-

Posts

2,274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

I agree. Italian leather is the tops. Only problem I have is after using it I have difficulty with some of what is tanned in the US. Ferg

-

I have a Cowboy CB 8810B I can sew two lines of stitching with my single needle that you would be hard pressed to know it wasn't two needle. Mine has top and bottom drive wheels. I have stitched within a Millimeter of the edge. I can only hope I really learn to use this machine. It is a "honey". Very quiet probably due to all the sealed roller bearings it has. Only a few spots to keep oiled. I sewed some 1/4" leather, (two pieces) the other day. Only thing you need to do is adjust the amount of down pressure on the upper drive wheel. Didn't try it with 138 thread. Had #40 on the machine set up for shoes . Size 12 needle had no problem with piercing the leather. Ferg

-

I haven't watched it completely. You are right, it is mesmerizing. I love to watch other craftsman with the skills he has. Ferg

-

I have no experience with an RB-1. I wouldn't trade my RB-5 for anything. Noisy? Never heard that before. When oiled properly, it sings to me every time I use it plus it has reverse. Ferg

-

Since I am older than most of you, eighty six in January 2020, I remember a lot of those things first hand. My only connection with the Prison System was a number of years ago. One in Southern Ohio made wood Pallets. They weren't getting them out fast enough so they were looking for a small wood shop to make the parts for the pallets. The material would be supplied by a prison farm sawmill and brought to our shop. The material would be Cottonwood. Grows where it can get lots of water and is obviously dripping with moisture. Later, they decided to supply "Junk" Treated material. When still wet from treatment this stuff can rust most any metal it is aligned with. We were very close to taking it on until I checked with some shops that were using the material. Ferg

-

I don't see your pic either. kJ is on the right track. You probably are not using the correct machine for the job. How many layers of what thickness material are you trying to stitch? Ferg

-

It is a great machine if it has been taken care of. $300 makes it worth looking at if you can, try it with some leather you will be using. I wouldn't trade mine for anything. Don't degrade it. That machine is equal to a CowBoy, Ferg

-

It was originally intended to be just a Data Base program I believe. I needed to count letters of different colors in personal names, it required one short line of code. Definitely not for everyone. It has gotten too expensive as most of the older software is these days. I just continue to use what I upgraded to several years ago. lol Ferg

-

You won't like my answer but this is a different twist to your question. I have used "FileMaker" since it's inception many years ago. Not free but if you wanted a program that will even talk to you. this is it. I have written every Data Base we have ever used with exception of the very first, using FM. Have written billing invoices with hundreds to thousand of entries that populate whatever I need. While it is automatically doing that everything is totaled for anytime I wish to access the info. It essentially does my taxes for me. I know, not the answer you were looking for......... Ferg

-

I know, I have been called more than crazy for having all the different use equipment I have gathered over my 70 years of questionable adult life. I am not counting the 16 years before I supposedly became an adult. LOL Try anything you wish. Some times that works, some times it doesn't. Ferg

-

I have the building, I have maybe $1000 in tooling and equipment, probably have four or five thousand dollars worth of dies for various and sundry items. I can make whatever I want at any time. I have a CNC two head router and write my own programs. Seems that is called convenience. Ferg

-

I have an old rejuvenated bender for steel rule. Don't get the idea that this is a piece of cake. High learning curve and expensive. I bought my bender at a good price, it weighs about 50 pounds. Dies are expensive and you need quite a few to make much of anything. Specialty router bits for cutting the grooves. A die cutter to cut accurately. Steel rule resists bending, Several thicknesses and widths available. I enjoy doing the dies, no intention of doing it for anyone but myself. Ferg

-

Kinda playing on Bob's business isn't he? Ferg

-

All I can say is...you haven't looked very hard. BTW: It is Toledo Industrial Sewing Machines, LLC Bob Kovar is one of the most honest dealers you will ever confront. I think my trip last Saturday to get another machine from him was either my fourth or fifth time buying from him and his son. Ferg

-

RYAN, I know mom and dad and your siblings are all very proud of you. First out of the bag, you are a fine Artist. My wife and youngest daughter fit that expression also. I can see very few problems. Having never taken on a Saddle project I don't know a lot about it. You done a fine job in my old eyes. Ferg

-

I believe your main problem is that you are wanting a machine to do two extremes. Sorry, but you need two machines. A flat bed that will handle #69 - #138, and a cylinder arm with an accessory flat bed table that will give you #92 - #207. #69 will be okay for most interiors of wallets and the like, you need to use minimum #92 for exteriors while #138 is better. Back packs and the like need at least #138. You utilize both machines in this endeavor. Sorry if that doesn't help your problem. Ferg

-

Some extra thoughts on your needs. I noticed you want to use the machine for making shoes. Your best bet for that is a "Post Bed" machine of at least 7" in height. Same machine is good for making bags among other of similar builds. The Cowboy post bed: Post height: 7" Gear Driven Top Feed Roller Foot Gear Driven Bottom Feed Roller Feed Needle Feed Maximum Roller Foot Lift: 7/16" Max Sewn Thickness: 5/16"+ At least two machines with different capabilities I think is ideal, the post bed if you wish to do the above, or a cylinder bed with the addition of an accessory flat table. I don't like needle feed machines. Cowboy 3200 will not handle thin leather well, it is a walking foot cylinder bed. I have a Consew flatbed, walking foot I wouldn't trade if my life depended on it. I am not familiar enough with other cylinder beds to give good information. I imagine my info will either help or confuse the situation for your even more. Lol Ferg

- 11 replies

-

- leather sewing machine

- 1-4 oz leather

-

(and 2 more)

Tagged with:

-

HideGear English Bridle Leather briefcase

Ferg replied to aaronthearcher's topic in Satchels, Luggage and Briefcases

Bell Skiver won't skive more that 1 3/4" and maybe 2". Most gussets are wider than that, with some exceptions of course. You can run them through again by turning the leather around, it doesn't work well very often. Lot of money when you would be better off getting a skiver that is intended for your use. Ferg- 7 replies

-

- briefcase

- english bridle

-

(and 2 more)

Tagged with:

-

HideGear English Bridle Leather briefcase

Ferg replied to aaronthearcher's topic in Satchels, Luggage and Briefcases

I think you should rethink a Bell skiver if you are intending to skive purse etc. gussets Ferg- 7 replies

-

- briefcase

- english bridle

-

(and 2 more)

Tagged with:

-

I wish to sell my Singer 29-4 complete with custom built stand and Servo Motor. Machine is in excellent working order, has been refurbished and painted. Will stitch up to seven or eight spi depending on material. I will sell the head only for $850.00. Complete set-up $1100.00 Ferg

-

Anyone selling a Skiving machine (Fortuna, Nippy)?

Ferg replied to mason1800's topic in Leather Machinery

mason1800, I will consider selling my Cowboy skiver, top and bottom feed. Have used it for all types of leather. I have found when you decide to use it for mostly chrome tanned for instance, you learn to use the machine for that leather type. Ferg -

Thought I should place the SHOES in a different topic. Haven't had a lot of time to work on wife's shoes. The tornado that swept through our area Memorial Day contributing to several large trees going down in our woods. We really don't need all the wood plus thousands of trees were blown down or damaged severely leaving many families with fire wood they cannot get rid of. Photo shows the Insoles attached and fitted but not trimmed. Wet them for a few minutes so they would work and fit around the bottom of the Last. Will let them dry for a couple days. Patterns, Uppers, Liners etc. in foreground. Insoles are of 10 oz to 12 oz cow hide. Reinforcement leather for behind the lace holes is calf skin 3 oz to 4 oz. Uppers are of that leather also. Lining is Kid Skin soft and velvety on one side. I have com-chawed a Domestic Singer one daughter left at our house. It will sew thin leathers but I won't use it much since the motor simply will not take the beating. Have never used any thread smaller than "69", it looks like rope in fine stitching. Have ordered some "40". My Consew won't sew more than 10 stitches per inch. Shoemakers sew up to 15 or 16 spi, a few use finer stitches than that. This is in the uppers only. I will stitch the Soles by hand with waxed thread that is rather heavy. Had difficulty finding much info on how to attach the lining. Decided that some areas need to be glued while others will be stitched on one edge. I spend 75% of my time reading and doing research, the remainder to the work at hand. For those of you considering a "Jump" into shoe making, read everything you can find especially if you don't have the time or money to take classes. Folks on this forum have much more experience at this than I do. I AM HAVING A BLAST! Ferg

-

YES, both doctors she has gone to were Podiatrists. First one disappeared, he made/had made the insert. It definitely helped for awhile but like everything else they wear out. Surgery is not out of the question. I realize orthotics are not always the answer. No harm in seeing what I can accomplish with building her a pair of shoes though, Right? Thanks for your communication. Much appreciated. Ferg

-

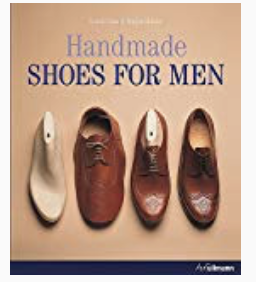

BOOKS: Pattern Cutting Step by Step, patterns for footwear by Frank Jones. He rewrote the book in 2008 to bring it up to date plus adding some additional info. Definitely the best book for detail and exact drawings that I have. Obviously it is for making patterns for shoes. BESPOKE SHOEMAKING: A comprehensive guide to handmade footwear by Tim Skyrme. Tim's book has a boat load of information. Illustrations leave something to be desired. Marcell Mrsan: Brilliant shoemaker. He is Bavarian, at least semi-retired. Resides in Savannah, Georgia I presume. Hundreds of videos on the Net. Very articulate and definitely knows what he's talking about. Marcell's Web-Site: www.cordwainertools.com. I have his STANDARD FOOTWARE PATTERN RULER. A video showing how to use the "Ruler" is on this site. https://vimeo.com/ondemand/shoemakingtutorials/332899515?autoplay=1 I found the Ruler very complicated as are most things pertaining to true shoe making. After using it to make the drawings for wife's shoes I am flabbergasted at the knowledge it took to devise the multitude of things you can do with it. I used it along with Pattern Cutting book. Also have: This book is very interesting read. Doesn't go into detail as to making shoes. BTW: Decided I didn't like the design of the uppers for wife's shoes. Changing a few things, not the main style though. Parts just didn't seem quite right. Ferg

-

I told her you would like to see photos of her feet. She said she didn't have any problem with it since it would be helping someone else. Thanks a million for your "Notes". I will place a copy in the "Shoe" folder. lol The only thing we have left from her foot doctor is the Insole he made for her a couple years ago. I have the metal for making a jig to hold the last with uppers when I am ready to attach the outer sole. Also making a couple other tools. Scrapped most of my design for the shoe earlier today. Just didn't look right. Been using some scrap leather I have had for some time in making this Throw Away. Will send some photos as I get a little further along. Ferg