-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Help with very dirty Singer 111w155

Constabulary replied to PMCREATIONS's topic in Leather Sewing Machines

Dried old oil and dirt often looks like rust. Try a hot water and washing soda solution - you will be surprised how much gunk is coming off. Submerge the whole machine and use some brushes for cleaning the mechanics. If you have a compressor you can use a spray / wash gun to wash out the inside of the machine with this solution. Long bottle brushes can help cleaning the machine inside. You can also use kerosene / diesel or paint thinner - however - be careful when using inflammable fluids in the wash gun. It however is very effective but it also causes fumes you better do not inhale. BUT - it is effective - at least for what I´m doing. Depending on the overall condition my 1st step often is the washing soda solution followed by paint thinner. The paint thinner will wash out the water and soda remains and when its all dried I oil the machine. Always wear proper safety equipment! EDIT: I just recently discovered this stuff but haven´t tested it yet. https://www.amazon.co.uk/Koch-Chemie-Green-Universal-Cleaner/dp/B011OKX44S -

Adler 69-72/E 42 Needles - Help please!

Constabulary replied to TomSchell's topic in Leather Sewing Machines

So you know the needle system, the size and what tip you want - now what is the issue? -

Agree - hook is to high. Bobbin case opener is in a lower position than the bobbin case. I would loosen (not remove) the 2 set screws on the hook driving gear and push down the hook. Then tighten screws again.

-

when the machine was not in use for a while (maybe years?) I would generously oil the machine and not only on the oil ports also where moving parts come together (and there are a lot of moving parts). Let the oil maybe soak in maybe for a day (wicks are probably dry) and then remove access oil the next day. Oil will find its way and will drip off somewhere. I`m personally oiling the machine not before using I´m oiling when I´m done with the work so oil can soak in and I can wipe off access oil before I stark sewing so it will not "spill" when sewing.

-

don´t worry to much about the oil, plain Lilly White oil works on most sewing machines you seldom really need special oils. Sewing machines Co´s back then tried to sell their own "special" oil, Singer and Pfaff did this as well.

-

and it depends on the pulley - some clutch motors have pulleys with a tapered bore and to my best knowledge they do not fit on any servo.

-

Jep - also my 1st choice! I`m buying 90%+ of my parts there and bought all my servo motors from them as well. Hoping BREXIT never happens!

-

No offense but this offer has ZERO information. It´s like you say you have a glass of water for sale. 3 phase Durkopp Adler can be anything or nothing... What model is the machine, is it in working condition or not? Any accessories? How is the overall condition? Please post pictures and a price.

-

Singer 31-15 Tension breaks the thread

Constabulary replied to iknowit101's topic in Leather Sewing Machines

I like his Videos but I agree. However most of us are not professionals and when you don´t have machines to compare its not easy to figure out wether you are wrong or not - or if just the other guy is wrong. Best advise always is - READ THE FXCKING MANUAL However manuals often do not tell all the details but they are (in most cases) are the best source for 1st hand information! -

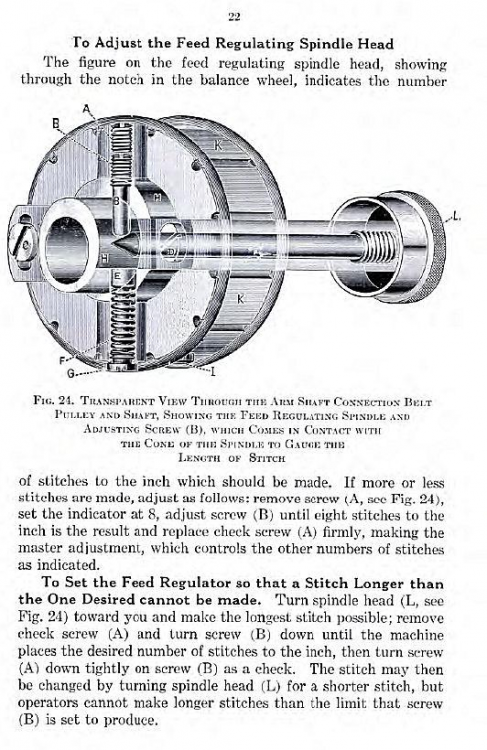

A Consew 227 is not a post bed machine and it often helps when you add pictures cause sewing machines sometimes come in variations. Furthermore - you have to be patient. We are all doing this for fun and not for money and not everyone is reading all sewing machine posts. I´m guessing your 227 is an early model with stitch length adjuster as used on the Singer 153 and w/o reverse - right? If so - turn the adjuster knob to the far right and pull it out (has a long thin rod with pointed tip). Installing is just the other way around. I have 3 Singer machines with this kind of adjuster so I know it works. This is an extract from a Singer manual - should give you an idea how to alter the stitch length settings.

-

It does not matter as long as it works. These multiple hole posts / thread guides are usually meant for getting a twist out of the sewing thread. However the "S" usually works well. If your thread is not causing problems I would just do the "S" (maybe top and bottom hole) if the thread has more twist I would use a few more holes - maybe like a double S.

-

Another Singer SV machine: 51W SV 2 As usual - no proper information available. I will pick up the machine next week and post a few more pictures then.

-

I´m looking for a manual (not parts list) for the earlier 51W post bed machines. In my Case a 51WSV2 - so pretty sure no one has manual for this specific SV machine. So I did some research and seems there are 2 types of 51w and the ones with subclass up to 30 (51W30 / 51W31) seem to be the earlier type with stitch length lever underneath the hand wheel and thread take up lever on the face plate side. So thats the type I would like to have a manual for. Its not that I need it for operating it (pretty sure I can thread it correctly just by experience) but I just like to have it and sometimes Singer manuals have included some good technical information for mechanics. I already figured the head part is pretty much identical with the Singer 12W / 14W class (at least some of them) I will pick up the machine next week - I have no idea if it works and how long the stitch length will be so I´m a bit excited A quick "teaser"

-

Experimental Nylon Gear Singer 29K

Constabulary replied to chrisash's topic in Leather Sewing Machines

looks like a fine toothed gear for the 29K5X series. I think you could increase the longevity when you replace all 3 pinions and the rack with nylon parts. -

How to thread a Pearson & Bennion A1

Constabulary replied to JohnShep's topic in Leather Sewing Machines

lovely machine - I once owned one. I unfortunately sold it because of space reasons. I hope you machine has all the parts - please post some pictures. I unfortunately cannot find the manual but maybe you can see enough detail on the pictures in the above thread. -

poor video sorry... too many thread hanging around and I cannot see what the actual top thread is and it is to fast to see the sewing cycle. Can you hand crank the machine (take off the V-belt) and watch the sewing cycle? when you start sewing do you hold the thread for the first 2 or 3 stitches? W/O knowing your machine and how it is threaded but this could happen when you loose the top tension (probably incorrectly threaded / wrong thread path?)

-

What's up with this thread I was given?

Constabulary replied to williaty's topic in Leather Sewing Machines

But you can buy thread from well known manufacturers - it may cost more but you for sure have less issues. It´s a good advice when you buy thread of a manufacturer who has a proper website and give you detailed technical information about their thread(s). Of course every dealer claims their thread is top quality but the key is that you know the "real" manufacturer - not the dealer or importer who probably but their own brand sticker on the thread cones. Just my 2 cents -

Download Adler 105 / 104 Manual

-

Is the thread coming off the bobbin from the right side? Are you holding down the bobbin while pulling the thread under then tension spring? Please post some pictures

-

Trying to identify this clone sewing machine

Constabulary replied to kayw's topic in Leather Sewing Machines

if the spring on the hook is worn / broken I would rather look for a new hook for a Singer 45K. The springs are not easy to replace sometimes because some have an odd little hook that goes into the hook body. These springs can also be slightly different depending on the hook manufacturer so they don´t necessarily fit universally. Guess how I figured -

We haven´t seen the complete machine yet but you for sure need a new feed dog (see what I have linked above - thats dirt cheap) as yours looks quite worn and as mentioned before the hook tip is blunt / worn so replacing hook is the next thing. Machine is skipping stitches as it seems (hook is not catching the thread loop from the needle - that's what makes the stitches look long = skipped stitches) - either because of the needle hook timing, the worn hook tip or the hook is too far away from the needle I guess. The timing procedures are mentioned in the manuals I have sent you. The values for hook timing, needle bar hight and how the adjust the hook saddle are the same as on the Singer 111.

-

88x1 and System 88 are not the same! 88x1 is a short needle mainly for industrial straight stitchers or sergers, system 88 is a long needle for patchers.

-

I have no source - sorry! I would have suggested SHOE SYSTEM PLUS but seems their smallest size is 100. At LANDIS the smallest size seems to ne 100 as well. Maybe LW Member SHOEPATCHER knows more.

-

If you want me to I can send an English Singer 111G156 manual and a German Dürkopp 239 manual - these 2 machines have a lot in common (especially the hook saddle, tension unit, hook and the presser feet) so you have some cross references. Just send me a PM with your email address.