All Activity

- Past hour

-

Thanks for your replies, @fredk and @AlZilla. We have fiber optic internet (a miracle, considering we’re in the boondocks) and no other issues with slow service. Occasionally this site loads quickly, but usually it’s a wait. Wasn’t the case until the last few months.

- Today

-

I don't have a significant lag most times but very often I get a "page can't be reached" message and the page loads a few seconds later. Both on my home DSL and mobile 5G. You may recall a few months back, we had a DDOS attack and it took the Boss a few days to get it straightened out. Maybe we're still being hammered and she's just filtered most of it out.

-

A veritable Aladdin's Cave! Did you buy the lot? (I probably would have!).

-

@Samer, if you have an Android, Google Translate will work with your phone camera and translate about 1/3 of the page at a time. Mebbe more with creative positioning... not familiar enough with iPhone to verify if it will.

-

All working fine at my end but, there have been reports that the Russians have been interfering with Western communication satellites and although its been going on for more than a year in recent months they've stepped up the interfering

-

I watched a video by Nigel Armitage Leather, on applying edge coat. While the edge coat was still wet, he burnished the edge. I have tried it and it works really good for my level. Now the dangerous point, I started thinking! would that also work for say an acrylic painted edge? Turns out, it does work well. I did a toconol finish and a waxing after letting the paint to dry. Durability? Don’t know, but it is on a working piece, so I will find out!…cheers!

-

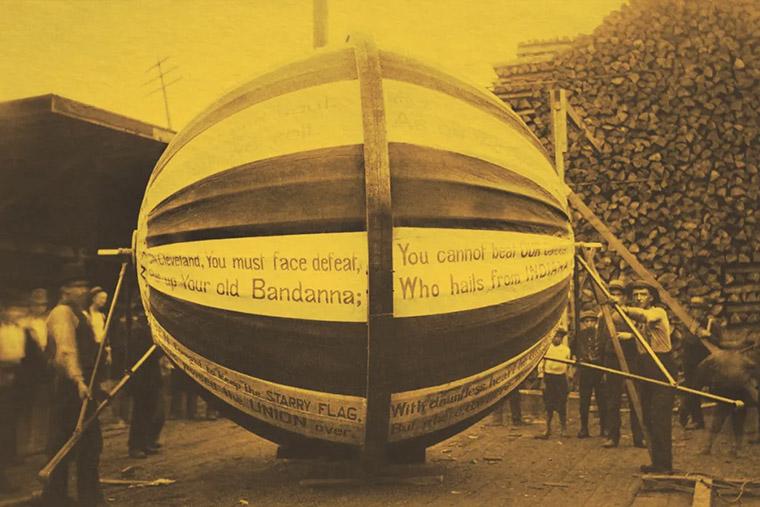

Here's a project that I haven't seen discussed before. President William Harrison's leather and tin ball, which apparently is the origin for the phrase "keep the ball rolling." https://wordsmarts.com/keep-the-ball-rolling/?lctg=3e121733-b5b4-47ec-a793-21d132d067fc. Now that I have your attention, my real reason for posting is to ask does anyone else have trouble with the leatherworker.net site loading slowly? For the past ~3 months, most pages of this site require about 20-30 seconds to load. It is a slow process to use the site. Is there a workaround? Thanks for your input.

-

There is a first year leather show coming up in Las Vegas January 7-10. Single location - classes, trade show, competition, and social events all at the South Point. general information here - https://illumeconnect.com/pages/event-las-vegas I will be leading a class on the morning of January 7th on purchasing second hand tools. Buying second hand tools can be a good way to expand your tool set and elevate your work. It can also be time consuming and intimidating. I intend to break it down for you and give the confidence and information to be comfortable with purchasing used tools. Some discussion points will be: - Why to buy secondhand tools - Where to look for and buy secondhand tools - How to identify leather tools - Evaluate the condition – what is acceptable/what is not - How to establish a value to YOU first then proceed with making an offer or accepting a seller's price - Discussion on restoration of common tools - techniques and how far to go - How to use and maintain some commonly found tools - When NOT to buy – seller price versus your value, just not the right deal, and tips to avoid getting scammed - A final event for the class with a guest instructor (Guarantee - You will have fun and get your money's worth just from this!) You will leave with a full book of my notes plus it will include a list of resources, and some printed resources as well. Here is a link to the class - https://illumeconnect.com/products/secondhand-leather-tools

-

Brilliant!

-

The file’s still there and I can download it. Maybe copy/paste that link into a new browser window or use a different browser.

- 180 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

Juki LU-563 stitch length eccentric play

Uwe replied to Helifixer's topic in Leather Sewing Machines

That video is helpful. It looks to me like the pin that rides inside the spiral slot is loose. If that’s the case, you most likely have to replace that slider, or the whole eccentric. Unfortunately that’s a bit of an operation because you have to remove bunch of parts to remove the eccentric. Sometimes that pin is a press fit, which is not really repairable unless you can weld it in place. If it’s a thread pin like the one in the picture, you might be able to tighten it . This could perhaps be done by disassembling the eccentric and separating the parts to gain access to that pin, without removing it from the shaft. -

Looks like it's ready to serve another hundred years. Great job!

-

Accurately cutting "stretchy" leather.

billybopp replied to Shadders's topic in Leatherwork Conversation

All good advice above, I've used all of them. Another thing to consider is that the leather needs to be relaxed before you start cutting (no no .. not like give it a cup of tea and a comfy chair relaxed). What I mean is that you'll want to lay out the leather flat and not at all stretched nor compressed before you start cutting. It's tempting to pull it taut to make cutting easier, but that will cause problems down the road as it shrinks back to size. - Bill -

Accurately cutting "stretchy" leather.

PastorBob replied to Shadders's topic in Leatherwork Conversation

+1 on rotary cutter, but scissors work well too. -

friggin awesome friend!! Heck yeah, it was worth it .

-

Accurately cutting "stretchy" leather.

chuck123wapati replied to Shadders's topic in Leatherwork Conversation

I use scissors. -

.thumb.jpeg.2101477021e843ad8ab0d716dd841942.jpeg)

Accurately cutting "stretchy" leather.

sportycliff replied to Shadders's topic in Leatherwork Conversation

Instead of cork backing, try using 220-400 grit adhesive backed sandpaper on your rules. Right to the edge, as long as you're slightly careful it shouldn't scratch the leather, and it will minimize stretch. I like the rotary cutters as well, but it's another tool to keep sharp. Just another option... -

brotherdave joined the community

-

I've long wanted a cobbler's hammer (mainly 'cos I don't have one!). I remember my dad had one but it disappeared a very long time ago and wasn't among his tools when I got them. Very difficult to find, particularly used, so I thought "why don't I make one?". Can't be that hard. Hah, should have known better! I found a ball-peen hammer head for $3 and away I went. First thing was to reduce what I think was a very large tent peg to fit the hole in the head to prevent it from collapsing during the forging. I don't know what steel it was made from but it was tough to move under the hammer! Then it was time to start widening the head and likewise I don't know what the steel is in old hammers but this stuff is also hard to move. Once it got below orange heat the hammer had no effect on it. Eventually I got it to a suitable width and then mashed out the ball part to a flat. This hammering, by the way, didn't do my tennis elbow much good!!! I cleaned it up on the belt grinder and then heated it to non-magnetic and quenched in oil. I thought I'd have to temper it but a file could still (just) mark it so I called it good. I suspect the mass of the head was too much to cool quickly enough in oil and suspect quenching in water would have been better but it should be hard enough for leatherwork. I decided to leave the oil-quench coating on to give it some rust protection and just polished the face. The handle is from some Blackwood that I cut down years ago and saved just-in-case, need to give it another coat of linseed oil tomorrow. Was it worth it? Dunno, but it's something I just had to do.

-

Right. It also depends where you are, it's also called a "loop".

-

Sand casting my own conchos....

Bobs Brassware replied to Chakotay's topic in Hardware and Accessories

Nicely done! Sand casting can be a challenge at first, but you’ve got those conchos looking clean. Appreciate you sharing the process. -

-

I noted the original post to alert any browsers to the new price, Beautiful looking stuff.

-

In the upper right corner of your post there are 3 horizontal dots, which is the dropdown menu. Click it. The EDIT option is there.