-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RockyAussie

-

Been holidaying a bit so sorry for the late answer here Spyros. I will get some pictures together and get back with some info tomorrow. P.S. Can you pm me your number as I am stuffed if I can find it at the moment.

-

Here are a couple of pictures from the set up up on my Fortuna that may help .... Re the vacuum ...consider just letting it run always when the machine is on. Just put a switch to turn it of or on when you need to sharpen perhaps. The Fortuna and the FAV machine I have have the vacuum always running when the machine is running.

-

Sorry for the delayed answer mate ...been having a bit of a holiday. I don't see any pics with the broken pin you mention. The clutch should disengage normally when you lift the lever up and it should want to sit in the hollow beneath it. When the clutch is engaged it should look like this pic To disengage it you should only need to push it upward like as shown To engage you just pull the lever forward and push it down ( in this pic note that there is a tab underneath that can be adjusted to hold the lever higher up if needed). Is the pin on the back of your lever missing??? Does is disengage when you hold the lever up??

-

Solaway sole remover

RockyAussie replied to ScottEnglish's topic in Shoes, Boots, Sandals and Moccassins

It all depends on the type of upper and the type of sole you want to remove. In most cases a contact glue solvent (thinners) is all you need and in most cases you just use a suitable brush to activate the glue. Open the sole back a bit with your large nail pullers gently and just work along slowly wiping as you go with the brush. The brush will need to be regularly rewetted. Sometimes a paint stripper gun can be used to gradually apply enough heat to activate the glue and peel back the sole with some suitable nippers. If you could post a picture of the project you want to do this on I could probably give you a better answer. All of this is done using a shoe last stand normally which helps to give you something firm to pull against. -

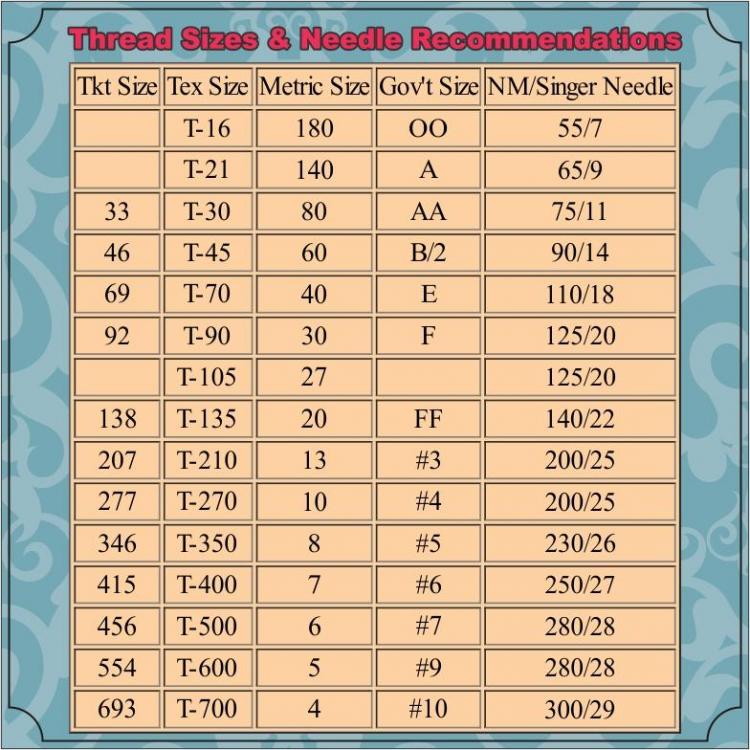

This might help some - Most of the recommended needle sizes shown above would suit heavy weight leathers in my opinion so for soft leather you may get better results by dropping back a needle size. This link shows a wider range of thread / needle recommendations and is often referred to on LW https://www.tolindsewmach.com/thread-chart.html

-

Hey Don, Have a look in this link and the video's showing them in use. If you want a set of them pm me with your address details and a email to send you an invoice to and we can make it happen. Brian

-

Show me some pics of the pins in the shaft as well. To be safe I will try and get some pics on here showing the gear section behind that shaft. You will need to take off the top cover and check that there is some grease in there and that the cogs are not all broken in there. Having that shaft not connected does not sound good. This is what that shaft should look like - This gear box at the back shows a top cover plate that can be removed with three screws - Inside you should see oily grease and if it looks dodgy you will need to clean it all out to inspect.

-

IF that is using an LR needle .....you can try turning your needle clockwise about 5 degrees to get a more slanted stitch then also back of your primary tension (the lower one on the end cover) about 1/2 to maybe a full turn. Don't turn the needle too far as it could end up too close to the hook but there is a fair bit off play room. They are one of the tamest well behaved machines I have ever used. Thanks for the good feedback @TomE. I am sure you are going to find a good improvement production wise on wide range than before. Merry Christmas

-

You still believe in Santa dontcha. These machines don't come all assembled and threaded and timing checked and check springs set and tensioned up for any given size thread and after all of a whole lot more than that ....pack it all up and box it all again. Generally you don't get much if any saving if you are buying a one off machine. Try a minimum of a pallet load. There is a lot more in it than a quick glance would leave you to believe. (Freight is like beyond a joke $$$$$$$ with so few regular planes in the air taking up the slack) . Do a lot of homework before you go too deep and maybe learn Chinese.

-

Sort of but not really. I am working on getting some into OZ at present but they will be a known brand as long as they past all my tests. (February 2022 I believe) Note: most dealers have to do a lot in the background to ready these machines up for the general public. My preference is needle on the right as that means if you want to say sew around the base with the bag down over the horn you don't have the body of the machine getting in the way while you work your way around. That is a big bag you are stitching in the picture above and I bet your glad you are not trying to do IT in the throat of the machine I have to ask.....have you got one of our narrow needle plate dog foot sets installed? Hope to see your bag when you finish it. I wish you a Merry Christmas Brian

-

I don't know what is around your area but if you search for high post bed machine 8365 you will get a lot of results. Here are a couple that show the product a bit better than many of the other ones you get. Take note of the needle close to the edge and also where in one video you can see where a tall tote can be stitched down the side so easily. https://www.alibaba.com/product-detail/leather-bags-8365-high-post-bed_60468228341.html?spm=a2700.7724857.normal_offer.d_image.591c2784YURSK5 https://www.alibaba.com/product-detail/Small-hook-8365-handbag-making-super_62418261641.html?spm=a2700.7724857.normal_offer.d_title.591c2784vIkM2T as you will see you can get them in different heights and left or right side of the post etc.

-

Correct, you would do a lot better with the left side presser foot installed but watch that you reduce the foot pressure down enough to not leave foot impressions all over the top. Using your thumbs you should be able to lift the back foot by hand about a 1/2". On the bobbin side stitching, a quick rub over with a bone slicker can improve the look and equally a quick rub polish will as well.

-

Just a thought ....if you decide to tighten the bobbin a bit make sure you undo the locking screw in the bobbin case before you try loosing or tightening the tension screw.

-

Congratulations @Spyros the learning begins. The needle you are holding in the picture is a LR needle and I am not sure if that is the same tip shape in the machine or not. Jess supplies TRI points as well I think but they don't usually give so much of a slanted stitch look. The bobbin side does look rougher than normal for sure and I would not expect to see it like that unless the leather was quite old and getting dry. Is the stitch quite tight down in the leather. Possibly the tension top and bottom could be tightened just a little but I would try another leather first.

-

The down side if any that I can think of with the tall post is getting a good height for the operator to get right. Some places do stand up stitching and some like me like to sit. No much of an issue really. As to the roller foot as against walking feet ..... the rollers are great if you are doing fancy detail work as they can give a bit better manoeuvring but can be a bit tricky to not leave fine roller teeth marks on top on some leathers. A couple of examples This above is done on this Adler with a driven top roller Basically its good but the distance of the needle from the edge is a bit far away on a lot of things and the shape of the horn is not very rounded which impacts on things like small circular bags etc.

-

The second drum thing after the impeller may be a spark arrester? There are quite a few different feed roller versions. In the stone versions you have a fine ,medium and course grit to choose from and I would suggest that the medium is what I would start with. The fine grit is not great at picking up and pulling through medium to heavy weight leathers and the course is more liable to have soft leather stick to it and wrap around. This link from Campbell Randall shows quite a few of the possible types - https://www.campbell-randall.com/shop/fav-fratelli-alberti The rubber feed types can be good on soft stuff but if you accidentally have the feed roll touch the bell blade it will cut right in and that's the end of that one. Had that happen. The steel fluted ones can be good on heavy weight leather but can leave a ripple up and down look and again if it touches the bell knife ......not good. As a general practice using the feed stone to clean up the burrs inside the bell after a sharpen is not normal except if for some reason you have had to grind out a large chip from the blade and there is a heavy burr inside the bell. I do it when I sharpen a bell for the first time but rarely after that. You do NOT want to do this and end up with any bevel inside the bell as it will make getting a predictable skive near impossible. The leather will dive downward. Cleaning the burr off with a stone tipped dressing stick is the normal practice and only takes a few seconds of pressure. There should be a brass dish shaped deflector in the bell which should be set about 15mm in from the edge, this you have to careful not to touch with the dressing stick when you are cleaning up any burrs. When you have it in hand I would post a few pictures showing underneath of the machine head mostly around the bell area and in from the end and straight on at the front around the bell area again.

-

It does matter and thankfully a lot of these machines have an adjustment underneath to move the stone back a little if need be. The width of blade angle you can see should be around 5mm wide or a bit more if possible. The wider bevel makes it less of a problem to get thicker leather to to pass through. If it is too short it will jam up more often and the feed stone will have trouble pushing it through. With the machine head opened back you can see me undoing the 12mm bolt to move the stone back in order to achieve a wider skive bevel. This pic shows the shaft is now fully back.

-

Many of the shorter posts I believe are great for doing shoe uppers as they are normally like a small table top. Most do not get their needle that close to the edge. Doing any bags that have a little structure in them will need more height than the common 7" to get down the sides and across the bottom. I am only advising you need to have a close look and consider the type of products and methods used to be able to construct them before you sink a whole lot of money into a semi useful machine.

-

If it helps I just cut off the top of the small aluminium soft drink cans and throw in small chunks of the wax while I melt it with a paint stripping hot air gun blowing down in and onto the sides.

-

If you want to do totes etc have a think about this one.https://www.techsew.com/us//techsew-85017-high-post-walking-foot-industrial-sewing-machine.html Having the needle coming down over that side leaves you free to do large jobs out in the open and very little to stop you going all the way around on bags like this circular one I made recently - ( having the needle come down very close to the edge is important and many post machines don't).

-

I highly doubt there will be a switch to just change over. First see if they provide any manual to advise the air pressure requirement. I would not go with the air driven set up unless you only intend to do short runs occasionally. As far as the feet go there are a lot available but I would be getting a roller foot version pretty early as I do almost any thing I want with a roller foot with the least problems. One of the dealers here has agreed to pay me some $ to do up a manual with pictures on how to set up and use these 801 type skiving machines which I will probably finish by March or April 22. Most of the manuals out there are not very helpful I am sorry to say. This here link if you check will show some of the feet available (you can see in my youtubes where I made one like the number 18 fit up and I would get the number 20 in case it was any better. https://www.aliexpress.com/item/33049213271.html Get a whole lot of scrap leather and take notes as you trial. (make sure you get a dressing stick for removing the burr occasionally inside the bell) Let me know when you have it in hand

-

Welcome @riy, as you will find there is a whole lotta stuff you can learn here and enjoy the interactions and help from other members. What may I ask are the sewing machine types available to you at the market place? Getting some good advise on the sewing machines suitable for your needs is always a great idea and there are many here can help with making that choice a god one. 3d printers and lasers are also something I use every day and would recommend highly to to anyone getting into producing leather goods these days. Recently I found I could make up good acrylic stamps with my little diode laser - With the 3d printer I can make folder guides for making up straps pretty much any width and thickness I want - Another regular use of the 3d printer is making the moulds for wet moulding products - Have fun and I wish you a Merry Christmas.