often -

1. your wax will be yellow-ish. That wax is the common wax; it comes from the honey stores after the honey is extracted. Some might come also from the brood frames if the bee keeper is renewing the brood frame. White bees' wax comes from the caps, the sealing tops, of the honey cells. They are sliced off carefully just before honey is extracted. For every 1lb of yellow wax there is just about 2 oz of cap wax. Its no better than the yellow wax. Yellow wax can be bleached white [almost to cap white] by leaving it in very bright sunlight for a while; the length of time depends on your sunlight 2. I use my medium hard mix for burnishing edges. I use a bit of linen cloth. I take some wax mix on it and rub it onto the edge, about 4 inches at a time, then rub the cloth very vigorously to warm the wax and burnish it into the edge. It only takes a short time to do both edges of a long belt. Sometimes I'll also use one of my wood slickers to go over the edge as well

-

Bees' wax melts at about 65*, its also very soft. I add a quantity of carnauba wax to it so it has a harder finish. Just that makes a good wood polish. But its too hard to spread into leather so I mix it with neetsfoot oil. The nfs helps feed the leather Don't ask quantities/measures; I have a very soft mix with more nfs and a little bit less carnauba, and I have a harder mix with more carnauba and less nfs, and I have a harder one with no nfs but with some (a very little) vegetable oil. I just mix it by - 'uh, thats about right'

-

Reading thru this and what Ed has added; we have very different sponge qualities between us. None of the various other sponges I've used has every broken up, flaked or gone hard with dye. I've been using the washing-up ones for several years now as they are handiest to get

-

I use the regular washing-up sponges available in multi-packs in normal supermarkets. I suppose Walmart would be to you what ASDA or Tesco is to us in the UK; cheap shopping prices. Sometimes I rip the green pot scrubber part off but mostly I just leave it on. Usually the sponge stays flexible even when the dye has dried on it. I tend to use a new sponge every dye session as they are so cheap. The sponges are about 3 inches x 2 inches x 3/4 inch; just the right size

-

Coffee Koozie!

fredk replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

A suggestion/idea to re-enforced the handle, especially at the top end. Undo the stitching of handle to Koozie. Make a piece of metal, preferably brass, or steel or aluminium, in a S shape turned sideways, long on the lower bit. It only needs to be about half the width of your handle. Slide the bottom of the S into the handle and catch the upper part under the stitching of handle to Koozie. This will take the upwards strain. The metal will resist and help keep the handle in the shape it is now. I had to do something along that line when re-enforcing some dagger scabbards which wanted to twist due the weight of the daggers. I used thick brass sheet sandwiched in the leather. -

You'll need an insulation layer between the leather and the metal handle. Something like wood. The constant regular heating of the leather will lead it to dry out, shrink and crack

-

Coffee Koozie!

fredk replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice work again whatsyournameagain I'm kinda a worried about the attachment and form of the handle. Is it riveted on? The handle sits nice now but after a bit of time that top curvy bit will bend upwards, caused by the weight. Without a re-enforcement inside it I think that curved handle will straighten out when the top joint bends upwards -

Two ideas; 1. use a sharpening stone and file to reduce the size of an awl bald to the necessary size 2. mount a glovers needle in a handle and us it as awl

-

Homemade tools and ways you have saved money on tools

fredk replied to JenGranger's topic in Leatherwork Conversation

Thats one way. After your suggestion I was thinking of glass bowls and such. Let the HDPE set and prise it out. Use it to mould over or use it as a male form to push the leather into the glass container. Someone (I can't remember who) posted on here; he used two glass bowls to mould, pushing the leather into the larger with the smaller bowl. But if you only have the one bowl? -

A. Data sheets on materials are a world wide requirement; but often only available from the manufacturer, rarely does a on-wards seller have them, but many do. Email or write to the manufacturer directly. Failing that; In N.I. we have a Health & Safety Executive Office, if you have something similar in your local town hall they can obtain the necessary data sheet. Anything marked Toxic must have a data sheet available to anyone who asks and in most cases it must be provided within 3 to 6 hours of asking B. 'Acrylic' refers to the resin. The carrier for the resin can be water, alcohol or cellulose. A mask should be worn whilst spraying any of these as the acrylic resin hardens to a sold when in the lungs. A strong smell on this might indicate its cellulose carrier based. Brushing on, sponging on or dipping, only good protective gloves need wearing. The fumes do not carry the resin C. When the acrylic resin is set and hardened it is an inert plastic; not toxic at all