nylonRigging

Members-

Posts

478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Opinions on these feed dogs + plate

nylonRigging replied to AbelJojua's topic in Leather Sewing Machines

Why ,.. Med. or Large feed dog and plate ---> If you sewing light/thin ? A 'smaller' size needle hole on the fine-tooth plate . You will get far less pucker, getting punched/shoved threw hole around the needle . . -

Are Zig-Zag machines exceptionally hard to find?

nylonRigging replied to williaty's topic in Leather Sewing Machines

The Craiglist here, 'industrial zigzags' and combo zigzag/straight-stitch . There been a few of them in this area popup steady . Industrial zigzags, They definitely not as prevalent as straight-stitch industrial. My area here I guesstimate it about 2% out of a hundred straight-stitch machines for sale are zigzag . Never seeing any in your AO is a little weird . . -

ya , if you are running the 'fine fabric' fine tooth feed dog setup on the machine . For thicker and heavier materials, they make a more taller bigger/heavier dog with a raised needle plate for that type common feed set-up. great for Slower RPM and thumping threw thick . On my old Mitsu. DB single needle, ( same parts ) as your Singer . I tuned for 135x17 needle, the heiviest Dog and plate set with slow servo RPM . I can 'Easy' sew ' 8-thick ' 1-k denier . urethane backed Nylon with using T70/#69 . I have couple different size Roller feet and needle plate and dog also for it . I cant remember parts#'s on those but it very common sold everywhere . Don't know if I seen any Heavy duty single-Dog needle plate setup's for the Roller Foot sets . If you sewing some soft thin leather you can grind off the sharpness of that dog to leave a softer bite . Heavy Dogs/raised Plate .. This one set here.. works really well on a Mitsubishi I have , same parts for your singer . https://www.cutexsewingsupplies.com/products/heavy-work-teflon-non-stick-needle-plate-feeder-set?variant=32221240000565 -

-

That bottom-feed design machine probably the most copied in the world under a lot of different name badges . 'Cheap' price for, and plentiful on those shank Feet , Dogs , Needle Plates ... and Roller foot part/kits , and other machine parts that are all over the internet for sale . Also.. you wanting a servo swap from the clutch motor . Easy and cheap, just get a small drive pulley for motor for betters low end control . And for your ( Stuck Bobbin Case ) question . are you saying ? , you Can't lift the small release lever, to take Bobbin out of the basket ? , Or , you lift leaver and Bobbin Case Wont Slide Out ? 2 things .. 'some' under/side bobbins , If your Needle is ( down on it's stroke ) You Cant take out your Bobbin Case . Or , If your lift lever is Stuck and ( wont lift ) . You ( Probably ? ) something blocking hing movement , maybe ? thread wrapped over the Lever, or there No Room for the lever to lift up ?? . That's one good thing ( i like ) about Top-Load if you get a pile of thread wrapped under the bobbin and lever won't lift , is that you can easy take off the Gib and remove and clean-out and put back in, because it staring straight up in the face at you under the slide cover . But .. You have a Side/under table bobbin assembly and is a little more of a pain in the ass, but still doable , and good learning lesson for basic sew machine maintenance mechanics . 'for me' , Easiest way I would do , but harder scenario ( for you ) , is that you loosen screws and remove the the whole assembly off the shaft . Easy to see all and asses the problem of 'why' , and put hands-on to fix . Then just re-time Hook and Needle . .

-

Don't know if I have any ..." skills " ??? . I will Seem-Bind objects that I have made more than a 1-k + of same thing . I will still screw-up something Binding them that I don't like, and then pick stitches and do all over again ....LOL I only know about, what i do a lot, and the more repetition you do with an item your making/selling, the better you will get seam-binding those one types/shapes of objects . Seam Bind is definitely not an easy discipline to just jump into . There just are are SOooo many ways of seam binding to learn with, flat-beds, cylinder-beds, needle-feed, compound-feed, single-needle, double-needle . Then the types of different machine Binders setups with strait or 90 deg . then there a truckload of different types of binding materials also with naturals and synthetics, all with there own problems of feeding . It's a rare guy, who even has seam-bind hands-on knowledge with even 2 or 3 of the different numerous sew trade disciplines in sewing that involve Seam Bind . .

- 23 replies

-

Here in the NW. US. , If I type-in 'sewing machine ' in the Portland, local Craigslist sales general search . looked today, It will pop-up 193 sewing machines that are for sale . Asking prices are all over the place, there is no rhyme or reason for some of the overpriced fantasy land, asking prices for used sew machines . You can find old clean treadle machine flatbeds anywhere from 75-$ to 200-$ .. but then when looking you also see some guy with a delusional asking price of 1100-$ for an old Beatup singer 29-4 . . Then also there is a clean Singer Model # 29K60 asking 400-$ . . Seen a old singer 48" longarm singer for 1500-$ last week . .

-

So the smaller inside turn you making, with stiffer the materials use, it is difficult and can be a pain in ass sometimes . Also there a difference between compound and needle-feed setups Binding, but Basically for both the tighter you can get your setup into and adjusted properly, tight to the needle the easier for the real tight turns. OK.. doing a .. ( real quick and dirty example here ) . after that last post just made, and just grabbed some heavy vinyl and, putting 1/4" foam in-between . My single needle cylinder bed has binder taken off for another run n item, and I only have my 2 double-needle flatbeds stringed-up for seam Bind 3/4" type3 . So quick couple pics. example of, 'scrunching' some small pleats behind the inside radius your turning/taping . - -

- 23 replies

-

If your 90 deg. Binder throat feeding is real close and setup to the needle makes easier . Don't know how supple flexible the material/panel is your binding ? Or if you have internal stiffening added to panel ? . Your Pic. it Looks a little thick but manageable . Larger inside radius Binding is lot easier . The more difficult tighter smaller ' Inside radius turns ' and Binding, is easier if you can physically grab material inside behind Inside radius turn you working on, With fingers , squeeze make a few small pleats to straighten the curve as you Seam Bind it . If your panel and has small tight Inside Radius , And you can't manhandle and scrunch material behind the inside radius to straighten little bit . Then you need to really learn ' your technique ' and practice on some practice panels before turning a tight one on the final product . And it does make a lot easier if your 90Deg. Binder throat is feeding tight to needle . Also maybe ? move to little 'shorter stitch per inch' just on that little inside turn might help keep tape tracking out and smoother . When stitch out of the inside radius, change SPI back to normal before the turn. .

- 23 replies

-

Who can tell me ??? , Is there any Sew machine brand name in 2021 , that does not subcontract some or all parts from China ? Juki is a solid machine . And the last New Juki I bought say's .. Made In China .....LOL , But It is all about QC and the quality of part Spec. by the manufacture, even body finish and outer coating . Even so, I have a couple clones that run like Champs and most likely will outlive me, to sold to someone else and used for years. .

-

Consew 146 RB timing issues; Manual

nylonRigging replied to Chelan's topic in Leather Sewing Machines

Hey also ..when you setting zigzag adjustment and doing Needle L and R on the Hook rotation . some needle have a little longer needle scarf cut , So make sure you not tapping the Hook top bottom of the scarf . . -

Consew 146 RB timing issues; Manual

nylonRigging replied to Chelan's topic in Leather Sewing Machines

You doing large skin/panels on Ultralites ? , just curious if you thought about getting a 2 or 3 point Cam for the work . And yes, that was the 146 I was looking at ...LOL , a good buy does pop-up every now and then. That is a solid machine . . -

Consew 146 RB timing issues; Manual

nylonRigging replied to Chelan's topic in Leather Sewing Machines

hey noticed that you up North of me . Did you pick that Consew up off craiglist ? , I noticed a couple of RB146's on there for sale few months back and one was cleam machine and a good pricing . II was even mulling over doing the long drive up and back I-5 to buy it . --- With you drive belt off the hand wheel . And with the Presser Foot in UP position off the dogs . Your machine should spin pretty free by hand . 1st look, easy pretty Common ---> Is the Needle Plate binding/rubbing against the feed dogs, when you rotate by hand ?? . after screwing down the needle plate look and see and 'feel' with turning machine over by hand that the Dog not being the friction spot . If you have removed the dogs and needle plate to service . When replace them back with leaving your 2 Dog screws not tight . then when screwing the plate down, you can align the feed dog for clearance . The 2 screw heads on Dog, easy seen and just tighten down . . -

Consew 146 RB timing issues; Manual

nylonRigging replied to Chelan's topic in Leather Sewing Machines

( Gib ) .. not, Jib . and I know . the factory book illustration looks like they hired a chimpanzee to do there drawing ...LOL the Gib is ( plate-part ) sits behind the Hook, that is part of the outer bobbin assembly, and the Gib hold the basket on it's guide track that spins inside the outer Assembly . The outside bobbin assembly Hook and Gib . the Basket that spins inside it, is what you snap your M-size bobbins into . It is something that I am not an expert in at doing because I might only 'Time' do it every 2 or 3 years on the 146RB , but I remember it all gets a lot clearer when you start doing and watching the needle plunge on that stroke on the bobbin assembly . And, to show you ... I just dug out an 'older' used , complete bobbin assembly for 146RB1A , that I keep in case I need to rob a screw or part . KEEP all old bobbin assembly's, when you repair. because all those screws on bobbin assembly are all obnoxiously tiny and very easy lost if dropped . ... LOL , And I already have robbed a screw off this old Gib . Popping a Pic. of it and try to point to ( Gib ) . and if you look at yours on your machine . You will see it is held on with 3 screws . The tip of my pencil is what the manual picture is showing , in relation to the needle plunging past end of Gib . .. also, everyday of sewing, put a tiny drop of oil on that little guide track the basket spins on . - - -

Consew 146 RB timing issues; Manual

nylonRigging replied to Chelan's topic in Leather Sewing Machines

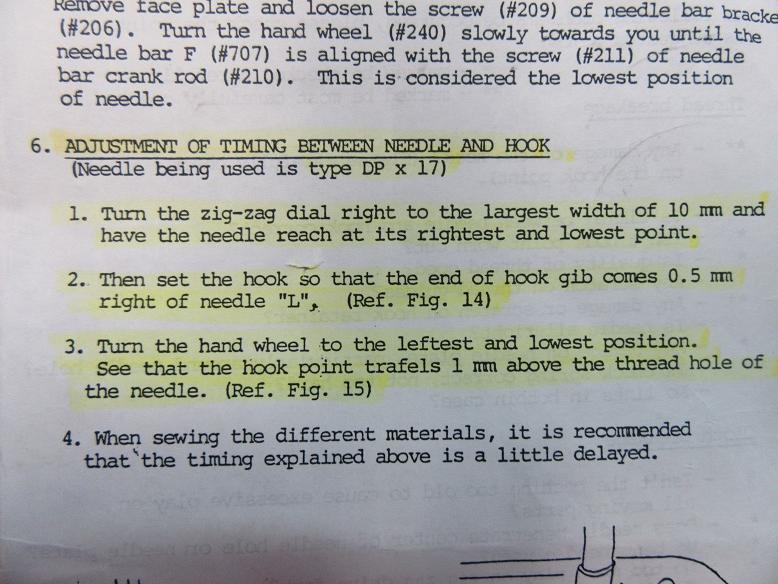

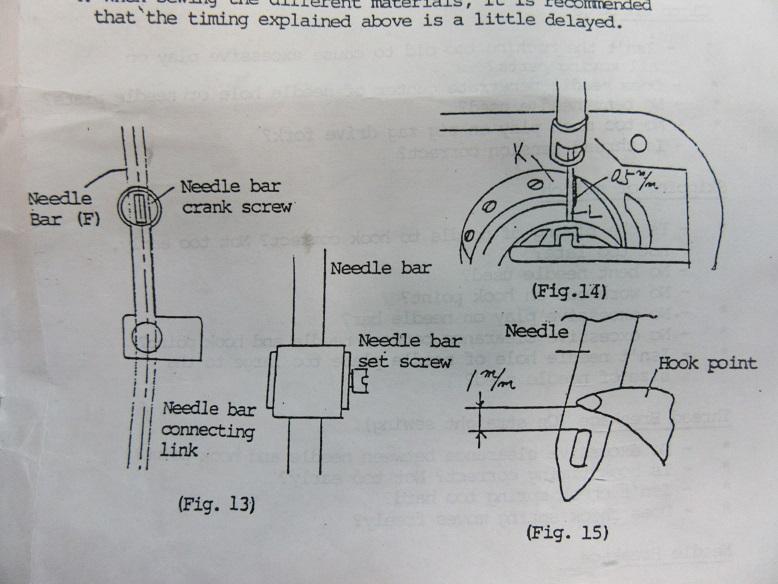

I got this machine and book , I always remembered it as being a little paininAss to get the timing just perfect . Tuning to get strait stitch and zigzag stitching threw all the stitch lengths, and plus all doing it all in reverse . That is a real Good quality straight/zigzag combo stitch machine and yours in the Pic. is made in Japan model to . I remember that when it say's .. " set Hook Gib 0.5mm " .. that there for me .. was just a tiny plus\minus to get it all to clik . also I remember 1st to set the needle center and to se the zigzag width all proper adjusted, before start on the needle-hook timing . - -

Appreciation sent for the time spent looking at this . The Needle and the 'Eye of ', is a small and overlooked thing, but the work quality we expect of it is big . .....thanks .

- 5 replies

-

- needle quality

- needly eye

-

(and 2 more)

Tagged with:

-

HAHAHA LOL .. I tried there service Dept. for a fix of new Consew servo I bought couple years back .. Servo is one of there nice model . 750 watt, 4 button programmable csm3000 .( No NPS ) . Looks pretty much same as your model Pic. Mine ... Turn on . It hammers-out 5 stitches on the power-up . Consew customer service Center . They are a Joke , and All They Could Tell Me Was , ... "send us a video of your problem " . I hung-up the phone and went back to work . Labeled---> ' PREMIER BY CONSEW ' .. my Ass . Consew CS is worthless on giving usable knowledge to customers mechanical problem . .

-

Having problems binding around corners

nylonRigging replied to chrisash's topic in Leather Sewing Machines

Hey, just poking fun . . and I can feel your pain, I spent last couple days binding on radius items. Over the years, I have picked out many a stitch out of seam Binding on an radius item, just to re-bind the job over again . Doing Single and double-needle binding radius, There is definitely some acquired technique to it, but a Lot of the battle is getting your setup tuned just right . . -

Having problems binding around corners

nylonRigging replied to chrisash's topic in Leather Sewing Machines

- modification of threads title .. Having problems binding around corners 'Radius Curve' . If you having difficulty binding around Radius curves ? Then you will find little Joy with 'Turning Corners' . .. LOL . -

for purchasing Binding and Webbing's , If I getting more than 1-k yards, or wanting a very specific dye color/tone for matching materials . I will just go direct to Bally Ribbons Mills . I live in Oregon, so if I ordering them from a supply Vendor, I usually just stay here on the US. W.coast here, and usually order/buy them from John Howard Co. down in Chino California . . I know I posting Pic. of Heavy Nylon Binding, 'But' I find the X-Over from Binding Leather or Fabrics is really very similar/same for Setting up Binder mechanics and feeding set-up. Is the 1st time I ever setup a machine with this large a needle for Binding . But the Second I seen those Pic's Uwe posted of the KH set-up, I had to get it to use . For last 30 years I just have been fond of, and sticking to just Needle-Feed machines, single needle and double needle, like Singer 111/211 and newer juki model also . There is a new learning curve I am grasping because the 441 clone/model is flatass just a brute compared to the machines I normally Bind with, but the thing will needle threw about whatever you can get shoved threw the binder throat . 441 shuttle also seams to work well with the lighter weight 138 and 207 threads . .

-

Quick Update Bump-up .. Finally been putting a couple hours behind that KH swingarm binder on the 441 shuttle doing a new pattern, and working out some small bugs with also getting a feel for the way it likes to be fed . I just using some 1" type2 nylon binding tape binding around radius's on some panels . It starting to shape-up to be a pretty decent working Binder . The Machine size itself is a little bit of a bully for binding, but better to have to much needle, than not enough punch power . - -

-

Thread/needle choices for sewing leather straps to canvas?

nylonRigging replied to LanceR's topic in Leather Sewing Machines

when in doubt ? , for the finish look and outcome of new pattern and materials . I usually just mock up some sample pieces/panels to punch holes and thread threw, and scrutinize top and bottom with my choices . You only using 1 machine ? . Test 1st to see what you can actually get away with on the thickness of the stacked combo of leather and fabric. Thread ? , looks like they just using 69E for thread on the canvas/oil cloth on the main fabric body . For leather pieces it your choice for thread size, but little bigger than 69 will look better. Needle ? . looks like you will mixing it up between using a fabric and blade point . Or . you can use just fabric needle for all . Your Pic's. example, for the shoulder straps and the top weight bearing load spot . show the Fabric/canvas in the middle, between leather on top, and a leather backer reinforcement inside . So I would assume they are using a leather blade point when sewing the leather . And if look at your Pic. there is a couple spots like inside bag top corners/closing flap, where there is a couple leather reinforcement backing square . canvas finish outside, leather inside bottom-side .Your going to use fabric needle on that because you will cut the Canvas thread weave on the outside finish . . -

Bump this back up .. Something that I just took note of . Is that I just changed out Press-Foot drive assembly for less than 100-$ shipped .. LOL .. Cant do that with Adler or Pfaff . - -

-

Tension disks on Consew 99 not opening when foot lifted

nylonRigging replied to Chelan's topic in Leather Sewing Machines

Also .. It maybe just a 1-minute simple Fix adjustment, so check this 1st . The whole tension assembly slides inward and outward . There is a small screw hold-down to your tension assembly @ about 3 or 4 o'clock R-side, that screws against the barrel of the assembly holding it secure . Loosen screw, and slide the Assembly inward just a little bit and re-tighten screw lock . See if this takes-up the gap to the push-pin, to make better contact for tension release. . -

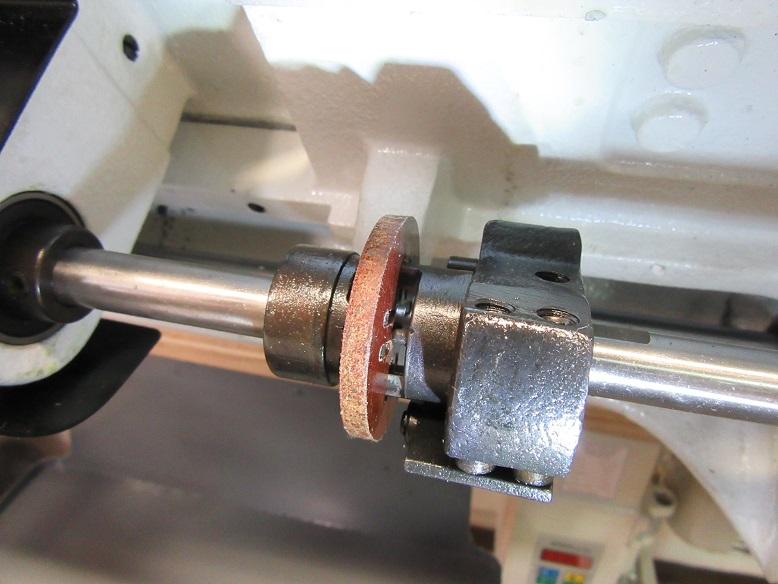

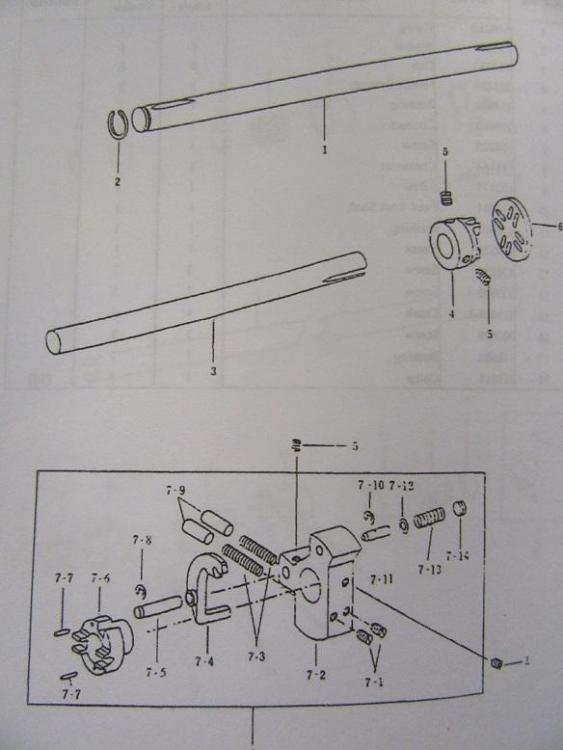

On this post bed design machine, Roller foot feed, with needle bar feeding assembly . It is a really different piece of mechanics to me . For what little I have done so far with it . I seems to be a real smooth/fluent with the feeding and stitching . Pic. is face cover off, and showing the links for the roller foot drive, and needle bar assembly. - Also, on the bottom underside shaft . There is a ( safety clutch block assembly ) , with a non-metallic composite connection plate in between .

-

----- I just this afternoon picked up the pallet and setting-up this exact model duel drive Post Bed you talking about, branded a Model 4618 by Artisan sales down in the bay area CA. All the sales description say these models are 'duel drive' , but also they say Needle Feed . It does have a small amount of needle walk on the shaft stroke . Does seem to be Very Common design post bed being bought by several vendors . I would also really like to know the Parent machine that it is copied from ? - -