-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RockyAussie

-

Hi Fat Dog Leather again I just found this post. Splitting on glaze skin will often be difficult and Still leaves the skin stiff and curly. I have to do a stack of bangles at the moment and I prefur to run them through the sander as it tends to break the tension and leave it in the end more flexible and able to conform to shapes better. I'll do a few pics of and send some tomorrow. Coming to skiving on edges - once it has been sanded and the tension broken you will find the skiving better. Do you have a roller foot on the skiver? I believe it is essential when working with glaze. With regards to the Cobra splitter I haven't seen or heard of one that is a band knife splitter. Have you got a picture of it you could post? Regards for now Brian.

-

Thanks for link on buckles Yuri. The Akubra looks a good fit indeed. The off-cuts of the croc belts above often go to Akubra for hatbands. I will pass on your regards for sure. See croc hat-band with croc teeth below. Oh yeah the braided belt with rings are generally done with Kangaroo lace and very common and popular here. Plaiting is one area I have not done much of myself, I mostly stick with crocodile and it doesn't plait well. Best regards for now Brian.

-

Thanks for that answer. If you come across any good buckle suppliers in that size range please let me know. I have done up knife patterns today and I will post some pics hopefully in 2 or 3 weeks. Funny thing and no bull I made up a 50mm double tongue belt for this fellow in Amazon Singapore a few months back and he emailed me today wanting a couple more. Horrible buckle but he likes it. What do you think?

-

Just a thought Red Cent I think if I had to do this I would make the elastic onto a clip strip that could then be replaced as a unit by itself. Advantage way cheaper to have spare wear part replaced. Elastic down on to webbing I'd say.

-

Never mind Victor you will get better... Ha Ha I'm not too sure how. Good to see someone else gets some interesting challenges with watch bands.I'll try and dig out some of my jobs and swap notes with you. Regards Brian

-

Looks good and interesting design Yuri. Surprised to see the lining done as you have. Have you found any trouble getting that 44mm through the pants loops? I am thinking of doing some backstrap crocodile belts in this size due to having so many too large to fit into my 38mm size width. Nice looking brass or stainless buckles for 44/45mm belts are also another problem. BTW nice work on the belt holder as well.

-

Maybe check your local shoe repair shops.

-

Is it possible to get a job in leatherwork with the skill I have?

RockyAussie replied to Sandgel's topic in Old/Sold

Your already there Eric. Not sure about your padlock cover on imgur. Some dabblers there will be happy to work with you and I doubt I can offer much advice other than be confident. -

Singer Leather Sewing Machines

RockyAussie replied to Trevor Baret's topic in Leather Sewing Machines

Hey Trevor I'm just wondering did you get my P.M.?- 53 replies

-

I must admit it's been years since I bought needles. By to expensive do you mean parts or the machines. I would have thought the machines would have been pretty cheap to pick up.

-

Hi Wizcrafts, The pic of the Gritzner by jimi above sound more like the machine you're after. This is very similar to the Frobana outsole stitcher which when I was doing shoe repairing was my favorite. I think I still have 3 or 4 floating around here somewhere but they are the full on cast stand versions.. Parts are a bit hard to get here.The presser foot above tends to wear off on an angle and is the only main problem I ever had. Regards Brian

-

How to make leather zip pulls in less than 1 minute per

RockyAussie replied to RockyAussie's topic in How Do I Do That?

Thanks catstamp, I hope to do a few more soon, maybe watch bands or bangles next. -

Why not keep it and knock up some sandles YinTx? Easier than bags.

- 11 replies

-

- sole bend

- 15 oz leather

-

(and 5 more)

Tagged with:

-

Singer 31K18 & 31K48 - help!!!

RockyAussie replied to Trevor Baret's topic in Leather Sewing Machines

Can you get a 3 prong puller over the middle of the 12358.Use leather or something to protect the paint. If so I"D use some WD 40 and leave overnight then try pulling next day when warmed up a bit.Mostly I think the grub screws would have burred up the shaft. -

Singer Leather Sewing Machines

RockyAussie replied to Trevor Baret's topic in Leather Sewing Machines

Yes QLD Rocky is right. Backstraps not much problems I've got about 2 to 3 thousand here ,but belly skin nearly impossible. I mostly just contract make for most of the croc farms and they want the products for their own sales... There's a cold one ready waiting for you see below. Regards Brian- 53 replies

-

Singer Leather Sewing Machines

RockyAussie replied to Trevor Baret's topic in Leather Sewing Machines

For anyone needing a Singer Manual this type of link file would be a real big help. I believe it should be pinned and added to in time. Thank you for your kind contribution to all.- 53 replies

-

I would try and get something like you would find for sale at the moment in LeatherLeagon profile page. I think it would be more versatile and a lot stronger. Shame he won't ship I'd buy it myself.

-

That is one very nice looking patcher. If it goes like it looks its worth a lot more.I don't know how you could come to selling it Ferg Sorry.

-

I cant believe I see no questions in regards to buy. If it were over here I would already be on your doorstep. Must be the GFC or something.

-

How to make leather zip pulls in less than 1 minute per

RockyAussie replied to RockyAussie's topic in How Do I Do That?

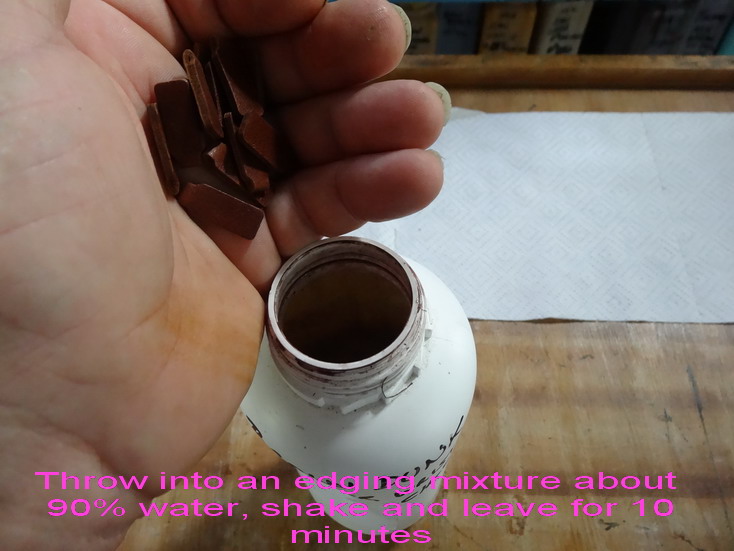

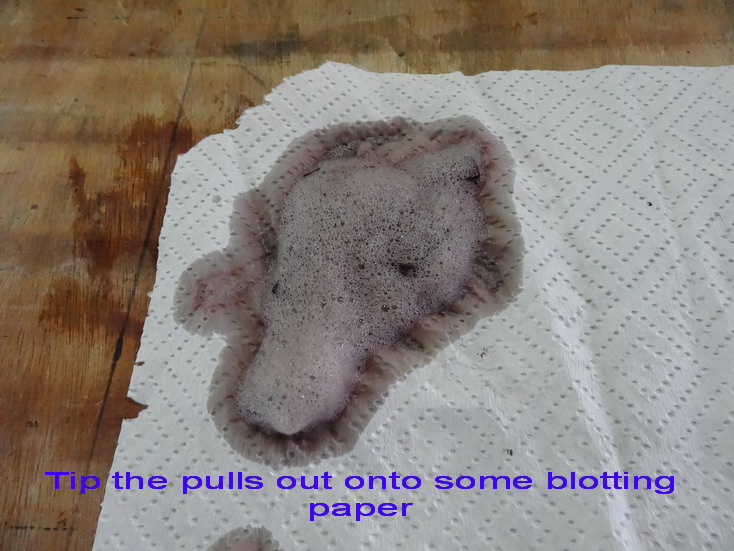

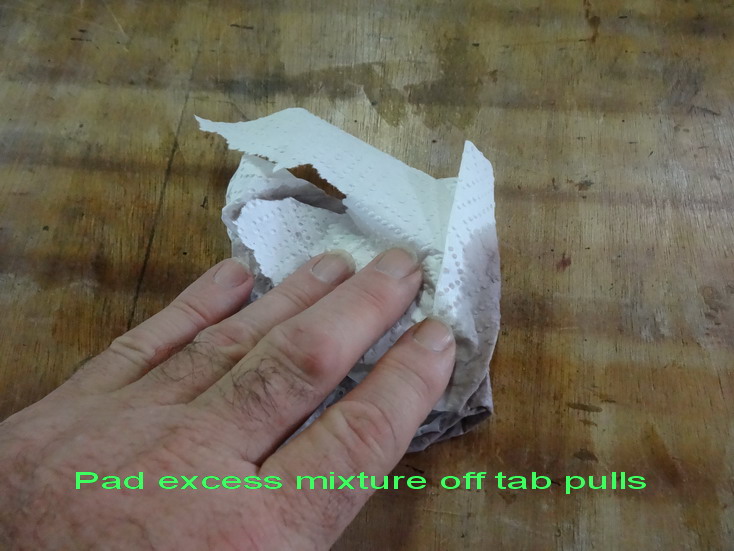

Firstly thanks SamB and Matt S for the positive feedback.That's not so easy to answer as the names here are different to what most would know. The Ares (italia) S.r.l. would be the main one but to get the huge colour range I mostly use the clear AR 6350 Neutro Denso and mix in pigments to get my own colours. In the U.S. the Fenice range would be the same I think and available from Campbell Randal. I commend them for having a decent colour card etc on the products unlike most. Also I use another that would be similar to the Giardini range and is good in some other respects. I need a lot of various colours and high quality properties as I hope the pics below show some. The mix is about 90% water and only to seal and colour the raw edging of the pulls in this case. It mostly absorbs in in this case and does the job well. -

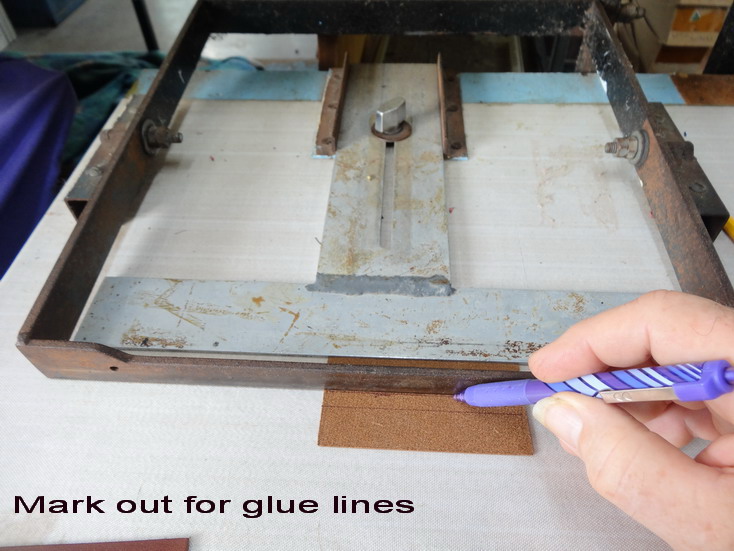

This technique could be done with a hand punch if the die were made in that way in case you do not yet have a clicker press. When a zip pull tag is so small it is difficult to work on in so many ways and can be very hard to do in a short time frame. I hope for budding manufactures this will be of some help. If some think that this type of thing is not the right place in this forum please let me know and I will delete it if possible. If you think it is suitable please say so and I will proceed to show more.

-

I messed it up

RockyAussie replied to Dunluce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice stitching and edging not to bad, can you not get an invisible cap under the lid piece? -

Now if we can just put the die grinder or dremmel into the tool post of the lathe.....

- 11 replies

-

- rotary blade sharpening

- rotary blade

-

(and 1 more)

Tagged with:

-

bridle sides from greenhalgh tannery

RockyAussie replied to Wedgetail's topic in Leatherwork Conversation

Hi again Wedgetail, I gave them a call this am and if you go up and talk to Terry and you are only buying Raw materials he will help you. Remind him of this conversation and if any worries let me know. Regards Brian. -

Welding/metalwork I would say no more. Check on google for the patent, that is fairly easy. If you cant find it after a heavy search then a patent application is not that dear. If approved you then have something to sell or license.Keep in mind if you can get a good batch done and the cost is affordable than many would buy from you anyway and the cost of patent is often debatable anyway. If you have not the money to protect the patent then better to you the money to swamp the market as best you can and they cant patent it if it is already common knowledge. Get my drillft.