Search the Community

Showing results for tags 'brand'.

-

I’m getting ready to start making belts. I have looked at numerous leathers still have not found exactly what I’m looking for. Money is not as much of a concern as quality. I want a single ply belt in the 9 ounce range that is super smooth on the back, scratch resistant, and won’t crack when bent. What leather do you use? I tried splenda BOM leather; it was everything I wanted except for the fact that it cracked when bent. I feel like there has to be something that meets these qualities.

-

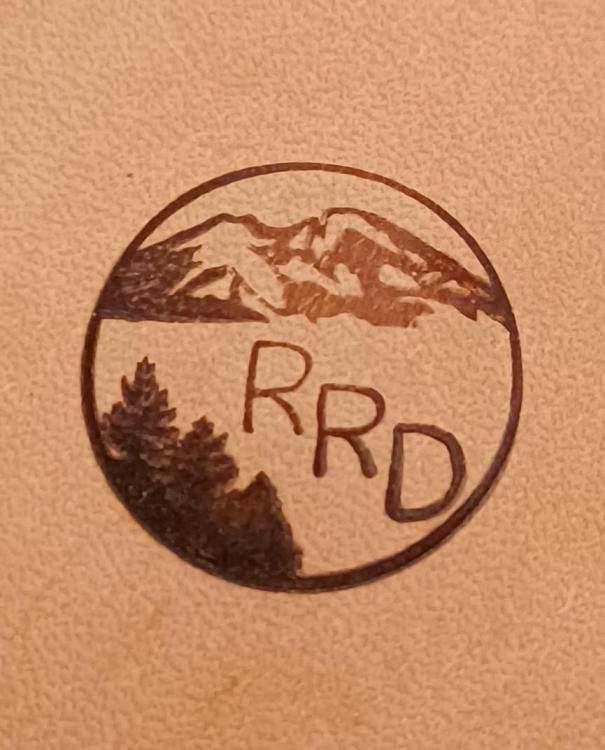

Y'all. I must have raised my kids right. Please forgive me while I brag on 'em. I'm just a hobbyist. I'm not planning on ever getting paid for my projects. I admire those of you who do. Every since I subscribed to this site, I have admired your brands, tags, hot stamps, or whatever they're called. That's a mark of professionalism I will never attain. I have always simply carved my initials into a tiny spot on my work, and been content with that. See my first picture. Well, my kids conspired this year to design and procure a custom hot stamp for me. See my second picture. The Coloradans on this group will recognize Longs Peak and Mt. Meeker. The Etsy artist told them that his minimum die size is 30 cm. They talked him into making a 20 cm die, smaller than a US 25-cent piece. It's perfect. Merry Christmas, one and all. Here's hoping for a better 2022 -- for all of us.

-

Hello all, Not sure if this is the right section to be posting in, but it seemed the most logical. I have a large brass stamp, 10cm x 10cm. It came with an electric branding iron advertised to handle that size of brass stamp, but it does not get hot enough to properly brand the leather. It will smoke the leather, but it wont singe it like with the smaller brands. I am planning on using it on both wood and leather, but the heater I have simply wont work, by the time it gets to its maximum temperature, it starts to melt the black handle. So, either I need a cheap recommendation (under $200) for a better electric iron, or I need some advice on how to heat it up alternatively. I have heard that you can heat it up over an open flame, so I was planning on getting a butane torch from walmart and trying that out, but I am worried that I will get the brand too hot and it will burn the wood/leather too much as I have experienced in the past branding when an iron gets too hot. Is there a good method for doing this? How long to hold the flame over the brand? If the brand gets red hot, is that TOO hot? Thanks! Zayne

-

Hello all, I have scoured the internet for hours and can't find the smallest inkling of information relevant to the maker/reputation, relating to the the quality of this leather knife. Is anyone familiar with this brand and the quality of the tools produced by this company? Thank you

- 4 replies

-

- round/head knife

- maker

-

(and 1 more)

Tagged with:

-

I found some old tools from my Great grand father. Unfortunately he died, so did my grand father and father. I heard he was a shoe maker. Can anyone identify the brand of the awl, I can't make anything from it ? Maybe it helps if I mention I live in belgium. Thx in advance Bert

-

Help please! I'm trying to sell this saddle and need help identifying it. No maker's mark anywhere on it. I think it was bought for barrel racing purposes, given the seat, but am wondering if I'm wrong and it should be listed as a pleasure/trail saddle. Does anyone know its maker and/or can identify its proper classification?

-

Hi guys, At the moment I'm using an inexpensive hand branding iron to stamp leather, but it's difficult to guarantee consistent positioning. I know you can buy branding irons designed to fit into a drill chuck, but they're expensive ($300-$600). Does anyone have experience sticking a hand branding iron into a cheap drill stand (http://www.ebay.com/itm/0-6cm-Working-length-Drill-Press-Stand-Work-Station-for-Electric-Handheld-Drill-/252212399269?hash=item3ab907cca5:g:GV0AAOSwfZ1WbnXg) ? Looks like it would work and for $30 I might just buy the stand and give it a shot, but figured I'd ask here incase anyone has tried a similar DIY solution. Thanks!

-

I am starting a leather belt company in London I need help making a quality leather belt with a similar design to the attached image (the buckle is a Sam-Browne buckle). I am located in London and would like to work with a manufacturer in the UK or Europe but not much farther. I would like this to start as soon a spossible and would appreciate if we could meet in person, hence closeness being a beneficial factor. And tips, links and/or advice would be much appreciated!!! Belt Info.pdf

-

- leatherwork

- belt

-

(and 8 more)

Tagged with:

-

Hello all, I'm about to finalize my logo and will be purchasing a stamp or brand. I've been doing some research on my own, but thought it would be a good idea to ask for some recommendations from you fine folks. Still trying to decide between a stamp or brand. The logo will have some fine detail found in small embellishments that I want to make sure will be evident in the final stamp. I will be stamping or branding on both veg tanned and chrome tanned leathers. Just looking to collect any information you'd be willing to lend and recommendations and experiences with stamp/brand suppliers. Thanks a lot! Look forward to hearing what you guys have to say.

-

Hi everyone! I'm hoping someone can help me with my dilemma. I have a logo that I want to emboss on my leather bags. I've done a bunch of research and it seems like an arbor press and brass plate are the way to go in veg tanned leather, BUT i use chromium dyed leather! I'm wondering if someone can give me advice here. Will an arbor press work on this soft leather? If so, do I need a 1 ton or 2 ton? And any recommendations on what type of stamp to get- do i need a brass one? or I've seen some people who are making them out of a durable plastic now for cheap... See the attached picture for an example of what I'm looking for! Thanks a bunch everyone! I'm so glad this website exsits, I can't tell ya'll how often I come here for guidance! Erin

-

-

- maker stamp

- phillips engraving

-

(and 3 more)

Tagged with:

-

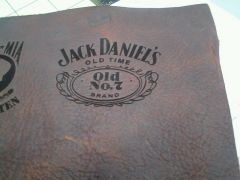

ive just completed my second wallet , it turned out pretty good with a very unexpected dying finish (Accidental) but the finish looks great , i first dyed all the inside pouches with med brown antique finish which turned out the expected antique brown. I USED A CLOTH TO APPLY THE DYE. Then i dyed the outside cover of the wallet with the same antique brown ..... BUT...... i used a brand new fresh NATURAL SPONGE which i took out of a packet. It was moist when i took it out, i'm guessing the dampen them before packaging to keep them fresh and soft. But the finish i got was completely different to the rest of the wallet. The only way i can describe it is an almost alligator grey/brown which looks really good ! On the outside cover i also incorporated a Brand which was on the leather i bought hince the name i put on the wallet "The Cowboy " By the time i was finished waxing and finishing the edges this evening the daylight was gone and i have really yellow light in the house , not ideal for taking pictures . but i did any way and here they are , Tomorrow when i finish work ill take good pictures outside when its still bright and upload them . By the way i was also wondering has any one else experienced the whole sponge changing the colour of the dye ? And if not its definatly worth a try ! Also i used olive oil instead of neatsfoot oil on the whole wallet so that could not have affected the colour . Let me know what you all think ! Ps the photos really do not do the colour any justice

-

Hello again! Back for more awesome information! So I'm about to pull the trigger on buying a good chunk of my first bunch of tools, and I still haven't been able to definitively find the answer to a pretty basic question looking online. Just some stuff that vaguely touches on the subject. I want to work with fairly heavy leather for belts etc. I want to do 12 oz and 14 oz. What size edger do I need? We should talk actual measurements in inches because the size number changes by brand. What I want to be able to accomplish is a completely rounded (so basically a half circle) edge on the pieces. Some stuff I'll probably leave squared off, but some pieces I will want round. I believe for this task I want the "Common" edger, not Western or some other type? It's not really clear with some what the difference is in the end product from looking online. Some websites have listed things on the bigger sizes size 4 or 5 (which is 13/64 or 7/32 etc) "Good for heavy leather 12oz+" etc. So I suppose the simple thing to ask is: do I want an edger with measurements that are the same as the actual thickness of my leather? It popped into my head one might want half the thickness of the actual leather since you do the top and bottom, but that doesn't seem right either. So should I try to match edger size with leather thickness? If so, how much fluff room is there to work with? 12 oz is 3/16, which is commonly available. 14 oz is 7/32, also available. So do I need both sizes optimally, or can I just get one since they're FAIRLY close and make it work? Obviously getting the "perfect" one later. Also while on the subject, I've read a lot discussing brands. A lot of people swear by some of the really boutique brands... And those may lie in my future... But they're just a tad bit more than I want to spend right now. I need to spring for numerous super basic tools, and I don't want to go too overboard with $100 single tools and whatnot when it sounds like 30 or 50 dollar ones are pretty solid. After looking at pricing I'm thinking CS Osborne or Weaver Master Tools. Whadda you guys think? I'm strongly considering Weaver punches over Osborne because it sounds like theirs are a bit better for not much price difference. This seems to be fairly consistent thought on the board, although it might be mainly that the Weaver ones come better sharpened from the factory. If I go with placing a Weaver order (the minimum is all that's holding me back since I have a Tax ID) I can pick and choose since they carry both. So are the Weaver edgers better, or Osborne? Thank you in advance, you guys are great!

-

LASERED LATIGO BY BLACK RIVER LASER

stitchwizzard posted a gallery image in Gallery- Our Leatherwork

From the album: Lasered Leather

Laser branded Latigo.