-

Posts

5,247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Actually I got a first hand lesson on this problem . . . and it was as you stated above. I went to a gun shop that was having a big sale . . . and holsters were like 50 % off . . . this was before I started making them. I had been looking for a certain brand of paddle holster for a full size 1911. He had one . . . and seemed really relieved when it went off the shelf. It was the color I wanted . . . and everything. I wore it a couple times out away from the house . . . and one day I grabbed it to go after a coon that was in my chicken house. I shot at him with the one that was in the chamber and missed . . . but when I went for the follow up shot . . . it just went click. As I looked at my gun . . . the mag fell out. The bandit got away. I took it in the house to try to find out what went wrong . . . exactly the problem you described . . . the hole was too small. Now when I do a holster for a semi auto . . . the mag release gets special attention . . . LARGE holes are left so they don't get inadvertently punched. And please be careful . . . some of them have releases on both sides . . . not many . . . but a few. Have fun . . . holster making is a challenge . . . and one I love to work in. I hope you enjoy it as much as I do. May God bless, Dwight

-

Actually you don't have to have a real gun . . . but you have to have realistic models . . . or at least stop and look at pictures before you go at the holster. Simply laying the holster over on it's face . . . and looking at the same side of the gun should have shown the hole that was needed for the mag release. I use wooden dummy guns that I've made myself . . . but I am very careful about the mag releases and safeties . . . on wooden guns . . . they are absent . . . on blue guns they are at least visible. May God bless, Dwight

-

Car 52 said: I’ve always like making. Doesn’t matter what. Just like making. ------------- Dikman answered: Nice job carr52, looks great. I'm impressed that you did a drawing first, I just make things up as I go! ------------------- I'm with both of these guys . . . love making things . . . seldom use a drawing as I either lose it . . . or forget to follow it. I have an ability that I've been told very few folks have . . . I can 3D blueprint something in my head . . . and then refine it as I begin to make it. Worst thing that happens . . . it's sometimes a bit on the big side . . . but that's easily fixed. But as others have said . . . good job. I'm gonna put one on here just as soon as I get it fixed for me. May God bless, Dwight

-

If you buy 5/16 thin sided square tubing . . . AND . . . sharpen the inside edges with a file . . . makes a pretty good punch . . . You won't do 1000 holes with it . . . but for something you use every now and then . . . or once in 10 years . . . it'll work really well. You can then take a nice piece of maple or cherry . . . cut it to a slight taper . . . ending at 3/8 square . . . it'll make your hole better than just about anything else. You can also use 3/8 thin angle iron . . . you just have to hit it twice . . . and that gives room for error that the square tubing does not give you May God bless, Dwight

-

Total noob w/ bullet loop question…

Dwight replied to Ravenshurst's topic in Gun Holsters, Rifle Slings and Knife Sheathes

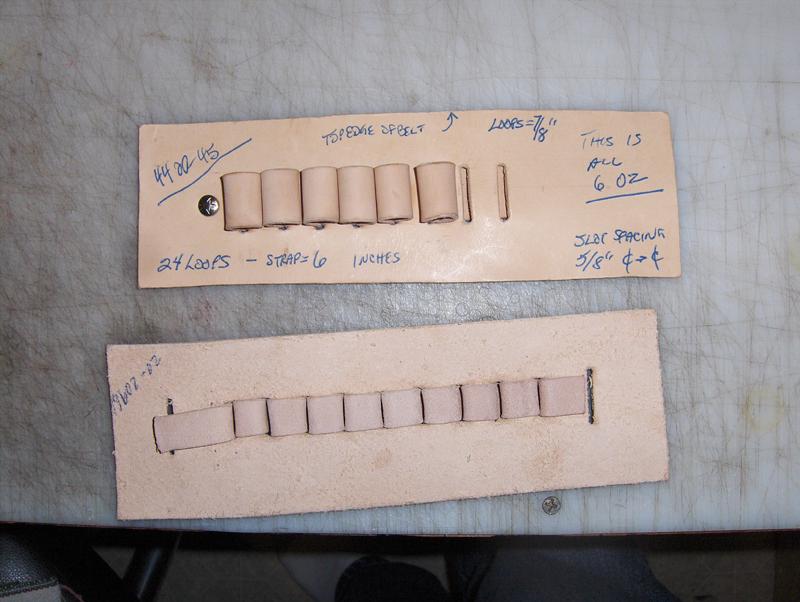

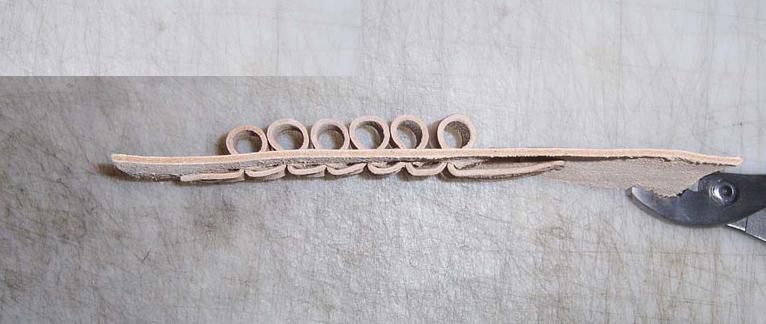

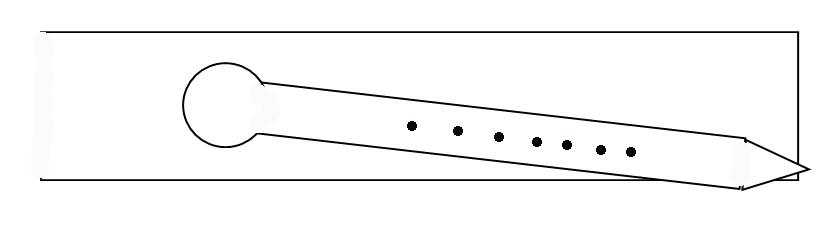

I have done bullet loops both ways . . . and do not like the long term results of those that are stitched. Old leatherworkers 150 years ago . . . didn't have sewing machines . . . and hand sewing belt loops is a real pain. Their alternative is my favorite way of doing them . . . and they should not stretch out and get loose as quickly as sewn ones. My cowboy belt is over 20 years old . . . still holds them well. Basically you make a vertical slot in the leather . . . pull the loop material thru the slot . . . turn it around and pull it back thru the same hole . . . and pull it tight on the bullet. As mentioned . . . DO NOT use fired cases. I like to use my own hand loads . . . because I know the cases are sized down. After pulling the leather thru both ways . . . insert the bullet . . . and pull the loop up tight closed . . . I normally use about 12 bullets . . . and when I get to # 13 . . . I take out # 1 and use it. The # 2 bullet goes into # 14 and so on. Don't leave them in too long . . . you want the leather still slightly damp when you slide the round out of it. Let it dry overnight . . . and dye the leather . . . then add your finishing. Most will be tight the first time you put them in there . . . and when you come home for the day . . . if you are not going shooting within 3 or 4 days . . . take the rounds out. Use calf leather if you can get it for the loops . . . or shoulder leather works well also. I make all my belts as double layer . . . that is why the belt is 6 oz. Two layers is 12 oz which will always be slightly over 3/16 of an inch thick. Make your .45 ACP loop material as wide as the case is long . . . minus the rim. When properly done . . . an inserted cartridge will show the rim above the loop and the bullet below the loop . . . and that is all. After you dye and finish it . . . the first time in with the bullets . . . it'll be tight . . . but they'll wear in. Have fun . . . may God bless, Dwight See the pictures I included in here. -

Can you reliably compensate for crummy lighting with Photoshop?

Dwight replied to AEBL's topic in Leather Photography

Put the grab on a free copy of Adobe Photoshop Elements 2.0 . . . I can almost say that if you can't "fix" it with that little program . . . it cannot be fixed. The only thing I've not discovered how to do is a clean background removal. But lighting things . . . and color adjust are pretty easy and straight forward . . . AND . . . it's a free download out there on the internet. Or at least it used to be a 5 dollar pickup on Ebay. May God bless, Dwight -

-

needing some help or guidance

Dwight replied to ShortApacheWrangler's topic in Patterns and Templates

It depends to a large degree on how certain you are of what you are doing. Generally I will make a paper pattern buy copy/paste onto a piece of printer paper . . . cut it out with scissors . . . tape it down to a manila folder. Cut out the manila folder and paper . . . toss the paper. Lay the manila folder down on my leather . . . get a black or blue ball point pen . . . and draw it out. I'm confident in my ability to draw correctly . . . having graduated from crayons a little over 70 years ago. I can see the ink very well . . . cut it right down the middle . . . or slightly outside . . . and go to work making the holster. If I should happen to have a line where it should not be . . . no big worry . . . holster will be black anyway . . . and if not this one . . . the leather goes into the folder for the next one that will be black. May God bless, Dwight -

I use the same "measurements" that I would for a typical ranger belt . . . The cowboy belt is simply 1 inch wider . . . and I make it a "finished" 4 inches longer. If I was making one for you . . . and I made you a 40 inch belt to hold up your britches . . . your gunbelt would be a 44 inch belt. I make them with 7 holes . . . 1 inch apart . . . and from the first hole to the tip of the tongue (where that fancy piece of metal is) is 3 1/2 inches . . . with the fancy metal tip hanging over the front of the belt body. Measuring your 44 inch cowboy belt . . . it would measure from the butt of the buckle (where it meets the leather) . . . to the center hole of the seven holes. That gives the wearer the chance to gain 3 inches of pizza . . . or lose 3 inches of lard . . . and still wear the same belt. I've only had to re-do one cowboy belt for one customer . . . he ordered a 55 and when he came to pick it up about 6 weeks later . . . he needed a 59. The buckle front lip hangs over the other end of the belt body. With a ranger belt . . . the tongue and the belt keeper are laid out and fastened straight as possible along the axis of the belt. With a cowboy belt . . . I lay the buckle end to the left . . . the tongue to the right . . . and I place the tongue so it is NOT straight on the axis . . . I lay it so the tip of it lays over the bottom corner of the belt body. That tends to pull the body upward . . . making it appear straight on the wearer. And of course I don't put a belt keeper on a ranger belt . . . to hold the body right behind the buckle . . . but there is always one on the cowboy belt. Haven't had a customer complain yet. May God bless, Dwight

-

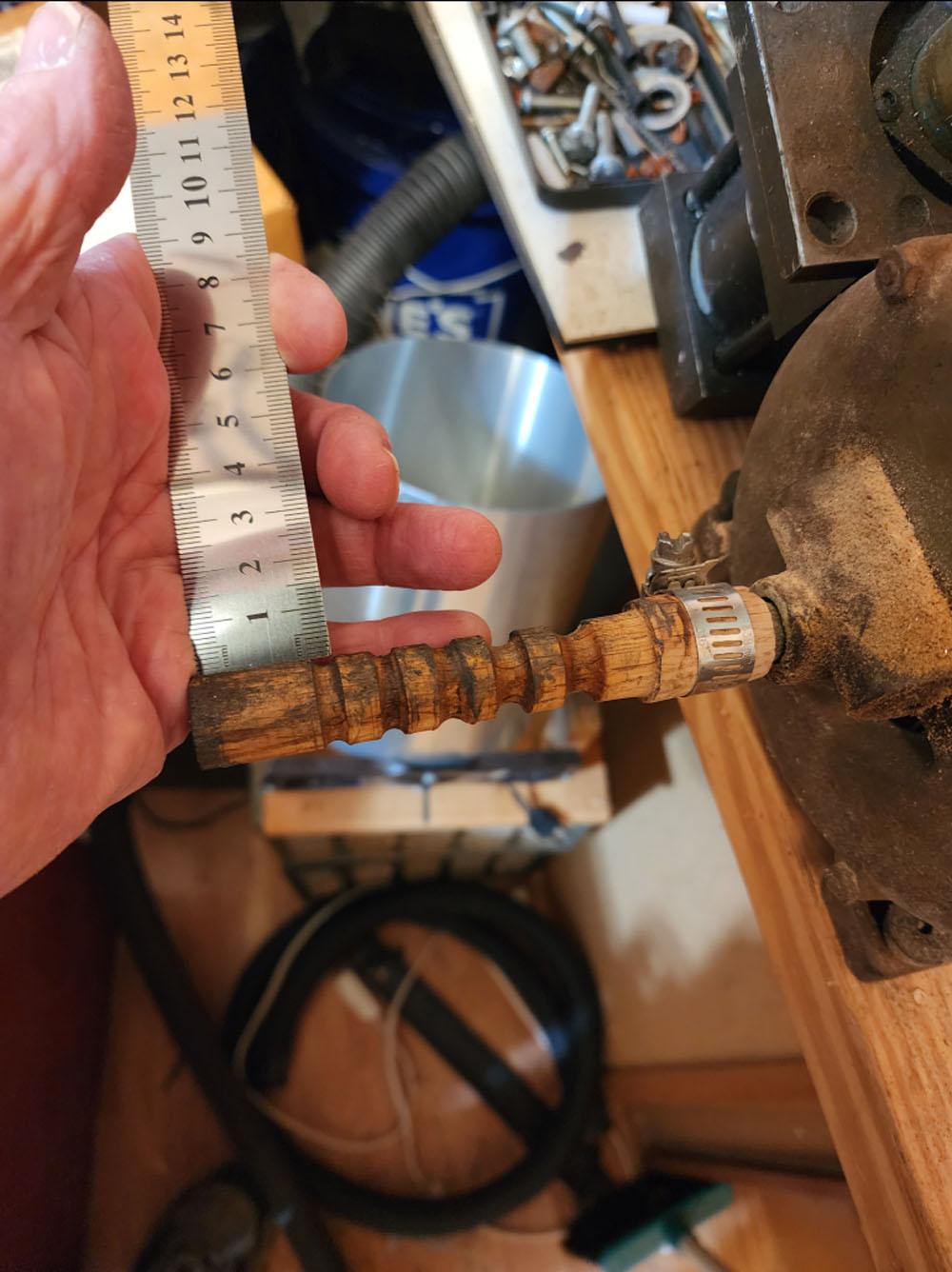

My setup is not as "pretty" as is many others . . . but it does the job. Took a piece of oak I had laying around . . . made sure that even though the grain is big . . . it was solid . . . no "splintery" trash on it. Semi rounded it out on my disc sander Drilled a hole in it to match the shaft of my little rusty old 1450 rpm motor . . . then slotted that hole so I could put a clamp on it . . . hold it tight to the shaft. Set up a block of wood on which to use my chisels . . . worked it down nice and straight and round. Then used the chisels to cut the grooves in it . . . gave it a good dose of solid bees wax . . . grabbed a rag and polished the wax. The two pieces of leather were just a scrap I had in the shop . . . used to test the stitches on my sewing machine. Hit the edge with a edger . . . put it in the groove closest to the motor . . . as it is the one I use for belts . . . after I dampened the edge. I didn't get fancy . . . wanted to show the basic burnishing . . . would look really nice if I had put some wax on it . . . The ruler is one of them kind that don't measure in inches . . . (lol) This has been my tool for something on to 5 years . . . had to scrap the other one . . . start switch went out on the motor . . . and shaft was different size . . . had to make a new one. May God bless, Dwight

-

I've never used that . . . too thin . . . and my experience has been NOT to use two pieces . . . one fat and one skinny. A 9oz and 3 oz will eventually find the 3 working loose in the glue . . . becoming bubbly . . . and looking ugly. Match the two layers as much as you can . . . I even cut mine back to back from the same piece of leather . . . It also dyes a lot better that way. Put your bullet loops on the curved outside piece . . . last thing you do before gluing and sewing the two pieces together. It makes the inside look better . . . and when you glue it together . . . you have glue holding the pieces of the belt loops . . . you don't if you add them later. If you can get it . . . use 3/4 oz calf leather . . . And think about your bending of the leather . . . doing so will make the bottom thinner . . . eventually becoming more flimsy than the top. It's better to make a pattern and cut them curved . . . that way they always remain the same thickness uniformly. I know the argument . . . "but you waste so much leather that way" . . . and it is basically garbage argument . . . as you lose some off the back side of the first one you cut . . . and off the front side of the last one . . . and all told . . . when it is done . . . you may have saved enough to make one side of a standard belt. Usually . . . there is a defect I go around . . . and that defect is in that standard belt piece of trash. YMMV May God bless, Dwight

-

Actually you don't have to do that . . . there's a really MUCH easier way. The program is Laser GRBL . . . and it is free. If you can make a drawing . . . and I mean anything on paper with a pen, pencil, or crayon . . . all you have to do it make a digital copy of it. AND . . . if you take your time . . . and play with it a while . . . you can even take certain photographs . . . digitize them black and white . . . and if you have even a 300 dollar laser engraver . . . it'll pick up the shading . . . you can put a photo on leather. I use cardboard as my test medium . . . when it is right . . . I cut a piece of the picture . . . try it on scrap leather . . . if that works . . . I do it. I do a lot with *.jpg pictures . . . they're easily scalable . . . and work great. You set the laser on a platform that is checkerboarded and each line numbered . . . note on your first good copy that the top left corner was at 24 horizontal and 18 vertical . . . and you can produce a thousand . . . setting your blank at that point every time. The enclosed pic is one taken from an army patch of a buddy . . . turned to *.jpg . . . one made is about 4 cm wide . . . the other was about 8 cm wide . . . he was tickled pink with both. . . . again . . . they were done with B&W *.jpg prints. AND . . . if you go to an auto part store . . . or lumber store . . . buy the absolute cheapest . . . ugly dirt cheap . . . black or grey PRIMER . . . you can spray it on your metal . . . do the engraving trick . . . and clean the paint off with a strong paint thinner . . . or use a drill and steel wool pad to polish it off . . . Yeah . . . it works. May God bless, Dwight

-

Metal Belt Tips for Gun Belts (1/4" Thick)

Dwight replied to llucas's topic in Hardware and Accessories

The simple answer to your problem . . . don't make the tongue and buckle end of the thicker leather. I still make double layer . . . but I go down in size . . . so I wind up with an 8/9 oz belt tongue. The one on my cowboy rig has been there for 20+ years . . . was done that way . . . and still works and looks good. May God bless, Dwight- 4 replies

-

- buckle sets

- belt hardware

-

(and 2 more)

Tagged with:

-

Wood actually does work great . . . several commercial leather suppliers make and sell them . . . Mine is I believe out of maple . . . which is the type of wood you want . . . it has a very close grain and is reasonably hard. Oak can be OK . . . just have to be careful of it . . . sometimes grain can be pretty open . . . which would make for a splinter producer possibly. When you first start it up . . . 1450 rpms or so is good . . . start it up . . . fold up some old canvas or some cotton rope . . . use it to get the wood warmed up . . . holding it tight into the grooves . . . then add sliced solid bees wax . . . back to the rope . . . more beeswax . . . more rope . . . until you get a really smooth surface. Fix up some scrap leather . . . edge it . . . rub beeswax on the edge . . . and force it into the grooves while it is spinning . . . and kinda let up slowly on the pressure . . . finish polishing it with an old handkerchief or tee shirt. Then each time you use it . . . hit it with the beeswax . . . or rub beeswax along the edge of whatever you are burnishing. You'll love the production. May God bless, Dwight

-

Finish them with a coat or two of Resolene . . . they last for a long time . . . look good and feel good. Before finishing . . . lay it flesh side up . . . slightly dampen it . . . and using a glass slicker . . . go over it . . . from end to end . . . only ONE WAY . . . It'll smooth right out . . . your customer will love you. May God bless, Dwight

-

I basically disagree with all your conclusions. Leather weighs what leather weighs . . . making a belt out of two layers of 5/6 will equal the weight of one layer of 11/12 oz. If the holster is slipping up and down . . . it is the fault of the design and the maker . . . the belt slot is too big . . . they can be made to fit. Making belts or holsters of 2 layers . . . glued together with contact cement . . . will make a very comfortable and enduring belt . . . to say nothing about it's superior looks. Making a holster "rough out" is only a personal preference . . . sometimes adding a certain "rough" beauty to the belt or holster. For a few dollars more and other westerns of that era had some of them. Double layer holsters also will grip the weapon better . . . be far less apt to deflate and become a floppy mess of loose cowhide. The smooth side out on a belt . . . only allows the belt to slide . . . if the belt is not made on a slight cresent contour . . . which makes it not only very comfortable . . . but will not slip down . . . even with two 4 oz revolvers and 24 rds of ammo in the back. Made right . . . they don't slip. Been making holsters for 20+ years . . . never had one . . . not one . . . negative complaint on any double layer holster I've ever made. John Bianchi taught me how to make them with his videos . . . still do it that way. May God bless, Dwight

-

Shoulder holster for a Ruger speed 6

Dwight replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Actually it is a really good job . . . and this is only a comment . . . not meant as a complaint. If it were mine . . . it would have a thumb break . . . especially if I were wearing it in the water. There does not look like there is a lot of leather that would hold it in if it needed to be held in. May God bless, Dwight -

Most all of us here will at one time or another . . . repair something made of leather . . . usually though only in the vein of work we normally do . . . ie: belts, holsters, purses, sheaths, satchels. But you can put me down as one who generally will take on repair work . . . I actually enjoy the challenge. May God bless, Dwight

-

Unless he's selling a couple hundred a day . . . he'll never pay for a full international patent . . . they're scary expensive May God bless, Dwight

-

But you do have to remember that your German patent is not good in the US . . . so the first customer who wants in on the action . . . may just jump on it . . . Things of this nature . . . even when they are patented . . . are always subject to "copy" so to speak. Not pushing the sales opens the door for another enterprising individual. May God bless, Dwight

-

I don't have one any more . . . sold it long ago . . . but if you really wanted to do custom engraving . . . it is really a simple process. First you make a copy of the item to be engraved . . . in some detail . . . and make it rather large . . . put it on a computer program that will print it out on paper . . . in a very large format . . . filling an 8 1/2 by 11 sheet of paper. Glue that to a piece of 1/4 inch plywood . . . and here is where the person comes in who is very talented. Non talented people will dismiss this . . . as will lazy people. Using a router with a very fine tipped blade . . . engrave the image . . . by hand . . . 1/16 inch deep into the plywood. You then take that image in the plywood . . . and using a pantograph router . . . set for 2:1 scale . . . re cut it into another piece of plywood. This will produce an image that is 4 1/4 inch by 5 1/2 inch . . . Using that 4 1/4 inch by 5 1/2 inch . . . you then use your pantograph router again . . . and this new smaller image . . . put a diamond bit in it . . . and engrave the buckle. The maximum size for that buckle engraved image will be 2 1/8 by 2 3/4 inches. Making the first image . . . being very talented . . . and willing to take your time . . . you produce an image that has flaws in it . . . for sure . . . but the talented part will not let many flaws erupt on the plywood. The second image reduces those flaws to not being readily seen . . . and the final engraved image is almost always very good looking. The first ten or so you do will take some time . . . but it usually isn't long before you get the hang of it . . . and it becomes old hat. Plus you can take the old ones you have already used . . . flip them over . . . and use the back side if you only engraved 1/16 of an inch down the first time. May God bless, Dwight PS: You may be able to substitute a carbide tipped router bit for the diamond bit . . . you would just have to experiment.

-

Your best bet would be to contact several well known auctioneers in your area. THEY . . . have "been there . . . done that" . . . as far as liquidating estates. And besides that . . . what little info you gave us . . . there is no way anyone here could take any kind of a guess at it. May God bless, Dwight

-

Has anyone any experience crafting custom cheek rest/ comb risers?

Dwight replied to PeltMe's topic in How Do I Do That?

Maybe before asking a question . . . you might read what was written previously. Might answer your question before you ask it. May God bless, Dwight