All Activity

- Past hour

-

What would your ultimate needle positioner/synchroniser do.

fibersport replied to beefy's topic in Leather Sewing Machines

Get yourself a Kinedyne needle synchronizer for accuracy but I'm pretty sure the servo motor controller is what really controls the functions, the synchronizer is just a switch to indicate where the timing of the machine is. The Kinedyne is an optical synchronizer and is super accurate. http://kinedyne-motor.com/products/HM-750SH/234.html You could just get the Kinedyne motor and synchronizer and be done with it. Just sayin - Talk to Ryna at http://www.neelsaddlery.com/ I have no affiliation with Kinedyne or Neels Saddlery, just a very satisifed customer. - Today

-

In keeping with my growing love of my newly acquired industrial sewing machines, I'm now getting myself absorbed in designing an electronic circuit and programming a microcontroller to make my own needle positioner. I've given up trying to get any sensible instructions for my cheap Chinese servo from the seller. I know it also doesn't have any heel press functionality. So far this is the functionality I'm programming for it: Single revolution/stitch from EITHER the needle UP position or needle DOWN position. This is done by a quick tap on the pedal, either forward (for needle DOWN) or heel tap (needle UP). Stop in needle DOWN position when foot pedal released. Go to needle UP position when heel tapped. Adjustable "coasting" speed when searching for either needle UP or needle down position. This is to have control over overshoot if servo cannot stop motor fast enough. Search for needle position is cancelled if operator presses foot pedal while motor is coasting and waiting for needle UP or DOWN signal. Safety feature - adjustable timeout for motor coasting and looking for needle UP or DOWN position. Coasting stops if signal not received within timeframe. This prevents the machine going on forever if some fault occurs like a broken wire, or faulty needle positioner. Are there any other useful features a needle positioner could have ?

-

Need recommendations for steel bar plate for work bench

Tom T replied to desullivan's topic in How Do I Do That?

Just use Carnauba wax on it occasionally after polished, it will keep it from rusting. -

Source for 12-14 oz quality belt blanks

wizard of tragacanth replied to wizard of tragacanth's topic in Suppliers

-

I thought it was for sheetmetal as well. Could be the cobbler adapted a metal shear to cut leather. Maybe someone gave it to him or he got it cheap and adapted.

-

Happy New Year, everybody!

-

Hi all. I recently purchased a Cobra NP4 skiving machine and received it right before I went out of town. Now that I've had a few days to use the machine, I think there's a problem with the presser foot handle. When I pull the handle down, it stops about half way. If I do this 3-4 times it will then go down once. After that, it's another 3-4 times before I can bring the foot down to skive. A friend with a similar skiver recommended that I lube a few areas, which I have done, with no change. Of possible note is that when I received the machine it was pretty filthy, which I thought was odd. It took a few wipe downs to get it clean. There is also a lot of grease at the top knob and where the handle rotates around the pin. The other issue is that the foot is leaving marks on the leather, so the foot isn't polished to the degree it should be. I haven't tried the other feet yet. Here's a link to a video of the presser foot handle in action: I emailed the company that I ordered through but haven't heard back from them. I plan on calling Leather Machine Co tomorrow, but was hoping to get some insight so I don't get the run around from them. Thanks in advance for your time. Neil

- Yesterday

-

That is amazing work! Absolutely beautiful! Thanks for sharing.

-

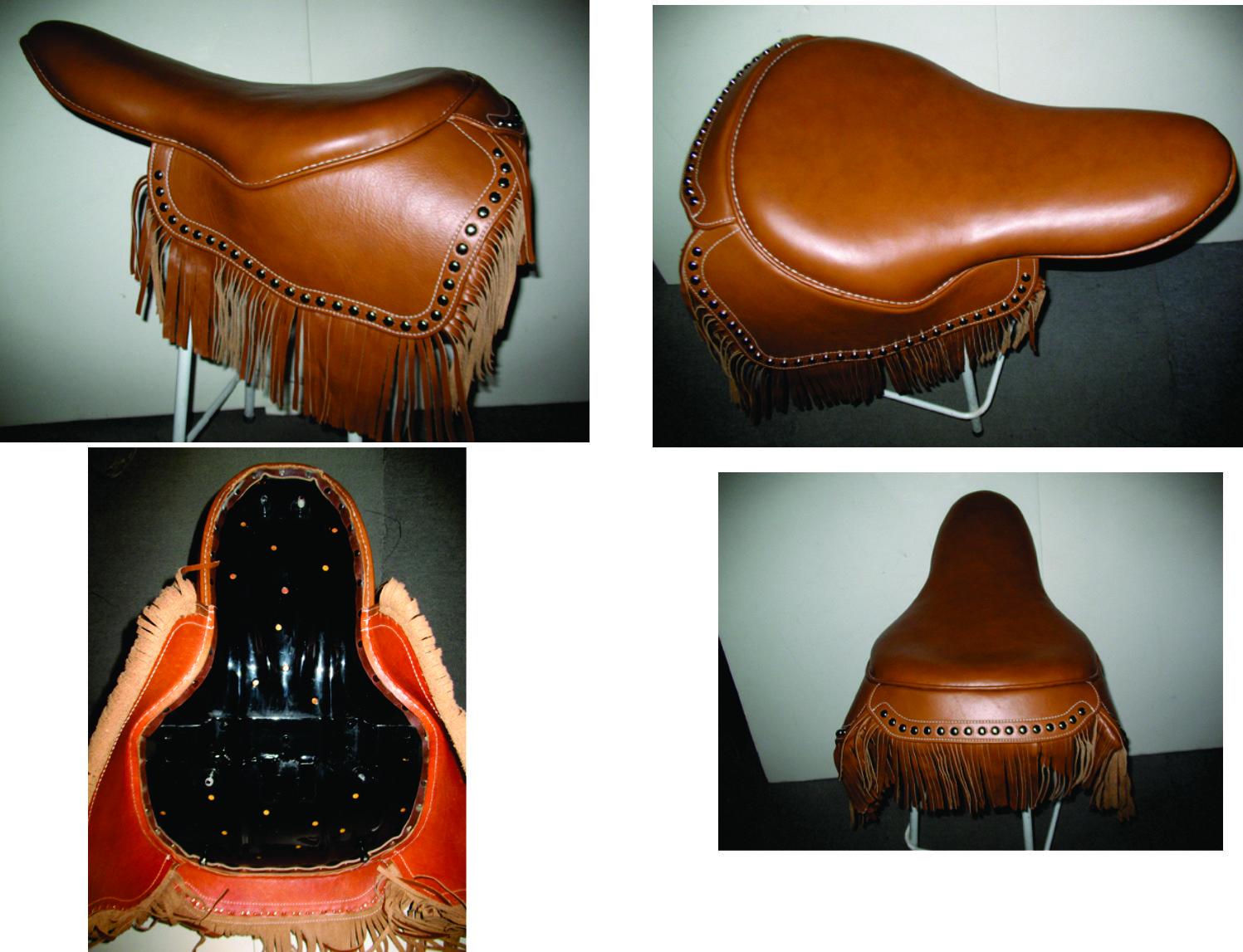

Just a few Indian Chum-Me seats I've done in the past, New foam, new leather with custom leather fringed skirt. Main seat uphostery was hand stitched. Skirts are machine stitched. I believe this was a Harley Buddy seat. Its been a few years. LOL

-

Hi! @KyLeatherMan where are you located?

-

Elk and deer hide knife sheath with black bear claws, deer antler button and Indian head snap.. Sheath was for a First Nations chief's custom made knife.

-

japa44 joined the community

-

iKonix Cylinder-Bed Lockstitch Sewing Machine - KS-335A

AlZilla replied to Nanamagic's topic in Leather Sewing Machines

@BurntLeatherCo hasn't been seen around these parts since May. But that tag I just did might send them an email that somebody is talking about them. Maybe he/she will check in and you guys can get together. -

artsynerd joined the community

-

No chance! I'm in hibernation mode. Besides, I can't run

-

Nice work. They look great. What do you typically use to line them with?

-

Now - more than 3 years later 😉 I checked with a known Chinese Ebay seller of sewing machine parts if he can get me the "Pfaff to Singer KB-PF1" foot converter. Few days later he uploaded a listing to Ebay and I have bought 2 pieces - now waiting for them to arrive. Reason I need them is that I found a Pfaff 341 (needle feed) and there are not really plenty of Pfaff needle feed feet out there but I have a good number of Singer feet so I will see how these converters work and I´ll post pictures when I haven em here. https://www.ebay.com/itm/168042808004?var=467644970296

- 2 replies

-

- presser foot adapter

- kb-pf1

-

(and 2 more)

Tagged with:

-

Heads Up:I am going to sell most all my leather "stuff"

Scoutmom replied to Ferg's topic in Hand Tools-Leatherworking Tools

Sorry to hear you've spent time in the hospital and are now selling your leather and tools. Praying for your health and your family. -

Happy New Year! Anyone coming for an icy run today?

-

ccleather joined the community

-

volk joined the community

-

Happy New Year

-

HAPPY NEW YEAR!!!!!!!!!!!!!!!

-

Source for 12-14 oz quality belt blanks

thewesternsaddler replied to wizard of tragacanth's topic in Suppliers

Hi Nick, Quality 12–14 oz belt blanks are a great choice for durable belts — that weight hits the sweet spot between strength and flexibility for everyday carry. Herman Oak is definitely one of the go-to options, but there are a few other U.S. vendors and leathers worth considering: • Wicket & Craig — similar veg-tanned weight, excellent for belts and heavy leather projects. • Schneider’s Veg-Tan — reliable 12–14 oz veg tan with consistent thickness and great tooling surface. • Tandy’s 12–14 oz veg tan can work well for belts if you’re okay with a slightly softer feel to start with. A quick tip when sourcing blanks is to check whether the hide is from the shoulder/neck area versus the belly — shoulder cuts tend to be tighter and stronger, which is ideal for belts. Also, getting them from U.S. suppliers usually keeps out nasty shipping surprises and supports faster restocking if you work through blanks regularly. What will you be using the belts for (E-DC, western carry, dress)? That can help fine-tune the leather choice. -

I'll try that too 👍

-

Hi guys…recently got back into making my hand made leather tankards after about 20 years….trying to find a quicker and easier way of lining the tankards primarily…looking forward to chatting and learning more about leatherwork here on the forum. just thought I would add a couple of pics of my hand made tankards, just gotta clean up the base of these tankards, and they are done. hope u like them.🙂

-

Loren S joined the community

-

Pedersen 309 Bobbin case wires question

Constabulary replied to Einherj's topic in Leather Sewing Machines

don´t know for sure but could be a heating device for warming the waxed thread. But its just guessing. EDIT: Rapid E 317 is the same machine AFAIK - see manual page page 8. Rapid E 317.pdf