-

Posts

208 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gigi

-

I once saw a demonstration of this machine sewing through Plywood: Dürkopp Adler 969. Really impressive!

-

Making a circle bag

gigi replied to Hahn's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Awesome work again!! Thanks for sharing -

Few more ideas on this topic:

- 23 replies

-

- skiving

- skiving knife

-

(and 1 more)

Tagged with:

-

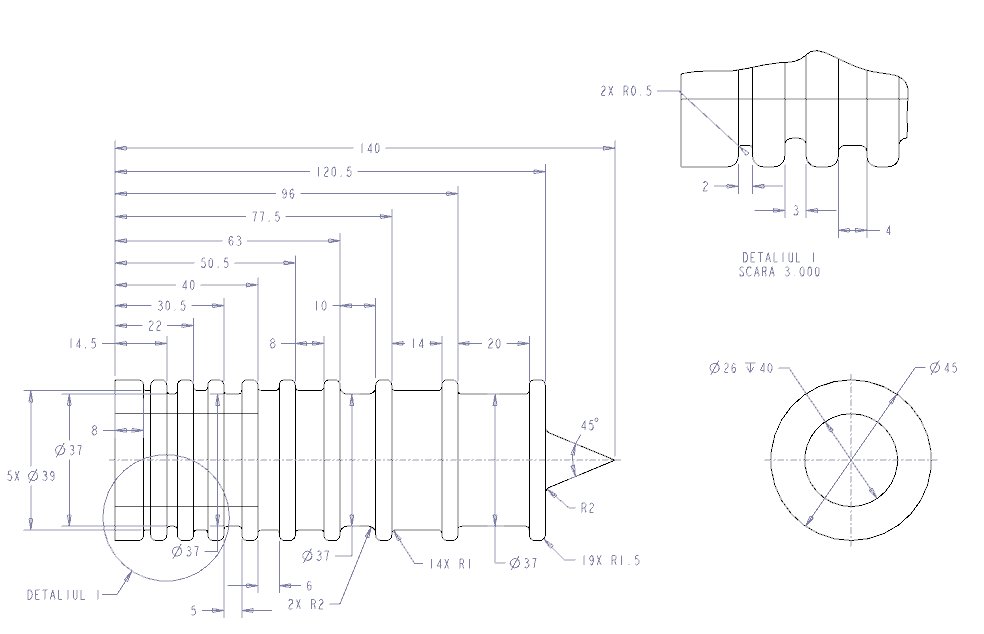

I've also made a sketch for a burnisher a while ago, with different type of grooves, bought the wood but never completed this project so I don't know how good it works :

-

Anything matters with thin leathers: most important - Is the knife sharp enough? Is the presser foot polished and has good geometry? Adjusting the tension for the driving wheel might help: softer tension for softer leathers. I don't think is necessary to adjust the pressure-foot height for each side (unless you don't mind small variations in thickness for each skived side).

-

I am not sure if I understood correctly: you skive one side of the square (for example from 2 mm to 1.6 mm final thickness) and flip over the leather (flesh side up) and want to skive the back of the same square-side (for example from 1.6 to 1.2 mm)? parallel skive or angled (beveled)?

-

Very well done with the spacing to allow removing the bobbins! Maybe can add a magnetic plate underneath the box to hold them in place when you accidentally flip over the case? One more design idea (Constabulary's idea) with a magnetic tool holder on the bottom:

-

Patterning the old way when the CAD is just too hard

gigi replied to RockyAussie's topic in How Do I Do That?

Thank you very much Brian for posting the tutorial and for the value you add to this forum!!- 40 replies

-

- crocodile cross body bag

- pattern making

-

(and 1 more)

Tagged with:

-

A video showing how the Italian leather boxes are made:

-

Pfaff 335 BB (older model) experience?

gigi replied to plinkercases's topic in Leather Sewing Machines

I think Pfaff 335-17 is a binding machine subclass (so the machine was originally a binding machine). Quote from the instruction book for the 335 old casting: 'The operational instructions given in this booklet pertain not only to the ordinary Pfaff 335-17 binding machine, but also to all other subclass varieties. The individual subclasses are fitted to suit different operational requirements. The various subclass organizations differ only in the type of rigid or swing-away binder or tape guide mounted on the feed-synchronized attachment bracket. An exception are the Pfaff 335-9, -09, and -09-33 which are specially designed for portfolio work and have a rigid tape guide mounted on the cylinder arm. The Pfaff 335-332 X 251 occupies a special position in that it is fitted with upper feed acceleration control rather than ordinary unison feed ' -

Pfaff 335 BB (older model) experience?

gigi replied to plinkercases's topic in Leather Sewing Machines

Congratulations! Those are great machines, I also have a Pfaff 335 old casting, mine is 17B H2L. I find useful the binding attachments, flat bed attachment, drop down guide. -

Pfaff 335 BB (older model) experience?

gigi replied to plinkercases's topic in Leather Sewing Machines

-

2 New Belts Finished

gigi replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice! How do you trace the sewing pattern? How do you prevent presser foot marks on the leather when sewing? Thanks! -

I am also curious (those LOXX seem very useful for handbags) so I just called the contact person Erika (+49 2324 - 9049 - 130) she is speaking English and is very helpful. She said they have requests for full brass LOXX: if enough people are interested in this they are willing to start producing them to be on the market in a few months. I understood they already made some full brass pieces, but are not yet included in the catalog. You can try calling her.

-

That's the page where they list the distributors: https://www.loxx-products.com/live/dealer-distributors/distributors.aspx (one of them is https://www.decocuir.com in France) and the contact page: https://www.loxx-products.com/live/contact-person/contact-person.aspx First time I've seen those LOXX fasteners was on a Textile fair in Dortmund Germany a couple of years ago.

-

Honestly, even if I know the circumference and number of impressions, chances are: I will not stamp perfectly. If the stamp is for example rectangular and two corners of the the stamp are resting on the circle line: that way the alignment will be better, I think. I usually stamp until I get closer to the end of the circle, and then I estimate if the last impressions should be a bit more spaced.

-

Below is the formula for the length of a chord. Given the stamp length (=length of the cord) and the angle (depending on how many stamps you apply ). You just need to extract the radius of your circle from the formula bellow:

-

Are you from Germany? ('Satten' sounds a bit like 'Sattel' = Saddle in German. Satten and Dorn are also German words. Attendorn is a town in Germany)

-

Recent Builds

gigi replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice work!! Excellent edge finishing, dyeing, stitching and wet-forming. High quality leather. Are you using vacuum forming? -

I use a wet sponge for casing the grain side of the leather (not a lot of water like for wet moulding). I always case the whole surface otherwise spots remains (if you only wet a carving area). Drying takes longer for the carved area. Largest items I've done like this are handbags, belts.

-

Prior to casing I apply transparent packing tape on the flesh side of the leather (before any stamping). I remove it after dyeing the project.

-

Thanks for the feedback, I will order an oval hole punch.

- 10 replies

-

Thank you! The belt width is 1 1/2'', made from 9 oz vegtan. Needle size: Nm 120/19 It is a 134-35 LR needle system, 'Gebedur' from Groz-Beckert. I prefer titanium coated needles because they slide better through many layers of leather, padding and glue. And they don't break as easy as the normal ones.

- 10 replies

-

I've decided to make a vegtan belt using some old Eco-Flo products for dyeing and finishing. It is machine stitched, using metric 20 polyester thread; lined with pigskin; stainless steel buckle; briar brown gel antique color; lightly oiled with neatsfoot oil; Giardini edge-paint.

- 10 replies

-

I've noticed the Dense one is very thick and it dries up too fast in the small plastic bottle cap where I put a bit of paint. I like the fact it dries fast on the leather though. Maybe I am too slow in applying the paint So I'm using the semi-dense one, with light sanding, 1 or 2 coats but I've noticed a big difference makes the colorless Extra Matte Topcoat, smoothing everything.