-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Old Pfaff 1245 with Quick-Rotan and Singer 211g766

Constabulary replied to m4rym4ry's topic in Leather Sewing Machines

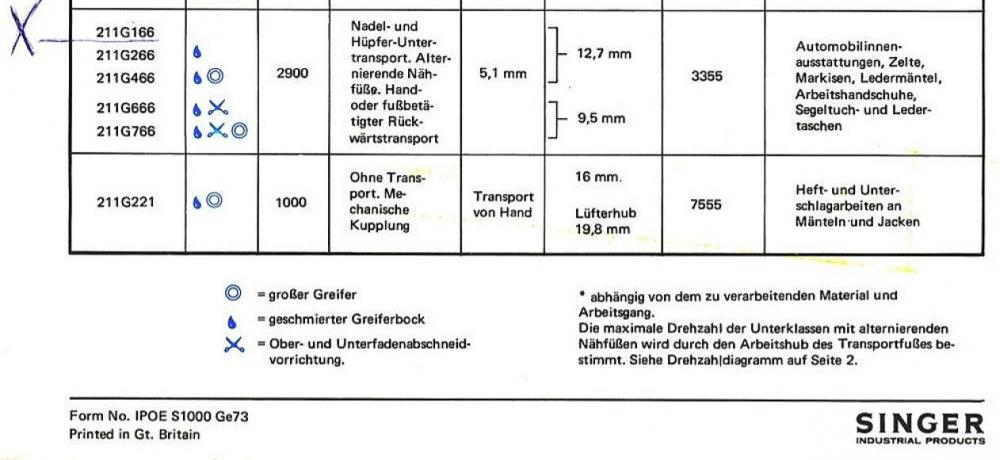

Just from looking at few pictures... regarding motor - if they work great if not do not waste time and money in this old clunkers buy a new servo motor instead - really! If I had to choose I´d choose the machine with the fewest electronically controlled devices! Why? Because they are OLD and the motors are "dead" and I don´t think they are not supported anymore. regarding singer 211G766 - see attachment Hope this helps I would probably buy them both refurbish them both keep one and sell the other one - maybe you break even and so you have the other machine for free or even make a profit -

Seems I misread - I was on 120/3 (which is a thread size and not the needle size) #23 is a NM 160 needle so I was a bit off with my assumption of max. 140. If it can handle larger needles than 160? I don´t know if I were you I´d buy some needles and thread and test it! It is a clone machine - you never know if they are set up like the originals. Testing a machine before buying it is ALWAYS the best bet! In a German sewing forum someone is using 180 needles on a Pfaff 335 clone (Shanggong 335 or so) - seems it works but that for sure is pushed to the limits. Personally I would use needles up to 140 on machines of this class and everything larger from 160 onward I would use a different machine with barrel type hook (like Singer 45K, Adler 5, Adler 105 or similar)

- 6 replies

-

- wimsew

- leather sewing machine

- (and 4 more)

-

Speed control by pedal force or movement?

Constabulary replied to Gymnast's topic in Leather Sewing Machines

Sorry to say that but for "just operating a sewing machine" this is a bit too much science for me. Pedal down force? Really? For what? Honestly I do dot care and I´m not event trying to follow all this. But as we say in German "Jedem Tierchen sein Pläsierchen" Good luck with this! -

looks like the Wimsew 246 is a clone of the JUKI DSC 246. Juki website says you can use up to 120 needles but often a bit larger needles like 140 are possible (but I only can guess). Check the specs on the JUKI website: https://www.juki.co.jp/industrial_e/products_e/leather_e/cylinder_e/dsc2447_2457_2467_244_245_246.html

- 6 replies

-

- wimsew

- leather sewing machine

- (and 4 more)

-

You can! I have it like that all the time. Never had any issues. Especially THIS forum really is!

-

Two questions about a first sewing machine...

Constabulary replied to tammaraki's topic in Leather Sewing Machines

well, I´d check the Mfg. web site and compare the specs . Guessing you are talking about new machines / latest models. http://www.consew.com/view/consew-model-206rb-5 http://www.consew.com/View/P1206RB -

if you don´t drop it it will most likely never crack. Singer 18 also looks fragile but never heard of a broke arm from just operating the machine.

-

Glad you found the information you need. I hope I did not sound offensive but as a (quite) long time member here I figured more and more people don´t do the obvious first - like contacting a seller / dealer or even more obvious reading the manual. Now you figured why Have fun with your machines!

-

Who says that? It usually is a question of how the machine is set up and if the OP has read the manual. Have you read the manual? Its mentioned in the manual how to adjust the foot hight. And its the same process as on the Pfaff 545.

-

When your are sure the timing is right (see manual) then only the needle is left. Try what I did - maybe it helps. BTW - my NB does not have the timing marks either. just checked my OEM hook again - I have not noticed the # on the bushing - its the same as yours - see picture: EDIT: No camera stand, camera is a Canon SX-1 IS It has a super macro setting - old camera but works well (even shows how dirty my fingers are )

-

Now I know what you mean - issue could be the needle. Some have longer tips than others. I wanted to switch to 135x17 needles but it was not possible because they have longer needle tips and they are scratching the hook BADLY. So I had to stick with 135x1. I have different 135x1 needles and they slightly differ in the tip length. You can try to raise the the needle bar a tiny bit or grind down the hook body a bit (in worst case). Most 135x1 needles I have are 36mm long +/- a little bit but just the one in size NM 120 I´m using the most is approx 1mm longer. So I raised the NB a tiny bit and now it works. Hook is still catching the thread loop w/o skipping stitches. I still have the hook... let me check... EDIT: The OEM Singer hook base has the number 244014. Not sure what the number of the complete hook is. Can post a picture later today. EDIT II: see pictures. Needle are all from differen Mfg´s (Schmetz, Solidor, SNF, Singer) SNF actually is Singer too.

-

Its another Chinese made clone of the Singer 29K71 with the difference of an older type (simpler) thread regulator.

-

Post some pictures please

-

W/O knowing all the parts number but you probably have to move the hook and hook shaft bushing a bit. This is my 108W20 I also have a link to a manual in the 1st post. I replaced the hook with a non Singer hook (NOS hook but from a German Mfg - works very well) and I also had to move the bushing a bit. Hope it helps.

-

that would have been my 1st question too other than that I unfortunately never have touched a Class 18 machine so I don´t think I can help.

-

Accessories for my new machine. Typical 441.

Constabulary replied to Gusta1's topic in Leather Sewing Machines

it´s a good idea to mention your country in your profile so people could probably point to certain dealers. Please update you profile. But seems you already found a source for the parts - what other information do you need? What kind accessories you will need depends on your work. I probably need other accessories than you and the guy next door needs something else.... -

where are you located? Essex in the UK? https://www.ebay.co.uk/itm/SINGER-132-K6-HEAVY-DUTY-SEWING-MACHINE/153660274459?hash=item23c6ddb71b:g:sQcAAOSwsVpdMGgU Other than Singer 132K - check for Singer 45K

-

Servomotor - Speedreducer - Needlepositioning/EPS

Constabulary replied to Pterytus's topic in Leather Sewing Machines

Thats why I never tried it again. I just removed the NPS - done. I think the 2nd magnet does not work for "2-Button" JACK servos because you cannot change the magnet settings (at least I wasn´t able to figure out how). Anyway, I think I will try this one day when I set up something new - maybe I will choose a different motor then. -

for small parts orders I`m sometimes using TROJAN sewing in the UK as they have fairly low shipping costs to Germany: https://www.trojansewing.co.uk/?s=194E&post_type=product

-

Servomotor - Speedreducer - Needlepositioning/EPS

Constabulary replied to Pterytus's topic in Leather Sewing Machines

-

Saved a Juki LU-562 from the scrap heap today...

Constabulary replied to Vinito's topic in Leather Sewing Machines

reg. larger hook / bobbin - a while ago I found this Video maybe it´s idea for you. And if you want to upgrade to a larger bobbin / hook it would be nice to if you could post some "measures" regarding paint job - Can't tell from the pic if the upper arm is rusty or dirty but why not painting just the flat bed in glossy black and leave the rest as is. AFAIK the earlier Jukis or Seikos had this too. -

well to me it looks like the take up lever is there its in its upper position. But seems both slide plates are missing What I would check is the condition of the timing belt. if it is brittle or cracked I would not buy the machine. You may get the belt for $30-50 or so but replacing it is a pain. I did that once for a friend and it was no fun. Replacing a timing belt on a Singer 111 is like a breeze compared with the Adler. I just checked - it was approx 4 years ago:

-

Me too.

-

maybe you can give us an idea where the screws are located on the machine EDIT: Google is my friend https://www.ebay.com/itm/5PCS-194E-JOINT-SCREW-FIT-FOR-SINGER-29K-/153446214078

-

Thread guide clearance issues

Constabulary replied to keithski122's topic in Leather Sewing Machines

I don´t know which machine you are using so I´m assuming you are using a 135x16 / 135x17 needle (or even shorter like 134R or 134-35?) You could use a longer needle - like system 190 (or 135x17 when you are using 134-34 or 134R). Then you have to raise the needle bar and the NB is no longer touching the foot.