-

Posts

2,274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

Nice work. I have several from various individuals.

- 29 replies

-

Need help b/c OMTech support nonexistent

Ferg replied to JonesCoLeatherworks's topic in 3D Printers and Lasers

The beam from your testing position M1 to M2 is way off. I don't even consider checking with M2 close to M1. Extend the M2 location all the way towards opposite to Tube side. If you get that centered then M2 to M3 with same idea, move M3 mirror all the way to the right side. You also need to check the beam from the nozzle to the working level of your lens. The adjustments on the mirrors are very sensitive, don't get carried away and only loosen the stop nuts very small amount each time. Ferg -

Need help b/c OMTech support nonexistent

Ferg replied to JonesCoLeatherworks's topic in 3D Printers and Lasers

There has to be something wrong in the method of attempting to contact OM-Tech. Have owned my CO2 60W over two years now, have never had a problem with help. You need to provide some more info. What software are you using? Did you follow setup info? I use LightBurn software best there is. I am confused with what you are providing for settings. Are you using G-Code? Arduino control? My settings for cutting are 10mm/sec speed with , 45%power. I can cut 1/4" MDF veneered material in one pass. My simplest setup for engraving is 150mm/sec speed with 25% power. Need a lot more info from you please. Ferg -

Machine for making delrin stamp for leather

Ferg replied to luckystudio13's topic in 3D Printers and Lasers

If you haven't used and experienced Light Burn software you have missed the best product for laser engraving and cutting and it keeps getting better. Opinion from a dedicated user. -

Dwight, You may try this. I use "Ozium" neutralizer on my laser cut wood products. Available in most hardware stores in a small spray can. Ferg

-

Have you done a test pattern on some scrap? I am assuming you are using LightBurn software, if not please do yourself a favor and get it. There are test patterns to run along with directions for doing "Ramp Tests". Correct settings of your laser for the material, air assist if you are engraving or cutting with ample exhaust. When I engrave or cut a new type of product I run exhaustive tests at different speeds and power keeping a written note of those settings until I get what I want. Time consuming I agree, necessary, you bet! Begin with low power and speed settings adjusting one or the other to see any change. Visit the Lightburn Forum at https://lightburnsoftware.com Ferg

-

Yes, the bender and dies are still available. I am unable to respond via telephone due to hearing problems. E-mail is a must for me. I am in Southwest Ohio 45432. Please let me know if you wish to visit to see and possibly buy the items. Ferg

-

I used to do sublimation which I accomplished on white dear leather. I have posted a photo of same before. Also used a Laser Printer Mono color to make whatever image/text I wanted. You can print on the better quality of laser copy paper lay it on your leather or whatever you wish to use. With a household iron you can actually transfer the image to the substrate. No messing with all the other "stuff." Ferg

-

-

I used this on a Cowboy 3200. It is designated as Juki but it fits other machines also. $45.00 plus shipping.

-

Bonded Nylon Sewing Machine thread. One pound spools 1 white #92, 1 white #138, 1 white #207, 1 Scarlet red #138. $25 each or all four $90 plus shipping.

-

-

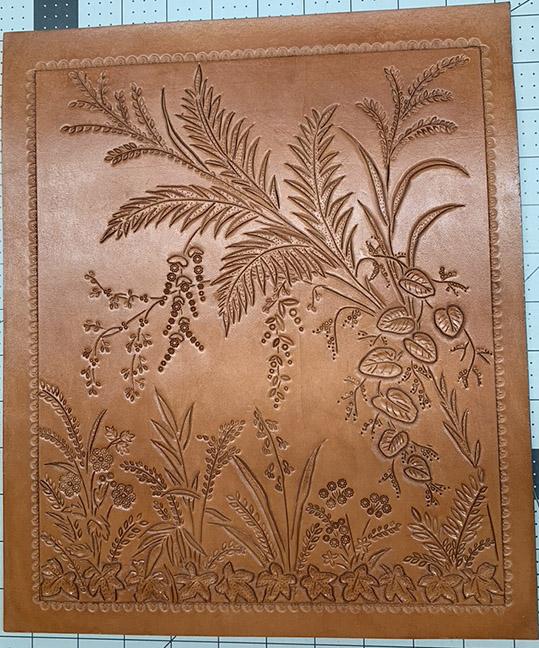

Probably 10 or 12 years ago I unearthed a piece of Veg Tan at least forty years old which meant it was bought from Tandy. I found a sketch in one of my art books that I decided to carve into that piece of leather. It wasn't dried out, stiff, or hard. I tempered it and carved this design. Stored under two other leather pieces I done about the same time. It has never been stored or displayed in daylight. Some day I will probably frame it and give it to my youngest daughter. Ferg

-

I wouldn't take the old ones without checking them over for possible mold or mildew. But Heck Yeah I would take them. Vintage sales! LOL Ferg

-

I am sorry, I posted the wrong selling price on this item. It should be $250 including shipping to continental USA. No Alaska shipping. They are Horse Shoe Brand. Ferg

-

The stamps have been sold. Ferg

-

I am presenting a set of five edge rounding tools numbering No1 through No5, made of stainless steel with hardwood handles. I don't remember who the manufacturer was I do know how much I paid for them.Emblem on them H S which may not mean a thing. Have never been used. Asking $250 plus shipping. Ferg

-

I have replied to this conversation personally. Anyone else need info on the items I am in the process of cataloging and photographing the items I wish to sell. I began my leather crafting when around nineteen years old while in the Navy. I am five months from being eighty nine years old/young. Believe me when I tell you with arthritis in both feet and ankles, spine, hands and fingers plus being deaf, life is a little fragile and totally exasperating. I would like to believe that working since I was eight years old and enjoying most every minute of it I can influence others with drive. Ferg

-

Due to escalating Arthritis and vision problems I am offering my Stamp set equaling 163 pieces. I bought a lot of these 60 to 75 years ago when Tandy's tools were made of good metal and chrome. There are several I bought from individuals who made stamps as a lifetime tool. I am asking for anyone possibly interested in these before I spend the time to catalog and photograph each one and price them either individually or as a complete set. My request may be a little unorthodox but please bear with me. I have large spools of sewing machine thread plus various and other tools for normal leather work as well as shoemaking. Also several boxes of hardware such as zippers, magnetic pieces etc. I am having a hard time letting go of the leather equipment and accessories. Any of you that have had the opportunity to spend a large part of your life with this hobby/business know what I am feeling. Ferg

-

A wee wallet

Ferg replied to GavinO's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

If I may make one suggestion. Make an open border around the edge of your product enclosing the stitching then do your basket weave or other inside the bordered area. Ferg -

You will likely think that I pushed the envelope this time but actually I didn’t. We have about 50 or 60 plants left from the greenhouse that I would like to plant with the least amount of preparation possible. Lowe’s had a plastic window box 35.75” x 6.6” on clearance for $3.19. Wife and I went to see if they actually had any. They were on the shelf with an original tag at $13.95. I went to the cashier in the garden center and told him they were advertised at $3.19 and asked him to check it for me. His info said the higher price but why didn’t I check at the service desk. Spoke to a lady at the service desk laying out the problem. She said her computer said $13.95. I showed her the page on my cell. It clearly said it was on clearance and only available in store. I told her I had become so dissatisfied with Lowe’s and some of their policies that I was going to stop shopping their stores. She agreed with me and said let me get a manager to speak with you. A man with the name “MAX” on his jacket appeared but was hesitant to come over to me and discuss the problem, she convinced him to speak with me. I should have known there was something up at that point in time. He was obviously agitated and didn’t really wish to speak to me. I showed him the page on my cell and went through the deal again. He said that isn’t our store. I said this page is from this Lowe’s and the price is stated as $3.19. He wasn’t going to honor it. I said, "You know Lowe’s is getting a reputation for being a bad place to shop”. He got crusty and told me if I didn’t leave the store he would have me thrown out! I laughed at him and said you have got to be kidding! I walked away and met up with wife and we left. After getting home and thinking about the episode for awhile, I believe he was standing somewhere very close to me while the lady I first spoke to was trying to help. He probably heard my conversation with her and was ready when I went to him for help on the matter. Obviously did not wish to discuss the matter of Lowe’s being Slip Shod. I wasn’t nasty to the lady or him certainly surprised by his wanting to throw me out of the store. I am still thinking about how I wish to approach this event with the home office. Lowe’s has definitely been getting worse with almost everything. No inventory when they say they have it, junky product, way overpriced, happening with many outlets not just Lowe’s. BTW: I checked the site when we got back to the car. The $3.19 clearance on the item had been removed with $13.95 inserted. It would have been nice to punch him in his round red face but I didn’t even think of it until later. LOL Wife and I have serious doubts about ever enjoying our lives as we used to. Ferg

-

I have at least one item I done a number of years ago on a piece of leather I had bought almost 50 years ago. I pull it out every once in awhile so I can see what I could do before all the Arthritis and other problems with being almost ninety years young. Nice work. Ferg

-

We have the fantastic ability in our Homestead to see many phenomenal things in Nature. The following video on YouTube is only 35 seconds in length. I sincerely believe any one of you will feel real special that you have witnessed this event, albeit second hand. Ferg

-

Thanks, Every day I turn the laser on I am amazed at what is possible. Have had a woodshop for over 70 years, I am 88 years young and taught myself to program our two head CNC beginning in the 80's. I am to this day amazed at what I can accomplish with the machine we paid close to $150,000 in 1986. Taught my kids to never look back. You can accomplish anything you put your mind to. Ferg

-

You have to remember my laser is a 60/50W. I probably have issues and differences in abilities that you do not have with your laser. Thanks for your outlining some of your experiences much appreciated. Ferg