kgg

Contributing Member-

Posts

3,364 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Yep, we are getting as bad as California and becoming a nanny state. The funny thing is if you want a gallon, 5 gallon pale or a 40 gallon drum, no problem but those little 4, 8 or 16 oz bottles are the devils juice reincarnated. Here is a link to the article on Zelikovitz Leathers site ( www.zelistore.com/en-ca/blogs/news ). kgg

-

Who did you order the 120 mm pulley from? kgg That calculator saves a few of the old remaining brain cells. kgg

-

He must have meant "new to you". kgg

-

To me it appears Used. A new one is about $3000 plus shipping. The best one probably would be @CowboyBob to comment on the age. The value depends on the operating condition whether it has a stand and motor, speed reducer, etc. I wouldn't consider it for a $500 plus shipping difference over a new one. For me it would have to be a complete package and sub $1800 but that's just me. kgg

-

Here is a good link to save you some time when designing your speed reducer and get a pretty accurate estimate of what you design will give you. https://www.blocklayer.com/pulley-belt kgg

-

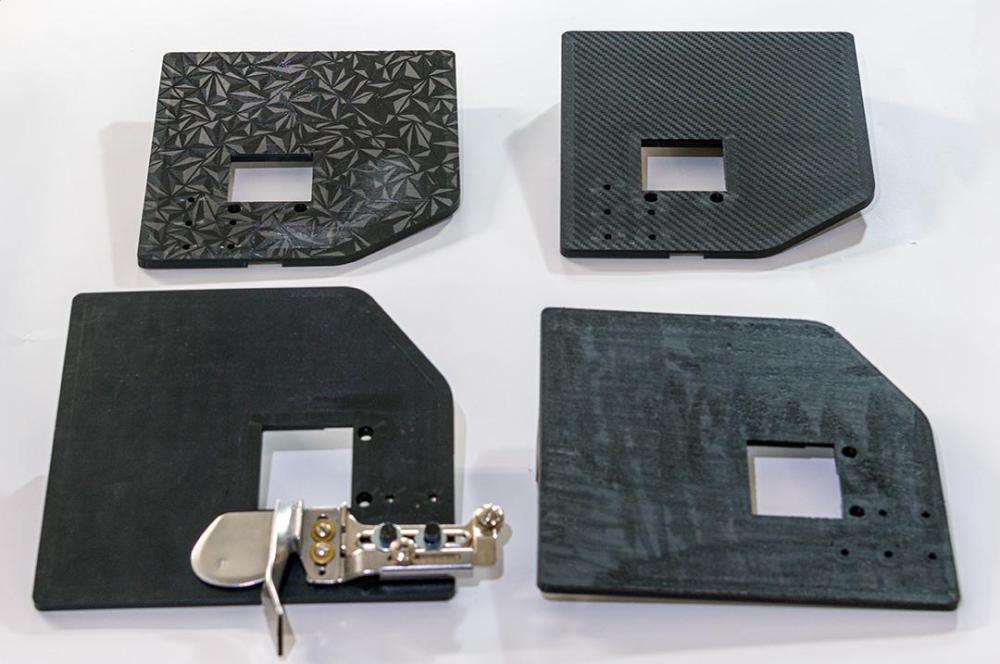

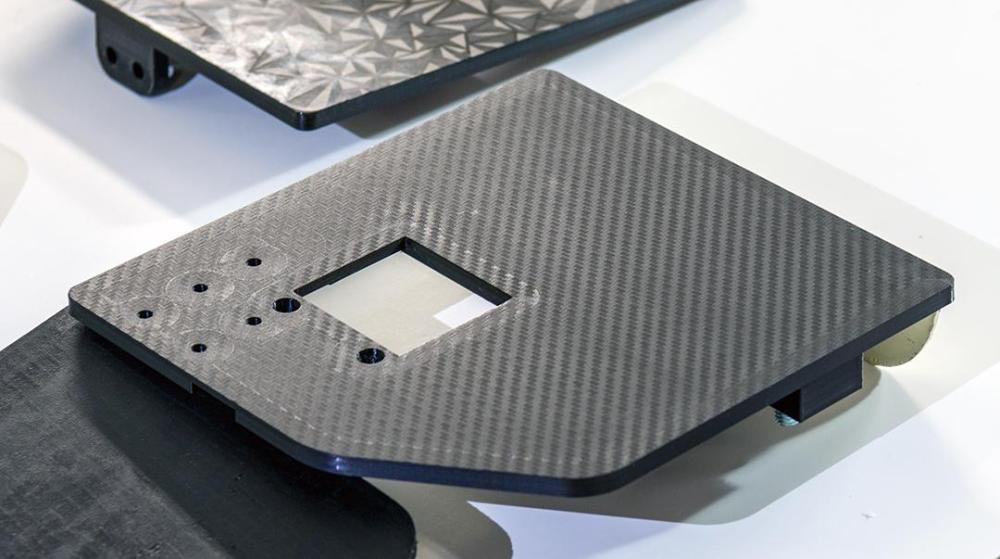

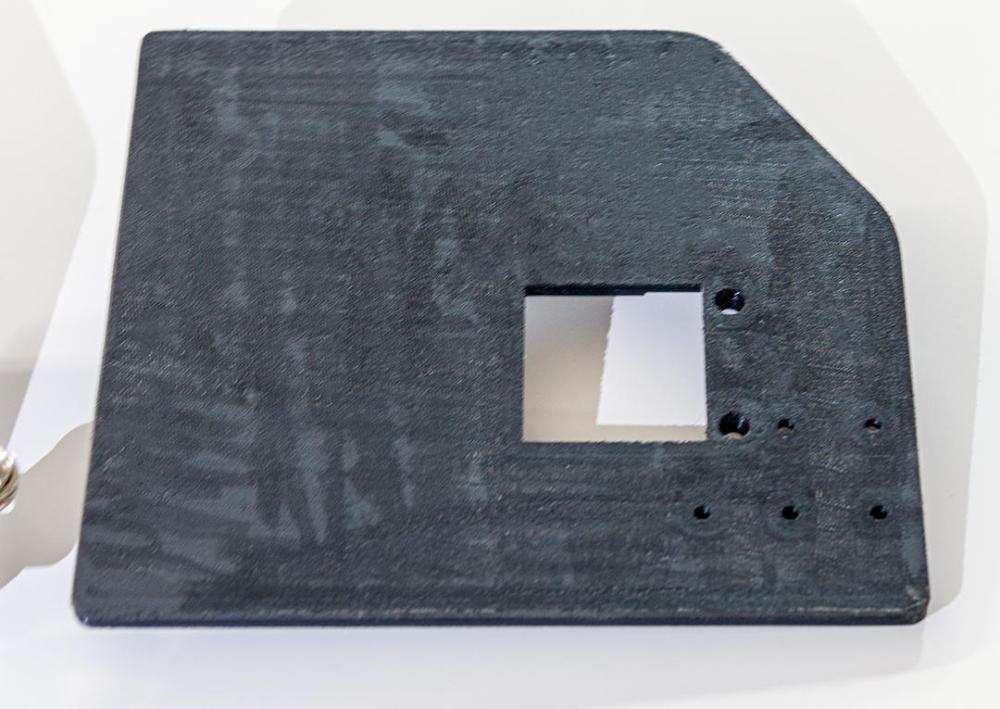

I know there are a few who use 3D printers with the majority probably being flatbed slingers or core XY machines and this may help provide some information on what to expect when printing parts using different bed plates. The example I am showing are of four final outputs using the same design .step files. All are acceptable from a strength point of view and were printed with 3d850 filament. The first photo showing the the four table top plates for the 441 are the same size but they appear to be different sizes in the photo due to the angle it was taken. The first photo is of the engineering plate which is similar to the Prusa 'Satin' Plate as it is a PEI coated plate that has more stippling grip that an old school PEI sheet but not as much as a PEI "textured" plate. Basically a compromise design between smoothness and 'stickiness'. We did not use it long enough to judge its sticky abilities before moving on to new tech plates. Aesthetically acceptable does have mild some grip to the surface. The second photo is carbon fiber pattern PET, a lower grade of PEO and basically the same as PETG without the glycol added. Its Glass Transition temperature (Tg) is 70C so once again great for PLA and 3860/3870 but PETG (let alone ABS) is a non-starter. Where it is not as robust as PEO the pattern in the sheet is more noticeable to the touch and the finishing surface is not as smooth. Still better than even 'satin' PEI sheets but not as good as 'smooth' PEI sheets. Parts do not stick as well to it as PEO, so when cool parts do pop right off, but while hot you have to rip them off. Aesthetically acceptable does have less surface grip to the surface. The third photo is a 3D pattern and my favorite a PEO sometimes called 'PEG' plastic. Similar to PETG but higher temperature resistance. The latest PEO plates can handle over 100C, the older ones can handle ~80C. NONE should be used with PETG filament as they probably will bind to each other. Causing you to rip the 'sticker' PEO sheet. These plates result in as smooth a surface as old-school 'smooth' PEI plates and arguably as smooth as glass with just as much 'shine'. BUT PLA sticks to it better than PEI textured plates. Even when cool it takes a tiny bit of effort to release the part from it. Aesthetically very acceptable has less surface grip then the other surfaces more like polished glass. The fourth photo is the least aesthetically acceptable with the greatest amount of surface grip and was done on Prusa MK3S with a full bear upgrade (bed slinger) and retained the glue tracking lines on the bed. It is also I think worthy to note that the printing time for the first three took approximately 5 hours each at standard speed and were done on Bambu X1 Carbon (core XY) while the last one was done using the Prusa MK3S with a full bear upgrade taking approximately 16 hours to print. All comments, discussion are always welcomed. kgg

-

HELP! Bobbin thread on top only when start sewing

kgg replied to Relative's topic in Leather Sewing Machines

I think on the 1541 you need to adjust the hook timing and it's position. Here is a couple of video's you may find helpful https://www.youtube.com/watch?v=cHyn5A1v-hs https://www.youtube.com/watch?v=5KtJCSfRafA https://www.youtube.com/watch?v=obvI-v7w0qA Also here is a copy of the Juki 1541 manuals kgg JUKI_DNU-1541-7OwnersManual.pdf JUKI DNU-1541 Parts List.pdf JUKI_DNU-1541-S-7EM01_SERVICE_MANUAL.pdf -

HELP! Bobbin thread on top only when start sewing

kgg replied to Relative's topic in Leather Sewing Machines

The problem as I see it, especially thinner items, there can be a few variables at play. i) if the forward and reverse stitches aren't in perfect syn then you could be dealing with a tension issue in the stitch cycle particularly should you decide to change direction ii) if the timing is off just a touch then you probably going to have a stitch problem iii) then you have to deal with how accurate the needle position software is as these units are generic in nature and typically not tuned for one style/type/manufacture of machine. Some of these don't work properly on some machines and work OK on others iv) how accurately and securely they are mounted to the frame of the machine. Some people love them, some not so much. I don't particularly even like brushless servo motors as the box of electronics adds another layer of complication when trouble shooting. Then add in a needle positioner and it can become a real problem to back track and correct problems. I guess I fall into the "not so much" group but that is probably just me. kgg -

I do agree they are big and I actually just got the other day a set of feet that I just haven't had a chance to install. kgg

-

Thank you both. So far the consciences is that a table top is not necessary, it was just a thought. kgg

-

HELP! Bobbin thread on top only when start sewing

kgg replied to Relative's topic in Leather Sewing Machines

I would just remove the needle positioner all together but that is me. A couple of tests you could try after making sure the top and bobbin tension are correct, bobbin is installed correctly and your thread path from the thread spool is set up proper( a couple of photo's of this maybe helpful): i) reset the needle positioner to the up position and see what happens ii) reset the needle positioner to the down position and see what happens iii) remove the needle positioner by just unplugging it from the box of tricks and see what happens. For Tex 70 ( V69 ) depending on the thickness of material being sewn I would go with either a #16 or #18 needle. A good reference chart for needle to thread combinations is located at https://www.tolindsewmach.com/thread-chart.html kgg -

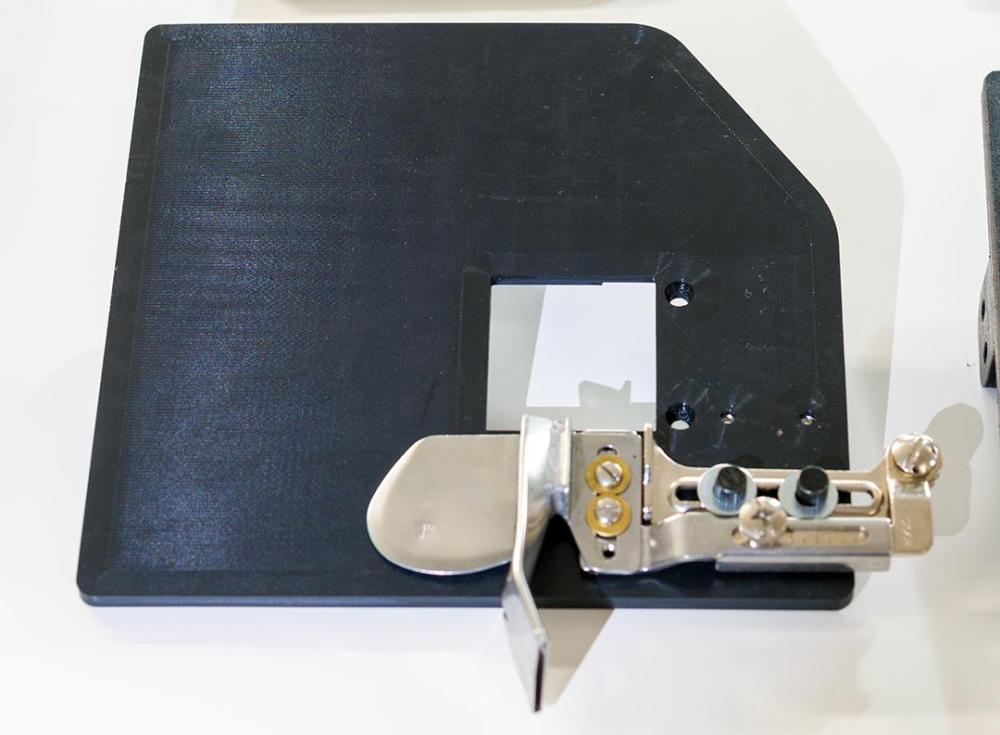

The binding attachment in the photo is just an inexpensive Single Fold Binder mounted to a swing away bracket. Binders use to be cheap in the sub $20 CAD range but I haven't check the prices recently. The swing away brackets use to be also cheap as well in the sub $10 CAD range. I think most people use the 90 degree binders which are expensive in comparison at about $60 CAD per tape size and type (raw or double fold edge). If I'm not mistaken on the 441 class machines the 90 degree binders bolt directly to the flat plate directly behind the needle plate. That said if I had to do really tight corners or only had a cylinder arm machine the 90 degree binders would be the binder of choice. Since I have flat bed machines and a couple cylinder arm machines I want to be able to move attachments from one machine to another and didn't want to invest in machine specific attachments. With the inline binders I found it to be a problem: i) going from the a flatbed 1541 to a 1341 cylinder arm so I had to design a little table top to do that. ii) going to the 441 class with the standard plate that comes with them a inline would work but was a real pain in properly setting the distance to the needle and you have basically no support under the folder attachment so I designed another little table top for that as well as the one in the photo's and video. The little binder specific plate can be seen slung under the cylinder arm on the Velcro strap in the fourth photo. My thought is if you are only going to use one tape size and type (raw or double fold edge) for your needs it probably would be best to go with a 90 degree binder setup. kgg

-

Thank you @Cumberland Highpower. kgg

-

Thank you @dikman. I do still wonder what a good size table top needs to be for holster type work? kgg

-

The problem I see with some table top attachments is storage. You have bolt them down to install then unbolt them when you don't need them then find a spot to tuck them away. So me being me again, I figured I could do a little better. I have designed an articulating table top that stores in both the vertical and horizontal position under the cylinder arm to either the front or rear side of the cylinder arm. The attachment to the articulating joint on the bottom of the table top also adds extra rear support to the table top. The short video is moving it from the mounted position to the front of the machine for storage in the vertical position. I did add Velcro strap through the needle plate opening to help support it but the articulating joints will hold it in place by themselves. The 3d printed table top in the photo's and video was printed using a PEI "cool plate" with 3d850 filament which is technically PLA but it is stronger then ABS without toxic odors to deal with. The last photo is of a sample that I printed using a PEO 3d plate which the finial table top will probably be printed in. The PEI "cool plate" print is smooth and looks decent but the PEO "3d plate" gives a 3 dimensional look to the surface with a slippery smooth glass finish. I will over the next day or so do a sample print with a PEO "carbon fiber " which will give a slippery smooth glass finish as well. The 3D printing was done with the Bambu Lab X1 Carbon core XY. What an improvement over the Prusa MK3S with a full bear upgrade both in speed, ease of use but most importantly quality of print. There is NO first layer calibration it does automatically so changing from one printing plate to another is as easy as changing your socks. This table top measures from the needle to left edge 4.25 inches and 7.0 inches from the front to the back edge. Photo #1 and # 2 are of the table top with an inline swing away binder attachment mounted. Photo #3 and #4 are of how the table top swings away from the cylinder arm from the install position. Photo #5 and #6 shows that is gets swung under the cylinder arm and hangs vertically. Photo #7 and #8 are the dimensions of the table top. Photo #9 is what the table top will look like when I print it using the "3 dimensional glass finish plate". For the photo we just laid a sample print on the surface of the table top. Have a look and all comments are always appreciated. kgg

-

How to answer the question "How much is it?"

kgg replied to Leatherinspire's topic in Marketing and Advertising

I like @fredk approach as it is not a hard sell but still allows for a profit whereas I find the OP's version more akin to a used car salesmen pitch particularly " how this sounds in terms of your budget ". kgg -

Bartack machine not completing the back stich

kgg replied to Cleggy's topic in Leather Sewing Machines

I know nothing about bar tackers but this manual may help. lk1850.pdf -

I would try some heat from a heat gun and if that work I would try some penetrating oil and if that didn't work a couple of drops of diesel and let soak for a few hours or overnight. Remember to put a soak pad under the needle. Sometimes a couple of light taps with a wrench will help before attempting to unscrew the screw. Once you get it moving back it out a couple turns and add a drop of oil then screw in a turn repeat until the screw comes out. Be careful not to shear the screw off or you will probably have to remove the presser bar. kgg

-

Excellent work. kgg

-

In the beginning 3d printers in my opinion were tinkers machines like the "Tinkers Delight". Now the new 3D printers have come a long way in a fairly short period. They have become more like an appliance sort like your stove, fridge or toaster. Today it is more about getting a decent item out without having to know all the quirts or the technology and that is a great step forward. Sort of like putting a slice of bread in your electric toaster and getting toast out without having to know anything about electricity. Remember the first microwaves??? It only took two strong people to lift them to the counter. Those machines really shine when you want or need to do items with great detail but the downside is the fluid but once again every machine has it's pro's and cons. I still wish I could get my hands on a machine that had a 24" x 24" x 12" print bed size. I figure before that happens the 3D metal printers will be available at a reasonable cost, so we can build our own sewing machines. kgg

-

As some of you know I do a what I would consider a fair bit of 3D designs and printing so I figured I would share my experience of the life cycle of my 3D printers. The first 3D printer a Prusa MK3 which was a kit that you had to put together. I was too cheap to pay the $500 + for a fully assembled machine. It did take a few choice words and about 40 hours to get it assembled. That unit came with a 1 1/2 " thick manual which had a couple of major assembly errors. The machine was overall very good for it's time and Prusa support was also very good back then. We pushed over 500 km of filament through that machine over a in four years period and then it had a hissy fit on an overnight print which caused a catastrophic failure that just wasn't worth the cost to rebuild. The 500 km of filament equates to approximately 1500 -- 1kg spools of filament. The second printer another Prusa MK3 with a Bear upgrade kit has about 40 spools through it and now is dedicated to being a backup machine. So there is lots of life still left in it. Once again a good machine but a bit temperamental. We just upgraded to a Core XY Bambu Lab X1-Carbon Combo 3D Printer and the speed but most importantly the print quality is unbelievable. With all the tweaking that we had done with the Prusa's they never gave us the print quality that the new machine now does in it's standard speed mode. An example is a print that would take approximately 6 hours using the Prusia Bear now is done in under 1 hour. Now we are getting closer to what I would consider acceptable rapid prototyping times. Another reason we went with the Bambu Lab X1-Carbon Combo 3D Printer was we were on Prusa's "waiting list" for their version of their new core XY. To be on that wait list we had to put down a small refundable deposit and we were I figure pretty patient but after 16 months of waiting we contacted Prusa and were basically told we will get to you sometime in the future with no firm shipping date. So enough was enough and we ordered the Bambu Lab X1-Carbon Combo 3D Printer on Wednesday afternoon and it arrived to my door on Friday. I think anyone could get this machine up and running pretty quickly. It took: i) about 10 minutes to unpack as it was really well packaged and all the packing screws that needed to be removed were clearly marked with big red arrows and the Allen key was even included. ii) about 10 minutes to place the machine and accessory parts. iii) about another 10 minutes to plug the machine in, read the brochure (which is actually 12 half pages), mount the filament roll and connect to their website for registration, etc. iv) about twenty minutes to let the machine run self testing for things like self leveling and vibration calibration. v) about 5 minutes to run a sample scraper. vi) Done. For most users they would be pleased and up and running. Those factory settings gets you to about 95 percent of it's capabilities and it then did take us about another 6 hours to tweak it to our needs. As a note I would suggest using the ORCA slicer instead of the Bambu slicer as the ORCA has more fine grain tuning, better calibrations options and offers portable install option. What are your thoughts. kgg

-

It maybe just the angle but in the video it appears that you have the bobbin winder up against the belt. There should be no contact of the large wheel with the belt when you are not winding the bobbin and the trip lever is in the rear position. If the large wheel is making contact adjust the base towards the front. If the wheel isn't making contact then remove the winding assembly from it's base and soak the large wheel with penetrating oil to free it up then oil it through the two holes. kgg

-

Every machine has it's place each with their own individual pro's and cons. On the manual heavy duty market there are presently three one armed bandits available, that I known of. The Tippman Boss coming in at about $1000 USD for a basic machine then you have the Cowboy Outlaw at about $1400 USD and the most expensive machine being the Weaver Master Tool Cub at about $2000 USD. I almost bought a one armed bandit last year myself but after a lot of thought I decide to go with a 441 clone. Stuff the item under the needle and push the go pedal. Everyone's situation is different and a manual machine may well serve your needs. Before investing in one be honest and consider the cons, do they out weight the pros. Once you buy one you are basically going to be stuck with it for awhile. What thickness of leather are you planning on sewing and with what size of thread? Since you are looking at the one armed bandits a cylinder arm machine like the Juki LS-341 or LS-1341 or similar clone with a table attachment may work. kgg

-

In a post bed are you considering a roller foot or a walking foot? From the info I have seen the roller foot machines will handle up to V92 thread while the walking foot style can handle up to V138. What size of thread are you thinking on using? kgg

-

Yes. As expected the dark cherry shoes dried out with Angelus dye. Its a powdered pigment based dye and is very hard on the leather. Even though there is less pigment in the bottle it also takes 12hrs or more to dry to the touch vs. dry to the touch in minutes and (basically) fully dry in a couple hours w/ Saphir. With that said Angelus is still better and results in a more supple leather than Rit-Dye which goes stiff as a board hard. Basically if Rite Dye is a 10 on hardness scale, Angelus is like a 7 and Saphir is like a 3 (Fiebings Pro is pretty much a 3 to 4). No. Also as expected when the saphire teinture was used on the the leather there was no major / noticeable difference in the flexibility of the leather. Saphir also is a powdered pigment based dye, but somewhat like Fiebings Pro 'oil based' Dye they first add the pigment to an oil, then add the colored oil to the Ethel alcohol carrier. Its a lot easier on the leather and dyes much better with a cleaner less splotchy end result. However, you still have to add an oil back into the leather at the end as they all dry out the leather. I personally prefer a jojoba oil (as close to old school sperm whale oil as you can get) + shea butter (via Saphir dye cream), then mink (to seal), then either beeswax or 'shoe polish' + carnuba wax finisher for polish. I should have added the process for the Process for the Dark Cherry shoes. Process for the Dark Cherry Shoes: 1 Coat Saphir Teinture Francaise Red 6cc + Saphir Teinture Francaise Bordeaux 3cc + 3cc 99precent rubbing alcohol Then immediately followed by 1 Coat Saphir Red 6cc + Saphir Bordeaux 6cc + 3cc 99precent rubbing alcohol Let dry in sun while doing this to other shoe Then 1 Coat Saphir Red 3cc + Saphir Bordeaux 9cc + 3cc 99precent rubbing alcohol Then immediately followed by 1 Coat Saphir Bordeaux 12cc This was a little too light for my tastes so added a fifth coat of Angelus WineTone 6cc + 12cc rubbing alcohol The high amount of rubbing alcohol, combined with powdered pigment allowed the fluid to hit and spread out into the cracks in the faux full grain better but was still enough pigment (when dry) to give the nice 3D look back to the trash-tier/faux ‘full grain’ leather. Took 12 hours to “dry” at which point I used a hair dryer to finish the drying. 3 Coats of Saphir Medaille d'Or Crème Burgundy to finish. Followed by mink oil to seal. Followed by bees wax and pure carnuba wax on toe box. kgg

.jpg.c120f291e7a6aaaf8bdb3bf94afad023.jpg)

.jpg.d44c25e5a60863c652f5287a5552ac4a.jpg)

.jpg.ff540cf8255c858d4507a04cc3489f13.jpg)

.jpg.7dc2b19109716cbc4c051ce1f14d70c0.jpg)

.jpg.c64cc48a1a2f3a150cdab18a75ecbe83.jpg)

.jpg.67f3fed8d08ede2eacf85f86f812fc96.jpg)

.jpg.ed7b174243f86d54bbd8edb940daee4d.jpg)