-

Posts

4,409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bruce johnson

-

Looks good on my phone! Thanks Johanna!!!!!

-

I have been updating a recently combined "Resources" section on my website for the last month. It will be a work in progress that I hope you find helpful. https://brucejohnsonleather.com/links-resources - Tool Talk is kind of a blog section - tool selection, tool care, trouble shooting, and announcements/thoughts/mild opinions - Tutorials - These are PDF tutorials I created to address some common questions and tips for using specific tools - Catalogs - I have PDF downloads on this section of older leather tool maker and supplier catalogs - Leather Tool Maker history - this is thumbnail sketch section of some of the leather tool makers of the past - Links for Leather workers - magazines, forums (like Leatherworker.net!), and videos/podcasts that are no cost or by subscription Please check it out and suggestions for more content are always welcome. Thank you! - Bruce

-

Good people to deal with.

-

-

Randy, I don't have a real horse in this race since I sell and have used both. You can get more pressure with control using a push beveler than a bevel blade. You can lay over it and lean into it. With the swivel knife - you get hand pressure and it can get tiring for deeper beveling on long runs. Long straight runs - push beveler. Shorter areas, lighter beveling, or larger curves on stemwork - swivel knife bevel blade.

-

By the construction early to mid 1800s. Steel is usually hard and can be brittle. Without a clear marking the value is pretty much as a user.

-

There have been two books written about tool makers in Newark. There were a bunch as billybop noted. If you could give us a picture of the whole knife that might help narrow it down some. I have never seen an Osborne knife that was size marked, but some earlier makers marked with numbers. A picture would also help establish a value too.

-

NEW - Resources Section on my website

bruce johnson replied to bruce johnson's topic in Leatherwork Conversation

Thank you Tom. This resource section has been a work in progress and still more to come. I have had more suggestions and links sent to me overnight. It is a fun deal for me! -

The two major parts suppliers I am aware of in the US for these have closed down. I would recommend Montana Leather. When we are through there I usually pick up a cutting or feed wheel or two I need for an upcoming refurbishing project. Patrick is the one I chat it up with when we stop - https://www.montanaleather.com/

-

More great work! You need to get back here for a show sometime!

-

Tonight we are going live with a new section on my website. The umbrella is resources and has 5 pages under that. - Blog - short common question answers about tools, insights into whatever grabs me that is leather related, and information/announcements - Tutorials - this page has more in-depth readable and downloads for PDF files for tool use and care - Historical Catalogs and Information - PDF files of old leather tool maker catalogs and historical paper - Tool Maker History and Information - short information on many early leather tool makers - Leatherworker Links - this page has links to current information sources for leather workers - Magazines, Websites and Forums (like here!), and Video links for YouTube channels that I and others have found helpful. Here is the link to the header section - https://brucejohnsonleather.com/links-resources If there are other resources you would suggest, please let me know! Thank you - Bruce

-

A coat or two of the thin to somewhat seal the surface, let it dry. Then thick body CA. I have only used this for bonding smaller pieces of leather to a non-leather surface. I have not bonded two pieces of leather together with CA. There are other adhesives that work more predictably for that.

-

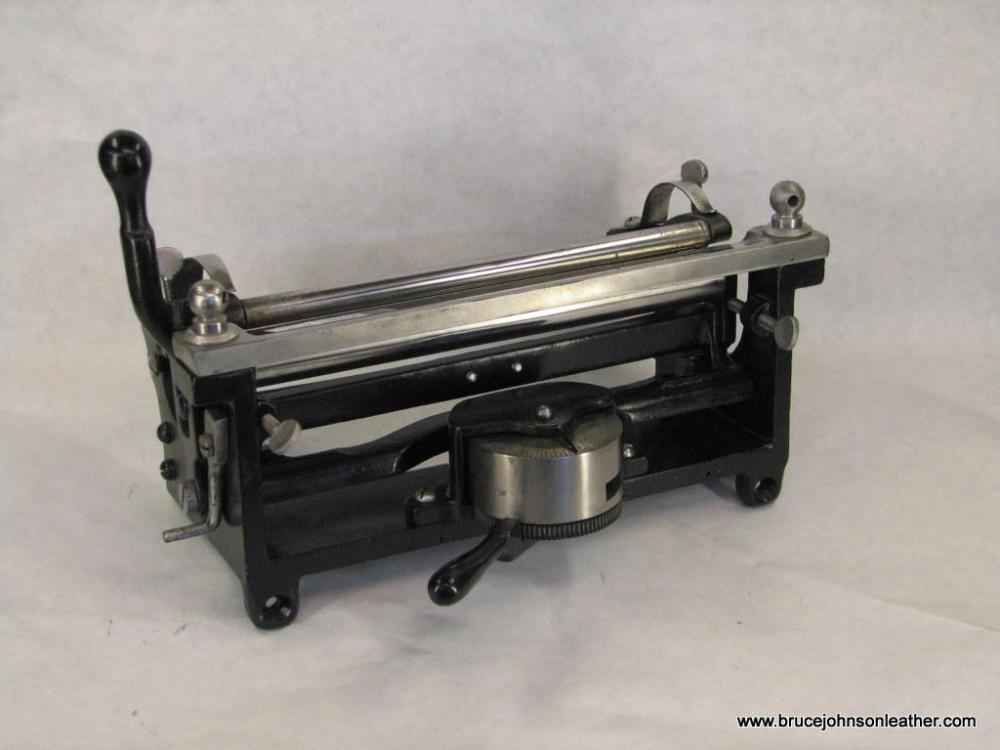

The splitter looks to be an original JD Randall. The hex handle and slot with set screw for the hold down was their pattern. If there is a tag anywhere or marking on the blade - Cleaned up - $700. If no marking then less

-

I agree with FredK on this 100%. Will also add this- Grooving helps to keep your stitches below the surface but also gives you a target to sew into. I don't care if you are machine or handsewing, that grooved line helps line up your awl if you handsewing or your needle on machine sewing. Scratch lines from a divider are not as obvious. No lines and unless you are an elite stitcher, it can look like a cow trail when you sight down the line. That strength issue is a non-factor. People claim that the strength is in the grain and you weaken that. If the flesh side is not much of factor how come we make saddles and belts from heavier leather than wallets? Take the thread of grain you groove off. Pull it apart between two fingers. Decide for yourself if that will make the difference between holding your work together or not. I'm voting with Fred also - buy a good groover. There are a few options out there - Barry King, some (not all) from Amazon, Horse Shoe Brand Tools has a compass style groover. I am bringing on a handled style I really like soon and am putting the final polish on the tips in the next few days.

-

If you want a straight up comparison of the Toro vs 26, call Leather Machine Co. Dave and Vince at Leather Machine Co both used to work for Artisan. I have no experience with the latest owners at Artisan but have a long running relationship with Steve and now Dave and Vince that all worked at Artisan before they started Leather Machine CO.

-

Krebs pattern CS Osborn #85 leather splitter rehab

bruce johnson replied to Zawlard's topic in Leather Machinery

The small lever Is to hold the roller forward. Push forward on the large handle and you can flip the small lever end in behind it to hold it open and feed your leather in. The broken spring - common place for them to break, that is why ShopTalk magazine used to sell replacement top and front springs and large handles because they were the most broken parts on a Krebs and the previous owner restored some. It will probably function just fine like it is as a user. Finding a replacement spring? Hard. Before somebody says "have one made" - The tension has to be just right - too soft and the roller will move forward and get uneven splits, Too hard and you will have hell opening it and you may say bad words if the handle breaks just above the pivot bolt. It happens. As far as cleaning it up, you will not destroy any value on most leather tools and bench machines. The only time I have ever had customers want anything "as-found rustic" was to hang on a wall for decor or photo and video props. One guy told me when he ordered a Krebs - "I don't want it to look like I stole it off the wall at Cracker Barrel". I've probably done 25-30 of them. I take them totally down to parts and blast them, inspect closely for stress cracks, then prime and paint. I just blast that loose chrome off the drum and paint it. Hardest thing on a Krebs is usually the lever on the adjustment drum. There is a little set screw in there that can take work getting out and then setting it back seated into the depression when you reassemble. When you loosen the lever the clicker and spring can sometimes go flying out - be ready with a towel wrapped around most of it to catch it when you work that lever down and out. They clean up really nice and worth the effort. I've attached pictures of a couple I have done. -

I'm glad to announce that Bruce Johnson Leather Tools LLC is now selling new Y-Knot Lace tools to go along with the Wayne Jueschke lace cutter we had sold for while now as well. These are nice lace cutting and processing tools in a few different styles. I've got experience with all of these from work in the past, and am glad to be able to carry them now in our inventory. Please check them out at https://brucejohnsonleather.com/products/braiding-and-lacing-tools/lace-cutters Thank You! - Bruce

-

Great job and clean work! I have a soft spot for Randall sheaths. Right now I am in a limited advisory role in the leather shop and most of the after-work time is spent in the tool shop. Once I retire from the day job then I plan do a few fun projects besides tools. A sheath for my Randall 1-7 is probably first up.

-

If you are machine sewing and it gets closer to the core, some threads can really have tight memory. Lay the spool on its side and let it unroll like a level wind fishing reel. My old pal used to sew off all his thread spools that way on closed eye needle machines.

-

Good books on making designs for leather carving?

bruce johnson replied to DaleksInc's topic in How Do I Do That?

Besides the folks already mentioned - Sheridan Style Leather Carving book - Clint Fay, Bill Gardner, and others, Creating Western Floral Designs - Bob Park Chan Gear pattern packs I'm forgetting a bunch but this will get you started -

Coming up on 39 years experience from doing my own crappy repairs to hobby/small income side deal to a full time custom/production side gig to refurbisher and seller of old and new tools. I had a series of articles in ShopTalk magazine (now Illume) about upgrading from entry level tools. Here are some points that don't overlap those much. Machines - The first stitcher I bought was a Boss. About 25 years they were $1600 with the basics, anything that sewed with power was over $5K. You can make a manual stitcher like that work and pay for itself. For about $1000 or so more - I'd consider the Cobra 26 from Leather Machine Co. Pretty darn versatile and good support. We have a 1245 and Ferdco 2000, had a singer 17, and my wife got a 26 at Prescott. She loves that machine. Belts, bags, whatever - it will do it. Clickers and cutting machines - a lot of the same thing? OK. Dies are not cheap but can pay for themselves if you are semi-production or more. You can use steel plates and LDPE cutting boards in a shop press to get started instead of a clicker and save that money for dies. Did it for years until I got a Weaver hand clicker in a shop buyout. Rundi still uses the shop press one a lot. Splitters - I joke with people that reason I know enough about different splitters is that I didn't know much about the differences and bought several over the years - none will do everything and they all will do something. I've had the $50 utility knife blade versions and the 18" Randalls through here. I've got favorites for different things. There is a tutorial on my website comparing different styles of splitters. Cutting tools - Good knives, cutting surfaces, and a sharpening system that gives good results and you can use reliably. Otherwise disposable blade versions of some variety. The self healing mats are OK for roller knives like the Olfa for soft leather. Use a straight blade and it will drag like a square wheel lead sled, then pop out of the mat at the worst time and you will say bad words. Cut on HDPE/Punch on LDPE. both are readily available and pretty inexpensive. For strap cutters - again a tutorial on my website comparing them. Punches - don't expect them to be sharp out of the box from most sellers. The best ones will maintain an edge longer if you stamp into the right material (sole material or LDPE) but eventually they will need to be sharpened. Stamping - Realistically - start with a solid base like a heavy built bench. You don't want flex or bounce and then you want to put something with some mass on that. People will tell you that free sink cutouts are fine. If it works for them great. Once I got a messed up headstone, it was a world of difference. I would never go back at that point. Granite inspection plates are a good option too. They don't have to be perfect and tight tolerances. Grizzly and other places have some that are more than adequate. When I built my bench I inlaid a Grizzly plate. People that try stamps out here can't believe the difference that a stamp rock makes. Next would be a good maul or mallet. Doesn't have to mean expensive - just fits and stays put in your hand and has the weight and feel that is comfortable. Stamps - I sell $5 stamps and $350 stamps. There is a quality/price point for them and everybody has different expectations. You can use some stamps like smooth shaders or bevelers forever. You can't fudge a basket stamp that is flat and not much contour. I tell people after you have made about 10,000 impressions with a basket stamp - the cost per impression is essentially nothing between a $5 basket and $50 basket, but the quality of your work has been different all along. Pick the set stamp stamping tools you use that will make a difference with impressions first. I made a lot of money with a cam border and a #500 Craftool basket stamp - good impressions from that particular stamp. Edgers - there are a bunch of choices in makers, styles, and quality. Some people just want corners knocked off and some want a 180 degree arc on the edge. There are no blanket recommendations for sizes. Size numbers and styles vary between makers. I've got favorite styles in vintage and new makers. Having a style that is easy for you to sharpen and maintain is the key. Again that pesky cost vs expectations raises up. People that know my story will understand. One of the best days in my shop was several years ago. I finished a full floral rope bag and was looking at it in the box. Start to finish, everything used on it from cutting to applying finish was appropriate. I did not have to improvise or fudge once. I was on the "pay as you go plan". Every tool and machine had been paid for with previous work.

-

Those look really good Tom!

-

That picture is from my current website. Please don't throw the baby out with the bathwater here regarding webp pictures. Eight months ago I had never heard of webp. Much as I didn't like to change initially, I was backed into using webp pictures with my new website. The old site was built on a platform version that passed support after 8 or 9 years and the new site had to built from scratch on a new platform. With a 1000+ pictures/files on my site and constant expansion in inventory the webhost said he could not carry my site anymore unless we drastically cut it down. It quadrupled in bandwidth since the start (BTW - thanks to all who made that happen!). Less pictures wasn't an option for me. He said webp was basically our best option to continue on. A typical jpeg used on the last site version was around 400 kb, the same picture in webp is about 50 kb. That is a huge difference in server space multiplied out. It was an acceptable trade off for me to have a site that works for my business. The bigger plus is that I still get support from the same web designer/webhost/business advisor I have established a relationship with for years. I was not relishing time away from shop stuff to stare at a screen though. For a few weeks after Sheridan I was doing nothing but converting pictures from jpeg to webp and then having to recaption them as well. Interestingly enough, I am seeing more webp pictures now in my downloads from other sites I frequent, especially the big time on-line suppliers. I can't find anything on the front side here as to what formats are supported for pictures. This may be something we need to address. Other than the string bleeders, there are some other options for bleed knots in general. Some people use chisels, some use a flat blade knife, Some use end nippers. They all work but the advantage of the string bleeder is because of the large cross section on blade, the hole stays open a bit to feed the tag end through. Making bleed knots in 1.5 inch leather is going to come down to a chisel or slot punch/bag punch as the choice for the best and cleanest results. What length to use will depend on the temper of the leather and how easily it will spread and "roll". It will take some trial and error to figure the length of the slit and make it look good.

-

You can say their names. Vince and David are two of the real bright spots in the entire leather industry. They are the first people and usually the last I see at any leather show. They come early to supply whatever machines are needed for classes at the shows besides being venders. They weren't in business yet when I bought my first machines, but were sure the only consideration when I bought the last three. BTW, Vincent is the king of sewing machine Jenga. While I was packing my booth he and a helper broke down the three machines and had the machine heads, stand parts, and parts boxes interlocked in the back seat of my truck with no rattling for 700 miles of rough highway.

- 7 replies

-

- customer service

- cobra4

-

(and 2 more)

Tagged with:

-

What type of Edge beveler do you use?

bruce johnson replied to Yukonrookie's topic in How Do I Do That?

Yes he does. The Ron's Montana edgers have narrower toes, cut a rounded profile, and good for thinner leather. Five sizes and we stock and sell them all. I also have the Ron's round edgers that are designed for heavier leather in a few sizes. I started off with the sizes a shop needs at a minimum and will be adding more sizes of the round edgers as he gets them finished.