-

Posts

5,764 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I know thats why I bought it (+ the heavy fly wheel). If it was a plain 16K straight stitcher I wouldn't have bought it. Not even for parts. But this one is quite special. Well, it´s a SV machine. -

well first of all that yellow thingy is quite annoying and disturbing - don´t what it is and why you shoot the Video with it. Also, seems you have no needle plate / throat plate on the machine - the machine will not sew properly w/o a needle plate / throat plate. Please post pictures of your machine so we can try to see if some other parts are missing.

- 13 replies

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Honestly - rather not because I don´t know what to do with it. I have no use but it is a nice and rare machine. I will revitalize it and then see what to do with it. Maybe I´ll keep it then and paint it purple with gray flower design - or the other way around No - really no idea... I bought it right out of curiosity. I have 132K6 and 111G156 so there is no gap this machine could fill. So.... ATM I just wanted to share pictures and as much information as I can get just for the case someone else will find a machine like this. I´m already checking for information and similar machines or different machine that could share parts. So far not much success - as usual on SV machines. But I figured the long beak shuttle is a bit different compared with the Class 17 shuttle. Its not the same as it seems. -

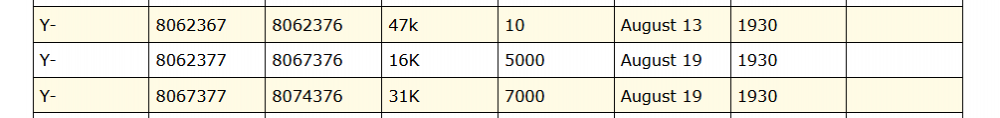

On my last road trip (before visiting the former Singer factory) I picked up a Singer 16KSV11 machine. When I bought it I already knew I have no use for it but could not resist -> Vintage Singer industrial machines and in this case another SV machine made me weak So here is is - yet not touched or test sewn. Interesting features are the jump foot, the very heavy fly wheel and a long beak shuttle similar to the Singer 17 shuttles. Table plate is badly worm eaten. Built in 1930 as it seems. Some pictures

-

Yes, former East Germany (GDR). Well Veritas was the brand name, it´s well possible that other sewing machine manufacturers used Veritas as a model name too. Unfortunately not. But in the exhibition they had some pictures of the clockwork. Not sure if the pics are online available. They BTW have approx 20 domestic machines in their exhibition (mainly Singer domestic machines and some Veritas), 2 TEXTIMA industrial machines (Textima 17 and 31 - which are the same as the Singer 17K and 31K) but I did not take pics because I`m not really interested in domestic machines. During WWII Singer Wittenberge still produced sewing machines as well as artillery shells and maybe other armaments. Durkopp did that as well. Imagine that - Singer USA produced weapons in WWII (like the .45 Mod. 1911) for fighting the Germans and Singer Germany produces Artillery shells for fighting the Allied troops. Crazy! But what could Singer USA / Singer UK do at that time - not much I think. However - finally Europe and Germany have been liberated - fortunately!!! And I´m still grateful for that! Story goes that the Singer plant was not bombed whereas the City of Wittenberge got bombed as well as a factory right on the other side of the Elbe river in direct view of the Singer factory - if that is true - I don´t know. Not sure if they were able to drop bomb that princely in WWII. After WWII (from mid 1950´s onward) Singer produced sewing machines in Karlsruhe (West Germany) where they took over the Haid & Neu sewing machine factory. Thats where the "G" Models came from (like 111G156, 212G141, 307G2 and the like) They closed in 1982 - sadly! Not all of them but approx 40 Co´s found their space in this facility as well as a school and I hope they will restore the unused buildings as well. Yeah - I really like these old brick building very much! Sadly the plant in Kilbowie, UK has been demolished. Or does someone know if some of the buildings have survived? How is it in Elisabeth, NJ - all demolished? I just found this Video - looks small , right? I´m pretty sure there where more buildings back then.

-

On my last weekend road trip I had the chance to visit the "Clock Tower" of the former Singer Factory in Wittenberge. I just wanted to see the clock tower because I thought it was the last remaining piece / building of the former Singer factory. I had no idea that A LOT of the original buildings are still present. I honestly though they teared it down in the early 1990´s. The buildings are still in use. Several smaller and larger Co.´s have rooms in there. The whole facility is now called VERITAS PARK named after the last sewing machine factory VERITAS. Why VERITAS and not Singer? Well, the Russians disassembled the Singer plant and took the machiens to Russia as war reparations but they never set up the factory again (they were not able to I have been told). After WWII Wittenberge was in the "Soviet Zone" behind the iron curtain so out of reach for the Singer Co.. After WWII they (not Singer of course) first produced under the name TEXTIMA for a while (until 1955 afaik) and later it has been renamed to VERITAS. I had ~2 hrs guided tour and took some pictures. I don´t want to tell the history here, I just wanted to share some pictures because I really was impressed of what is still there. Hope you like it

-

Check with a industrial sewing machine dealer - maybe Keysew in PA or Toledo Sewing Machines in OH. Needle screw should be the same as for the Singer 111 - for the other screw I would tab a new thread and add a common screw if you can´t find the original screw.

-

Thread tangling around the needle...

Constabulary replied to Dantan's topic in Leather Sewing Machines

I agree! This could be the problem if the thread isn´t the problem. The check spring should hold the thread under "tension" until the needle touches the material (+/- a little bit) so it may depend on the material thickens you are sewing how to set the check spring. -

Not exactly sure what you mean. With: "interferes with" you mean inner foot touching the outer foot. Probably foot bars are not properly adjusted / centered? If well centered and it is just slightly touching you probably can grind down the feet a little bit. Can you post pictures or a video?

-

yeah - to me it looks like based on the Singer 300W but too many variants out there to know all details: https://www.google.com/search?q=singer+300w+long+arm+sewing&source=lnms&tbm=isch&sa=X&ved=0ahUKEwiVnYzS6r3kAhUH6KQKHUVsBjIQ_AUIEygC&biw=1280&bih=869

-

What machine do you have? The one in the picture seems to be a Pfaff double needle walking foot machine with tape guide. What you are looking for is called GAUGE SET and depends on your type of machine and tape width / needle distance Maybe these folks have what yuo need: http://www.khsew.com/index.php?route=product/category&path=208_209

-

its not a Durkopp - its a Singer - guess how I know Looks like a 29-1 or so - there should be a oval data plate on the right side. Worth? Between 50 and 500 - depends on condition, accessories, stitch length, machine stand, has it a motor or not and your local market. However from this picture it looks like an unloved barn find. If you want to upload multiple pictures you have to reduce the size.

- 13 replies

-

- information

- pricing

-

(and 1 more)

Tagged with:

-

a few more & larger / close up pictures would be nice. From what I see I would guess it is a 5 needle chain stitch machine. Probably something Singer 300w 'ish

-

The 45K89 is a jump foot machine - drop feed presser feet do not work for this machine

- 18 replies

-

Singer (to my best knowledge) only equipped their 45K machines with a very simple flip type bobbin winder. However - they are very hard to find as spares up to nearly unobtainable. But I have seen one on Etsy for crazy money https://www.etsy.com/de/listing/622230555/sanger-45k-industrie-nahmaschine-spule Not worth the money in my opinion but if you are in need of these parts you probably have to pay the price. What I have is a spare automatic bobbin winder from a CLAES machine but it is lacking the mounting base so thats what you have to DIY. Its not a too big task but depends on your DIY skills and if you have the tools. I´m using one of these winders for my DIY electric bobbin winder. Maybe a solution for you. Here are some pictures of the actual winder I could offer you. last pic shows a similar one mounted to a machine. So basically you have to make a sturdy L-shaped bracket for the winder for fit your machine. And you may need some sort of thread guide on top of your machine which guides the thread to the bobbin winder.

- 18 replies

-

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thanks a lot Glenn. Parts update: These screws for the needle plates also work for the early 51W. Stocking a few spare screws can´t be wrong https://www.ebay.de/itm/143152157578 -

45K´s are very forgiving machines - I have restored one thats came in a lot of machines that were used as garden decorations for some years. It was rusty and has been brushed with black paint again but after cleaning it thoroughly it turned out as a really nice machine and tolerances are still very tight! If you need new slide plate (left of needle plate) and mounting plate (right of needle plate) the ones from the Singer 132K are the same and can be found at College Sewing - JFTC they are badly rusted. https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-132b-132k-133k-parts I also still have a bunch of 45K parts from my restorations so if you need something drop me a note. EDIT: I would not necessarily dunk the whole in Diesel first. If the mechanics is seized I would drip some solvent (maybe diesel but I prefer paint thinner) in oil holes and mechanical parts. Also a tub of hot washing soda solution also may free the machines (not kidding it worked for me) and also solvates old gun too (old gunk on sewing machines prats that looks like rust often is just dried oil / grease and dirt) If you want to remove the external paint and rust I would try electrolysis (DIY) Electrolysis also may break free the mechanics and you can re-use the washing soda solution. I did that on a 29K1 head a while ago - it really worked very well but takes some time.

-

Don't expect too many information from a 45K manual - the information in manuals of the 45K class are rather basic. This is not for the 45K25 but the other 45K manual give pretty much the same information. If you have technical problems please post some pictures of your machine and give some more details of what wrong with the machine. Here is a PDF of a basic manual for the 45K class. 45K Manual.pdf

-

Hoping for help with my new patcher (Adler 30-1)

Constabulary replied to Vinito's topic in Leather Sewing Machines

deleted -

Teflon Foot for a Pfaff 545-H4-6/01

Constabulary replied to danielsedlacek's topic in Leather Sewing Machines

Also, if your 545 has a double leaf spring remove one spring. Often just 1 spring is enough - just check and play with the settings. -

Above your last post I have linked to my 51W restoration thread. I have linked to feed dog / needle plate sets that fit my machine - however they may need modification and I´m using a non standard hook so things may be a bit different on my machine than on your machine. I guess my machine is older because I do not have a W suffix Singer Serial number. Looks like mine still has a Wheeler & Wilson serial number but I don´t know for sure. I also have posted a few pictures of the thread path (see above link). The original needle system was 128x2 / 128x3 (short needle with thin shaft) but I have changed out the needle bar (which was kind of bubba'ed). I took a NB from a Singer 111w needle feed machine (not the same as for 111w walking foot machines) so I had to modify my machine with a needle bar guide on the top end. Thant's probably not your cup of tea and you may want to use the original needle system. The round part that is missing on the face plate most likely was a piece of felt that served as a thread oiler. Would be nice if you could pots pictures from front and back just for documentation because there is very little known about this early 51W model. EDIT: If your machine has the same rotary hook with caped bobbin basket just as my machine had then these bobbins should fit: https://www.ebay.com/itm/162656003877

-

Hand cranking on this particular machine (one of the very early 29´s) will not be too much fun since you do not have a front hand wheel. I would not necessarily buy this machine because of the parts situation but It may depend on whats available on your local market and your budget. However if it produces stitches of 4mm or longer its a good score. Personally I would recommend a Singer 29K with 50, 60 or 70 subclass. Best would be a 70´s subclass (like 29K71) because the higher the subclass number the more likely it is to get parts for it . Especially gear box parts which are critical - even 50´s, 60´s subclass are critical when it comes to gear box parts. Download a manual and read it or print it an take it with you when you check out the machine. You at least should know how to adjust the stitch length and how to thread it. Make sure the shuttle hook and the long leave spring on the backside are present

-

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I meant: cannot move the hook to the right (cannot alter the post) I also have ordered a slide plate / cover for the hook from College Sewing part number is 221215. It also works fro the early 51w model. Original slide plate is a lot nicer because it is full metal and the new one is just stamped sheet metal but it works. I will try fo fit a binder attachment to the new plate (just for playing around a bit). This is the OEM W&W foot and needle bar in comparison with the Singer parts (W&W to the right - Singer to the left). So you can well see where Singer got the idea of the 111w / 107w (f.i.) feet from. Unfortunately they are not interchangeable (screw holes do not line up) so I switched to the Singer NB so now I could use all the 111w needle feed feet and 107w feet. But as mentioned above atm I have installed a NB with roller foot. I will add a Singer decal when the machine is fully set up. If you mean the floral design - well that's not what I really like. -

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Quick update - above mentioned hook has arrived - it fits but the hook tip is touching the needle and I cannot move the hook to the left. So the GEH-820 hook does not really work for my 51WSV2. So back to the Durkopp hook. -

What kind of help do you need? Please post pictures of your machine. I just recently bought an early model 51WSV2 myself - not yet setup with table and motor but functional already. I have replaced several parts incl. presser foot bar so now I can use Singer 111w (needle feed) and 107w type presser feet. I also changed the hook and needle bar so I now can use 135x17 needles. I also figured you can use needle plates and feed dogs from "up to date" post bed machines. This is mine: https://leatherworker.net/forum/topic/86292-siger-51w-sv-2-post-bed-machine-restoration/

.jpg.6343ea984da55f44c4fc724d6b454302.jpg)

.jpg.58a70b38c9b73236ac5b5d24844fdee7.jpg)

.thumb.jpg.a2878df3432b4a4adb53931853643675.jpg)

.jpg.ae90a65cc998e1a1642d5a430f0dbca2.jpg)

.jpg.e1f8338df7a659c3b9040adf5e35807b.jpg)