nylonRigging

Members-

Posts

477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Timing issues Adler 267 flat bed machine

nylonRigging replied to AndyM's topic in Leather Sewing Machines

PM, sent on mechanic info . You down hwy. 84 E. out of Portland somewhere ? . -

WHERE on the table do I want my machine?

nylonRigging replied to kevinkay's topic in Leather Sewing Machines

what ( JJN ) says . you needs to be ( 1.5" ) thick . easy to laminate and add to it . Just 'Glue and Screw' cordless driver or use Air-gun staple to be fast . I used commercial gun last time I did this and was great . Don't run screws or staple/nail in the Cut-Out spot where you got to cut . you need to do it on a flat patio outside or flat inside concrete floor . just get good Plywood, Dont get crappy plugged finish plywood . You can use the particle board, but Ply. is better for not getting a Bow on the top over the long run years latter . Just Cut Ply. same size as top . glue and walk along with your body weigh and Screw it all down . Then go back in half hour and wipe all the excess glue that will press out the edges with wet sponge . leave sit for few days to cure . . -

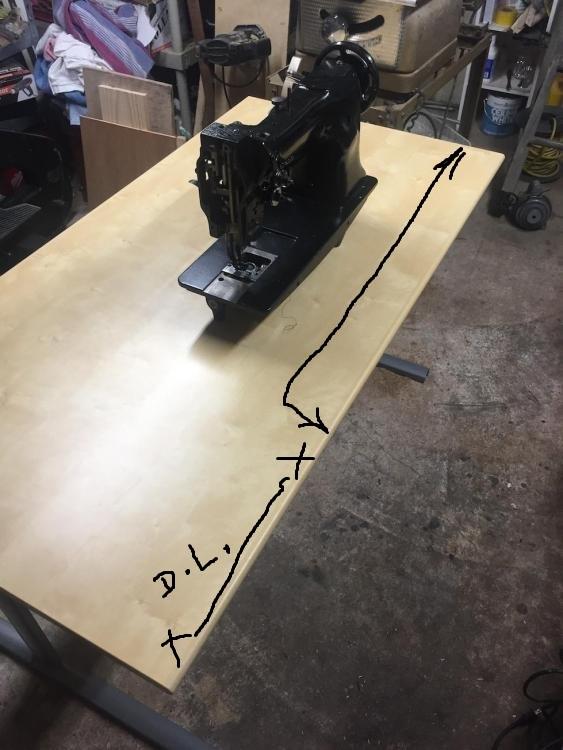

WHERE on the table do I want my machine?

nylonRigging replied to kevinkay's topic in Leather Sewing Machines

As long as that table ( top is thick enough ? ) for an inlet. That is great working size top . Also you need check-look and mark on top-side where the underside metal table frame is located before commit cutting . also make sure your belt-cut-out and if running reduction wheel ? it has room on underside from hitting frame . IF it were me .. because of large size top .. I would keep it about where it is and make an set-in cut for where operator sits . So you get a little more L-side for materials to hang on the larger size patterns you stitching . ' Roughly ' . I marked with Line in Pic. for Cut Out where you Sit . Also where I marked ( D. L. ) . It EASY to hinge a Drop-Leaf that can swing-Up an lock for even more top when needed , and then just swing down and out way when not needed . - -

I just guilty of having pride in my quality work and in the machines I sit behind . I have nothing against Old machines . I still have/use regularly a, 1951 112w140 and a 1957 269W141 . I just have a thing for keeping all my machine I use clean and tuned, and with the shop floor swept . This 29 is old but it is just to dirty to keep in my sew room with other machines I own . And I do plan using the 29 and it will come in handy I am sure from time to time . I don't think I am ?? just slathering some lipstick on a pig, with paint on surface cover . I am going threw all that moves also, cleaning off years of dirt/old oil with a brush and solvent . It still stitching nice, and for it's age and I think I can get a year or two out of it still . in ( 1/4" thick ), it is still doing 7 SPI . So it not quit a sloppy parts donor machine yet . .

-

Ya I pondered that for a while and the decals are there but are pretty worn and gone on some of them especially the floral on arm and the one on top of main body . About the only ( 2-color ) complete sets of 29 short and long-arm ( Factory decals with the floral ) that I can find that look worth putting on a 29 restoration . Is the Keeler Sales out of lakeland Florida. . but they wanting almost 70-$ usd for entire sets . .

-

On the Head now and slowly tearing down and cleaning between sewing orders and other projects . Treadle Stand I Powder Coated . but i will only shoot the head with Enamel and clear-coat with some new decals . -

-

Suggestions needed for Back pack straps breaking

nylonRigging replied to Sharon Mallory's topic in How Do I Do That?

( Looks Like ) .. when load bearing, Is your ( 1" ) Webbing breaking and shredding the weave on your toothed friction lock-bar on the Buckle ? . If so it's the type- webbing your using and you need to change to different . Where Getting, and what Webbing you using ? .. Nylon is strongest for friction and strength . Polyester is pretty strong and best for UV sun damage . and definitely If you using the cheap Polypropylene webbing, It will do this in the Pic. every time . edit add: Also under heavy load Bering, like a main lift of heavy packs and container systems . your webbing wrapped over any friction surface for best long life . It good to run a ' chaffing strip ' under the webbing wrapped over the hardware that load is hanging from. . . -

As much as I love to own a 867, it is definitely not in the budget. I hate even watching Vid. of it's performance and all it's factory extra bells and whistles because it just makes me want one more . the 867 is in a class of it's own . I will have to Slumdog it, ....LOL . The Juki is in my-$$ range though, and I know it is a real workhorse with also affordable parts . .

-

Everyone should have one ...LOL . 29-4 is cool little stitcher . I was going to slap it on a spare table with servo and just make more modern up-date . But the more I looked at the old Cast metal, the more it just made sense to preserve and keep it all together as a whole unit . Price was not to bad 200-$ for the powder-coat job at shop down the street. I will put a little time into the Head and clean it up, will just bolt Treadle stand on a caster wheel frame base when I done, and keep over in the corner with a couple other machines I got on caster wheels . .

-

Slowly getting cleaned up and looking presentable . Was way to dirty to be put with rest of my machines . 29-4 /1914 . took apart and stripped the Treadle Stand and Top . had it all Powder-coated black and putting back together . - -

-

having more lift would be great. I have been eyeballing that juki for a awhile also, and It has the punch and power . I still wanting some more Lift , and been using a heavy Consew RB1461A for a lot of years on the heavier side of things, it has good punch threw multi-layer of materials . I wish my Consew had more lift, but there does come a point when you just run out of needle with a 135x17 length and material height. That Juki LU-2810 has more lift, and I am getting one of them sooner or latter when the ( money materializes in my wallet ) the opportunity comes by me . The RB1461A does good but I think the Juki definitely has a couple more +plus's going for it . Here is a Pic. of , 2-layers of 1000 den. .. 1/2" scrim backed foam .. a piece of 1" webbing fold-over the top . more lift would be a great asset. -

-

Turn sliders to go either way . I always use ( Coil zippers ) when I can, And buy zippers by the rolls. So I cut to random lengths to what I need . mostly use #5, but the larger items I always try to give strong/beefy if possible with #10 's . edit add: I guess some people buy the zippers that are already prefab. with stops and the sliders installed . The illusion of one-way is there, but I think a lot of teeth are multi-directon of zip, with the Slider determining the zip/unzip direction .

-

The Direction of Zipper closing ...LOL couple weeks ago I did a few sets of uh60 door covers for a order. done this pattern several time and was no biggie . I get all finished, and am hanging them up and giving them all a quick inspection before box and shipping . Instantly my heart jumps to my throat and sinks to the floor ..." Oh this is Bad". because I just see that all the #10 coil zippers are closing the wrong direction on all the padded bag covers . It takes me about 30 seconds of beating myself up to realize and the light-bulb to shine on top my head . No Biggie . Just pick-out the closing ends holding stitches of the Zip . and just ' turn-around the Sliders ' to slide the zipper teeth, in the other direction . Screw-up's all fixed in an hour . .

-

I have done this a couple times with finding a good head and setting it up on tables . The Head still needs a check-over timing and look for spots to clean and oil/lube . Things you need .. Table with proper inlet/Hinges . Motor drive/Belt . You need to work-out a Knee-lift and linkage, or at least a pedal pull chain for presser foot lift . Also you need a Oil Pan . side-table bobbin rewind . Some extra Bobbins . String it all up, Get it all rolling and workout al the bugs to get it stitching like a champ . Do you like to work on projects ? . or would you rather save a few hundred more-$ and buy something that you can just Plug-in and sew ? .

-

Are you sure it the exact same pitch TPI bolt as it should be ? , being it is so loose now ? Or is the threads just so worn in screw and hole both, that maybe it so loose ? ( it does happen ) . If someone has over torqued and eaten-up/stripped some of the thread that were tapped in the hole . You can dissemble the part . then drill/ bore over-size a tiny bit , then just Thread-tap the hole to a tiny big larger Grub Screw ? Easy job to drill and tap new screw . the longest part of the job is disassembly and re-assemble again . .

-

As it was listed as in 'Excellent Shape' and 105 years old, Curiosity got me, So I did go check-out the 29-4 that I linked above because the nicer 29-4's are slimmer pickings to find now in the 21st century . It Still sewing 5.5 to 6 SPI . It is dull and not shiny, But original paint and decals are thin . Original wooden table drawer and leather strap stop . The hardwood Treadle drive shaft still perfect shape on the original cast table stand . I really not needing another machine. but you only need 1 guess ? to where it is sitting now .... LOL .

-

- what ( Kgg ) is thinking . tight area and a Patcher . Over in Portland/Vancouver area there is a used Singer ( 29-4 ) on the Craiglist for 575-$ . You over on the coast but maybe only a half day of your time to checkout . https://portland.craigslist.org/clk/for/d/vancouver-singer-29-4-shoe-patch-sewing/6938357061.html - Edit Add: I just noticed the Phone # and I know 'ryan' . he easy guy to talk to and knowledgeable on the machine mechanics . 575-$ is a lot for old 29 . it have to be a excellent condition for the price . All depends on how much life still in the oldboy. pics look good though that was posted . . .

-

Techsew 2600 table came damaged, repair ideas?

nylonRigging replied to JC2019's topic in Leather Sewing Machines

Was it wrapped/boxed sitting on pallet on your signing and Pick-up ? Was it visible like it was dropped ? ( did ? ), looks like some jackass on loading or unloading, with the forklift punched it with the fork when it was on the pallet . if so it was the trucking in-between the seller and you most likely that did damage . forklifts have some power so check if table frame really bad out of square also . Just asking, in past I have picked up new machines boxed and shrink wrapped on the Pallet when they delivered to local trucking hub . I sign and have the loading guy set on my truck to take back with me. I look hard, BUT Unless it was obviously 'looks visibly, dropped/damaged, it really hard to see prior shipping damage on machines, and it a double-edge-sword, as trucking hubs really not in favor of you un-cratting and inspect before you sign and pickup . . -

- Yamata and buying off Web. like Ebay or Amazon . It is no doubt a good machine and it is not hard to put it together and get running . ( You Should ) get a Tech. to fine-tune and time 'for your application' and for your peace of mind after you get it set-up and running . Well worth paying-$ a hour of his time and see your starting off with good wear pattern and have it running good. That Yamata ( spec. Sheet ) also might be a little bit exaggerating on the #207 thread and 135x17 needle ( rotary hook ) . (imho) that 207 is maybe? pushing it, and It sure be suited better up to #135 thread size . --> Research what presser feet it takes ( are they common ) easy to get . It Always nice to have extra sets to cut and shape to your needs . Also in that Add Link you posted say's, FREE 'standard' shipping all way from Florida ??? holy crap that will save you money ... For that price you buying . I can just about guarantee that they not even looking and touching those machines they shipping out to you. they sending them out in same boxing they get them in from there distributor. It's a trade-off . You getting a machine that is a good design and will work for you for years ( At Lowest Price ) . But you have to pull it out of factory crate and clean-up, put it together and work the bugs out of it and then get timing set-up to your satisfaction . -- Artisan ( as mentioned also ) , is good also on there cylinder beds machines or flatbed. and it nice that if you have question or need a part . that all you got to do is call them down in Cal. and you will get a real human being to talk to you . I have there newer version 12" arm Artisan 3200 and run it for a lot of hours and I got absolutely no bitches about it . ( Machine Repair ) I use/call few guys that off in Portland, Salem and Vancouver for mobile Tech. repair . But You over in Newport on the coast, where/who you call for any Mobil repair over on there ? .

-

(standing on cutting table) Can't quit catch all of it in this Pic., but this is my imperfect and crappy little sew shop . -

-

That is a combo straight/zigzag stitch ? , & Drop/bottom Feed ? .. Probably nothing wrong with the thread tension all by itself . That a good machine, but when you start stretching out the stitch With that Machine and feed, ( bottom/drop feed ) . It a combo problem of the Suede most likely the material and grabby texture under Foot & when you ( Stretch-out the stitch length ) . The Suede not feeding in unison with the Dog and giving you all that slop on the bottom side . I run a couple drop-feeds along with walk foot/needle feed/unison feed . and that ( I find ) is common problem with different materials with bottom-feed only and certain materiel under the press-foot and texture of certain materials that don't flow well under the Foot . Stretching the stitch size Big just accentuates problem and it not flow unison with the Dog under the Foot. You will get that Sloppy thread mess underside . Try slowing down stitch-speed and with pressure-foot tension. maybe try a Teflon Foot . Try to figure out a good-Happy stitch length it will flow with . Best way to fix is to run a materials 'pull attachment .but that a spendy-$ fix . Or if you in love with having a combo straight/zigzag . buy that Consew machines big brother, Walk-foot ( 146RB-1A ) . I got this japan Consew and it is a 'strong' workhorse, combo straight-stitch/zigzag machine . .

-

Was thinking about this also . that class7 cast iron handwheel . with someone who is current at what there doing. It is probably GTG to be able to Brazing it back together with real nice looking repair and structural sound. it will forsure be a couple hour shop time-$ , but I think only way for you to find a replacement would be finding a junk donor head . .

-

Please give your opinion on my sewing machine purchase

nylonRigging replied to Louiesdad's topic in Leather Sewing Machines

- You can't see me, ...but I am on the floor in the living room in-front of my PC. . ' Bowing Down ' , to you sir .. A full size Pool Tarp on a 111 ... you are the man. .....LOL . -

LOL .. ya, I slide all kinds of currency/picture/paper under there . I use a 1/2" thick glass top for a hot-knife cut table . .

-

That will work great . All a Hot-knife is, is a glorified soldering iron . Until I bought production hot knives, all I used to do is just buy those Radio Shack 100 watt solder guns . Then put/fix a two-prong blade on it, in-place of the solder tips . The smaller watt Solder wands work great also for specific jobs . I cried the day they quit selling those radio shack solder guns with the 2 screws tightening on the end . . I still got a couple of them and one I never used & I always keep my eye's peeled at junk stores for those old 100 watt guns . - .