Search the Community

Showing results for tags 'sheaths'.

-

Hi! My name is Chip. I’m new to leather working. I instantly loved it because it involves sewing with a sewing machine and reminds me of wood working (which I also love). I want to make nice bags and wallets for both women and men to sell. No website yet as I am just getting started learning about this, but… I’ve already made two bags using a Singer 128 and a Kenmore Model 21 “Purple Monster”. The Singer does not have reverse, so that was a bummer. The Kenmore has reverse and is a left homing needle (kind of an annoyance, but works). Both of them had their issues and I realised I can’t use them for quality work. Even still, both prototype bags I made came out “ok”. Those are going to be gifts. I have not settled on what specific items I will be making for sale, but totes will be on the list! Chip from CHIPPER BAGS

-

Some more things I got finished up. Both snapping turtle. The sheath I believe I’ve posted previously, if so my bad.

-

Hi all, Here are a pair of kitchen knives and sheaths, made as Christmas presents for my parents. Originally I had planned for them to have different sheaths but simply ran out of time to design something new, so they are the same except for a subtle colour change on the borders. For an outdoor belt knife I would have added a welt or put the seam down the centre on the back, but as this is just to protect the edge while they sit in a drawer or something I think the simpler design shouldn't be a problem and I doubt there is much chance of them slicing through the stitches. The tooling is of course some Western swirly acanthus stuff, and due to the lack of belt loops is on both sides. Stitching is by hand and is with waxed linen. For anyone interested in the knives themselves, they are both hand forged from 1080 high carbon steel, with cocobolo grips and sheet brass bolsters which extend down the tang. A little more time would have been preferable really but overall quite happy with the end results. I hope you like them and Happy Christmas everyone! Alex

-

Greetings from Nor'Easter region, It's been close to a decade since I did any projects but after getting a Single Action Army and a new skinning blade blank I've gotta dust off the cobwebs and see what I remember. I started on a Tandy beginners box set that was probably made for teens but after a few projects on some oak shoulders and scraps from a friend I started getting into it. Past projects where coin purses, messenger style bags, sheaths and a few whips, the stand out ones where the 8ft bull whip and the cat o' nine tails. Recently I acquired a SAA revolver and the holster I plan to make will probably be worth more than the gun itself, no offense H&R, she's a fun little .22 and I like her. I also found some new knife blanks that may or may not be the greatest but I've only had them a few days and they feel nice and they need a proper dressing. I've been a carpenter/woodworker my whole life so I have the handle ideas down but I will have questions on ideas for sheathing styles and patterns. Suppose since I will have enough veg tan left after the SAA holster I should make one for my 9mm but I may put that on hold while I try a run at a Tombstone replica rig for the single action. Heard rumor Doc carried double action revolvers in real life so I might not match the guns but I will try his suspender style rig, looks a little awkward but probably functions well, I do prefer a cross draw. I will post a picture of my first project because it's really how I started years ago, Tandy precut and all, also I will post the the two new items that need some new clothes. I will be asking a few questions here and there if I don't find them in the forum search. I think tonight I'm just gonna skim the forums and work on my Dubbin mix. Found some local beeswax from the same guy that sold me our Christmas tree and gonna put it to some use.

-

-

-

-

Thank you

-

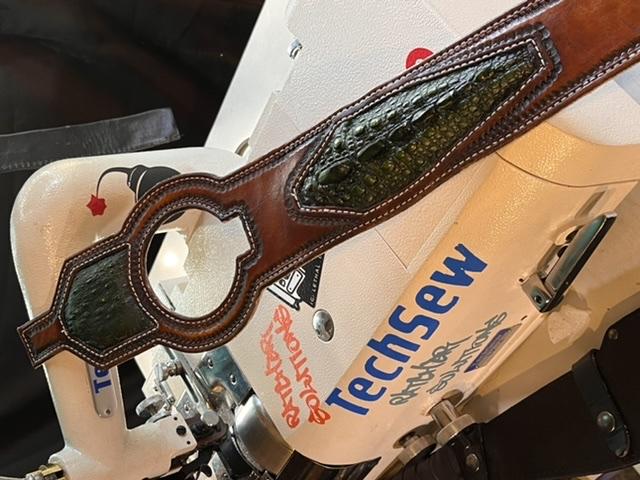

Here's a couple of recent things that I've made. A custom seat that I did for a customer's Triumph Bobber project and a tooled knife sheath.

- 5 replies

-

- motorcycle seats

- knife sheaths

-

(and 2 more)

Tagged with:

-

Hey all, I'm Graeme from not-so-sunny Scotland just south of Edinburgh. I started leatherworking a few years back as I needed to make protective covers for my greenwood working tools i.e. axe masks, knife sheaths, billhook covers, etc. Then my old belt gave up the ghost so I set about making a new one and learned a lot along the way. I've just started back leatherworking after a hiatus of several years due to illness and a marriage break-up and am really enjoying it. Made a few belts for myself and a few others which were very well received and a few dog collars and leads (are they called leashes in America and some other countries?). Got a batch of vinegaroon brewing and a made some saddler's grease all thanks to to this very helpful and knowledgeable forum. I figure if the answer ain't on here then there ain't no answer! Anyhoo, I ain't great with technology and am shocking at taking photographs so you'll need to bear with me in that department. I'll pop up from time to time with questions and try and help others whenever I can but I'm pretty sure there are others with way more knowledge and experience than little old me. Lastly, I'd just like to say what an amazing forum this is and thanks very much for having me. Kindest regards to all, Graeme Red Kite Crafts

-

How's it goin' everyone! I'm a newbie here and just recently found this sight a couple weeks ago. I've always wanted to get into leather craft a few years back and just recently bought me some stamps! I'm mainly looking to make belts, knife sheaths and the occasional wallet. When it comes to sewing machines I am lost! What type of sewing machine do I need for these types of projects? anything that I can buy at the store and readily available? Or do the older/vintage machines do better for these types of projects? Any info is greatly appreciated!

- 5 replies

-

- belts

- sewing machine

-

(and 2 more)

Tagged with:

-

From the album: Bigfoote

Bunch of slings and sheaths I made. -

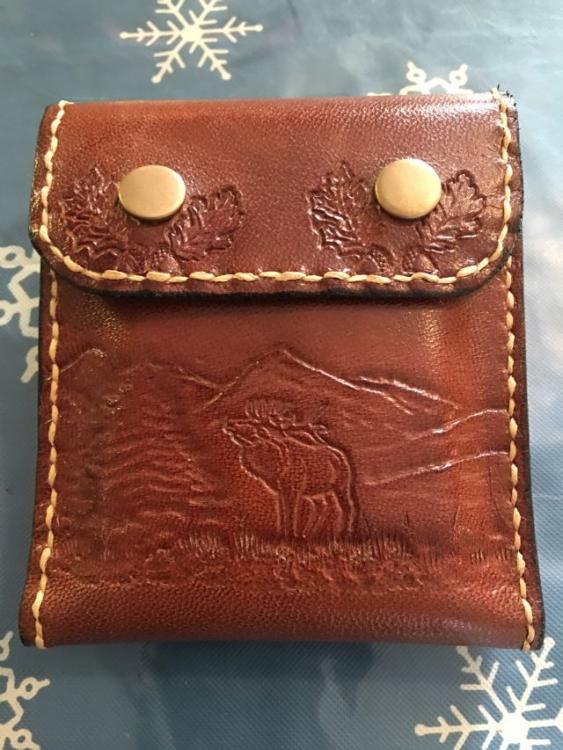

Hello, My name is Juddie (pronouced like muddy but with a "J") and I have new to leathercraft. Just started doing this back in June of 2016 when I made a sheath for my Leatherman. After doing that I made a few knife sheaths for fixed blades and a couple folders, then started into making some holsters and it just keeps going. I been looking for a site that I could ask questions or maybe even get some ideas on ways to improve. I am a member of several Facebook groups about leather crafting. Here are some examples of some of my work. I am very tuff skinned so any comments whether good or bad, any suggestions are appreciated. Thanks for allowing me to join the site. Juddie (aka WVHunter129)

-

I am fairly new to leather working. My father did it for many years and I would occasionally join him when I was a kid. After he passed 5 years ago, I inherited all his leather working materials and in the last six months have started making a few things. This is my latest item to make it a bit easier to hold my work while stitching. I have made three sheaths and a cabinet to hold my leather working tools. I am looking forward to learning a lot and focusing on learning correct tooling! I have also started work on a sheath and tooled for the first time! Looks pretty ugly, but it's a start! Thanks for looking and would appreciate constructive criticism!

-

Hi folks! I'm a leather worker in Eugene, Oregon and have run across a problematic situation a couple of times with leather, making marks under or on the surface of fine steel blades. It's happened with a lower end production knife called 'The Seguaro Survival'. That time the rust was appearing before my eyes. It literally was like a viral growth and took considerable work to stop it before it did serious surface damage. I chalked that up to the quality of the blade. Lately I had another blemish appear on a blade. This one was a high end custom knife. The customer called after having the blade in the sheath for a month and said two small blemishes have shown up. He tried using a metal surface polisher to no avail. In this sheath, I cured the constructed sheath in a low heat oven for plenty of time. I'd hoped this would take the offending chemicals or interaction away. The sheath is lined with a 3-4 Hermann Oak. Outer is 7-8 HO. I used Eco Flo brown on the outer and on the lining. At this point I must assume the fault is with the Eco Flo. My mentor, Dave Shelgren suggested not dying sheaths and only Neetsfoot them. This would stop it, but would lend to a restricted product offering. Any thoughts? Thanks in advance, John.

- 7 replies

-

- sheaths

- abbrasions

-

(and 3 more)

Tagged with:

-

From the album: Sheaths

Belt Friction Sheaths for Doug Ritter RSK® Mk1 Folding Utility Survival Knife© Lecuir.net

-

Belt Friction Sheaths for Doug Ritter RSK® Mk1 Folding Utility Survival Knife

adonissawan posted a gallery image in Gallery- Our Leatherwork

From the album: Sheaths

Belt Friction Sheaths for Doug Ritter RSK® Mk1 Folding Utility Survival Knife© Lecuir.net

-

- survival knife

- leather

-

(and 1 more)

Tagged with:

-

Hello from Oregon USA fellow leather workers! Hope this finds everyone is great spirits. I just joined the group. I'm not so new to the craft, but have recently become quite interested in what others do, how you do it and why. I've already picked up on some great tips just by eyeballing your work. I'm a custom holster maker. I've been told I have a nose for this sort of thing and by the looks of things so do many of you folks. I think I'm in some pretty good company. I actually retired from radio broadcasting in 2003 and never thought I would be as interested in anything again, but here we are - and having a fantastic time at it. Hope to talk with you folks and wish you all the best in your travels. I already feel I know the lot of you, simply by our mutual attention to this affection we've found. Oh hey, would you go to my County Holster Eugene face book page and like it? I need some likes on that so I can look successful:) Take care, John County Holster & Leather, LLC

-

Here are some of my holster pics. I have been hand stitching and am getting far too busy to keep up! About to pick up a Cobra 3. Trying to keep quality work going out.

-

Hello everyone, I recently went into a knife sharpening spot near me to get my skiving knife all straightened out. The owner started inquiring about my work and was asking about leather knife sheaths. Having some Veg scrap I began making a couple samples and quickly realized its not what I'm set up for. I am setting and resetting my machines and it's just creating more of a work load than a one man show can perform. If anyone in LA needs some work and knows the ropes on a good finished veg tan product please pm me. I am going to inform the client it isn't working out this week and would like to make an introduction at that point. He's a great guy and I don't like leaving anyone hanging out to dry. All the best, Rich

-

From the album: Rendezvous Special

back of knife sheath. I know, I forgot to bevel/background the lower loop on the "Q" OOPs. This was my first try at using the D.o.I. Declaration of Independence) font. Again, wanting to use only "period" style, methods and materials I fashioned a locking lace closure for the belt loop on the knife sheath. -

From the album: Rendezvous Special

closer look at the front of the sheath, complete with buffalo hide fringe (first time trying that out).