Search the Community

Showing results for tags 'juki'.

-

I have recently bought a juki lu1510, my purpose is to sew thicker multi layer leather garments with it (such as a layered leather corset, mediaeval leather gambeson, maybe some experimental shoe making). It is the 6th sewing machine in my collection but first industrial machine and I'm having trouble understanding the thread specs (what each number means) and sourcing appropriate thread that matches my needles. I found the needles I needed from schmetz and got some nm130, 140 and 160. Could anyone help me find the thread I'm looking for? If anyone also has a supplier they recommend, I'm based in the UK. It may well be to do with the fact I only half know what I'm looking for, but I don't seem to find many stockists of heavier thread. Manufacturer specifications: Needles- 135×17 (at the time of delivery) (Nm160) Nm125~Nm180 Thread- #30~#5, B46~B138, Nm=60/3~20/3

- 8 replies

-

- juki

- sewing machines

-

(and 2 more)

Tagged with:

-

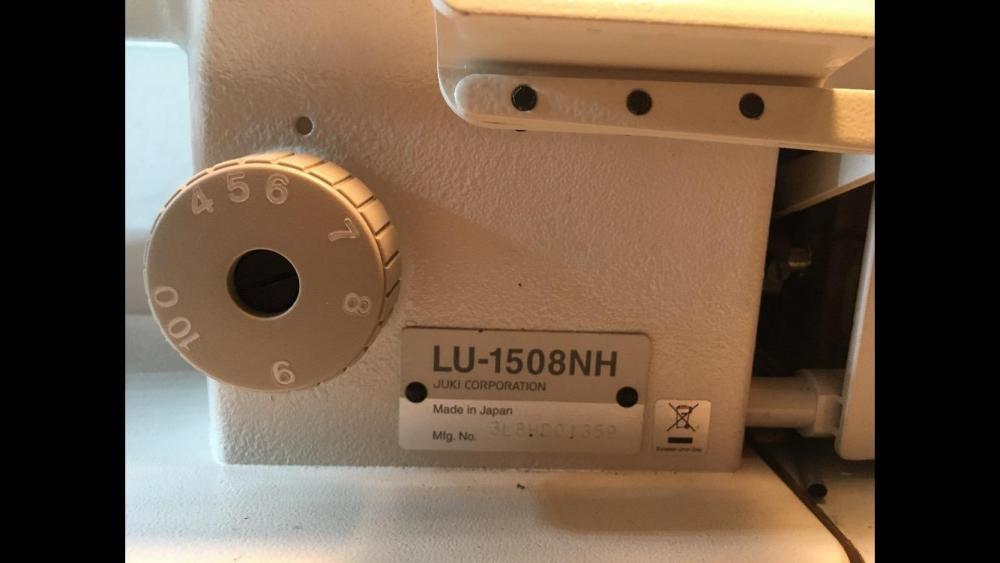

Machine has inconsistent stitch length, is this play normal, checked and adjusted with the help of @Uwevideo’s with no change. Any insight would be appreciated. Thanks Mark IMG_5190.mov IMG_5191.mov

-

Hi there, This is my first post. I have read various threads over the last 3 month in preparation for making up my mind on what machine to buy and I finally settled on a used Juki 1541S. She is something like four years old, was used less than 50 hours for making cushions and seems generally to be in a good shape as far as I can say and here my problems start as this is my very first industrial machine and I do not really know anything about it. The first problem I have now is that after oiling the machine (I do not think that I put too much oil on the machine) I find oil on the backside of my sewing and is look like the bobbin thread is a bit oily too. Any idea on how to troubleshoot this? Thanks a lot Martin

-

Hello! I acquired a Juki 9010a-SS needle feed a while ago and am wondering if it’s easy to switch out the throat plate and feed dogs to the larger SH heavy duty pieces. I can’t find much info on this but am wondering if anyone else has successfully done this without replacing other parts on the machine.

-

I had a Juki Lu-562 that was in pretty good mechanical shape, but needed some paint touch-up. I experimented with several hammered spray paints, including special order products. In the end, the one that was a dead ringer for my lu-562 was an off the shelf Rust-Oleum color that I found at Home Depot. The color is Rust-Oleum "Rosemary" hammered finish. It is a dead ringer for the dirty gray paint that Juki used. There is a subtle hint of green as well. Hopefully this saves someone the guesswork in the future!

-

$1,100 obo In great working order! Located in Monterey Park, California 91754 May be able to deliver locally for a fee

-

- juki

- juki dnu1541s walking foot

-

(and 1 more)

Tagged with:

-

Howdy! I recently purchased an experienced Juki LU 563. As I have been acquainting myself with the machine, it has been working very well. Yesterday, as I was sewing some canvas and leather, the needle broke. This seemed to throw off the timing, as the bobbin hook isn't picking up the needle thread. There aren't any repair guys within about an hour and a half from here, so I'd like to learn how to adjust this myself. Can anyone offer some pointers? Thank you very much! -Peter

- 18 replies

-

- juki

- juki 563. timing

-

(and 1 more)

Tagged with:

-

Hello! I recently bought an industrial Juki that came with this servo motor. I was under the impression that the dial in the front would adjust the speed, however nothing changes when I turn it. Does anyone have this motor? Is there a way to change the speed? Photos of the motor are attached. Thank you!

- 5 replies

-

- sewing machine

- servo motor

-

(and 1 more)

Tagged with:

-

I am looking to get a good walking foot machine that is a true triple compound feed. So far the 1541 models are the ones that fit the bill and the Thor looks good at its price point but I am wanting to make sure I have long term quality. I would like to get a cylinder arm but financially it's not in the cards right now. I would prefer to stay in the 1500-1700 range if I have to in order to get a quality triple compound feed machine. I have been reading different posts and kind of using Wiz's tips as guidelines but with so many its just difficult when you can get the whole setup for a few hundred dollars less and it "seems" like the quality is the same but I was hoping for more insight from those who have had more experience with "knock-off" brands of the proven manufacturers.

- 4 replies

-

- reliability

- quality

-

(and 7 more)

Tagged with:

-

I just bought a new bobbin case and hook for juju 1508 cause mine tension spring was a messed up I was wondering about converting to a side load style like the 1541 that I read about. Does anyone no the machine that the parts come from to switch it Over and part numbers and also how do I sent bobbin tension correctly I have played around a lot and seen all the Videos of how it should be just loose enough to fall when not supported but mine is all the way loose and still to tight it seems. Is that tension I mentioned only for light fabrics. Cause like I said both mi e r tight enough to support the weight of bobbin with the screw backed all the way out. And how do I know when it’s right. Also I have been having to tighten my top tension almost all the way to even it out. Also is there any I stuctions to set up the take up spring cause I can’t find anything On that online or in the manual. Thanks

-

Hello, Leatherworkers! First off I would like to thank you for your sharing your extensive expertise. I read @Wizcrafts' sewing machine thread and have been lurking around this message board for weeks. I've definitely learned more about machine mechanics and specs here than anywhere. I really appreciate the breakdown explaining the various machine types, feeds, walking foot vs add-on foot, etc. I'm a professional seamstress with a market opportunity for alterations in Irish Dance dresses. Think Riverdance. Modern show/competition costumes are constructed with a particular double pleat skirt, with extensive stiffening materials (sometimes plastic or cardboard), on thick fabrics (duck, velvet, heavy satin, sequin, embroidered). This is to create the distinctive flat, sticking-out skirt. The skirt-to-bodice seam easily can be in excess of 1/2" thick. Example of a dress here: https://irishdancedresstoimpress.com/product/dress-11916/ My kids are Irish dancers and since I have done some alterations on their costumes, as well as some friends' costumes (mostly rescues from the damage done by local tailors), I now have many requests. But I can't get that blasted double-pleated skirt-to-bodice seam through my domestic sewing machine. Hence, researching industrial machines. My goodness. I had no idea there were so many possibilities. I asked my group of specialty Irish dance seamstresses what they recommend, but no one comes even close to this group's ability to break down the why's and wherefore's of my options. I'm pretty sure I've narrowed my search to a true walking foot machine with more than 1/2" clearance under the presser foot -- though some of the seamstresses say they are doing fine with high clearance on a regular double-toe foot. Juki was originally recommended to me by a trusted seamstress, but Wiz raves about his Consew machines so much, my horizons have expanded. :-D What I'm hoping for here is maybe to connect with someone with a used machine for sale, a dealer, or any and all advice & guidance the group might be able to offer. I think I will need to buy something used to get me through the upcoming fall seasons and then save up for an "ideal" machine. I know most of my particular craft doesn't apply to leatherworking, but the best mechanical information is here. Perhaps somebody is able to "interpret" my needs, or can point me to a different group that has a closer specialty (but can also explain the mechanical pros and cons). I'm located in Jacksonville, Florida. Thank you very much for reading my message and considering my questions.

- 9 replies

-

- machine

- industrial machine

-

(and 3 more)

Tagged with:

-

Excellent condition. Very little use. Accessories included. Pick up in Murrieta, CA Phone# 9513170040.

-

My Juki LU 562 is not moving fabric through as it sews. I think it’s because the stitch length is set very short (I had a safety clutch trip, and whist fixing that, somehow this has happened). When I press the button to adjust the stitch length, the hand wheel is jammed and will not turn at all to change the stitch length, although it moves freely when that button is not pressed. Where should I start in trying to fix this?

- 3 replies

-

- jammed

- stitch length

-

(and 1 more)

Tagged with:

-

Inner hook guide Trapped thread I am a fairly new owner of my juki 1510. I was chugging away sewing the other day when I heard a horrible sound and got an error message on my motor. I immediately switched off the machine and took out my work (thankfully just some prototype bits), I gently turned the hand wheel and noticed it would not do a full rotation. After opening the bobbin flap I saw there was a lot of thread wound up in it. I cleared most of it but there is still some trapped in the mechanism (pictured). I have followed a YouTube video trying to remove the bobin case so that I could clean it but am unable to remove the casing itself. I think what is preventing the wheel from doing a full rotation is the position of the inner hook guide (akso pictured)? I am unsure if it is sitting right or what I should do with it. If anyone familiar with the machine could give me some pointers it would be much appreciated!

-

Hey everyone, this is my first post on this wonderful forum but after much searching I haven't been able to find any posts that address this specific issue. I feel like I've tried so many things to fix the problem but its a bit of a mystery to me at this point so if anyone has advice I'd love to hear! For context I work mostly with soft upholstery type leather, with a small business doing custom jobs - bags, accessories, products with decorative appliqué and such. Working with a Juki model LU1510N-7 and Cansew Tex 70 bonded nylon thread. The needles are generally 135 x 15 R size 19 and are changed regularly. I have been having the problem of intermittent 'knots' appearing on the underside of the leather - these are made of the needle thread over-twisted around its self to form a tight ball of thread which when pulled and unravelled leaves a loop of several stitch lengths worth of thread on the underside of the leather. There is no fraying or catching of the thread as it goes along the thread path from cone to needle, and the bobbin thread seems to be running smoothly as well. I've tried different cone placements and thread paths as well to try to get the thread to feed as smoothly as possible off the cone. We have tried adjusting the tension depending on the material being sewn and even when the tension appears balanced between the needle and bobbin threads it doesn't eliminate the knotting altogether. Some days it seems like the machine will behave and sew perfectly and other times there will be 6-8 knots within a 10 inch line of stitching. Sometimes I will rethread the machine and wind another bobbin and it might go away for a while and other times that doesn't help at all. Also have tried with no real improvement: Needles from size 18-22, silicone thread lubricant, changing bobbin tension, different tension when winding bobbins, different heights for the thread cone. I have a suspicion that after switching from A&E brand thread to Cansew this was when the over twisting and knotting really became an issue - the quality between orders of thread varies and some colours of the cansew thread seem to be very stiff and tangle easily where others almost feel like a lighter weight even though they are both tex 70? Some colours in particular are bad for this, especially the darker ones. The knotting happens more frequently on some machines than others (they are the same model of Juki) which makes me think it isn't only a thread quality issue but something that is happening with the machine it's self. Here are a few pictures of the knotted thread before and after the knot is untwisted. Has anyone else run into this problem before? Hoping someone could shed a little light on the situation, at this point I don't know what else I can be doing to try to improve the stitching.

- 1 reply

-

- thread

- sewing macine

-

(and 5 more)

Tagged with:

-

A couple years ago I purchased a new Juki DNU-1541s. I haven't used it much, but now I'm in a position to ramp up my usage and my learning curve. I have many questions, but one right now in particular. What is the purpose of the knurled knob on top of the machine above the walking foot. As you can see from the pictures, the knob appears to adjust the spring tension going to the walking foot. The spiral around the post coming down from the knob is the spring that I'm talking about. I'm not sure if this spring adjusts the downward pressure of the walking foot or the tension of the foot lift lever. I have turned the knob clockwise and counterclockwise, counting turns as I go so that I can bring it back to the original setting. I can't really tell that anything changes. Does anyone know, or want to venture an informed guess? Thanks in advance.

-

Hey all, I've been in the search for a Juki 5410 and it seems not too much information is available out there online. Even more so true for the the older models! I quickly learned that this site has the most comprehensive information regarding different sewing machines and all you could know about them! After reaching out to many industrial dealers, I've also seen results discussed in the thread created earlier but have also had some good experiences with some folks. First and foremost, this machine would be for sewing lightweight 7d .5oz/yd nylons, polyesters, mesh, up to at most several layers of 8-10oz nylons/laminates. I would use from tex35-40 up to t70 bonded nylons. I know, not leather, but I come here because of the vast sewing machine knowledge. If I had all the means, I would search out a new Juki 5410n-7 (or 9010). I understand the newer (n) 5410 models come in different versions depedning on the weight of the material being used from light duty to heavy and jeans versions. I am specifically looking for the light duty version as I'm going to be using needles 9-18 with materials from 7d nylons and mesh to light weight backpack materials. The older versions seem to also be available so i have been looking at the 5410-6 as I prefer to have the auto features. My hesitation is that I can't find any information or instruction manuals regarding the older models and if they were offered in different weighted versions like the newer 5410 machines. I have an opportunity to purchase a 5410-6 within my budget but I'd like to confirm I'm getting the machine that suits what I'm looking for. Do the older 5410-6 Juki's have different variations like the newer ones? If this is so, how can I distinguish light from heavy on the older models without physically examining the parts? Something in the serial numbers? I also understand the different versions can be changed by swapping out just a few parts. Again, I'm not sure if this is also true regarding the older versions? Also can anyone give input as to the reliability of electronics in some of the older Juki industrial machines? Any insight would be greatly appreciated, Thanks

-

In a great condition, new servo motor, wonderful for leather work. Local pick up only ( Los Angeles) $800 or best offer.

- 1 reply

-

- walking foot

- juki

-

(and 2 more)

Tagged with:

-

Hi there, I found a forum "thread" from 2012 and I have a question similar and wonder if anyone can help! The info about decreasing the hook oiler was great and helped. But I'm wondering if I have a different oil issue. I have a Juki 1541S (actually a Yamata knock off) it is new. I am using it to bind notebooks, all paper. When sewing, oil starts to splatter from above the needle and of course splatters on the covers of the notebooks and oil surrounds the holes of each stitch. I've seen the oil drip down the needle. My first question is: Is there a way to regulate the oil from the wick up on top of the machine? The extra oil release is not consistent but happens enough to lose many notebooks. I had decreased the hook oiler when I first had this issue and it helped. I did oil the machine very very slightly yesterday so maybe it was already over oiled..... Really appreciate any ideas. The machine is new to me and still working out the kinks. I'm attaching a photo where you will see lines of sewing with oil surrounding each hole. Sometimes it is less than starts more oil inconsistently. Thanks! and all the best, Kathryn

- 5 replies

-

- juki

- juki 1541s

-

(and 3 more)

Tagged with:

-

I have a Consew 225 I’m willing to trade/part trade for the right deal. It comes with a servo motor, larger head unit pulley/smaller servo pulley for ultra slow speed. I just want something newer. I’m located in SW Washington.

- 1 reply

-

- horse tack

- walking foot machine

-

(and 5 more)

Tagged with:

-

Hi everyone! I am planning to buy a sewing machine for a small business that I will start preferably next year. The sewing machines that have been offered to me are the following: 1. Juki DU 141NH 2. Juki DU 1181N 3. Mitsubishi LY2-300 BOB The machine that I need must be able to handle medium to heavy materials (I’ll be using a combination of canvas fabric and leather), as I’ll be making bags (backpack, small pouches and totebags). Also, the machine must be user-friendly and if changes need to be done, the machine parts must be easy to source. Each of the machine is being offered to me at $650.00. So I really need guys your expertise and recommendations as I am very new to this thing so my money and first sewing machine will be worth it! Looking forward for your suggestions. Have a good day everyone!

-

Just wondered if anyone had the meanings of the prefixes on the model numbers as to what they mean, or is the decription of what they are meant to sew etc just in the numerals as a type

-

Selling a turn-key leather goods business (www.gifthighland.com) with over $2.2M in sales since 2012. Second kid, two companies and classic cars take precedence at this time. Wanted to store equipment with the hopes of starting up again in the future, but doesn't make sense at the moment with my growing family. Located in design district of Dallas, TX. Asking $95,000 includes everything below: Leather Equipment Fortuna 12' Band Knife Splitter w/ new blade Atom 20 ton Clicker Consew 206RB Sewing Machine Techsew 2700 Sewing Machine Brother Walking Foot Sewing Machine Cowboy CB4500 Cylinder Arm (all black model ) Cobra NP4 Skiver Cobra NP10 Double Feed Skiver Rossley Pneumatic Edge Folder Kwickprint Debossing Model 86 Kwickprint Debossing Model 64 (pneumatic setup, foot pedal activated, mounted on cast iron stand) Gluefast 20" Colonel Glue Up Machine RC50 Edge Painter Hand Press Rivet/Button Setter (x2) Heritage Foot Press Weaver Power Edge Sander/Slicker Misc Steel Clicker Dies (105 dies - wallets, key chains, mouse pads, coasters, portfolios, etc) Font Sets (x4) Company Logo Dies (200+...Nike, Adidas, JP Morgan, Gulfstream, etc) Speedtron 2403cx photography setup (all lights, controller unit and all cables in perfect working order) misc tools, needles, threads, heat stamping foils, cutting boards, snaps, buttons, etc Misc Shop Equipment Uline Plastic Bag Sealers (x2 - 12" and 8") 10'h x 8'w x 4'd Metal Warehouse Storage Racks (x8 Units) Small Metal Warehouse Racks (x3 units) Rolling Metal Storage Rack for shipping boxes Rolling Kitchen Rack w/ 12 trays Rolling Stainless Cart Air Compressor Quiet 5500LB Pallet Jack Packing Paper Roll Cutter 4'x8' Wooden Work Tables (x3) Misc plastic uline storage bins for tools, snaps, conchos, etc Customer List - I will provide historical sales data and all contact phone numbers, emails, company names, etc. (sample of customer list - MGM Properties, Gulfstream, New York Jets, JP Morgan, Montage Properties) Website & Product Photography - www.gifthighland.com , all hi-res product images (hundreds), latest product catalog in Ai format Leather and Misc Inventory- Approximately $5k worth of leather sides (Sepici, Horween, Hide House) and $20k of excess inventory from old orders including check book presenters, key chains, portfolios, tote bags, golf club head covers, briefcases, etc. I am including this inventory at no cost since some items have corporate branding. Consider it as free marketing materials. Manufacturing Partners- I will also introduce you to my manufacturing groups in Hong Kong and Los Angeles, perfect for large orders, custom products and anything you cannot make in-house.

-

Hi, I am brand new to sewing machines, I purchased a new double needle post bed sewing machine recently (ZJ24028-2) and I’m having an issue with the handwheel being hard to turn at 1st and now it does not turned at all, I oiled the machine and still nothing the bobbin case is empty there’s no thread or anything in it, I’ve looked online to try figure it out but I’ve found nothing to help me figure out why it won’t turn... id really appreciate the help thank you.

-

I own Juki 1508s . GOLDSTAR GSM550 will not let me go lower than 1600 RPM. I have speed reducer installed. This model uses a needle positioner that I like. Question- need a new motor that allows RPM 500- 3500 but also has needle positioner that fits Juki AMCO shaft. ( see picture of needle positioner) Or how do I tell the servo to go slower from computer module...Any opinions?