-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RockyAussie

-

Zipper installation multipurpose guide

RockyAussie replied to RockyAussie's topic in 3D Printers and Lasers

Here's the thing ...It costs about $25AU dollars to get a small parcel to the states which is way more than the cost of the pieces in a typical order and I could send probably 5 times as many pieces for the same postage cost. What would someone want to be paid to send out orders from over there I wonder and if anyone would be happy to do that? ANY suggestions welcome... Brian -

I have a similar machine and have a fair bit of experience with stitching sole leather as well but not with this machine. Not that it could not I guess but here is the main point....Whenever I have done sole leather I soak it in warm water with a little detergent until it becomes softer and pliable and behaves more like a bridal leather feel. This is sometimes left to soak for some hours and then put into a damp towel to mellow overnight. The needle should be a triangle shape tip or at least an LR shape but definitely not just a round point. You need the hole to allow the needle and thread to pass through easily. Lastly with regards to the thread breaking back off your bobbin until you can just see the loops showing on top and then re tighten a bit and back off the top tension a little. For some reason running a looser bottom can work and and stop the thread breaking. May not be smack in the middle but do you think that matters here?

-

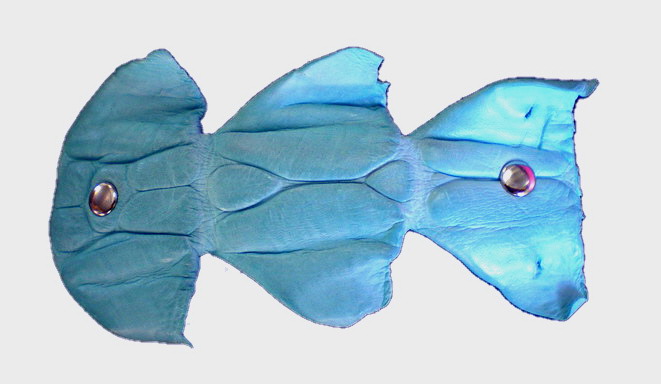

I am sorry but this picture makes the pain so real and has made that thinking part of me go into overtime. To quote you - "I have some hair from her and was thinking about a bracelet but not quite sure how to go about that". I can think of all sorts of elaborate ways but here' a thought - What about a tassel of hair done up like a small tassel like a charm. Stick a line of hairs down onto some sticky tape about 1/4" up from the edge and make them in a row a few inches along. Then firmly roll the sticky tape around on itself until it is perhaps 3/8" in diameter. Whilst rolling the tape try and keep it from closing at the end so that it leaves a hole into which you can put in some clear sealer to start with. When that has dried off make a loop of leather to go down into the hole and put some araldite in and place in the loop to dry again. Then make a circular piece of leather to cover the top and a little of the outer edges and stick that into place. Follow this by making a leather band to wrap around the tape and finish it off. These pictures below are done a bit along the lines I am trying to describe and probably help to make it clearer. You can attach it to a bracelet or whatever you like then.

-

Zipper installation multipurpose guide

RockyAussie replied to RockyAussie's topic in 3D Printers and Lasers

Thanks for the feed back Brian. You would not believe how quickly they have fallen into every day use here and I am starting to worry just how the hell we ever did most of the zips here without them before. I saw someone asking about how to do them on here recently and I previously used many different jigs and line up marking tools and I honestly don't use almost any of them now. Amazing how quickly you can forget when you don't need to remember. -

Zipper installation multipurpose guide

RockyAussie replied to RockyAussie's topic in 3D Printers and Lasers

Yes can do if you want. Let me know what zip sizes you are using/wanting and I will get you some costs sorted out. -

Not sure if this will help you or not but here's a post I did awhile ago may be worth a look.

-

Strap Scrap...suggestions please ;)

RockyAussie replied to JazzBass's topic in Leatherwork Conversation

Nothing to apologise for @ABHandmade your English is fine ...I'm just being creepy showng off again These pics show a hair clip attachment and this one shows the clip.... and the fact that I can make a mess of the edging too at times -

How to make a press for moulding leather pouches and such

RockyAussie replied to RockyAussie's topic in How Do I Do That?

Thanks and I'm glad you liked it. Hope to see something from you where it helped one day. Give us a call if you need any assistance.- 74 replies

-

- moulding leather press

- handcuff pouch

-

(and 1 more)

Tagged with:

-

Strap Scrap...suggestions please ;)

RockyAussie replied to JazzBass's topic in Leatherwork Conversation

?? like these Or perhaps the hair bar would be easier. Many just use a wooden dowel but I reckon a piece of cow horn looks a bit flasher SORRY I just coudnt resist -

Strap Scrap...suggestions please ;)

RockyAussie replied to JazzBass's topic in Leatherwork Conversation

No That shape would not work for inter joining links but maybe in useful for feeding some rope through and folding over to have another rope slide between. Horse halter type stuff maybe. -

Strap Scrap...suggestions please ;)

RockyAussie replied to JazzBass's topic in Leatherwork Conversation

If you have a press of some type you just keep making use of the shorter bits ...depending on the value of material used somewhat. Don't have much problem getting the tongue holes in the right place with this method either. -

How to make a press for moulding leather pouches and such

RockyAussie replied to RockyAussie's topic in How Do I Do That?

I had one printed in for that purpose originally but it broke off under the tension. I thought about drilling it out and replacing with a suitable nail size but as you say the hole would likely stretch longer and out of shape. It may be worth a try though.- 74 replies

-

- moulding leather press

- handcuff pouch

-

(and 1 more)

Tagged with:

-

I see lots of problems here, and having just gone through my photo collections I can not see any that can show enough to be much help. I will try and get something together over the next few days. First up for now you will find it of help if in the corner of the gusset you take out a small V section to relieve the pressure there. There should be no edging done until the pieces are put together and sanded smooth and rounded. In some cases it could be stitched first if that helps by allowing the stitch to be in from the edge enough to allow later sanding but I usually prefer to get the sanding done first and sometimes a couple of edge coats done to assist it to stay together. A tip that should help is the use of a heat gun which if used carefully will reactivate the glue and allow you to reshape and press down all the up and down wobbly bits. This can also be used to singe away some of the furry leather bits after sanding before the edge coat application. The Cowboy 4500 is most likely too large for this job a bit especially with the standard feet and throat plate. Do not try and stitch so close to the edge or your under/bobbin side will be all over the place. You may find this post of interest- I have to get some work done for now so I will try and get you some more info later. Brian

- 48 replies

-

How to make a press for moulding leather pouches and such

RockyAussie replied to RockyAussie's topic in How Do I Do That?

The top open edge is difficult to not get pulled downward toward the bottom where a lot more pressure is being applied so I generally put the outer mould piece down at an angle at the top so that it pulls the sides tight before the bottom comes into play. This is done by hand a fair bit before going into the press. In the mould above the sides are very tight and and I do get a 2mm to 3mm gap in the middle where it has pulled downward. Thankfully that has been allowed for and it all comes out fine at the end.- 74 replies

-

- moulding leather press

- handcuff pouch

-

(and 1 more)

Tagged with:

-

Moulds for veg bags - wood or steel?

RockyAussie replied to LottyAfrica's topic in How Do I Do That?

A post I did awhile back may be worth a look at if you go through to where I show how I made up some moulds for handcuff pouches. The advantage of going this way is you can get exactly the same duplicate mould made as many times as you want, with out having to spend any time much on making them. The method shown also allows minimal waste of leather unlike many I have seen on the tube. -

@carmela If you would post some pictures of the problem and a description of how you went about it I would be happy to try and advise. Is the leather oily/greasy? What glue type are you using. If you are using edge paints you should not apply any waxes until the very end. Burnishing is also not advised. A picture of the cowboy set up showing the needle and entry point area may be an idea as well.

- 48 replies

-

Sorry guys. I have been in this all weekend and with the fitting of all the T nuts in place and drilling the holes,sanding and polishing the acrylic edges,wiring in external switches, fitting the suction motor and more shelves along with taking pictures and videos of the testing I just ran out of time. For now here's a couple of pictures of where I am up to. Good news is that it all works and well and the video of the testing looks good. I just have to find some time to do the video editing and uploads now. This first one shows where I am applying the foam around 3 sides to direct the air flow. The video will show that later. Will get more of the building progress pictures through later this week along with the videos.

-

Thanks for sharing your input on your experience with owning a C02 laser. I am glad to see a positive reflection on owning one and I would love to see more if you have any on how they are useful in the leather working world. It was not my intention to rubbish a Co2 by any means, as I said there were many reasons I felt best to go with a diode laser to start with. Firstly at the time when I researched into this most people that found their lasers useful with leather were seldom using them for cutting. By far most are using them for engraving purposes. Those that were using for cutting in a business like way were using 100 watt upwards and the prices and the size at that point goes up into the $thousands pretty quick. 2. The cutting size of 8"x12" (96sq") that most of the 40 watt lasers you mention come with is way too small for my uses. The little A3 Eleksmaker can use 12"x 15" (180sq") and that is not really big enough either but is nearly twice as big. A lot of my bag patterns go bigger than A3 size. When I found out I could cut card stock with the little laser I was pretty much hooked as that meant when I drew a pattern up in my cad program I did not have to print it out and then cut it out to recut it out again on leather by hand. The little A3 laser set me back about $300AU to start and once it showed its potential and paid for itself in about a week making product boxes I decided to spend another $300 thereabout to make the cutting area 27"x35"(945sq") There is a few dollars in that for an extractor fan ducting etc that should all go in place this weekend along with the acrylic shrouding. Already before this I cut enough product boxes in the last 2 days to pay for the extra cost.A lot of the pieces in these boxes are bigger than A4. 3.There are no mirrors to line up + focus or keep regularly clean and no water pump that needs distilled water or chiller. Mostly cutting the leather leaves some charcoal residue that can be time consuming to clean up and is therefore a reason not to consider it for any production type work. Even the best powerful lasers still have this problem and in most cases if you are doing production like me you would use a clicker press and knives. The cutting time per piece is around 30 seconds from 1 piece to the next. Also knives tend to push the leather down and give a better look to the job. Getting knives made can sometimes be expensive and doing some sales testing on a product that is laser cut can be of help and in some cases like this pattern of an non stitched product shown below the knifing costs would be very expensive and you would really want to be sure its a seller by trialling with a laser first. AS for the life of the diode laser ....this depends as well on how hot and long you are going to run it but this link was the first one google showed me when I asked how long does a diode laser last? https://www.myomron.com/index.php?action=kb&article=673 If I get 50,000 hours I would be I am working on a cooling fan over the top of the laser at any rate with the idea of using the blow by to give some air assist at the same time. Will post that when done. Here is a couple of the progress pictures so far. This one shows the size difference This one shows the wiring and everything else is working as it should so far. I will have some more pictures and news Monday I think.

-

-

I think you would be lucky to not have troubles even if you ran a pipe cleaner through every hole before the needle. My experience with the charcoal produced when cutting with a laser says it is just not the way to with any thread that can absorb it. I have tried putting several coats over surface charcoal to see just what it would take to seal it and came up with no good answers really. Trying to seal the holes would be near to impossible so my thoughts are to go to the chisel method instead. If your laser can operate with a dxf file in a program like T2 laser you could set it up with green lines turned down to just etch the surface to give you a guide line to follow if it was the trouble.

-

Thanks for sharing that info Jimi some interesting good stuff there.

-

How I now straighten leather for strap cutting

RockyAussie replied to RockyAussie's topic in How Do I Do That?

Thanks for the kind thoughts and may God smile on you always. -

Looks Dam nice to me Damon and extra strong.

- 5 replies

-

- custom dog collar

- leather dog collar

- (and 2 more)

-

I would say if your holes are laser burnt holes every time you put the thread through a hole it will be picking up a fresh piece of charcoal to dirty the thread. I guess you could try black thread but other than that I would try nylon or poly to see if they don't absorb the charcoal. Let us know how you go.

-

How I now straighten leather for strap cutting

RockyAussie replied to RockyAussie's topic in How Do I Do That?

A door should be long enough...set it up so you have loose pins in the hinges and lay it down on some horses when you need it. The steel could stay hung up with it as well.