kgg

Contributing Member-

Posts

3,350 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Belt cutting machines always slightly narrower than "belt width"?

kgg replied to nstarleather's topic in How Do I Do That?

Have to checked with a caliper the spacers to see if they are actually flat, with no wear, the spacers measure out to 1" long and the two smaller ones are .25" and when combine give you 1.5"? A quick check would be to use a piece of 1 1/2" Al edge trim from you local hardware store and see if it will properly between the blades. kgg -

Binding with a right angle binder on a walking foot machine

kgg replied to Dave9111's topic in Leather Sewing Machines

I wouldn't comment on the 90 degree binder as I generally don't use them but I do have a couple suggestions when using the inline binders. i) get a proper platter that the coil of binding tape would sit on so the tape is not being dragged on the table top. ii) set the binding tape platter up so: a) the platter is off the table top and can spin freely. b) the tape is coming off the platter pretty close too but not rubbing the inside edge of the machine. Which also means you will probably have to install a tape guide between the platter and the binder that can give adjustable back tension. c) the platter and the binding tape needs to be high enough off the table top so the binding tape enters the binder at the right height and angle. iii) The front edge where the tape exits can be slightly widened or closed with a pair pliers to add tension or make adjust for thinner or thicker binding tape. This can also be done on the end that the binding tape enters the binder. iv) When finishing a run and you are overlapping the binding tape where you started from cut you binding tape and tuck it into the binder. That way you get a nice finished edge rather then a raw edge finish. kgg -

Yes but it requires you to turn the item as per a poor mans reverse. No, a lot of lockstitch machines never had a reverse level think of the old Singers. From your photo it appears to never had a reverse lever. No. kgg

-

Keep in mind they are still in the 60 to 70 lb range which can over time cause the table to sag if not supported. kgg

-

Not that I am aware off. But I haven't really looked. Most what you see is the cheap stuff from China. The main caution I have is that with the "U" shaped tables the front end really should be support as the Class 341 will bend the table top over time as it is about 80 lb or so and not being properly supported. When I done a hybrid form of the "U" shaped table for my 441 clone I added a support leg as the machine is roughly about 120 lb. The table top is your basic 1 1/2" cheap Chinese top so it definitely needed support. The best mod I done was put the sewing thread under the table. kgg

-

To get a long lasting and sturdy table top I would suggest: i) If you are handy go to your local building supply store and buy a sheet of 3/4" plywood and some Formica, cut two pieces of plywood to the size needed, contact cement them together then glue the Formica top on and trim. Or ii) Go to your local cabinet maker and have them make one. What machine are you planning on putting on the table top?? Class 341 or a Class 441 kgg

-

I was mainly considering the construction of the leather part of the collar but for the price I would have expected better hardware. This type of pong collar is mainly used to hide the fact the owner is using a prong control system all the time rather then a training tool. My experience is that for the "pullers" a regular properly sized and adjusted pong collar works well and once the dog pulls that first couple of times like you say it can be turned inside out or used in combination with a regular collar where the prong collar is just draped around the neck but not used. kgg

-

I think they are basing the sizing for most types of fabric verses sewing leather. Remember when sewing leather the hole the needle creates has to be large enough so the fibers of the leather don't catch the thread as the needle cuts through. Example the Juki LS-1341 is rated for V138 with a 180 (#24) needle for sewing thick and tough material rather then rating the machine for Tex 210 (V207) based on the capacity of the needle. Just because you can stuff the thread through the eye of the needle doesn't mean it will stitch consistently or correctly. Some factors that need to be considered, thickness of the item being sewn, material type (cotton vs ripstop vs Kevlar vs leather(chrome tan vs veg tan)) and the shape of needle tip round to separate fibers or cutting to slice through to name a few. kgg

-

If you want to use V138 buy a machine like / similar to the class 341/1341 like a Juki LS-1341 or an older Juki LS-341 or their clones. Otherwise reduce the thread size to a max of V92 with the correct needles in your projects. Personally I think this is the wrong class / type of machine for your needs in 3.5 mm leather. If most of your projects are leather be done with it and get a new / used Class 341/1341 machine. kgg

-

The needle size is incorrect for Tex 125 (V138). Reference needle size to thread size ( https://www.tolindsewmach.com/thread-chart.html ). That size of thread you should use a 140 (#22) or 160 (#23) and in thick or tough leather 180 (#24). That said the PFAFF 335 is regarded as a binding machine with the older casing machines rated for a 120 (#19) for a Tex 90 (V92) thread. Reference manual ( http://docs.uwe.net/Pfaff-335-Instruction-Book-Old-Casting.pdf ). The newer body machines are rated to a 100 needle. When you go above the rated max's of the machine you could or probably will have problems with needle to hook clearances, etc. which then can result in other stitching / tension problems. kgg

-

I did check with the Canadian main distributor: The Juki LS-1341 is still available, the Juki LS-1342 has been dropped and the LS-1342-7 has been replaced with the LS-2342-7 which has a longer arm. kgg

-

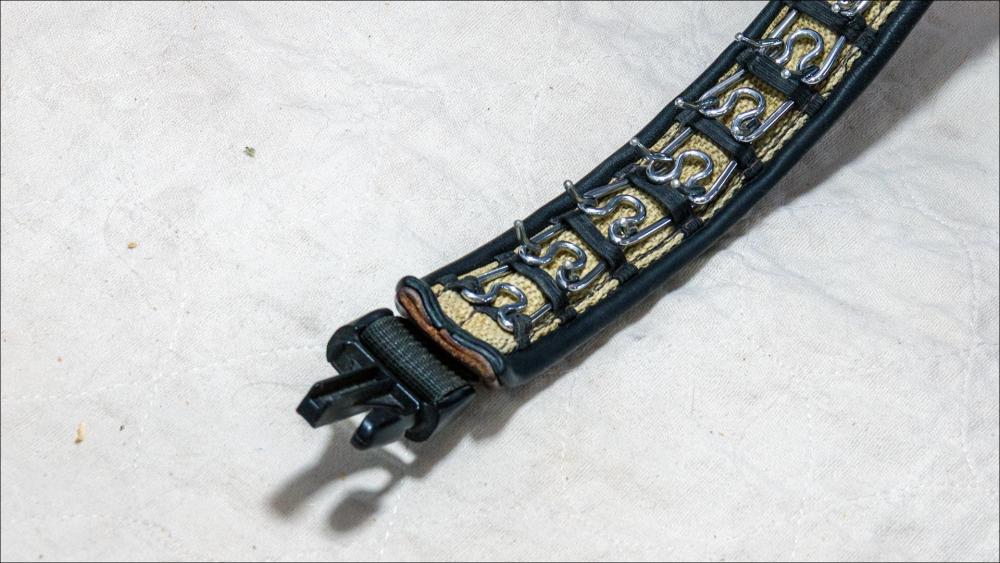

This collar was brought to me to see if I could make it functional / serviceable again. The collar is a US made product that is in my opinion: i) well constructed padded collar with good quality 4.4mm diameter metal parts (4.4mm diameter), ii) Good quality prong collar inserts, with no burrs on the prong tips which is critical when using a prong collar, iii) Decent quality nylon main strap, iv) Weak nylon used to connect the body of the collar to the metal square ring. v) Weak nylon used to connect the body of the collar to the plastic quick connector. vi) Frayed out nylon at the "D" ring that connects to the dog lead as will as some thread failure where the ends of the nylon were overlapped and sewn. vii) Use of a 10 cent 1" plastic quick connector which failed. Nothing worst then being stood there with a dog lead in your hand attached to a collar and no dog. Ask me how I know. viii) Weak thread used, appears to be V46 and V69. To replace the collar the owner was told it would be somewhere around $300 CAD that is why it landed on my doorstep. The first 5 photo's are of the collar as it arrived. The last 4 photo's are the collar almost completed but functional again. Any comments: kgg

-

Where are they made??? kgg

-

This depends on your particular needs. The two main differences between those models: i) LS-1341 has the standard (large) throat gauge while the LS-1342 has the smaller throat gauge for doing smaller items ii) LS-1341 does not have the adjustable vertical walking foot adjuster (big round knob on top of machine) like the LS-1342 Here is a link to Juki LS-1340 series machines that shows the differences ( https://www.juki.co.jp/industrial_e/admin/pdata/filedata/332/ls1340.pdf ) kgg

-

Personally I would not purchase a machine that has been used in an industrial setting as you are really dependent upon not only the machine having good bones but the competence of the person / company refurnishing it. The factory is getting rid of it for a reason. Look for a hobbyist owned machine or if you can afford it buy a new Juki LS-1341 or 1342 or buy a new clone. If you decide to go with a clone try and get one that is more like the older LS-341 rather then a hybrid clone and go through the specs carefully. kgg

-

To me I would say your concerns are justified. Looks to have been stored in a damp environment and poorly maintained. kgg

-

The 7mm is touch over 1/4" and would be close or above the capabilities of the walking foot machine you listed. Also you are going to be limited to a thread size maximum of V92. kgg

-

Selling Brother LS2 - getting a Sail rite LSZ

kgg replied to MarkWorsnop's topic in Leather Sewing Machines

Be aware of what some of the short comings of the Sailrite you are planning on getting: i) The Sailrite is made in China not Japan like like, I'm assuming, your older Brother. ii) The Sailrite is a walking foot not a unison feed like the brother you have. iii) Uses a domestic Singer Class 15 Bobbin. iv) Max thread size you can use is V92. vi) No safety clutch. vii) Requires special presser feet. viii) Stretch length varies as the thickness of material increases. ix) The Sailrite Ultrafeed LSZ is a "portable" walking foot sewing machine but with the rigid carrying case the term "portable" is a relative term. Sort of like the old "portable" microwaves that took two people to move across the kitchen. With the machine sat in it's rigid carrying case it turns into a very clumsy package weighting probably close on about 50lbs. Coupled that with the size of a very well constructed rigid carrying case (about 21" long x 14" high x 10" wide with only one top mounted carrying handle) and you are going to get a good workout. My experience of owning the Sailrite® Ultrafeed® LSZ, with the rigid carrying case which had their new "servo" motor, the shine of being able to move it more then a few feet very quickly dulled. I would suggest that you makeup a cardboard box about the same size and put say 40lbs in it. Then see if you can lift it with one arm or hold it on the bottom and then walk up a flight of stairs or across a parking lot. Maybe it may fit your needs but I would suggest trying one first because once you buy it's yours for better or worst. Buy Once, Cry Once kgg -

My kind of workplace, Not. China isn't much better. This is why most decent manufacturers can't compete. That said it is amazing what can be done with simple / simpler tools. kgg

-

Keep in mind that NO one machine will do everything that is why some of us have more then one or six machines. You need to figure out: i) your max budget dollars ii) what is the thickest thread you want to sew with, V69 (domestic), V92, V138, V207, V277, V346, V415? iii) what is the thickest you want to sew including the seams? iv) what are the articles you are planning on making the most? v) You need to read this article to help figure what would work for what you want to sew. kgg

-

Should I buy this Ferdinand 900b sewing machine?

kgg replied to Gael's topic in Leather Sewing Machines

With any sort of odd ball machines finding parts can be a chore and then add only one supplier of parts I would personally steer clear of the machine. That said if the price was dirt cheap, not $800, then maybe. kgg -

From the Thread Exchange website ( https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=needle-systems-singer-148-to-231-SV-12#Models_178_to_211-GX ): Singer Model# 196-K 301 uses needle system 287 Equivalent to 287 H, 16X21, 16X269, 376, CANU 11:60 That will bring you to their selection of needles for that machine choose the correct needle size based on the thread size you are using. kgg

-

Save your money personally I think you will be disappointed with the abilities of the that machine it is not an industrial sewing machine. Those machines and their clones were meant as machines to repair sails when at sea. I have owned a few of the Sailrite machines and their clones. They are really meant for limited use in thin stuff. It will: i) leave marks in leather as the standard presser foot and feed dog are very aggressive. ii) uses a domestic Singer Class 15 small bobbin iii) thread size is limited to V92 thread iv) stitch length will vary as the thickness of the material increases and the list goes on. kgg

-

Are you using a speed reducer between the servo motor and the needle positioner? I would first replace the belt. kgg