Search the Community

Showing results for tags 'sewingmachine'.

-

I recently purchased a Pfaff 138-6/21-BS and I'm looking for information I can get on the specific machine. I've been trying to figure out what it will be capable of and how I can help make it capable of chaps and maybe some lightweight tack. I've heard multiple different answers as to what thread and needles it's able to use, and I'm just wondering if I can get an answer for what it's maximum is. I also had some questions on the feet and the drop down feeds on it. Here are my questions: 1. What are my machines maxes for thread and needles? 2. Will it be able to do sets of chaps like I'm wanting? 3. What kind of feet are available to me that would be suitable for chaps? 4. Will the drop down feeds tear of the grain side of chrome tan leather or vegtan? 5. If it does, is there anyway I can potentially avoid the problem? Thank you so much in advance! I'm super excited to have this machine as well, as it's my very first sewing machine. I'm just starting out as an actual leather business and I'm hoping this machine will help me get started!

-

We have watched the videos online, but haven’t found any forums or videos on this…. When the needle hole plate is not lined with the timing of the needle. Needle does not go into hole hits top of plate instead. What should we do for timing or adjustments? Our timing with bobbin is correct.

-

Hallo everyone. I want a buy that Seiko sewing machine. Does anyone know what a type or model is? Unfortunately, there is no number or symbol on it. I don't know where to look for the manual and information on it. I'd appreciate your help. Greetings. Mike

- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

Hello everyone I graduated from a leather course where I've used the Durkopp Adler 669 cylinder arm machine. I am looking for a machine that can be comparable to that, but preferably cheaper. I'm making small leather handbags - it needs to have a cylinder arm. I would like to make belts and wallets as well. I would say I need something that sews through medium thickness, is simple and can sew slowly and precisely when needed. I am looking at the Consew Model 277R-3 and PFAFF 335 and Techsew 2600 Pro models at the moment, but I am also open to find a model that is used or just an old type, but not too sure which brands are the most reliable. Thanks for your help in advance Blanka from Montréal

- 22 replies

-

- handbag

- cylinderarm

-

(and 2 more)

Tagged with:

-

Hello, We are looking at new sewing machines that will be able to sew with a v138 thread. Ideally we would like a new machine but are trying not to spend thousands of dollars, a hefty ask I know. We did find the Sailrite Fabricator but again that's up there in price. Does anyone know of a machine that will handle this thick of thread that is under the $1000 mark? We did find a Rex machine on Amazon but that has mixed reviews about the v138 thread. Any advise or guidance is greatly appreciated. Thanks, Stephen

-

I have a Sailrite Ultra Feed LS1 for sale at £1200 in the UK.This machine is as new, it is the premium version with the heavy flywheel, binding attachment, flight case and all the other gubbins advertised.In addition, there are over 60 needles ranging from medium to heavy and also leather, two feet, magnetic and swing arm guide, thread stand, light, light flywheel for faster sewing, manual and toolset.It comes with 12000 meters of thread in various colours and a bunch of bobbins. This is a beast and punches through almost anything you can fit under the foot. Sailrite has a whole range of videos on this machine and each machine flys out of the shop. It is fitted to work in the UK and can be tried here in the workshop. I bought it for canvas work and dog harnesses which I'm no longer making. It can also be adapted to work by hand if power is an issue making this an ideal mobile workhorse. It is heavy so can be collected in person or you can arrange for a courier. IMG_5390.MOV IMG_5382.MOV

- 3 replies

-

- sailrite

- sewingmachine

-

(and 2 more)

Tagged with:

-

Hello you all ! I am owner of a Pfaff 491 industrial sewing machine with the folllowing problem: when stiching, the loop thats is build by the upper thread and is normally caught by the hook sometimes isnt staying in a 90 degree angle to the hook but turns backwards so that the hook misses the loop. This results in missed stich. https://youtu.be/aKOQkTJQ338 I made a video to show the problem. In case you have any ideas I would be very happy for suggestions. greetings ! ssl2013

- 1 reply

-

- pfaff 491

- sewingmachine

-

(and 2 more)

Tagged with:

-

Hi everyone! I am planning to buy a sewing machine for a small business that I will start preferably next year. The sewing machines that have been offered to me are the following: 1. Juki DU 141NH 2. Juki DU 1181N 3. Mitsubishi LY2-300 BOB The machine that I need must be able to handle medium to heavy materials (I’ll be using a combination of canvas fabric and leather), as I’ll be making bags (backpack, small pouches and totebags). Also, the machine must be user-friendly and if changes need to be done, the machine parts must be easy to source. Each of the machine is being offered to me at $650.00. So I really need guys your expertise and recommendations as I am very new to this thing so my money and first sewing machine will be worth it! Looking forward for your suggestions. Have a good day everyone!

-

I purchased a sewing machine for a price I couldn't pass up. However, I know nothing about this machine. Any identification related to manufacturer and model have been removed. Here is what I know.... Its a walking foot machine It has the same body/head design as a mitsubishi yu-360/330 and dy models (assessment of online images) It has a gigantic wheel. It was manufactured until the late 1980s Its serial number is 988038 I can't find much info online. Does anyone know what model this machine is? Or know who makes a similar clone? It sews fine now, but Id like to keep the info in my pocket incase it ever needs parts. Does anyone know where I might be able to find a manual?' You guys are awesome! Thanks

- 4 replies

-

- mitsubishi

- sewingmachine

-

(and 1 more)

Tagged with:

-

Hi there, i have recently got got my hands on a singer class 7-5 with no information on it and Only part of the manual. I have managed to get it running and sewing but the bottom thread appears too tight in the stitches and I cannot find a tension screw on or around the bobbin casing to loosen it? Could anyone advise on this ? Machine works beautifully otherwise Thanks in advance

- 4 replies

-

- sewing

- sewingmachine

-

(and 1 more)

Tagged with:

-

Has anyone ever replaced the thread take up lever on a juki lu562/563? What needs to be done?

-

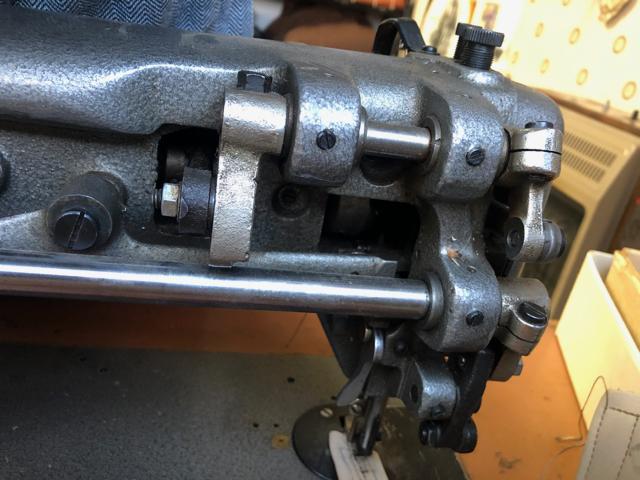

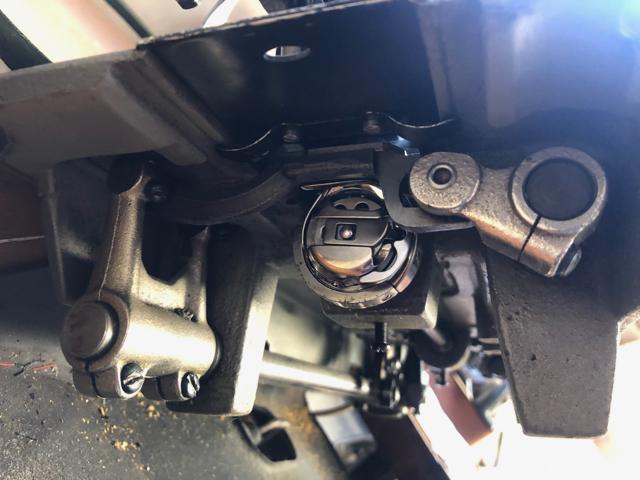

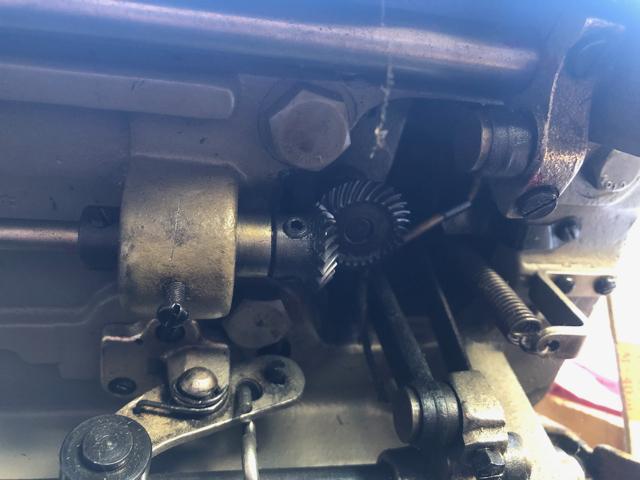

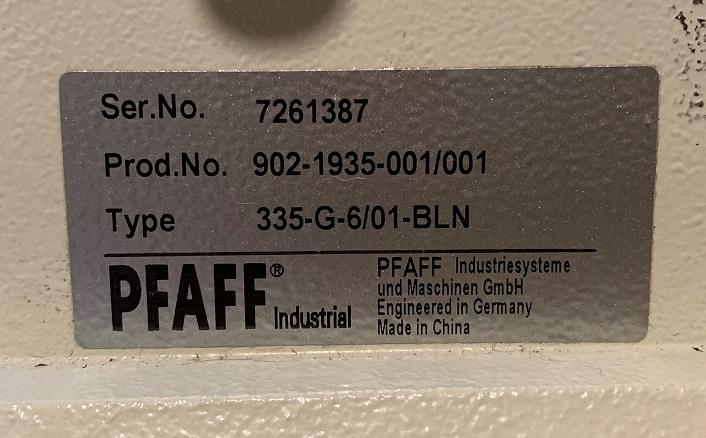

LIKE NEW PFAFF 335-G-6/01 BLN Cylinder bed Single-needle lockstitch machine with unison feed, large hook and alternative presser foot(walking foot)- I have three sewing machines and this one is getting used the least. Purchased a little over a year ago. One spool of thread has been ran through the machine. Makes a perfect stitch. Only reason I'm wanting to part ways with it is because I have a Pfaff 1245 flat bead that can do my lighter stuff and a larger cylinder arm for the heavy. This cylinder-bed sewing machine can be used for: Leather bags, purses, wallets, belts, straps, upholstery, chaps, etc.It is suitable for:working on tubular or pre-attached articles , standard sewing work on leatherware, bags and leathercraft articles , binding of shoes and leather warewith leather, imitation leather or textile tape , piping work on bags, suitcases and upholsteryALSO INCLUDED Complete Binding Attaching Parts For Pfaff 335Binding bracket complete with tape guide & screws / Needle Plate / Feeder / Set of Feet / 1" Raw Edge BinderTurn your cylinder bed machine into a binding machine cl 17/01 $1,900

-

Hi I had my eye on the ADLER 669, but I have the feeling little information is available, except from the standard folders from the firm. Does anyone own such a machine and give me some pointers on whether I should go for it, or consider another machine? Thanks Didier

-

Brand new Techsew 2600 walking foot sewing machine. Purchased a few weeks ago and has only sewed samples. Machine has been timed, tuned and inspected by Techsew and is ready to sew. Comes with a really beautiful tabletop attachment made by Uwe. The machine can be used as a standard flatbed or can quickly be switched over to cylinder arm setup. Comes with the following: Machine head and table Custom table attachment Premium Techsew motor with optional needle position adapter (sold separately) Swing down roller edge guide Double toe presser foot Left toe presser foot Manual Inspection certificate Magnetic led sewing light Needles Tool kit $2850 CAD. Local Pickup only, located in London Ontario Canada. Any questions, please feel free to pm me.

-

I finally bought a sewing machine, a Juki 1541s after months of deciding witch one to buy. I was going to buy one from one of the banner ads but didn't want to pay shipping. I found out I live 30min away from Keystone sewing and could pick one up . After a couple emails and a few phone calls to @Gregg From Keystone Sewing helped me pick out a machine that would suit my needs. The level of customer service that this company provides is just not found anymore, Gregg spent over 2 whole hours going over the entire machine with me. I actually felt bad for taking so much of his time up, but he insisted that I was comfortable before I left. When I first got there and walked threw the old wooden doors I was nicely greeted by his mother running the front desk. There shop has an old style vibe with the solid wood floors, the place probably hasn't changed much since the day it opened except all the new machines lining both sides of the store. I told Gregg it reminded me of one of the machine shops I used to work in that had the pulley system on the ceiling. He then asked me if I wanted a tour of the place and his machine shop, of course I did I love this kind of stuff. I wanted some left and right single toe presser feet that were smooth on the bottom, he was actually out of stock so he took some double toe ones and made me some while I was there. I was also interested in a binding attachment so he went over different setups with me for binding attachments. I could go on and on about my whole day there but don't want to bore everyone with the details. Thanks to this forum I found a place I can get great customer service at, I am sure the banner companies provide the same since there always here to help anyone. I am just happy Keystone Sewing is in my own backyard, my next purchase I will be buying a bell skiver from Keystone Sewing and a cylinder machine. Thank you again @Gregg From Keystone Sewing for all your help next Philadelphia Eagles Parade I owe you a beer, hopefully next year. I also practiced sewing with 92 thread and 138 and had no problems at all, was a little nervous on my own but nothing time won't fix.

- 16 replies

-

- sewingmachine

- juki 1541s

-

(and 3 more)

Tagged with:

-

Hey There! I am needing a little bit of help on a few machines I am running in my shop. They are both brand new machines and I have not really gotten them to run properly since receiving them. We predominantly hand stitch but are using machines more and more. I purchased an Atlas AT-318 & a TechSew TS-3850. I am having generally the same issues with both machines. I'll start with the Atlas. I got the Atlas running great but the minute I switch from 2 layers of 2-3oz leather to 3 layers of 2-3oz leather we are finding that our thread frays, skipped stitches and a general low quality of seams. I have adjusted the tension, switched needles, adjusted thread thickness and it will still always fray. I have had issues with the timing on this machine and it seems like Atlas has fallen off the face of the earth when I have reached out to them. The TechSew has never run properly. When I received this machine it was running.... barely. I switched the thread to the same size and color of the sample thread that it came with. From there it went downhill. The machine keeps throwing it out of time. I was on the phone with their customer support for a few hours and the technician said it was super rare for these to come in the condition it was in when it was sent to me. Every single time I retime this machine and run a stitch it throws it back out of time. I have sent them videos of threading the machine as they suggested with no response at all. I really would like to get these up and running. Seems like a waste of money for them to be sitting in my shop collecting dust. I am turning to all of you guys since I can get the support needed from the manufacturer. Thanks so much!

-

I want a walking foot leather sewing machine. I found a couple of used machines available in my area - a Consew 206RB-4 and a Chandler (Adler) 67. I would use to sew veg tan leather - bags and other similar items. In general which would be a better machine? The used Consew is more expensive, but I am more interested in which one will be a better machine over time. If they are roughly equivalent I may go for the cheaper Chandler. What thickness of leather layers could I expect each of these machines to sew through? Will one sew through a thicker layer of leather than the other? Thanks for any comparative advice. The Chandler is fitted with a servo motor, not sure about the Consew.

- 7 replies

-

- sewingmachine

- consew

-

(and 1 more)

Tagged with:

-

I have a walking foot machine - Techsew 2750 (similar to 2700, but with a bigger bobbin). Happy to have it. It's set up on with a table attachment to sew two flat pieces of 3-3.5oz together, 1/8" from the edge. Tension looks like its good - lock in the middle, machine running smoothly... except.. as it sews it veers the material, pushing it to the left (pushing the stitch line closer and closer to the edge). The only way I've been able to sew so far is to wrestle persuade the material to feed thru the machine at an opposing angle to somewhat try to correct it as it goes along. That doesn't work so well, and is leaving too much room for error on important pieces Upon a closer look, with and without the needle, the material is moving very slightly to the left, each time the feed dog and needle first come into contact with the material (center and walking foot still down (with walking foot about to lift if action continues). I've tried increasing presser foot pressure; all types of edge guide combinations, guiding by hand; no guide, no thread (with / without needle), and just running the machine at a slow speed to see how straight it sews on its own -- still shifts. I was originally using a center & left foot combo, but then switched to center & double foot to see if that would help with more surface area on the back of the feet touching the material. That didn't fix the problem either. The feed dog seems to be at a good height and has worked out well in keeping leather from getting pushed down, while not horribly marring the back as much as a sharp-toothed feed dog did (it's a smoother version, as the sharp toothed cuts up the leather). For a clean slate, I've set the machine back to the lighter presser foot pressure I have been using for a while now, and ready to keep trying to figure it out.. Since it's not a viable option for me to sew then cut material to size, what are some other things you all recommend I can try on the machine to correct the way the material is feeding thru? I've seen people just let their machine sew on it's own and it goes straight. That's ideal, but I'll even settle for a partial fix. Thank you in advance for the help! P.S. Techsew suggested increasing presser foot pressure so far, which I tried, but also looking forward to getting more feedback from this community as I continue to work with this out from all angles.

- 20 replies

-

- edgesewing

- materialfeed

-

(and 2 more)

Tagged with:

-

I have a singer 300u 205 double stitcher , a singer 300w 201 double stitcher , a reece keyhole machine, 2 juki keyhole machines, several single needle lockstitch machines, a couple single needle chainstitch machines. I really need to sell! Please message me with questions

- 2 replies

-

- sewingmachine

- heavy

-

(and 8 more)

Tagged with:

-

Ok, I got a Pfaff 545-H4-6/01. I know this is a really good machine but now I am trying to learn it and I could really use some help. I am very new to sewing machines but I am going to do what it takes to learn them. The first thing I need help on is the motor, I want to put a servo motor on it for better efficiency and being able to sew at slower speeds etc. but this machine has a lot of extras I have not seen on a machine and I do not know what exactly changing out the motor would involve. I am attaching a lot of pics to show what is on this Pfaff. I cannot even turn the motor on yet because the power cord is a 2nd phase cord (I think) and I only have the standard outlets in my shop. Anyways the motor is a Quick Rotan Synchro 6040. One thing that has me kind of baffled, the guy who I got the machine from said something about needing an air compressor hooked up to raise the walking foot. I think that is what he said but I am not sure if that is exactly what he was talking about. So this is a clutch motor right? Can I change the motor out and put a servo motor on the Pfaff? And what are all of the extra hookups on the back of the machine head? Thank you in advance. I can also take pictures of any specific part of the machine if someone needs to see it. the first 9 pics are of the motor and the last 3 are pics of the attachments on the back of the head of the sewing machine. Thanks a lot!

-

Hi everyone, I have a very lightly used cobra class 4 for sale. This machine has 2 hours, if that on it. We purchased the machine in hopes of keeping up with our orders and spent an hour + practicing on the machine. We took a one day break (as these are in depth machines, as anyone can tell you), and the very next morning we were approached by a manufacturer who has picked up our product line, hence the sale of the machine. We purchased the premium package which includes: * Left Toe Presser Foot * Open Toe Center Foot * Double Toe Presser Foot * Right Toe Presser Foot * Work Platform * Ten Size 25 7x4 Leather Point Needles * Ten Size 24 7x4 Leather Point Needles * Ten Size 23 7x4 Leather Point Needles * One 8 Ounce Spool of Thread * Holster Plate * Stirrup Plate * Slotted Plate * Blanket Set (Inside & Outside Feet w/ Feed Dog) * Heavy Duty Roller Edge Guide * Pair of Thread Nippers * LDA - 1 Magnetic LED Light * Oil and Tool Package * Four bobbins * Owner and parts manual * Instructional DVD I also have 5 extra packs of needs and extra spools of thread that came with my particular order. The machine includes a fully transferable Lifetime Warranty from its manufacturer, The Leather Machine Co. It's definitely a sturdy workhorse of a machine. We're asking $2200 and if you need it shipped we are willing to ship the item, but the cost of shipping will be the responsibility of the buyer. Local pick-ups in Las Vegas, NV are also welcome.

-

Can an Eversew class 15 be used for saddlemaking?