Search the Community

Showing results for tags 'bobbin'.

-

Hi everyone, Yesterday I bought a old Adler leather Maschine at a Atelier closing which need for my studies… it’s been standing for some years so I bought it without really being able to try it out( it was quite cheap). after trying it out I noticed that the bobbin is not turning. Turning the Handweel (which was already very hard) only makes the metal bar in part 2 turn ( referring to the picture provided) the longer bar and everything after is not turning. I tried turning it by force thinking it’s stuck but even after turning it by hand a couple times it didn’t change. I also tried opening the two bolts (2nd picture) but they are too stuck to move. Before I have to carry my machine to the mechanic I thought maybe someone else had had this problem with older, longer not been used Maschines and can help me. I’m usually quite handy and fix all my mashines myself but I’m out of ideas here… thankfull for any help! Thanks

- 9 replies

-

- leathermashine

- adler

-

(and 5 more)

Tagged with:

-

Hi everyone! I believe the phrase "long time listener, first time caller" is apt here even if we are not on a radio station. I'm a general maker but mainly I'm a leatherworker. I make a plethora of things from wallets to hats. I recently acquired a Sieck 269-373 sewing machine, which I can only assume is a Chinese copy of the Durkopp Adler with the same numbering. So it is fair to say I am new to the august club of sewing machine owners. I have had problems even finding a good manual for the machine so I'm not even sure it's threaded correctly. I have included pictures which show the threading. I am also significantly confused over what thread size this machine can handle. Wherever I look I see different opinions on this matter but as of right now it is (hopefully incorrectly which might make for an easy fix) threaded with TEX 135 bonded Nylon both above and below. I have included pictures of the threading for reference. My problem is mainly the tensioning. I don't know if this is because the thread is too thick or because of a setting. I have tried cranking the tension right up but I get the bobbin thread basically sitting flush and not being pulled into the leather at all. I've included a picture of a flipped over piece of 5 oz veg tan that I tried to put a seam in. I now ask for your help to see if anything stand out as wrong or any ideas that pop up. And please, do not think that anything might be too stupid for me to have done as I am a complete novice with this machine. Thank you.

-

We are trying to setup an old singer 236w100...I need help please. Should the bobbin be twice as tall as the bobbincase? This is way different from home sewing machines. Thanks

-

I am new to using my Cowboy 4500 machine. We have sewn several items, but now the needle keeps hitting the bobbin. The bobbin case appears to be upside down (not in the right position) from when we began sewing with this machine. When the needle is in the highest position, the bobbin case is upside down. I have made sure the needle is installed all the way in. What are some other things I can try so we can get back to sewing? Thank you in advance for any ideas.

- 6 replies

-

- cowboy4500

- needle strike

-

(and 1 more)

Tagged with:

-

I have a Singer 29-4, circa 1902, S/N K3403-02 While working to restore this machine we have met several challenges but thanks to the web we've been able to fix most of the issues. We have reached one that we can't seem to solve and are desperately hoping that someone here can advise us. The issue is that the needle thread will not capture the bobbin thread. We aren't sure if the shuttle needs to be realigned or is there something that we missed? We haven't been able to find anything definitive that explains how to set the timing for this specific machine. Thank you in advance for ANY help. Sincerely, Nancy & Jeff

- 16 replies

-

- singer 29-4

- 29-4

-

(and 4 more)

Tagged with:

-

I just bought a new bobbin case and hook for juju 1508 cause mine tension spring was a messed up I was wondering about converting to a side load style like the 1541 that I read about. Does anyone no the machine that the parts come from to switch it Over and part numbers and also how do I sent bobbin tension correctly I have played around a lot and seen all the Videos of how it should be just loose enough to fall when not supported but mine is all the way loose and still to tight it seems. Is that tension I mentioned only for light fabrics. Cause like I said both mi e r tight enough to support the weight of bobbin with the screw backed all the way out. And how do I know when it’s right. Also I have been having to tighten my top tension almost all the way to even it out. Also is there any I stuctions to set up the take up spring cause I can’t find anything On that online or in the manual. Thanks

-

Open to sensible offers for these rare SD28 parts..in pounds sterling £ Will post worldwide at cost..buyer is responsible for any import duties/taxes. Shuttle/hook with 2 bobbins...hook looks good and it picks up thread in my machine, has some surface rust and pitting on the bottom. 2 more spare bobbins. Super rare harness stitching plate with edge guide and screw..in great condition. Needle strike plate or whatever it is called...size 5/6 14 used needles...some have slight surface rust and or wax build up but could be cleaned, sharpened a re-used? Mostly size 6 with a few 5s I think? In my other post I have a fully working Junker & Ruh SD28 with needles for sale.

- 9 replies

-

- junker and ruh

- junker

-

(and 9 more)

Tagged with:

-

Urghhhhhh!!!!! I've been cruising, with my new to me machine.. but my bobbin ran out.. I wound another one, and put it in, and now for some reason I have absolutely no bobbin tension.. I didn't touch anything!!! I swear.. I did re-thread the needle side too, but that seems fine.. On the bobbin I can literally just spin the thread out, and I put it in, and it spins counter clockwise like the instructions say.. Here are the instructions.. www.consew.com/Files/112347/InstructionManuals/225.pdf I'm not sure what to do??? Any thoughts? Thanks

- 11 replies

-

- consew 226

- bobbin

-

(and 1 more)

Tagged with:

-

I regrettably popped out the entire bobbin ensemble. I put it back in as best as I could remember it and was able to sew away for a while. Now, the upper thread keeps getting caught in and under the bobbin. I must have put the three bobbin parts back in incorrectly. Everything else is unchanged and looks okay. What is the name for the piece I am holding in the picture? The one I wish I never took out of the machine.. Can you tell me the correct orientation of this piece, and thus the bobbin basket, while the needle is at its highest position? The needle reaches its highest position on my machine when the handcrank is at exactly 12:00. Where should the crescent on the piece in the picture be at this point? If you could provide a photograph, that would be extremely helpful!

-

Up for grabs is my trusty old Junker, perfect working order. Stitch length adjustment etc all works fine. It comes with.... Rare edge guide plate. 8 x Nr5 needles 10 x Nr8 needles 3 x bobbins Original parts tin with a few bits in it. An original old hire purchase a document. I've also got an original English manual which will be included if I can find where I put it! Open to sensible offers in Pounds sterling and happy to ship international from the UK....Buyer is responsible for any import duties/taxes. UK shipping £15 Europe £25 USA £60 .Canada £70 I will also be posting for sale a spare Shuttle/hook with 2 bobbins, a rare full width harness stitching plate with edge guide, a 5/6 needle strike plate and 14 used needles.

- 7 replies

-

- junker and ruh

- sewing machine

-

(and 4 more)

Tagged with:

-

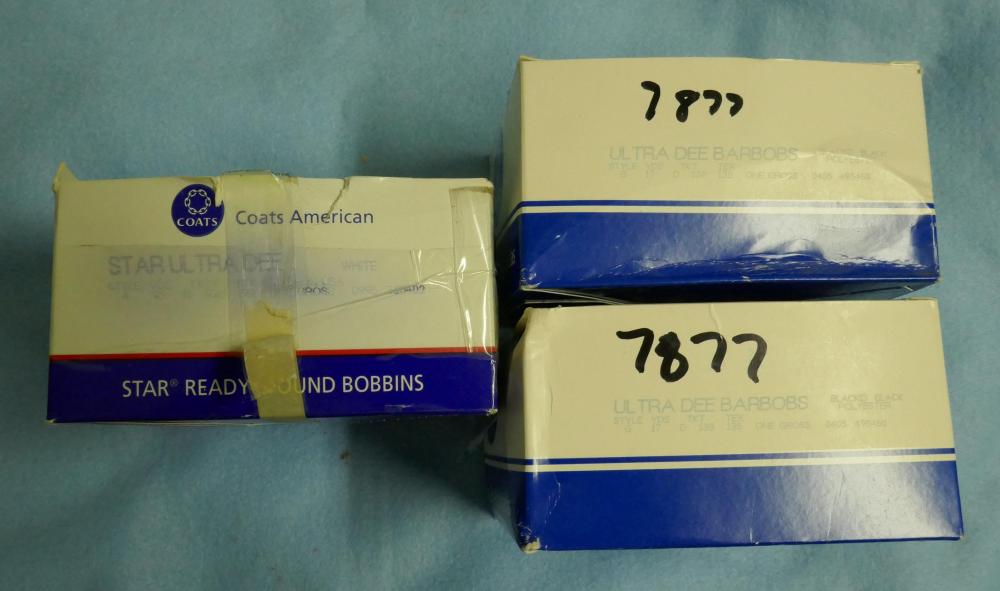

I have 3 boxes of prewound thread for sale. 2 boxes – Ultra Dee Barbobs, Style G, 17 Yards, D-138, Color = Black. 1 box - Star Ultra Dee, Style A, 25 Yards, D-92, Color = White I cant guarantee they are complete full. IE, all 144 bobbins are there in each box. I have attached photos of the boxes open so you can see. You can get all 3 boxes for 100 USD including USPS Priority mail shipping to your USA address. USPS Money Order is the required form of payment. If you cant or wont, then IM me and I will consider other forms. Thank you for looking

-

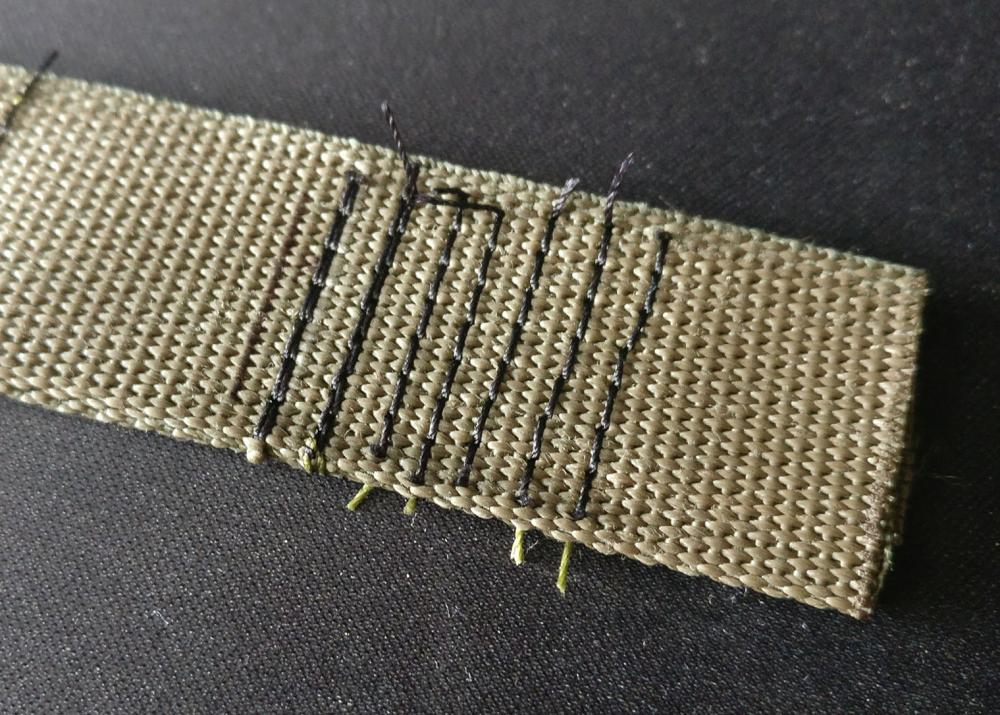

I'm trying to sew 2 layers of 1" nylon webbing and am getting the top thread showing on the bottom regardless of how tight I set the top tension; See images attached. The black thread is topside, green thread is bottom side. Both threads are size 69 bonded nylon. In the image of the bottom side I've tightened the top tension a little bit each time, until the final row where I maxed-out the tension. As you can see there is virtually no difference. I've tried two different needle types with the same results: Organ DP x 17 125/20 and Groz-beckert 110/18 RG. The organ needle is the largest one I currently have, and should be adequate for the size of thread I'm using. I'm wondering if the type of webbing I'm using requires a specific size or needle point? Things I've tried with no improvement on the bottom side stitches: Increased top tension all the way Reduced bottom tension to almost nothing Re-timed my machine Removed and cleaned the bobbin case/assembly I will also add, the tension unit is brand new, but I did take the time to calibrate it so tension engages and disengages properly with the knee lift. Images of the tension assembly attached. Is there something special about setting up this machine that I've overlooked? Any recommendations on things to try would be greatly appreciated.

- 12 replies

-

- bobbin

- industrial

-

(and 3 more)

Tagged with:

-

Can someone look at my attached pictures and give me any ideas of what I’m doing wrong? I’ve done everything I know to do. Wound a new bobbin, retreaded top thread and bobbin. I’m not sure what brand my machine is. The labels were removed. Any ideas of what you think it may be will be helpful. Thank you.

-

Any help please my friend got a 97-10 he can not get bobbin out he thinks there is a special tool to get out ---- can he make one?? --does anyone have a picture of this tool?? maybe buy one ??? Thanks BE

-

Hello, The machine is properly threaded and makes near perfect stitches through, both multiple layers of interfaced cotton fabric, and leather. Test swatches are about 9 inches long. After about four passes (straight stitching, then lifting presser foot and changing direction) the machine begins to malfunction. Stitches are no longer forming properly and the bobbin tension has gone haywire. After cutting the thread and removing the bobbin case, it is apparent that the thread has come unthreaded from the bobbin case. We've cleaned and oiled the machine including removing and cleaning the shuttle driver and race to remove old thread dust and gummed oil. This problem started before removing the race. Attached is the test swatch top and underside. Any thoughts on why the thread would come unthreaded from the bobbin? Thanks! Scott

-

I've been sewing a lot, but only on others machines (industrial walkingfoots as well). I picked up a Brother LS2-B837 the other day and changed from a thin cotton thread to a tkt 20 (tex 150) nylon thread. It had a 130 needle, which would be about right accordingly to the thread brand (120-140). Seams to do well on the slide test. (Tried 120 and 140 as well) At first I tried with original thread tension, but it broke the thread. I losened both top and bottom tension a little, the bottom so that the bobbin doesnt slide down holding it in the thread, but loose enough to slide a bit with a gentle "jojo move". I would say its on the looser end now. The top tension I did loosen a lot, because the thread did not move at all, to a point where it falls off from the tension wheels. By the moment it will curl the top thread, and do a lot of birdnesting. Ive tried all day, with my limited error searchings skills, and I'm not even close to make one normal stitch, feels like a needle in a haystack!

- 23 replies

-

- leather

- birdnesting

- (and 5 more)

-

I regrettably popped out the entire bobbin ensemble. I put it back in as best as I could remember it and was able to sew away for a while. Now, the upper thread keeps getting caught in and under the bobbin. I must have put the three bobbin parts back in incorrectly. Everything else is unchanged and looks okay. What is the name for the piece I am holding in the picture? The one I wish I never took out of the machine.. Can you tell me the correct orientation of this piece, and thus the bobbin basket, while the needle is at its highest position? The needle reaches its highest position on my machine when the handcrank is at exactly 12:00. Where should the crescent on the piece in the picture be at this point? If you could provide a photograph, that would be extremely helpful!

-

So I acquired a singer 16-188 recently and I figured out how to thread it and I am pretty sure that I've got the top thread done correctly, the bobbin I'm not so sure about. I think I have got it correct but when I go to sew, it just tries and tries and tries but the bobbin thread just sits there and never gets picked up by the needle. Also the (I'm new to machine sewing so forgive me for my more than likely incorrect terminology.) feeder, the little guy with teeth that pulls the material along, isn't doing its job correctly and it's almost like the material wants to feed backwards from back to front?? Also I'm sure I don't have the correct needle or thread so I'd take any advice ya got for me on getting this old machine running. oh and for the time being I am using this machine without a motor, and just turning it to hand. Thanks in advance

-

I'm new to sewing leather. I want to start by recovering some leather seats. I found a Consew 206RB (no version number) with a table and clutch motor for $500.00. Someone cut off the Made in Japan part of the nameplate as you can see in the picture. I don't know if the RB was made any other place. It came with 4 cording feet, R&L zipper feet , the regular walking foot and 12 bobbins. I assume this machine is 30+ years old, but looks like it just came out of the box. No paint wear, no rust, very tight tolerances, turns easily by hand, but dry as a bone. So the first thing I did was lube every oil hole and everything that moved. But I don't see any requirement to lube the bobbin case, or procedure to do so. So do I, and how if so.

- 5 replies

-

- consew 206rb

- bobbin

-

(and 1 more)

Tagged with:

-

Hello All, I have a PFAFF 335. It's new and I only purchased it a week ago. I'm pretty inexperienced with sewing machines. I believe I have it threaded correctly and it sews nicely. But 6 or 7 times out of 10 when I lift the presser foot and removed the material I find two threads coming from the bobbin. If I hand turn the wheel one thread will release and its usually about 3 or 4 inches long. So obviously its getting caught up somewhere. Can anyone tell me what I'm doing wrong? I usually have about 10" of both bobbin thread and top thread pulled towards the back of the machine when I start to sew. Thanks for your help Chuck

-

I bought a Cobra 4 a couple of months ago. It's brand new and needed a little adjustment when it arrived to get going. Things were going great until three weeks ago. When I returned from a convention in Texas, problems ensued forcing me to hand stitch the projects I have waiting. I contacted Steve, but we don't have a resolution yet. Here are my issues I can use help with. Presser Foot: It is coming up as the needle is traveling upwards at the end of stitches. Needle: Bending on shuttle and breaking. I've had to force the needle up higher to see the end in the window. I've been using channel locks and a lot of elbow grease to get it done. This cannot be the best way but is necessary. Bobbin: I can pick up the bobbin thread with my needle when initially change out the bobbin, but after that, nothing. I find myself just poking a lot of holes in my leather rather than stitching. I'd be grateful for any assistance. I have projects customers are waiting on, but I'm having to hand stitch everything from chinks to holsters, saddle skirts and harness. Thanks, Philip Crabtree www.CrabtreeSaddleWorks.com

-

Would really appreciate some help in resolving a problem that I've been having with my Cobra 4 stitcher. I know I probably am not using the right words to describe a problem that I'm having but my bobbin hook doesn't line up with my needle as the needle starts to come back up and I'm having a problem with skipped stitches. My hook isn't lined up and I don't know how to move it into the right position. The bar holding the needle is in the right place when it is in full up position, but the hook on the bobbin assembly isn't and I can't move it either... so that is my question how do I line the bobbin hook up so that the timing of the bobbin is correct. I am just trying to get it into proper position to correct the stitching problem Thanks Debbie

-

I apologize, i might not be using the correct terminology here. Tonight my Cowboy 3200 developed a problem over the course of an hour. I didn't make any adjustments or changes, so I'm not sure what happened. It started out with the bobbin just hanging inexplicably and not letting any thread feed off of it, so I cleaned out any dust and debris and lightly oiled. Now, when I sew, the thread just keeps wrapping around the bobbin.shuttle and I have to cut it off. I've been trying to figure it out for the last 2 hours. Any suggestions would be appreciated. Gary

- 6 replies

-

- cowboy 3200

- problem

-

(and 2 more)

Tagged with:

-

I am having another issue with loops showing on the top of the leather. I am using a Cowboy 3200. I think the issue may be the bobbin tightness but not sure. Sometimes the thread coming up from the bobbin is so tight it won't pull out. At first we had the bobbin in upside down but we sewed with it like that for quite awhile (2 weeks) and then i had to change the bobbin out and put it in still upside down and now its doing top loops. I have fiddled with EVERYTHING and checked the manual over and over again. I just can't figure this one out. Can someone please shed some light on what this might be? Thanks!

.thumb.jpg.bd465a1ac087aff70a0be9b5916ae014.jpg)

.thumb.jpg.e42a5c3d7b4f60055a4c0f284425d761.jpg)

.thumb.jpg.81ec802b4691f4d72ceb2008d3574afa.jpg)

.thumb.jpg.b4a97f8ed100a8b60348b81659c0c5dc.jpg)

.thumb.jpg.7ae3796ef0aaadd3a3265f5c070a101d.jpg)

.thumb.jpg.7290c9b7679d11cc9f0b84102412a947.jpg)

.thumb.jpg.810f5bf1ce9c731fa0a64bad4b0fdc3b.jpg)

.thumb.jpg.759be88b49f421c6626bfef6cbc120db.jpg)

.thumb.jpg.d82928e4d2983aff29723e0f2f142985.jpg)

.thumb.jpg.eb098932b0d82c34692eb0c5d398bb06.jpg)

.thumb.jpg.1232903bbab395a0bb37b28a48d882ab.jpg)

.thumb.jpg.980baff6a6bc4aec1e4a0618391b647f.jpg)

.thumb.jpg.7a0834b06763e4ec7004b22633a78bf6.jpg)

.thumb.jpg.a90ecc4b1afc34a4a04da2c79ffd00a0.jpg)

.thumb.jpg.96c4e8197a560f7e8c10ae03f775b25d.jpg)

.thumb.jpg.d0b2dcd8abbaae9fb8f98341cde0c3ca.jpg)

.thumb.jpg.b3a34ce9ede9df15b38d7b2b472da25f.jpg)

.thumb.jpg.d8872f6ccc650b7dde88eb108257f07e.jpg)

.thumb.jpg.eae337ff431eb157681f1b8f0105543d.jpg)

.thumb.jpg.e9d3c15f7c191d8faf22ea9048933902.jpg)

.thumb.jpg.be863582fe51905e01ac833bb037dcef.jpg)

.thumb.jpg.82ccdcb38506e3fe81c28008d391855f.jpg)

.thumb.jpg.63273766bc4225b27a042562d734a94f.jpg)

.thumb.jpg.5a5267f573f851550c187dccbd774e1d.jpg)

.thumb.jpg.6b4bcc6259a353d650d1d90b3f7f8b1e.jpg)

.thumb.jpg.8b2c6bd28154342b1e7fca4483eb9d1e.jpg)

.thumb.jpg.6f851d5efbe3be46d714d3eba2ee244d.jpg)

.thumb.jpg.255d3611e1434000dfb340502cbd4db1.jpg)