nylonRigging

Members-

Posts

477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

may Not be that plate ? . I just guessing .. but it just reminds of that flat plate-clip with 'screw slot' for sliding back and forth that is there on top by feed-bar link . Pretty Funny , if someone just throws extra parts in by your machine head, that are totally unrelated to your machine, just to screw with you .... LOL.. .

-

- Your Pic. ? question of the ' Plate '. Is that the Slide-plate, under the needle plate . the Plate slides slightly L-R and is held down by an adjustment screw . The plate used to limit horizontal Lash (back and forth slide) of the Feed Dog assembly . It looks like it . and with that little 'tab' (on left-side) that hooks over and hold the unwanted Lash . you loosen the plate screw , push plate to the 'Right' and tighten down screw to hold . .

-

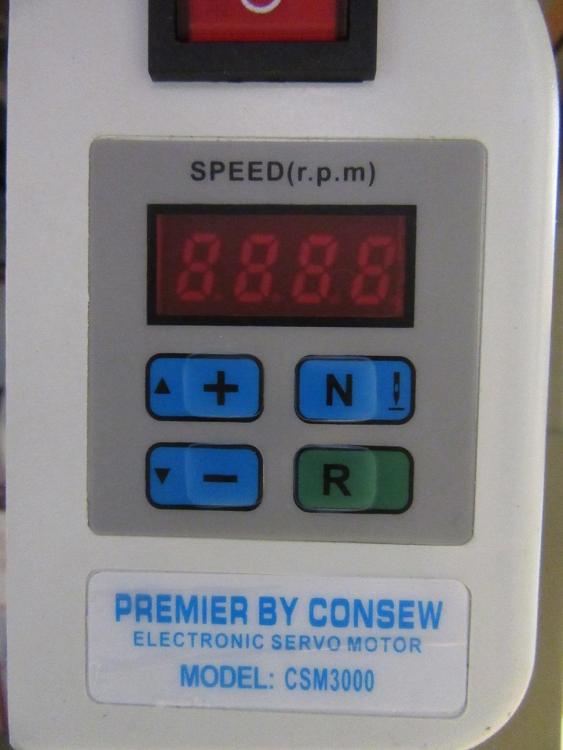

You can find reference of Consew listing it online. CSM3000 is a Brushless, 750 watt 1hp . . the CSM 3000 is (without PS) , and the CSM30001 is ( with NPS) . The Consew , ( Brushless Motor User Manual ) , that came with it in the box is just simple single piece of paper with the usual .. speed setting / rotation change / needle position setting / return to factory setting . The control , is a 4 -Button control panel that makes It very easy to program the necessities . The 'return factory setting' is only for NPS, .. but i did still try that on 1st day I got it . It's rebranded . But the OP posted exact machine as the one I bought, and mine new out of box hammers-out 5 stitches on the power-up . So. I will Never buy another like this model and I will not recommend to others looking to buy . Like I was saying before I called Consew day after getting it, I explained the problem, told them what the new motor was doing, but all they suggested was I make a video and send to them . And that is ( All They wanted to hear from me ) . The factory help guy was offering nothing else but me making and download a video to him . So I just said ..." I will get right on that ". then just went back to work . After that experience with Consew CS ( my Opinion ) , If you have a problem with a New bought motor . Consew Customer Support phone # , pretty much worthless, they are Lazy with little to no skill, visualization of problem solving on the products they sell . .. But in all fairness, there customer service does like to watch video at work. Consew is dead to me . .

-

It a ( CSM3000 ) , and it has a 4-button control panel . The package the OP posted looks exact to the Consew I have . .

-

Ahhhh Hey....You sure you don't want me to make and send you a Video of the motor banging out 5 stitches on power-up ? .... LOL . Consew should hire you for a Tech. Rep. for customer problems, because as of right now your sitting a plateau above there hired Staff for knowledge and customer service . The Consew service factory phone # , offered absolutely squat for my needs . Is that ( Advanced Signal ) something that I can 'code' punch-in myself on the reader control board ?, like offered with the speed, and motor direction of turn code . I did not want, and purposely bought the Consew w/out position sensor, It was sold to me without and was told not coming with PS . I can pull it off the shelf and out of the box . power it up to punch-in a code if you know of of one ? . If I could get rid of that glitch i will use it for another build, or a back-up motor . .

-

ya just a rebranded Consew . I bought one and mounted it to a heavy walk foot machine, ( draws 6 amp ) It a strong puncher on the slow starting stitch . smooth and strong on the faster RMP also . nice power for the money , BUT --> the one I bought has a factory glitch with it from 1st day I set it up . ( every time ) When you turn-ON power and touch the pedal, It will start sewing without stopping ' 5 Stitches ' from day 1 . I called Consew and asked them about the problem day after I set it up and ran it, but all the Consew guy told me was to make a video of it sewing the 5-stitches and send it to them . They never even tried to address my problem with the new motor .. I Not in the business of making videos , I sew . I will Never Buy Another . .

-

What .Wizcrafts. is all saying .... and Dude I would buy that in a heartbeat because I dont mind little projects . it does look 'somewhat' similar design to my heavy 146RB . but it looks 'even more heavier duty' in horizontal shaft size and linkage from the Pic's you gave . It looks Clean, and If it rolling and stitching ( Get It ) for tag/300-$ . you also saying less-$ price like 150-$ ? ..that a steal . If they will take less-$ than 300-$ , then it all gravy after that . You can take your time and research and X-reference all the usual parts that normal wear . If . . ( Head Only ) GET THE HINGES IF THERE THERE . but easy to order off ebay or amazon if not . you setting up a table for it, not that hard to do . Probably uses common knee-lift linkage for raising presser foot . And a oil drip-pan easy to make or buy . I would bet a weeks pay that the table cut-out is common also . .edit add:.. reason it probably looks clean as it does for it's age, is that is looks to be set-up for slow turning RPM and heavier thick work . It probably still really solid and not sloppy . Get It .

-

Not sure if it a totally resembles Consew design ? . Price tag say's ( 300-$ for Head ) . If that Head is operating and laying down nice stitches, (if were me) I would not hesitate a second to grab it, would be an easy table set-up project. Pic. Feet and Dogs 'are probably' look pretty common . What size needle ? and what does it use for a Bobbin Assembly ? . the Backside of the machine pic. horizontal shaft and linkage looks hell stout, and that huge hand wheel is a lot of inertia by weight when it gets rolling, so looks setup for punching slower RPM . .

-

Thread tangling around the needle...

nylonRigging replied to Dantan's topic in Leather Sewing Machines

- Getting 6-ft.+ of thread routing from the Cone to the Needle is easy . 'Increase Distance' of the thread routing travel, will let thread relax more, on it way threw it's path, before it gets to the Needle . ( the Std. ) industrial thread tree sold that screws to your machine top, is all the same design . There just a 2-piece of 'short' , O.D. 5/8th" Pipe, with a clamp-coupling in middle . Simple fix . just remove the top section of Pipe on the Thread Stand . Then replace it with a piece of 5/8th" pipe that is ' LONG ' . ( rise the Cones up ) and the ( top thread arm to the top ) , Above/away from clutter of machine area, with also gaining the distance for thread distance it routed . I run 8 machines, and I started a couple years ago getting the thread Cones above and away from all the work done at the machines . It not hard after you do a couple the rest of the tread tree stands goes pretty quick for extending UPward . The Pipe used is common and inexpensive and found any hardware . It is just Copper water pipe usually sold in 10-Ft. sticks at any Hardware store . - - ( in pic. below ) . There is also arm extensions that mount to the Thread Stands . That you can get to Guide\Route your Thread to the 1st Thread-post of you machine . I have a couple of them but wish I had more of them . they look like this , and are clean effective routing arm to hang-off the Thread tree's . ( if ever find let me know ) as I could use more of them . You will find every machine is going to be a little different on it's needs for thread routing, like double-needle, or single-needle, or your heavy thread-cord machines . You get more distance and with that fact, basically you want to keep it all orderly and going threw it's eyelets to the Sew machines 1st thread-post , and also route down to the machines Bobbin winder . - -

Thread tangling around the needle...

nylonRigging replied to Dantan's topic in Leather Sewing Machines

For helping get the thread relaxed when using thread with higher memory and curl coming off the Cones . I think most people are thinking way to small for the length of travel of there thread, from the Cone to the eye of the needle . On my machine thread tree's . For the length of thread travel, From the Cones to the Needle . I average more than 6 Ft.+ of travel length in it's routing . I am a true believer in this, and I don't get these problems since I just expanded on the Thread Stands and gave ample free-range for the Threads to relax some along it's travels to the eye . . -

Mitsubishi YU-360 - looking for info

nylonRigging replied to Jooleus's topic in Leather Sewing Machines

ya .. The old ( YU model ) is Mitsu.walkfoot ...' I think ? ' the DU models were Needle-Feed ... Mitsubishi made a boat load of All-similar looking heads back then . also Those Pic's posted, looks just like the exact cast Body style of the 80's era Mitsubishi DB models ( bottom feeds ) with it's Body shape and color, stitch length knob and narrow black reverse lever and hand wheel . I still have an old DB-170, with parts galore still able to x-reference . . -

Mitsubishi YU-360 - looking for info

nylonRigging replied to Jooleus's topic in Leather Sewing Machines

Looks like the YU-360 mdl. was discontinued around 87, but machine new-old stock probably sold well into the early 90's . ( If the price is good ? ) with machine clean and running good . Take some cordura and webbing over there and run the machine to check it out . Jap. Mitsubishi's were put together solid back then . ALSO .. ( i sure there are ) there has to be parts/accessories for it that will fit the YU model . but you need to do work in finding the copy/clone models that resemble that design, and Feet , Dogs , needle plates , Bobbins..etc , are also shared across the board on many machines . . -

Recondition ? , a 29-4 Bell Crank Lever .

nylonRigging replied to nylonRigging's topic in Leather Sewing Machines

- ya i hear ya on the new generic BCL's and really no reason not to keep it working in the bell . The new BCL part sells really cheap-$ and will bring new life to your 29-4 stitch length . ( The new-sold 'generic' BCL's ) , that will 'Not' just Drop-in to a 29-4 and work .. Now that I figured out what to remove/grind resurface on the 1st one I bought . I could could modify another one a lot easy and faster . It really not that hard . I surprised a lot more people not doing it . On those aftermarket china BCL's . all you need is a couple hours with a small Vice , Dremel , File and a magnifying loop to do a good job to getting it to fit-in and running good on your old machine . thanks ... for the ( bent angle Pic. ) , the original BCL that I took out still looks and sits at straight angle . So I will get my buddy to braze and I will resurface . . -

Recondition ? , a 29-4 Bell Crank Lever .

nylonRigging replied to nylonRigging's topic in Leather Sewing Machines

The aftermarket part is working satisfactory (after working it over) and nothing to really bitch about . But ya, just think it the right thing to do is keep it all original #'s parts because of the age and condition . I am into it now for a lot of my time on the head and also put a couple hundred+$ into stripping Treadle and powdercoat . It is handy machine but No Doubt it not practical with time and energy put into it to get it respectable to sit in my sew room . really it will sit with a cover over it more than it will ever be used sewing . . -

Recondition ? , a 29-4 Bell Crank Lever .

nylonRigging replied to nylonRigging's topic in Leather Sewing Machines

wow .. 28 of them to do. that's a lot of listening to that Dremel screaming in your ear .. LOL . . I called one of buddies who lives about an hour from me and he is pretty good and current with welding small items, and I pretty good with a Dremel. so I should be GTG and get it done pretty easy . . -

Recondition ? , a 29-4 Bell Crank Lever .

nylonRigging replied to nylonRigging's topic in Leather Sewing Machines

I really want to get it done good . The old factory parts had a good hard surface tempering to last, so that was my concern about Brazing . sounds like Brazing might work OK also if it hard enough surface and bond to last . Welding Rod and Wire can be had in different hardness, but laying down a tiny clean precision bead is where i need to find a real craftsman . the area to build-on is small and no place to be practicing skills. - -

hey as Metal and welding not my forte, 'Question' ? , Have you, or anyone you know ? . Welded a Bead to the surface on the ( both top and bottom side ) , of ( worn/flattened ) , radius tip of the Bell crank Lever ? . To then just resurface back to Spec. roundness again . I bought an aftermarket Bell feed Lever replacement part . I got it all working and getting a solid 6-SPI threw 5-stack of 1000 den. nylon . And that not bad for a 105 year old 29-4 . The 'generic' aftermarket Bell Lever that is sold , ( did need some resurfacing on the outside of Round Loop ) at bottom of the forks , as the loops wall thickness was bigger than old factory part, to get it to 'rock back and forth' and align correct . Also was needed for the 2 factory mount screws, to pass-by outside wall of the loop to remount it . I got the aftermarket part functioning great in the machine , BUT ... I Really want to keep and replace back, the original 'factory #'s part ' Bell Lever back into the old 29 again if possible . So if I can get an opinion as to weld bead to the old metal part, that would be great . .....thanks - -

-

Singer “Patcher” machines 29-4 and 29K71

nylonRigging replied to ironwrx's topic in Leather Sewing Machines

Old, Vs Very old ...LOL . . my old 1914 29-4 G code, has '1887' Patent dated stamped on the cast iron stand . Newer machines are where it's at for sewing everyday . But The cool factor of having and keeping these old patch machines together, alive and stitching is priceless . . -

- Thank You . these two Pic's. saved me and ( you cant see me do it ) , but after a couple hours of mumbling cursing and greasy fingers , I am tipping a single malt in a chilled Waterford with also giving you a salute . Tonight I had the bottom cover off gear drive bars and machine slipped off my blocks when tipped back . Drive bar fell out as the Hand wheel turned and gear timing went out in relation to needle stroke . To say the least, it was a Large PIA . But these Pic's I found helped bigtime . .

- 16 replies

-

- singer 29-4

- 29-4

-

(and 4 more)

Tagged with:

-

Cool you got the bigboy 16" arm . you will like it . I got a 16" longarm flatbed single needle and all that extra room is nice sometimes . Just a HeadsUp .. You got to carry it up any stairs when you get home ?? ...LOL . . That Pro2000 16" head , is going to a lot heavier than you think when you put your back into it to pick it up and carry to your truck . .

- 42 replies

-

All the 441 import cylinder arms sold in US are pretty competitive priced . I would go with what is closer for pick-up or delivery . Your down in California.on your profile, so why not go with Artisan Toro down in Cal. ? . and there ( 3200 mdl.) with ( ped 500 ) . Same specs. as the cowboy and Cobra . But It has 12"inch Work arm and on-board bobbin wind . looks like it's 2420-$ on the Artisan website . Artisan sews good and they answer there phone, stand behind what they sell similar like cowboy and cobra sales . .edit add .. you live close to Sacramento/San fransico area, pretty big population so must be a lot of used sew machines . Can you find Used 441 clone down there ? if worried about funds . .

- 42 replies

-

has anyone tried the "polyamide thread" from black crown garage

nylonRigging replied to coma44's topic in Sewing Leather

( thoughts asked ) .. My thought guess ? , polyamide 'might be' very similar feel to an para-Aramid thread/cord ( kevlar , nomex..etc.) . Aramid thread are pretty tough abrasion, UV resistant, but the Aramid threads ( if polyamide similar ? ) , Aramid ( i have couple rolls ) feel pretty rough abrasive texture . Only way you will know for sure you can use it, is get 1 roll and see how it runs in your machines . . I just thinking .. ( Thread Tension ) and how nice smooth bonded thread flows and tensions so much better than stiffer and rough threads . -

Accessories for my new machine. Typical 441.

nylonRigging replied to Gusta1's topic in Leather Sewing Machines

ya, the aftermarket 441 foot are sold cheap on-line . Dremel , file and grinder all you need . just make sure when shaping feet for any machine that you have a cold water cooling bowl there to quench and keep the Temp. down as you go . The metal on the aftermarket feet sold is actually pretty hard . R-side cut-off, shortened and narrowed some . . 'middle' , Trimmed short, with feet narrowed . . and there is a full size Foot to show stock length and width . . -

Accessories for my new machine. Typical 441.

nylonRigging replied to Gusta1's topic in Leather Sewing Machines

LOL... because rest of the world not sewing leather, it the most widely used foot for 'heavy' synthetic and natural fiber/weave materials . It also great Foot to buy several of, to grind , cut and shape for specific jobs . . -

Chinese Imported Sewing Machines

nylonRigging replied to willford's topic in Leather Sewing Machines

- You got to remember that a majority of people that are learning to sew, or that do sew with machines, don't have acquired enough machine mechanics knowledge, to feel confident enough to order a machine on-line, sight unseen from China and then drive over to a trucking delivery hub pick it up, pull a machine out of a crate and put time in for set-up and timing . Also, The majority of people want to just slide a sew machine into a station, plug it into the wall, and go to work . You are charged a Fee-$ for the privilege to just ' Plug & Play ' . You Can't fault the ' Middle Man Dealer ' . They are offering running a ' legitimate service ' . ' post sales Customer Service ' . Retail Mark-up-$$ , it is a business service and You pay several hundred dollars more for it . .