-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

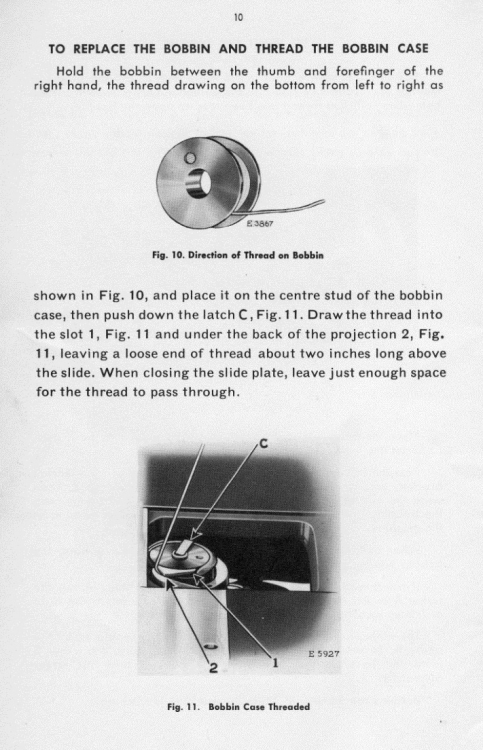

I don´t see any issues with the bobbin case - looks like mine. Spring looks good. This is an extract from the Singer 111 Manual (same procedure as for the 239). While drawing the thread through the slot #1 (see picture) you have to hold down the bobbin with your fingers. BTW - the hook I have linked is a bit different. You probably have noticed the "cap" for the bobbin case! However - it works for your machine but requires different bobbins. Just wanted to have it mentioned.

-

The entire hook saddle on the D. 239 is the same as on the Singer 111 so an English Singer 111 manual will help you with how to thread the bobbin case. I however can send you a German language Dürkopp 239 manual by Email if you want - just send me your Email address by PM If you are looking for a better feed dog (and maybe needle plate?), there is an Ebay seller who sells used Dürkopp parts for fair prices - if you need other parts just check the sellers offers: https://www.ebay.de/itm/Durkopp-241-Stichplatte-mit-Transporteur-7544/303071333332?hash=item4690758bd4:g:Nz4AAOSw19dcb7M5 Dürkopp 241 and 239 are using very similar parts (depending on subclass) but the above will work for your machine This would be a new hook for your machine (if needed) https://www.ebay.de/itm/Greifer-Durkopp-Adler-228-238-241-249-New/263541951800?hash=item3d5c530d38:g:4TUAAOSwEOpaHu64

-

How do I find that part for cylinder bed machine

Constabulary replied to Chamod's topic in Leather Sewing Machines

check google or eBay for "Singer 17 shuttle hook" if you can import it depends on your country customs regulations but I doubt it will be a problem. However you only find out when you check with them. Most folks here are most likely not familiar with the Sri Lanka customs regulations. -

Okay, good to know you are aware of it, so no worries and no offense But honestly a size 20 thread is what is the max. for most medium duty / upholstery type sewing machines in the leather trade and you try to run it through a tiny domestic machine - that does not make much sense. Its not just the thread - the whole machine is not designed for this type of thread (or work) including the thread path, tension unit , needle plate and hook. I basically understand when you want to find out the max capacity of your machine (we all want to know the max. cap. of our machines) but I honestly think this experiment with a domestic machine (Singer 201 I guess) is a bit over the top.

-

I honestly never faced a serious thread twist problem. Gymnast - I guess you run an (probably oversized?) (bonded nylon?) thread through a vintage domestic machine and you are not using a proper thread stand - rule of thumb on this regard (as far as I recall): The position of the guide hole in the boom of the thread stand should be at approx twice the height of the thread spool (or more) and centered directly above the spool. Furthermore - this machine for sure is not meant to work with thread or thread heavier than approx #69 . I´m sure this machine will run perfect with polyester or cotton thread of a size up to #69 (or less). This machine has no serious thread guides as used on some "real" industrial sewing machines that can handle heavier thread. F.i. the Singer 111 has several thread guides / guide holes for "untwisting" thread - and that's what they are meant for! In some cases it even matters in what angle the thread "enters" the tension unit - it can well be that the thread pops out of the tension disc when the angle is wrong and/or the thread is too lose (no proper thread guide before the thread enters the tension unit). For this reason some manufactures have a thread guide of which you can alter the angle. So - using the right machine also matters - it´s not just the thread that causeuse the problem. Using the right components (incl. the right machine with the right thread for a certain operation... concluding - meaning the whole setup) but as always there is no right or wrong - the truth is somewhere in the middle. However - I´m not using any nylon thread at all. I`m mainly using polyester or poly/cotton core spun thread or - not kidding - very old US made cotton thread (for historical purposes). I´m f.i. sewing harnesses for BC-1000 back pack radio with this cotton thread (like they did in the 1940´s) - I never got a complaint because of broken seams but that's a different field - I know. I understand that a lot people are using bonded nylon because of its braking strength - but - folks should ask their self if their products really needs this breaking strength. Will there ever be so much "force" on the seams of the finished product that it will break the thread? I honestly think that for most purposes a good quality polyester thread is sufficient and is most likely will solve a lot of "thread feeding" issues and it most likely will never break.

-

And firepower... and German beer.... and Italian pasta... and Singer sewing machines

-

Not sure if I get you right but during the sewing cycle there is no tension release, just as on all other sewing machines too. You only have a tension release when you lift the presser foot with the lever on the backside (then the cup will be lifted and releases the tension). If you have too much top tension I would also check the bottom thread tension, it could bee to high as well. What thread are you using (probably too thick for a patcher machine?). 69 or 138 thread is what most patcher can handle. There is not timing between thread lever and tension disc that you could adjust. You can adjust the travel of the thread lever with the adjuster but that is just for the material thickens (if ever needed). I have no Adler 30 I could post a video of but I have successfully restored a few of them. Most patchers (Adler 30 & Singer 29K) pretty much have the same sewing cycle and movement of parts. They differ a bit but the mechanics are very identical.

-

This parts has nothing to do with the tension (guess you mean the thread tension). It regulates the foot lift hight when sewing. Slide it to the left you have lesser foot lift, slide it to the right you have more foot lift. Please post pictures of your machine. I think there is either a bent part or a missing part when the tension is not releasing. However, the worn tip can be brazed or welded but it is not too bad worn. Yes the Singer 29K slider looks a bit different but should work, both machines have the same tension leaf spring on the back side. There was a time when Adler 30 and Singer 29K had a similar slider.

-

$50 white whale SCORE! Singer 29-4!

Constabulary replied to ensitmike's topic in Leather Sewing Machines

29-4 only have very few parts in common with the later 29K71 - so be careful with parts from College Sewing.if you are unsure compare the parts lists / parts numbers. However a few parts can be modified to fit the 29-4 (like the bell crank lever). New parts for the 29-4 are almost unavailable. You may find some used parts but questions is are they better than yours? I once have restored a very similar 29K1 - just to give you some hints: -

$50 white whale SCORE! Singer 29-4!

Constabulary replied to ensitmike's topic in Leather Sewing Machines

would have bought it for that money too. Hope its not too worn. But you find tons of information in the forum how to restore it. -

how to change the length of the stitches

Constabulary replied to Chamod's topic in Leather Sewing Machines

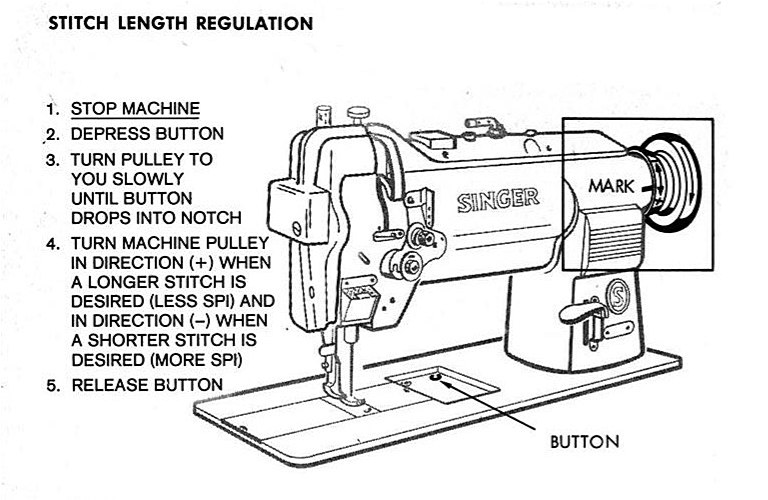

I don´t know this particular model but usually there are 1 or 2 buttons in the flat bed. One for the safety clutch and one for the stitch length. If you have two buttons the one to the left is for the stitch length. I think your machine is based on a Singer 111 / 211. So I would assume the stitch length regulation is similar. If you already knew this I would guess the stitch length regulator is gummed with old oil. -

There is no way I would install things like this, neither the freakin Alexa thingy (or similar) nor something that can control my heating or fridge, power supply or what ever via smartphone / internet. This technology makes "us" more vulnerable. There may be some niches in life where it can support you but I was able to survive without this BS until today and I for sure I will crawls around on planet earth for a while w/o having this stuff around me. What happens when the smart-home stuff no longer can be updated - like Win XP or soon Win 7 and the smart-home stuff is not compatible with Win 10 (just to draw a picture ) or the fancy startup Co who installed all the shit disappears from the market and tech support is no longer possible? Buy all that shit new? Njaaa - I don´t need that! On / Off switches are good for me and are fool proof (most of the time). Yes, I´m on "freakbook" but do not (but barely did) post or "like" anything that has to do with my self on my personal life. I do not "like" other peoples / friends pics or posts or what ever... I even deleted most of my "private" FB posts and comments. I´m just checking in there from time to time to smile about what BS some of my "FB friends" posted there. I don´t even take new friendship requests. ITFDC. Yes I have an google account but just for posting (mainly) private / not listed videos for certain purposes and delete them when I think they are no longer needed. I do not follow anyone on YT nor do I "like" other peoples Videos there or elsewhere. I have no "Insta" account and don´t need one. I´m not on Twitter. I have an Pinterest account with a fake name. I´m not using any smartphone messenger (even my sister is moaning) - never did and when ever possible I never will. Not saying the smartphone is not a useful tool but I just don´t like it very much because I do not know what "it" knows about me or what data is "spreads" so it is in a drawer 90% of the time (no - it´s not wrapped in alu foil ). I sometimes even forget it in the drawer or in my car and find it uncharged after a few days. Missed a phone call or two or ten - WTFC - I don´t Leave a message and when I think it was important I probably will call back - or maybe not. I´m not wearing an aluminum hat and no copper or magnet jewelry to protect my self from "earth waves" or "outer space radiations" but I just do no like all that freakin way over done social media BS. If people like it - great - go ahead but and spread / share your life or what ever you want but I don´t. Yes, I left online traces but I´m trying to control it a little bit. I´m so fxcking 90´s - and I like it and now you can draw a picture or try to analyze of me and my "social media life" - if you want to. So I think form a nowadays view I think I´m antisocial and again ITFDC - and hell I like it that way. Makes life a lot more "unagitated". Note to my self: I´m staring to prattle

-

The blue is blue cause its blued spring steel - I guess.

-

post pictures please but If I got you right you should loosen the set screw on the stopper (adjustment ring?) and reposition it (if we are talking about the same stopper) but please post pictures!!!! Could also be a problem with the knee lifter it self but different models are out there - so pictures please

-

Pretty sure UWE had a video on this but with a different machine - as far as I recall... or not?

-

springs likes this often go inside the bobbin case to prevent back slash of the bobbin.

-

a video w/o material under the foot gives a better view on what what the feed dog does

-

Video is quite blurry but could it be that your feed dog is too high or rises too early?

-

SEIKO - What kind of sewing machine is this?

Constabulary replied to Seom's topic in Leather Sewing Machines

agree with Jimi - it´s needle feed machine, you can see the hole in the feed dog and the pivot point for the needle bar. Don´t know the model but if the price is right I would buy it.- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

What is the modification - the short cut in the right foot? What is the advantage? 135 thread is quite tick for a Singer domestic machine. You calculate tension in percentage - are you a scientist? Maybe its just me but I don´t get what you want to say - but maybe its just me.

-

is it probably a needle feed machine?

-

I want to restore a Singer 111W153

Constabulary replied to kevinkay's topic in Leather Sewing Machines

you can get decals from Keeler Sales. https://singerdecals.bss.design/ They sometimes have single pieces from reject decal sets. Just browse their website and send them an email with what you could use. I´m sure they can help you. -

I want to restore a Singer 111W153

Constabulary replied to kevinkay's topic in Leather Sewing Machines

I think the brochure is newer than your machines and I´m sure it does not cover all subclasses. Singer probably dropped some subclasses and some new subclasses where added... I don´t know... -

I want to restore a Singer 111W153

Constabulary replied to kevinkay's topic in Leather Sewing Machines

all triple feed / walking foot machines have a vibrating presser bar - this just means the outer presser foot bar (when you look form the left side it is the bar on the left) is holding the material down until the needle penetrates the material and moves up when the needle bar and inner foot + feed dog are feeding the material. Moving up and down means vibrating in Singer-English. BTW - not sure if I posted this brochure already. It´s a 1950s sales brochure for the 111 type machines Singer 111w Class Machine Brochure.PDF