-

Posts

5,764 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Saved a Juki LU-562 from the scrap heap today...

Constabulary replied to Vinito's topic in Leather Sewing Machines

reg. larger hook / bobbin - a while ago I found this Video maybe it´s idea for you. And if you want to upgrade to a larger bobbin / hook it would be nice to if you could post some "measures" regarding paint job - Can't tell from the pic if the upper arm is rusty or dirty but why not painting just the flat bed in glossy black and leave the rest as is. AFAIK the earlier Jukis or Seikos had this too. -

well to me it looks like the take up lever is there its in its upper position. But seems both slide plates are missing What I would check is the condition of the timing belt. if it is brittle or cracked I would not buy the machine. You may get the belt for $30-50 or so but replacing it is a pain. I did that once for a friend and it was no fun. Replacing a timing belt on a Singer 111 is like a breeze compared with the Adler. I just checked - it was approx 4 years ago:

-

Me too.

-

maybe you can give us an idea where the screws are located on the machine EDIT: Google is my friend https://www.ebay.com/itm/5PCS-194E-JOINT-SCREW-FIT-FOR-SINGER-29K-/153446214078

-

Thread guide clearance issues

Constabulary replied to keithski122's topic in Leather Sewing Machines

I don´t know which machine you are using so I´m assuming you are using a 135x16 / 135x17 needle (or even shorter like 134R or 134-35?) You could use a longer needle - like system 190 (or 135x17 when you are using 134-34 or 134R). Then you have to raise the needle bar and the NB is no longer touching the foot. -

I´m using an 8mm V-Belt on my 108w20 - no problems!

-

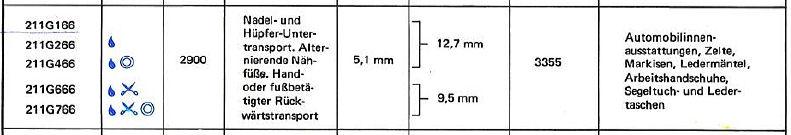

sorry - mistyped or misread - you have 211G266 - not 166. Still, the 211G266 also has 5.1mm stitch length. Here is an extract from a Singer sales brochure:

-

well, when you already figured your problem is on the underside of the machine then a picture of the underside could probably help. However I guess the stitch length "problem" is solved since you have a 5mm stitch length on your 211G166, right? Anyway - the 211G166 has 5.1mm and the 211G165 has 7.3mm - thats true. But as far as I can tell the 211G165 has no reverse.

-

The longest stitch length on the 211G166 is 5.1mm so when you are at 5mm you have reached the max. I´d say. Better post pictures of the actual machine.

-

Agree with Bob - however, I once had a pals 45K darner on my table and he asked the same thing. Fortunately his 45K (don´t recall subclass) had all necessary parts. I guess back then Singer or maybe a dealer took a 45K sewing machine of the shelf then just removed and added some parts an converted it into a darner. So I was able to convert it back into a sewing machines. But you never know - when the parts are not present it makes not much sense.

-

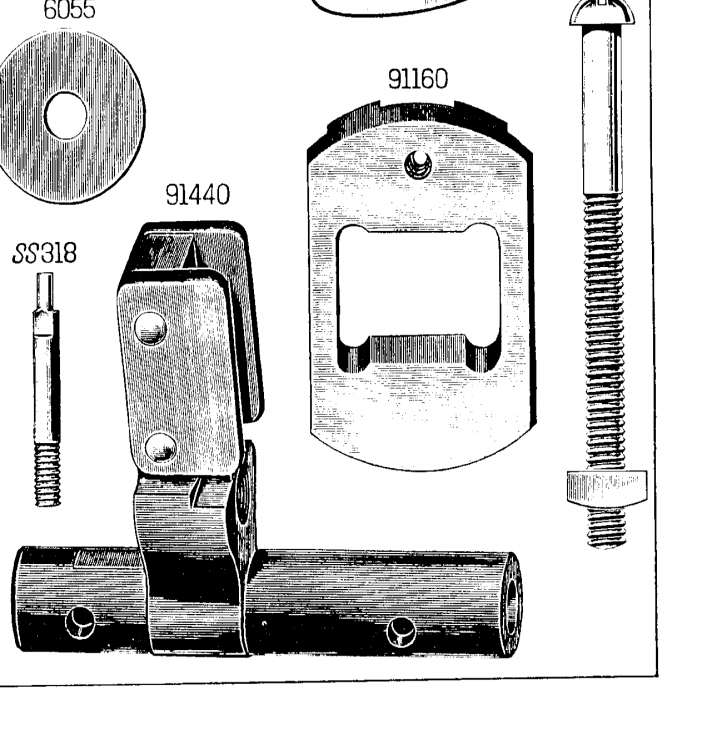

Post some pictures please. Remove the needle plate and check if the lifting cam frame to which the feed dog is attached is present. It looks like this (91160) and rides on the bushing of the shuttle driver (98608) the shuttle driver needs a "bulge" on the bushing because it controls the up and down movement. Most important is if the machine has the shaft that controls the back and forth movement of the feed and if it has a stitch length controller "device".

-

Post some pictures so we probably can ID your machine. Could well be that the badge is from a different machine . Maybe one of the former owners (not necessarily the last owner) had different Class 17 machines in use... So true! I´m always surprised what I find in my own drawers.

-

Shuttle race looks like a plain CB shuttle race. Noting unusual as far as I can tell from the backside of the race. Im not 100% sure but the 44-79 seems to be a shorter version of the 31-19 so the timing values should be the same. You can download a manual for the 31-19 here Manual for Singer 31-19

-

it was just an idea I have to look up the machine similarities as well but the Seiko or Consew website may show machines similar to your Singer 168w or 17

-

or lower the tape guide and / or set it further way from the foot towards the operator - but I only can guess cause I don´t know the whole setup.

-

What is called a service manual often is just an "advance user manual". I have never ever seen a real service manual for the vintage Singer industrial machines. I mean in terms of stripping and reassembling a machine. Not saying there are none but I have never seen one or even heard of them. Often the user manuals include some advanced technical information for timing and replacing timing belts (Singer called it arm shaft connection Belt) and the so forth but that's it Maybe there is a chance when you look for later made Singer clones of your mentioned machines (like Consew or Seiko). Maybe the clones have more detailed service manuals (but I honestly doubt). A lot of the nowadays clones are based on the older Singer machines. However, if someone has a service manual I hope he´d share it here!

-

D or S tip needles are indeed hard to find in system 328 / 214x2. Unfortunately I have no source. I would check with SCHMETZ or GROZ BECKERT customer service maybe they can help you. R tip needles you can buy from College Sewing in the UK. https://www.college-sewing.co.uk/needles/groz-beckert-industrial-needles/214x1-groz-beckert-needles maybe they have other odds and ends you could use like bobbins, thread nips, screw drivers, needle threader.... I always order thinks like that.

-

Needle should be system 16x4 if not set to a different needle system (f.i. 137x17) - thats not unusual. See attached manual - it should answer most questions. Machine should be pretty much the same (beside the B and W suffix). Minor differences may be possible. If you are looking for information or parts look for Singer 136w machines 136W100,W101.pdf

-

That is because of the LR tip needles. I would use S or D tip needle for a straight seam. Check this website: https://www.schmetz.com/en/industrial-needles/needle-compass/cutting-points/ Or check this PDF brochure: GrozBeckertCuttingPointsBrochure.pdf

-

Adler 205 Used vs Typical 441 New?

Constabulary replied to Gusta1's topic in Leather Sewing Machines

Adler 205 came in different subclasses - what subclass are you talking about? -

Adjusting walking foot height

Constabulary replied to dreamsicle23's topic in Leather Sewing Machines

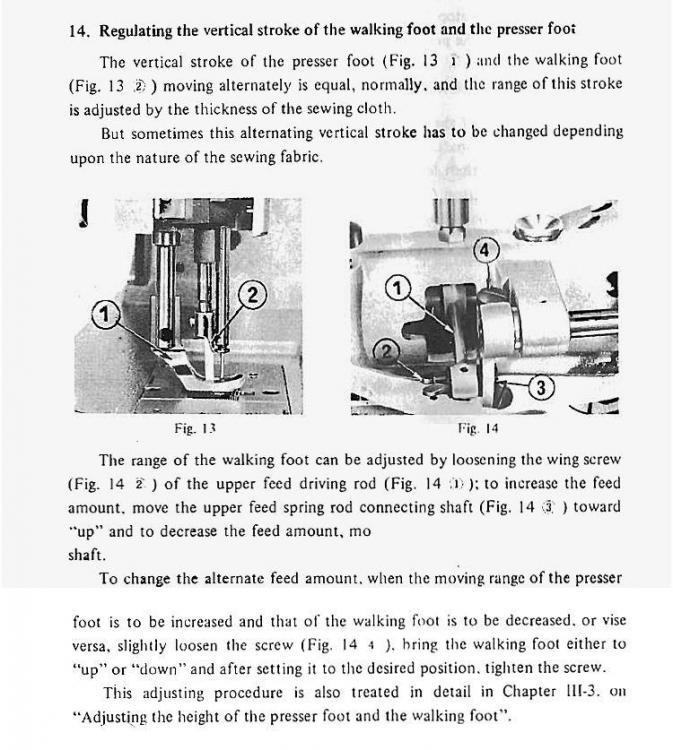

I´m not 100% sure but do the 111 clones have the singer type "Foot Lift Eccentric" on the top shaft as well? AFAIK the clones have the slide cam (right word?) just as the Pfaff 145 / Adler 67. Or am I on the wrong track? Like this? EDIT: The manual came from Keystone Sewing: Juki_LU-563_Instruction_Keyfooter.pdf -

Adjusting walking foot height

Constabulary replied to dreamsicle23's topic in Leather Sewing Machines

and what clone is it? Please post some pictures. Hung on the raised material I guess , right? Usually there is a cam on the backside where you can adjust the foot height. -

BY FAR - one of the coolest leather bags I have seen! EXCELLENT!!! They should sell like sliced bread I think!

- 41 replies

-

- messenger bag

- shoulder bag

-

(and 3 more)

Tagged with:

-

interesting that nowadays everybody is expecting a video instead of looking for a manufacturers manual. I googled it for you ls341n.pdf

-

I guess its a SEIKO made but Singer labeled machine. Serial number does not help (me). The 51w has a shorter bed and a slimmer body / upper arm than the 136w so to me it looks like a 136 class machine.