-

Posts

5,764 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

I meant the fork type part but in the end you figured it

-

Not sure but try this: loosen the set screw (from mack side) and adjust this thingy here with a screw driver - there is a slit on the top side. You can also raise it a bit just carefully hammer it a bit upward

-

The Seiko SK-8 manual gives a lot more information than the original Singer 132K manual but I´ll attach it here too Check this thread: Singer 132K Manual.pdf

-

I don´t know your sewing process but I would guess you have to increase the foot lift or hold down the material with a bone folder or the like

-

206 RB-1 Knee Lift/Presser Foot Pressure

Constabulary replied to Teslabolt's topic in Leather Sewing Machines

All my machines are a older that me - one is even approx. twice as old as me.They will survive quite a while even if they do not get oiled regularly. But regular oiling should be a habit, thats true! The more you use em the more often you should oil them. I usually oil AFTER sewing so the oil has time to penetrate and before sewing I wipe of access oil so it is not sprinkling / dripping from the parts. When I haven´t used a machine for a few weeks or months or... I oil them before sewing too. But thats just me... -

211w151 bobbin case opener adjustment

Constabulary replied to medivh25's topic in Leather Sewing Machines

Parts are gummed with old oil I guess. Try a heat gun. -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

some more. Interesting the hint "Bei Bestellung bitte Muster senden" - thats means: "Send in the original parts when ordering spares". So that makes me think that only a few of these parts (or 16KSV11 machines) were made but have not been mass produced - AND - I guess the company who is seeling these "special parts" probably made these parts for Singer and most likely only for the Singer factory in Witternberge, Germany. Remember - I found this machine approx 30km west of the former Singer factory in Wittenberge! I also guess this particular SV machine COULD have been produced or modified exclusively in the Singer Wittenberge factory. This of course is just my wild guess but it could well be. But I don´t know. -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Investigation went on and I figured some interesting details on this old work horse. I´m not into domestic machines but the long beak shuttle hook seems to be the same as for the early Singer Class 15 machines. How do I know? It happens thats I´m studying old manual parts lists and catalogues to find cross use of parts (if you know what I mean) and a while ago I found an old 1940´s parts catalogue from a German aftermarket parts mfg and by the Lord - they have parts of this particular Class 16 jump foot machine in their catalogue Now that really surprised me! -

DIY Magnetic Bobbin Holder -> Singer 132K / 133K

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thats no problem, the magnets here are rather weak and not as strong as neodymium magnets or magnetic edge guides. I´m using the orig. Grabobbin holder (with Bernina logo) for years and the bobbins are not much magnetized and it is not not causing any issues. I think when you have an anti backslash spring in your bobbin case it is causing more "rubbing". If you do not have a router + bits and you need them for standard G style bobbins you can buy them quite cheap on Ebay https://www.ebay.com/itm/233448635373 I just wanted to make one for my larger size 132K bobbins but figured I have a few other bits that fit for my other bobbins so I went on and made some more... little funny weekend project. Jimi as you know the earth curvature is different in Spain and I´m sure you can use aluminum magnets. You only have to put them in a solution of type A moon water and type Z unicorn dust first - problem solved! -

Manual / instruction book needed

Constabulary replied to John at Byson's topic in Leather Sewing Machines

don´t know how your machine looks and what model it is but maybe this Techsew video gives you an idea , or check the BONIS website: https://bonisparts.com/owners-manual/ -

DIY Magnetic Bobbin Holder -> Singer 132K / 133K

Constabulary replied to Constabulary's topic in Leather Sewing Machines

It bent not too much but when I tried a 2nd run for another bobbin holder I noticed the grove became wider and wider (just 1mm overall but still...) so the bit went to the trash immediately! I just made a few more bobbin holders from an old oak plank - one for the 45D91 and one for the 108w20 (with a different bit of course and step by step). I´ll make a few more tomorrow... Ouh - in the 2nd post I wrote birch wood - but I meant beech wood -

DIY Magnetic Bobbin Holder -> Singer 132K / 133K

Constabulary replied to Constabulary's topic in Leather Sewing Machines

few more BTW - I killed the cheap round router bit, the 6mm shaft was a bit to thin and bent but still worth it I think. Birch wood was too hard I guess. Should have dome this step by step and not in one run However - 8mm shaft was not available and 12mm shaft was too thick for my router. -

Some may know the useful magnetic bobbin holders sold by GRABOBBIN and the like, you find them everywhere for approx 10€ / $12. They usually hold approx 20 G or A style bobbins (~20-22mm diameter) but I wanted one for my Singer 132K6 bobbins (34mm diameter) and none are available so I made one. My bobbin holder is ~300mm long and can hold 19-20x Singer 132K style bobbins. What you need is: a piece of 2" x 1" wood from the scrap box cheap magnetic knife holder: https://www.ebay.de/itm/312739525221 32mm round router bit: https://www.ebay.com/itm/401789386660 6mm router bit (already had one) You can make 6 fairly long bobbin holder from the 3 knife holders. If you need fewer just look them up but the set of 3 were the cheapest I found broke down to 1 magnetic holder / 2 magnetic strips. I will make some more bobbin holders for other machines so I bought the set of 3. Decal is a left over from a restoration project so its a nice add on here I think. Some pictures - last picture shows a Grabbobin holder in comparison.

-

Singer 29K71 hand wheel hub assembly

Constabulary replied to ironwrx's topic in Leather Sewing Machines

Looks good! -

It´s not a secret that they do not produce the machines they sell, they buy em overseas and put their brand sticker on them. Consew is in business for a long time but afaik they never produced their own machines. Afaik they always have sold foreign made machines (made in Japan, China ...) and relabeled them. But that does not mean the machines are bad.

-

Singer 29K71 hand wheel hub assembly

Constabulary replied to ironwrx's topic in Leather Sewing Machines

Check if the a gear on the main shaft is present! Often the machines w/o the wheel hub on the front do not have gears on the main shaft. Even if it is there it could be worn and you may need both gears cause used and news parts sometime "do not play well together". VT is Vermont, right? So I would probably check with TECHSEW they sell 29K clones (Techsew 2900) so maybe they can help you with parts. -

Well, looks like your machine is not set up to run with 160 needles. You probably have to buy a foot and feed dog with holes wide enough to accommodate the 160 needle + thread (or open up the holes with a Dremel or similar) and you probably have to move the hook saddle a bit to the right the way the thread can slip thought the gap between needle plate and bobbin case (maybe gap is wide enough already but I of course do not know) EDIT: Wiz was a tad faster. Some machines of this class can handle 160 needles but not all - my singer 111 can but I do not use needles thicker than 140 with this machine.

-

thats the food chain

-

or to be dinner We are very international here so Yes, because its easier to provide information when you at least know what country she / he is from. Often folks like to buy materials from a domestic dealers or a dealer form their "continent" (or similar) rather then from overseas dealers (meaning that causes higher shipping cost and even import taxes and so forth). Also recommending a sewing machine dealer / service is easier. I doubt many will import machines from the US, UK, Canada Australia or... when they can buy similar machines from their own country or continent! No one needs the name or full address and no one gets hurt when they provide country and / or state they live in.

-

The 30-6 Adler (if not mistyped) is the same as the 30-5 but was originally fitted with a tape binder attachment. It has a small hook but is using the longer 332 LONG needles so you should be able to sew approx 10mm thick max.. But keep in mind, this is a patcher machine not a heavy duty leather stitcher. It´s meant for repairing ( patching things like shoes, boots, bags, pouches and small repairs on different other things - in best case the stitch length ranges between 4-5mm but could be less depending on the wear but overall condition seems to be very nice. This is not a 105-25 - this is rather a 5-25 (the predecessor of the 105) or someone put a "fake label or badge" on it. For more details a picture of the backside of this machine would be interesting to see. However the Adler class 5 or 105 usually can sew approx 12mm material. If it really is a 25 subclass it has bottom feed and a driven top feed with independent stitch length adjustment for top and bottom feed - its quite special. You can downland a Adler 105 leaflet with technical information here http://sew24.blogspot.com/2012/02/vintage-leaflets-for-adler-sewing_23.html But as I said - the shown machine is an Adler 5 - not 105.

-

Vintage pfaff 335G-h3 stitching problems

Constabulary replied to tibee's topic in Leather Sewing Machines

Yeeeah - bad overall machine you have there (no Singer = bad machine) **kidding** sorry - I somehow have not noticed it´s your machine. I was just scrolling down and noticed the dialed down tension nut so... -

Vintage pfaff 335G-h3 stitching problems

Constabulary replied to tibee's topic in Leather Sewing Machines

BTW - when I look at this picture - you probably should install a heavier beehive spring on the tension unit to achieve more top tension - at least I would do that! -

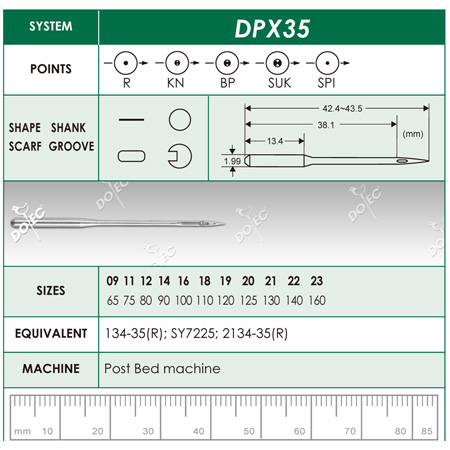

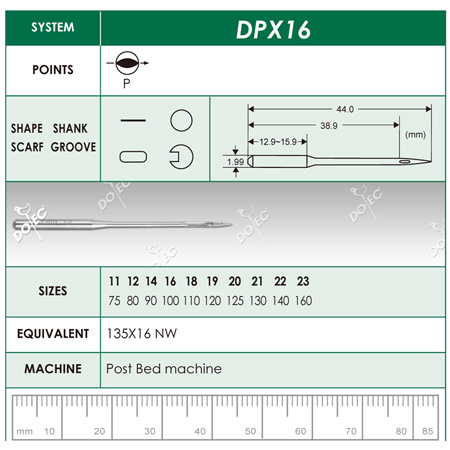

You basically can use either needle in either machine when you adjust the needle bar height. 135x16 is a little bit longer than 134-35. So if you want to use 135x16 in your Pfaff 335 clone you have to raise the NB by the amount the the 135x16 is longer than the 134-35. Looks like approx 0.8mm + some fine tuning. Measured from end of shank to right above the needle eye. I have set the majority of my machines to 135x17 / 135x16 just for the reason that I do not have to stock different needle systems. Some technical data sheets from the DOTEC website:

- 3 replies

-

- 134-35 & 135 x 16

- pfaff 335

-

(and 1 more)

Tagged with: