-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Searching for a 3/8” gauge set for Mitsubishi LT2-230

Constabulary replied to pgc's topic in Leather Sewing Machines

@pgc That is a great information - I love figuring what parts are interchangeable between different brand machines. Often the Japanese brands and a lot of nowadays Chinese made machines seem to have a very similar "standard" (if not the same) and are often Singer based. The gauge set you linked (just from looking at it) looks pretty much like the Singer 212 Gauge sets. Thanks! -

Bradbury patcher vs similar German patcher

Constabulary replied to DonInReno's topic in Leather Sewing Machines

I know like nothing about this type of patchers but I think LW Member @shoepatcher knows more. I just dipped my toe into the DURKOPP Class 17 machines and figured that they are amazing and I got mine to ~7mm long stitches. But the DURKOPPS are quite different to the Bradburry but I would love to see a front view of this one. My biggest concern would be if the machine has a functional shuttle / hook and matching bobbins. I´m not sure if other brands have interchangeable shuttles / hooks. -

turn it away from you until you feel it will not screw out any further and then simply pull it out to the right. It may feel as if it will not come out - just pull... if not gummed. Its an approx 11.5cm long rod (~13.5cm total length) with a pointy tip. When you put it back shove it in and rotate it until it stops and then push it further in (will have some resistance) and then turn it in further. Do not hammer it!

-

You can also DIY speed reducers. There are many different versions on the forum. It just require some tinkering. https://www.google.com/search?q=diy+speed+reducer+site:leatherworker.net/forum

-

No mystery. It depends on what you sew (leather or fabric....) and how experienced you are as a sewer / seamstress. Speed reducers are not a must have but they make things (sewing machines) easy to master speedwise. I have speed reducers on all my 5 sewing machine setups. I still can go from crazy slow (leather or short seams as on box tacks on 1" webbing straps / ~10mm thick f.i.) to quite fast (loooong seams on canvas, sunbrella...) even with the speed reducers. Just a personal preference and IMO it makes the machines more versatile. If you don´t need a SR you don´t need one but I prefer them. Run your machine w/o a SR and if it is too fast change the pulley if still to fast and you need more torque (for thick materials) add a speed reducer.

-

Clone Patcher problems

Constabulary replied to bigcreekleatherworks's topic in Leather Sewing Machines

The "coarse needle plate" allows needles up to #23. I usually do not go over #22 with my Singer 29K71. https://www.college-sewing.co.uk/82234-needle-plate-medium-coarse-singer-29k-71.html Keep in mind that it is a repair machine and not really a machine for the serious production of leather goods! -

maybe the manual helps Rex Chandler 26-188 Singer 16-188 manual.pdf

-

Videos are blurry and shaky and do not show "the whole scene". Anyway - as far as I can tell you have installed the needle bar and needle holder incorrectly and the needle clamp screw probably blocks the foot when lifting the foot lever. With other words rotate the whole needle bar until the clamp screw faces right. But I only can guess here.

-

@Icho Just checking. Any progress here? Did you get the parts and have installed them?

-

Top load bobbins and needle guide

Constabulary replied to MainiacMatt's topic in Leather Sewing Machines

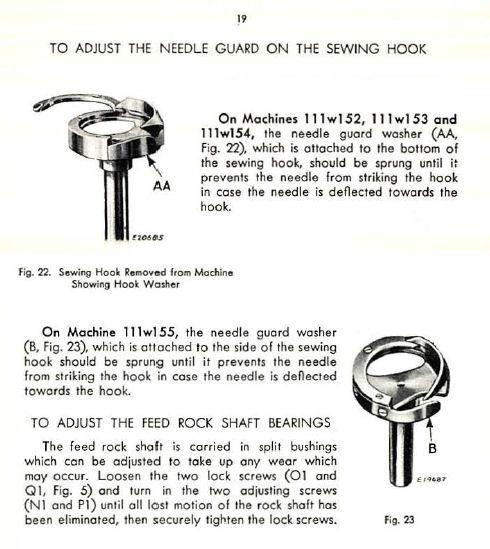

This thingy here is the needle deflector on machines with top loading bobbins. I think Singer called them needle guard. There are no other extra needle guides except the needle hole in the feed dog (if you want to consider this as a guide) and the needle hole in the inner foot (if not open to the front). I think that was just misunderstanding (guard... guide...) or saying something but meaning something different (that happens) - I think he meant the needle deflector / needle guard. EDIT: This is an extract from the Singer 111 manual: -

Meisi Superfine waxed linene thread

Constabulary replied to Redbeeerd's topic in Leatherwork Conversation

Ha - they are in Germany - never heard of them before but worth checking their inventory! Thanks for the link -

Top load bobbins and needle guide

Constabulary replied to MainiacMatt's topic in Leather Sewing Machines

With needle guide he probably means the needle deflector. -

Does somebody recognize this cylinder bed machine?

Constabulary replied to milkman's topic in Leather Sewing Machines

This is a CLAES 233 - German made (in former GDR), parts are rare (feet f.i.) but hook is the same as for the Adler 269 (large hook). Maybe it can use Adler feet but I´m not sure. I have a German language manual for it - send me a PM if interested. -

Singer 29, worth the asking price?

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

What 29K model is it - 29Kxx? The compete top tension unit is missing (still available) + the front drive shaft with bevel gear (available for 29k71 but I´m sure if tit will work with this hand wheel) but maybe the parts are in the drawer? Ask for a picture of the rear side and check if the long leaf spring is present - except it is a 29K51 then it has a coil spring in the head. Do you have more pictures? -

Bad experience with Ebay or the seller on Ebay? That's two different stories. Ebay is not the seller it is just the platform for selling things. If it was me I would order this NOS Singer part. Just 10 bucks incl shipping. https://www.ebay.com/itm/265243181471 I cannot imagine that it will not work However - you are aware that this type of machine came with different style hooks and therefore different bobbin case opener right? Are you sure 267351 is the one you need? Just checking w/o knowing details of your machine.

-

If it was me I would buy it but me is "Singer Idjit" I don´t know how different the parts are but usually getting Singer spares are rather easy but the machine itself is a rare bird. However - from just looking at the pictures it seems just the tension discs, beehive springs and nuts are missing. But maybe the parts are in the drawer.

-

I have a manual in German language if you are interested. The machine was manufactured in Wittenberge Germany and is a quite rare bird. This machine AFAIK was only made in Wittenberge and nowhere else in (Singer) World. If it is in good shape and all parts are present and not super expensive I would buy it. It can sew light weight / garment type leather.

-

What machine makes this stitch?

Constabulary replied to Happy Hooligan's topic in Leather Sewing Machines

Right side of the picture looks like a french seam and top and bottom thread appear to be of a different color. I´m not sure but I would say this was done with at least 2 machines. One double needle machine (with 1/4" gauge set I guess) and then a serger or fur sewing machine for reinforcing the inside seam. But I´m really not sure. -

SERVICE Manual for Adler 30-70 Patcher ?

Constabulary replied to wintertree's topic in Leather Sewing Machines

check your emails - it´s on the way. -

SERVICE Manual for Adler 30-70 Patcher ?

Constabulary replied to wintertree's topic in Leather Sewing Machines

Are you sure you are using the right needle? The 30-7 is using a longer needle than most other Adler 30 or Singer 29K patchers. The needle system for the Adler 30-7 / 30-70 is 332L. The L in this case means LONG. I have a Adler 30 mechanics manual but file is too big to upload here so send me a PM with your email address -

Can I change my Singer 111 needle bar to 135x17

Constabulary replied to SamColt's topic in Leather Sewing Machines

Just for the records - what shank diameter has 126x11? I have not found any data on 126x11. -

Can I change my Singer 111 needle bar to 135x17

Constabulary replied to SamColt's topic in Leather Sewing Machines

I don´t know if there is anything special on a 111w154 but if 126x11 has the same shank diameter as 135x17 you only have to adjust the needle bar height and you do not need a new needle bar. EDIT: This guy here has a 111w154 as well and says at sec 0:26 he is using 135x17 so it should not be a problem. https://www.youtube.com/watch?v=3dS_tfBNN_s -

Yeah, I´m really not into any kind of domestic sewing machines (not at all) but just recently I came across this post coincidentally... https://naehfabrik.forumprofi.de/t11737f114-Anker-RZ-Automatic.html and worded if this kind of decorative sewing machine stitching (done here with an ANKER RZ) would not be interesting for thin leather projects like watch straps or so. Maybe someone is doing this already but I haven´t seen this yet. I´m just curious