-

Posts

5,805 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Some pictures would be nice. Could well be that just the needle bar is stuck. I´d also check the bobbin case & the hook and see if some old thread is blocking mechanisms. Oil the machine and maybe put some drips of kerosene / Diesel, paint thinner, benzine or other mineral spirit / solvent in the oil spots and to all moving parts (especially needle bar guides) and jiggle the hand wheel a bit hack and forth.

-

Beside the casting design I´d say if both are H3 (the number following the H describes the foot lift) and have a similar subclass I would say 595 is gear shaft driven and 1295 is belt driven (meaning the connection between upper and lower shaft) other than than compare manuals and parts list because the Pfaffs often have an odd subclass number you have to decipher (if that matters). You should find manuals and parts list by doing a google search.

-

Chinese Imported Sewing Machines

Constabulary replied to willford's topic in Leather Sewing Machines

Jimi - thats just because of the earth's curvature I fortunately mainly had luck with chinese parts, except that they once have sent left toe instead of right toe feet but it was so cheap I didn´t even complain. I agree - its a gamble but there are some "good parts dealers" on Ebay who sell sewing machine parts only (always check what else they sell) so they pretty much know what they do (and sell). But a complete machine - well I was thinking of that too but didn´t dare! And being honest, I have found all my machines used so there is no real demand but a 227R / 153w clone is what I wouldn´t mind to own - and a Singer 97 (but no clones available ) Joke aside - I agree with AMUCKART. If sewing machine and their mechanics are not what you are "used to" it could end up as a big loss. I would rather check with a dealer or try to find something used. Don´t get me wrong - I´m not saying it will a fail in general but chances are high! -

Shuttle problem with Cowboy 3200

Constabulary replied to CarlosURSUS's topic in Leather Sewing Machines

Does it act like this when you have removed the complete shuttle race? You know what I mean - remove shuttle race and hook and check again. Just to see if it really is the shuttle race.... -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Right, thread guide on clamp is missing - I think it' s broken off. It´s present on the pictures in my 1st post. Will check if I have a replacement. 135x17 works 81 is longer as you said. I just have checked the Sys. 81 needles I have. I will stick to 135x17. Pretty long stitch length for this machine class I´d say. It comes close to 6mm EDIT: Thread guide replaced - thanks for the hint. -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Yep - the135x17 needle works well. Machine works very well, really nice stitches with 140 needle and #25 Aman RASANT thread. Check spring needs to be replaced (oddly bent) but still works. Sooo - I will clean it, replace the check spring and then... I don´t know... A quick video of the 1st sewing attempt after I don´t know how many years or decades. -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Measure twice - cut once... Always good to compare needles direly and not just by measurements. The orig. needle seems to be something like 29x3 / 332 but with a longer tip. The needle eye is almost in the same position as on 135x17 / 135x16 (just a tad higher here) - so it should work. So no junk box diving today. First test sewing later today.... -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

still checking things - todays "challenge": the needle Naaa easy task, right? NOPE! Fortunately one original needle was insert... took a measure... hmmm odd needle system (46.5mm long)... so I thought I set it to 135x17 - as always - easy task I thought... removed some dirt from the NB connector and was looking for the set screw... none on the front, none left, none right - WTF - how did they do this? Taking a very close look at the front side of the NB connector I figured this freakin needle bar is pinned What was todays challenge: the needle finding a needle bar connector for the 7.2mm NB I guess a 31K part with # 24041 could fit - hope I have something similar. But the other end of the connector has to fit to the NB connecting link - hoping Singer didn´t put in another "Special Part" in here (have to check the #) So today we are diving through some junk boxes -

The Guesstimeter is always right - not matter if thickness or length or even volume (cubic guesstimeter)

-

Pfaff 471-755/01 Postbed, Single-needle

Constabulary replied to unionattic's topic in Leather Sewing Machines

Scroll down here: https://www.sewingwishlist.com/pfaff-industrial-manuals.html or maybe try Pfaff 491: https://www.manualslib.de/manual/354966/Pfaff-491.html -

I have no idea what a NS797 sewing machine is - please post some pictures. This is what comes to my mind in therms of vintage Singer machines for the shoe trade (just to give you options). Singer 236G has a top and bottom driven feed (has a 2nd built in motor that drives the top roller foot by a small V-belt) Singer 52w is a 2 needle post bed machine so it produces 2 parallel seams with approx 2 distance. Singer 110w / 110K is a very nice gear driven flat bed machine will roller feed dog. It has 3 pre set stich length (all rather short) - maybe you like this video https://www.youtube.com/watch?v=GrykrTMM7sk

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

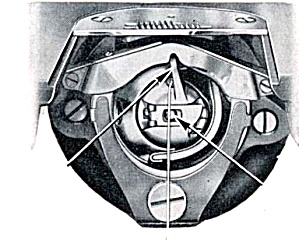

Top feed (material feeding by a mechanically driven and mainly toothed presser foot) and jump foot are different. The jump foot goes forward with the feed dog but is not driven mechanically. They are usually spring loaded and jump back at the end of the stitch cycle. Advantage of the jump foot and top feed compared with the plain static presser foot is that there is no friction between the material and the presser foot and the foot puts permanent pressure on the material so thats a safer material feeding especially when when you have multiple layers of slick material like faux leather or the like. They also can be adjusted to "climb" over raised seams. Singer, to my best knowledge, has called these feet "vibrating presser feet". But as always no one knows all machines and there might be differences or variants so this is just my explanation. There are several different jump foot systems on "leather trade" machines. Some well known machines are Singer 132K6, Singer 45K89 or Adler 4, and 5 or Adler 104 and 105 (depends on subclass) and several others. The long beak shuttle is a hook type with no bobbin case. The hook has a spring loaded "trap door" which holds the bobbin in place. Its is an oscillating hook like the CB hook but as far as I know (or guess) it can handle larger thread sizes but it has a smaller type bobbin f.i. compared with the Singer 15 or 31 type CB hook sewing machine. This is a class 15 CB Hook (I have no CB machines so pic stole from the WWW) And this is a long beak shuttle hook from the above Singer 16 machine -

Compare Heavy Duty 1/2" Machines

Constabulary replied to jrprottas's topic in Leather Sewing Machines

maybe an idea for a small foot print stand https://leatherworker.net/forum/topic/72789-singer-45d91-restoration/?do=findComment&comment=552471 Or DIY a stand with Kee Lite tube system https://www.google.com/search?q=kee+lite+tube&source=lnms&tbm=isch&sa=X&ved=0ahUKEwjR9YrZ_szkAhUOLFAKHR6JAwIQ_AUIEigB&biw=1280&bih=869 Or out of black tubes: Just some ideas .... -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

SV mean Special Variant / Special Version of what we think is a predecessor of later standard machines or machines with special technical features or special accessories that differ form the standard "off the shelf" models or the like. -

*HELP* Special Binding Parts for Juki DSC-245

Constabulary replied to StepDa's topic in Leather Sewing Machines

Ebay is your friend - sometimes https://www.ebay.com/itm/143258614372 https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Juki+DSC-245&_sacat=0 -

Scroll down here to Pfaff 6 - maybe google translation will help you https://www.naehmaschinenverzeichnis.de/verzeichnis-der-naehmaschinen/pfaff-bis-50er-jahre/

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I know thats why I bought it (+ the heavy fly wheel). If it was a plain 16K straight stitcher I wouldn't have bought it. Not even for parts. But this one is quite special. Well, it´s a SV machine. -

well first of all that yellow thingy is quite annoying and disturbing - don´t what it is and why you shoot the Video with it. Also, seems you have no needle plate / throat plate on the machine - the machine will not sew properly w/o a needle plate / throat plate. Please post pictures of your machine so we can try to see if some other parts are missing.

- 13 replies

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Honestly - rather not because I don´t know what to do with it. I have no use but it is a nice and rare machine. I will revitalize it and then see what to do with it. Maybe I´ll keep it then and paint it purple with gray flower design - or the other way around No - really no idea... I bought it right out of curiosity. I have 132K6 and 111G156 so there is no gap this machine could fill. So.... ATM I just wanted to share pictures and as much information as I can get just for the case someone else will find a machine like this. I´m already checking for information and similar machines or different machine that could share parts. So far not much success - as usual on SV machines. But I figured the long beak shuttle is a bit different compared with the Class 17 shuttle. Its not the same as it seems. -

On my last road trip (before visiting the former Singer factory) I picked up a Singer 16KSV11 machine. When I bought it I already knew I have no use for it but could not resist -> Vintage Singer industrial machines and in this case another SV machine made me weak So here is is - yet not touched or test sewn. Interesting features are the jump foot, the very heavy fly wheel and a long beak shuttle similar to the Singer 17 shuttles. Table plate is badly worm eaten. Built in 1930 as it seems. Some pictures

-

Yes, former East Germany (GDR). Well Veritas was the brand name, it´s well possible that other sewing machine manufacturers used Veritas as a model name too. Unfortunately not. But in the exhibition they had some pictures of the clockwork. Not sure if the pics are online available. They BTW have approx 20 domestic machines in their exhibition (mainly Singer domestic machines and some Veritas), 2 TEXTIMA industrial machines (Textima 17 and 31 - which are the same as the Singer 17K and 31K) but I did not take pics because I`m not really interested in domestic machines. During WWII Singer Wittenberge still produced sewing machines as well as artillery shells and maybe other armaments. Durkopp did that as well. Imagine that - Singer USA produced weapons in WWII (like the .45 Mod. 1911) for fighting the Germans and Singer Germany produces Artillery shells for fighting the Allied troops. Crazy! But what could Singer USA / Singer UK do at that time - not much I think. However - finally Europe and Germany have been liberated - fortunately!!! And I´m still grateful for that! Story goes that the Singer plant was not bombed whereas the City of Wittenberge got bombed as well as a factory right on the other side of the Elbe river in direct view of the Singer factory - if that is true - I don´t know. Not sure if they were able to drop bomb that princely in WWII. After WWII (from mid 1950´s onward) Singer produced sewing machines in Karlsruhe (West Germany) where they took over the Haid & Neu sewing machine factory. Thats where the "G" Models came from (like 111G156, 212G141, 307G2 and the like) They closed in 1982 - sadly! Not all of them but approx 40 Co´s found their space in this facility as well as a school and I hope they will restore the unused buildings as well. Yeah - I really like these old brick building very much! Sadly the plant in Kilbowie, UK has been demolished. Or does someone know if some of the buildings have survived? How is it in Elisabeth, NJ - all demolished? I just found this Video - looks small , right? I´m pretty sure there where more buildings back then.

-

On my last weekend road trip I had the chance to visit the "Clock Tower" of the former Singer Factory in Wittenberge. I just wanted to see the clock tower because I thought it was the last remaining piece / building of the former Singer factory. I had no idea that A LOT of the original buildings are still present. I honestly though they teared it down in the early 1990´s. The buildings are still in use. Several smaller and larger Co.´s have rooms in there. The whole facility is now called VERITAS PARK named after the last sewing machine factory VERITAS. Why VERITAS and not Singer? Well, the Russians disassembled the Singer plant and took the machiens to Russia as war reparations but they never set up the factory again (they were not able to I have been told). After WWII Wittenberge was in the "Soviet Zone" behind the iron curtain so out of reach for the Singer Co.. After WWII they (not Singer of course) first produced under the name TEXTIMA for a while (until 1955 afaik) and later it has been renamed to VERITAS. I had ~2 hrs guided tour and took some pictures. I don´t want to tell the history here, I just wanted to share some pictures because I really was impressed of what is still there. Hope you like it

-

Check with a industrial sewing machine dealer - maybe Keysew in PA or Toledo Sewing Machines in OH. Needle screw should be the same as for the Singer 111 - for the other screw I would tab a new thread and add a common screw if you can´t find the original screw.

-

Thread tangling around the needle...

Constabulary replied to Dantan's topic in Leather Sewing Machines

I agree! This could be the problem if the thread isn´t the problem. The check spring should hold the thread under "tension" until the needle touches the material (+/- a little bit) so it may depend on the material thickens you are sewing how to set the check spring. -

Not exactly sure what you mean. With: "interferes with" you mean inner foot touching the outer foot. Probably foot bars are not properly adjusted / centered? If well centered and it is just slightly touching you probably can grind down the feet a little bit. Can you post pictures or a video?

.jpg.6343ea984da55f44c4fc724d6b454302.jpg)

.jpg.58a70b38c9b73236ac5b5d24844fdee7.jpg)

.thumb.jpg.a2878df3432b4a4adb53931853643675.jpg)

.jpg.ae90a65cc998e1a1642d5a430f0dbca2.jpg)

.jpg.e1f8338df7a659c3b9040adf5e35807b.jpg)