-

Posts

456 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Littlef

-

Are Basket-Weave Stampers Negligent!?!

Littlef replied to RVM45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I see no purpose to stamp, carved or otherwise decorate the backside of a holster. When I draw out the main panel, I wrap it around the front edge, and stop at a point just where is goes out of sight. If that makes me lazy, so be it. I can live with that. -

Nice looking holster. The plug is a clever solution. I'll have to note that for a future project.

-

That Looks beautiful. Its a clean design. One thought from a functional perspective. It has no kind of way to close the top, so if its knocked over, the contents would spill out. Some sort of a snap or a clasp might add a little functionality.

-

Novice having trouble making my first pattern

Littlef replied to UnimportantSomebody's topic in How Do I Do That?

I'd pick up a few sheets of craft foam from Michaels/Hobby Lobby. They are a buck or two a sheet. They have more thickness and pliability than using paper or cardboard. Then you can cheaply prototype. If I'm working on something I haven't made before, I make my initial drawing and measurements on paper. When I work that out, I make it in craft foam. Once I try it in a 3D foam mock up, I often find things that need to be tweaked before cutting expensive leather. -

knife sheath with feathers pattern

Littlef replied to WyattEarp's topic in Gun Holsters, Rifle Slings and Knife Sheathes

wow, that's nice. well done -

+1 for straight cuts I use a utility knife, and I keep a large box of replacement blades. As soon as I feel any kind of drag or pull from the leather, versus a clean easy slice, I replace (or flip) the blade.

-

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

As with any well-crafted tale, they tend to take on a bit of exaggeration over time. But it does illustrate the importance of understanding the equipment you are using, and approaching it with a degree of respect. In this same area where I go, someone constructed a bowling ball canon, loaded it up with a large black powder charge. The bowling ball came down a few miles away. It went through the roof of a barn and killed a cow. That guy went to jail. The machinist who turned the barrel for this mortar, had been making them for several years. With several years of development, he determined the max charge should be 200grains. I'm operating at just under half of that. I'm dropping these within a couple hundred yards, in an area with a clear line of sight. I mark the location of each one with a flag so I can see the distribution as I'm shooting. I also plot each one in my GPS, so I'm compiling more data after each trip. My goal is to be able to drop a can right where I want it to land, versus just trying to put cans into orbit. I think it makes for a much more interesting meaningful session. I picked up some hardware from Tandy yesterday, and made some revisions to my preliminary leather pattern last night. Hopefully this evening I'll start cutting leather for the battery case. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

lol, that's funny -- that's not too far off from the mortar I built. Growing up, I couldn't ever find m80's in my area, so we'd put a few m60's together. Doing plenty of nonsense that we shouldn't have been doing. -

I like that. I need to make something along those lines for 22 ammo. If I throw a larger box of 22 in my range bag, about half the time it pops open and spills in transport.

-

Spontaneous Combustion and Safety With Chemicals

Littlef replied to Sheilajeanne's topic in Leatherwork Conversation

I'm in a condo, so lighting a bucket on fire on my patio would not be appreciated by the neighbors, or the HOA. I take my rags and lay them out flat for a day to let any solvents fume off. For BLO or Tung oil, I save orange peels and apple cores or whatever fruit I have, and wrap rags around the fruit to help keep them from getting balled up together. Then, I walk them out to the steel dumpster. It also helps that I'm just a hobbyist, and not running a business, so my oily rags are minimal. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

The battery is agm. I think plywood might be way too thick for this size bag. I was contemplating on adding a piece of Formica; however, the battery itself is a hard plastic box. I'm not sure that adding another layer really changes the equation. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

It makes for a highly entertaining day. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

Yea its a good time. It can lob a concrete filled coke can (about 2 pounds) about 300 yards with 200 grains of black powder. I'm slowly scaling up the charge. I put together this little video of it being fired last time I went out. You can skip ahead a bit and not listen to me talk to just see it fired -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

This is no where near the size of a car battery. There's more than one way to skin a cat. I could do it with a lessor battery, but I have this as an extra battery for my motorcycle, and its rechargeable. I'm not hiking with this all day. Its basically just taking it from the car and walking 30 yards out into a field. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

Oh, and sorry.... the battery is to fire a replica Civil War Mortar that I built. After I built it, I was reading the fine details of the regulations where I planned to fire it. I caught that there is a prohibition against anything fired by lighting a fuse. (I assume that is to prohibit people lighting fireworks.) So I reworked it, and modified model rocket igniters to fire it. Using battery power is definitely an anachronism, but ....Need to stay legal. I want to make this, so the aesthetic, at least visually, goes with the era. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

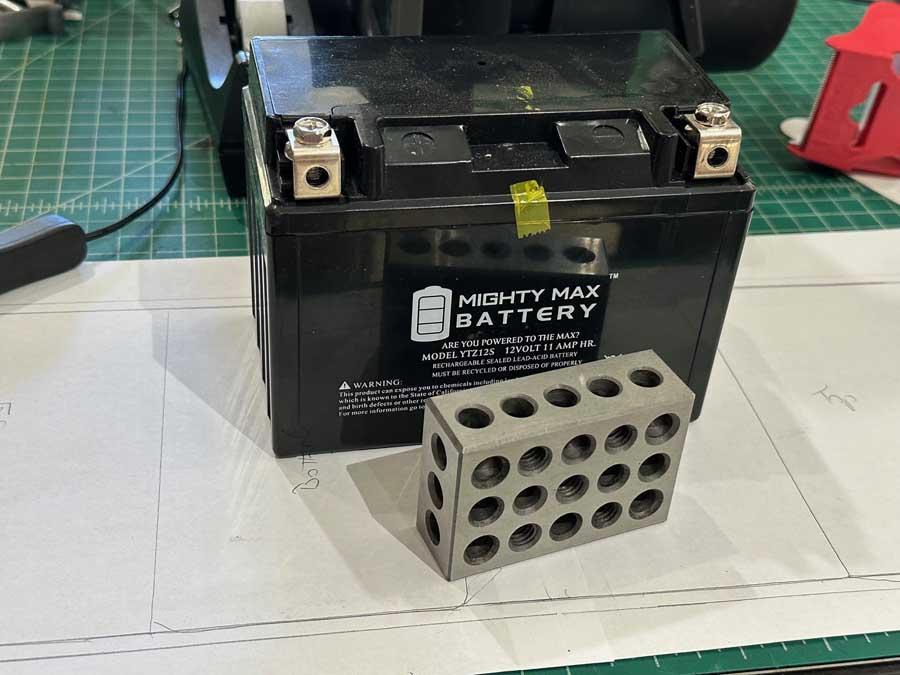

standard sized motorcycle battery. Its about 7.5 lbs. That's a good idea. Adding a couple rivets or screw posts would probably make it bullet proof. Cool, thanks! -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

Thanks chuck, that's basically how I was going to approach the construction. One long rectangle to loop around the battery, and then sew the sides in place. appreciate it. -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

yea, its a modern sealed battery. - That sounds like the right direction. I'll work it up with 2 bands going around it, and the carry strap looping under and going through the two perpendicular bands. Glad I didn't try to make it without the extra support. - Thanks for the suggestions -

Reinforcing: Leather case to carry a motorcycle battery

Littlef replied to Littlef's topic in How Do I Do That?

Its about 7.5lbs which is 3.4 Kg. I was planning on sealing the leather good, and also putting some sort of plastic bag/liner around the battery for a little extra protection. I always wax my thread, but putting a little extra on the interior seams wouldn't be a bad idea either. I'll work the design using some reinforcing straps. The shoulder pad isn't a bad Idea either, although I'm not really planning on toting it around any great distance. I appreciate the suggestions. thanks. -

Working on an odd project. I'm gonna make a leather case to carry a motorcycle battery, with a shoulder strap. I'm picturing the aesthetic of a civil war era cartridge box. I'm planning on using 9-10oz leather. Its a fair amount of weight. Do you think I need to reinforce it with a strap going underneath? I'm a little concerned about stressing the seams over time, if its not reinforced.

-

How to answer the question "How much is it?"

Littlef replied to Leatherinspire's topic in Marketing and Advertising

I'm only a hobbist, and I'm not selling what I make. However if I, as a consumer, find something I would like to buy and I ask, How much is it?.... If I don't get a straight answer, with a price, I'm done. No one likes to be jerked around. I don't see a problem with adding context of what work went in to making the good, but there needs to be a direct answer with the real price. --One guys opinion. -

Looks like you've been busy. You do beautiful work.

-

Pancake for a Kimber 10mm Rapide

Littlef replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

man, that's clean. sharp looking holster. -

This won't fix the problem after the fact.... But, before I cut leather, I make a test fit using craft foam. A sheet of craft foam is only about a buck a sheet. Craft foam folds and bends much more similar to leather and gives you a far better idea how its gonna work, as opposed to trying to wrap a paper pattern around something.

-

Ooo, yea, finding press in tubes won't be easy. In fact those probably were not designed to be replaced, which is why it took so much effort to get them out.