-

Posts

1,018 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by TomG

-

Tandy rapid rivets either bending or not holding. Help!

TomG replied to nevadabob's topic in How Do I Do That?

I've used Tandy double-cap brass and nickle plated rivets for 10 years. I've had very, very few problems with them and 99% of those were me. 1/8" is too tall. 90% of the time, the post is going to lean or shift to the side. Especially if the hole is too large. The hole should be just big enough to let the cap set all the way down. 1/16" is the recommended height for all rapid and double cap rivets to the best of my knowledge. To use a "too long" rivet, I use a pair of fine, flush-cutting cutters to trim them to size once put into the leather and then reshape the post with them as well. I've had maybe 5 failures in those 10 years that I am aware of. I've also set them with and without the concave base. I've never seen any difference other than visual - flat base vs domed base. All of this being said, I recently bought the Goldstar press and dies. I have set countless double caps that were at least 1/8th" above the surface and had zero posts leaning over. I leave the dies in all the time and just grab it, set it on the bench and go. Just be aware that the Goldstar double cap dies are marked in mm size and Tandy rivets are all mis-sized. I beleive the mediums are marked as 7mm and are actually 8mm. So you have to buy a die size larger. Their Line 20 snap dies are not cut to fit the Tandy snaps either. They fit everybody else's, per the guy at the store. Good luck -

If you just want a table to cut sides, get one of those 6 foot folding tables from Sam's or Home Depot/Lowes. Under $100 and folds up for storage when not in use. But don't use it for pounding. Too much bounce..

-

Yup. It's a 135x16 leather needle. I'm getting ready to sew another batch of these and just spent over an hour adjusting tensions, presser foot pressures, etc. Looks like I have it as good as I'm going to get it... Not absolutely perfect, but I don't think it's possible to get the bottom to look like the top <g>... my definition of perfect...

-

Thanks Mongo. My main problem was the amount of text in the area allowed. It's a moot point now. He just told me he found a biker shop that can do it with hot press. Thanks for the help, all.

-

Thanks for the suggestion. That was one of the options I mentioned to him as a possibility, but really didn't know if they can print so small. I also mentioned typeset lettering that can be filled in with paint....

-

I have a customer who wants a black patch 2" x 3.25" with the following on it. _________________________________________________ LTJG JIM DICKSON USS TICONDEROGA (CVA – 14) _________________________________________________ The only issue I have is that he wants the letters in gold or bronze. I have nothing this small that will fit and still be able to be colored. An suggestions? Thanks

-

Ditto on JLS's recommendation. Great folks to work with. I recently had a request to match thread and leather color. I sent them a sample of the leather and although they did not have an exact match (no surprise there), the recommendation was actually as near perfect as I could expect. One interesting thing I found out is that not all colors come in all sized spools. I have always tried to buy 4 oz or smaller spools until I see if I will be using that particular color. then I buy the 16 oz spools. That's a LOT of thread unless you as sewing every day, all day... If you want something closer to home, try a major sewing machine store. Here in Atlanta, we have Southeast Sewing. Great folks as well. They sell and repair industrial/commercial machine so they carry a nice selection of Fil-Tec threads

-

Hi Olie, I'm not sure how you came up with that figure. You didn't say what size belts, but figuring a 1-1/2", 72" long strap, is 108 sq in. (72*1.5). Divide that by 144 to convert to sq ft and it is .75 sq ft. At $8.20 sq ft, that is $6.15 ea. Tandy has 1-1/2" x 72" straps for $24.50 ea - wholesale pricing. Which seems a whole lot high to me. They have some precut belt blanks with snaps for around $15

-

Thanks Ferg. I did the sliding needle trick. The 21 had a little bit of snag as it went down, but that may have been me lifting the thread too high, come to think of it... I'll tighten setting up tomorrow and try again. And Wiz.. Yes.. Please jump in <g>...

-

Still learning the new Consew 227R and loving it. Have a question about the "quality" of my bottom stitches. The photos are 2 pieces of 7/8, glued together, 138 nylon thread top and bottom, both fee set to as light a pressure as I can get to avoid marks, but there is no lifting that I can see. Size 22 leather point needle. Longest stitch length the machine can be set for. Is there any way to improve the look of those bottom stitches, or is this just how it is? Thanks

-

Looking forward to seeing them!

-

BigMatt... Did you ever get the Sailrite binder to work on the 227R? Sure would liek to see some pic or even better a video of it working

-

Haha. Must be Abbey of England... Naw.. Not for 10 pounds .... I think I'm paying around $3 each for nickel plated. I have 1 source for brass plated here in the states, but they only have 3/4" now, and the first - and last - time I ordered, it took 3 months to get them. He was out of stock and waited until he had a really big order of stuff to get more... He orders from China.. Probably Alibaba...

-

Didn't know that. But the Singers, Consews and clones have tons of feet as well. How does the Harness machine handle the studs? His edge looks so thin, I don't see how a foot would be able to get good traction without marking the leather, and I'd think it would have a tendancy to fall off the edge unless you were very, very careful.. and lucky <g>

-

I am not a pro by any means but it looks like there is not enough edge for a pressor foot to run on. Maybe Wiz or Kevin will chime in. But I have to know.. Where did you get the brass martingale chain? Tom

-

White Dye

TomG replied to Hooper26's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I agree with Electron. The white dye is not going to work. And it stinks pretty bad. I use the high end heavy pigmented paint for white. I dilute a bit with water and put on the first coat. Let dry totally and then use light coats of the full strength pain - assuming it's not too thick. Sort of like pudding maybe. maybe a bit thicker. you need to to flow a little as it drys to erase any brush marks. -

Mike, you are not being harsh at all. Just honesty, which is what I wanted. That's why I posted the question to begin with <g>... I can see where a wallet might be too small to bind nicely. I did the hand binding on a wallet (my first) because it has hair-on cowhide for the back piece. Not conducive to burnishing. I did try to wrap the leather around the corners and you are right. It was a mess.. even putting 90 degree notches in them. I wound up using individual 45 degree mitres and sewing separate strips to each side and the bottom. Still ugly, but not as bad as the fold. thanks for the input. It IS greatly appreciated. Tom

-

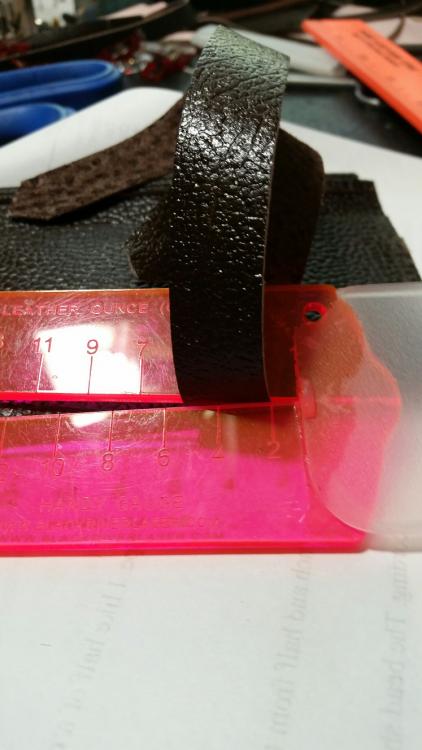

Here's the wallet I am working on now. I'm having to use a double-sided tape to hold the strip in place and then sew. The leather strip is 5/16th (17mm) wide and is a tad under 2 oz. The edge of the wallet is about 9 oz at its thickest.

-

Binding material will be a light leather, probably 3/4" or 1" strap to get a 3/8 to 1/2 inch edge. Raw edge is fine. I'm getting into wallets, bags, purses, etc and looking for a starting point. I'm really not sure of the difference in a swinbg and a stationary binder as to uses and functions. I'm also not sure that the differences are (usage-wise) between straight, 30 degree and right angle ones. Thanks

-

Is there a binding attachment that will fit a Consew 227R-2? I know I can have a custom one made but I just need something to put light binding on wallets, bags, etc. Thanks

-

I had the same problem when posting my Singer yesterday. I had to close my browser and go back in, starting over making the ad. Then I uploaded 1 small photo - 58K. After that, I could drag and drop the others in. The site limits us to 1.46 MB of photo uploads. I use a free program to make "email" size copies of my photos to post online. Called Fotosizer. Fast and allows you to automatically create a series of unique filenames for the new copies.

-

Walking foot in good working condition. Was serviced about 18 months ago and has light use since then. Has the Consew CM-1000 servo motor with small pulley.. Motor has the "Slow-Down" mod to allow better low speed control. Note: Edge guide and lamp seen in photos are not included. Local Pickup only unless buyer arranges packaging and shipping. $725 OBO

-

How Do I Use A Two Prong Hand Spot Setter?

TomG replied to jv leather crafts's topic in How Do I Do That?

This is what I use now. Have the set of 4. I use it almost exactly as shown in the Tandy video. 1st, make 4 lines with a fine sharpie on each side of the sleeve, 90 degrees apart. This gives you 2 lines to line up with the legs of the spot when you push it into the sleeve. The one of the other lines is used to point towards yourself, assuring the legs all go in the same line. You will likely have to spread the spot legs slightly to hold in the sleeve. Put the leather on a piece of scrap and hit the tool, driving the spot through the leather. It may curve the legs a bit, but you can straighten those out next. When you get all the spots driven through, flip it over, make all legs tilt inward and set them with the domed part od the anvil. Then you can flatten them with the flat side of the anvil. Done.. Really quite easy once you try it.- 10 replies

-

- spot

- setter hand spots

-

(and 2 more)

Tagged with:

-

I'm moving this to the proper forum... I am making a tote bag like in the picture attached out of hair on leather. But the test piece I was playing with leads me to believe it will be a bit to floppy without some additional support. But I don't want it to be too visually intrusive, if that makes sense. Since this is my first try with hair on, and since it is the customers side, I only have 1 shot at this. Suggestions MORE than welcome Thanks