toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

No-one!

-

This came to the fore again after Dikman started talking about airbrushes. Thought about doing it many times because I think having a charged up spray can of each of your most used dyes is a great idea but never tried doing it until now. Let me begin by saying this is a fail but not by much. Read on. I started off with an empty paint can and one of those rubber nipples you use to blow up your car tyres. Wanted to see if it could be done the same way it's done on your car, ie no glue, so I drilled a hole a bit smaller that the grommet. There was too much meat on the nipple. Couldn't get it in the hole so I cut away some of the meat. Once it was in I undid the valve and poured in some thinners to clean it out. Then I pumped it up gradually to see if it would hold and it did...... for a while. It held at just over 100psi Until this happened and it blew out. So cutting the rubber away and brazing or soldering would definitely be the way to go or maybe even araldite. The part I'm not sure of is the spray pressure. I was checking by pressing the the top now and then but the air coming out didn't seem right for the psi but that was with an empty can. When I held it against my skin it seemed reasonable. What are the hive's thoughts on whether it would be better with some fluids in it? I know if I filled it to about a third I definitely wouldn't be putting 100psi in it. Would the setup work as is with fluid and maybe only pumping up to around up to around normal tyre pressure, maybe 30psi. I'll have another experiment but it would be useful if you guys chipped in.

-

Skiver upstairs, Large compressor downstairs. If I want to use the vacuum on the skiver it means a long hose between the two. What's the smallest compressor (quiet) that will drive the vacuum pump? Thanks peeps.

-

This is not about design per se but it might help with any project that you take on. It's about your starting point and logic. I've got more fasteners and hardware etc than you can shake a stick at but you can bet your arse if I design for a 1 inch strap, when I get there I won't have any 1inch strap ends or buckles and if I do they won't be the same colour as the rest of the hardware. So work backwards and collate everything you need beforehand even down to the dye colour and the matching or contrasting thread. Hand sew or machine sew will be a massive difference. Hole punching on a curve will gradually bring those two pieces together around the curve. Try doing that on a machine. Not saying it's not possible but a whole nother ball game when designing for it. Good luck.

-

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

Have a listen to Arthur. He's probably a really nice man but I can't handle it. This is not one of his worst.

-

I think you should go slow or even use slow motion to show a difficult or intricate technique, in fact it will be appreciated but for me I can't do slow for no reason. There's one guy in particular talks so slow I can't watch more than about 30 seconds.

-

Never heard of it before but a good practical piece. Well done.

-

OK Yin! This is just my opinion and I only say to help and maybe show a different viewpoint. Back to the painters tape - I'm thinking it will stick much better if applied when dry, also hold the casing longer maybe. Don't know, never used it but tape is tape right. And maybe explain somehow how much the leather will expand under what techniques especially for people who want to make something to fit in a frame. The videos - With the amount of content out there these days you have to do everything you can to hold their attention before they move on to something else. You have to be ruthless. I think you could shorten it by half and not lose anything important. Doing one video on something as simple as casing on it's own would be a definite no no. more content but only long enough to get the point/technique across and move on. If aiming at beginners you have to think like a beginner. For instance, would a beginner know to search for "casing leather"? Love the intro and the structure and wanna see more vids. You're almost there. Good luck.

-

I would scrub the whole thing in a very hot bowl of water with some washing up liquid. When dry go over it thoroughly with leather balm/food/conditioner/beeswax etc to put the oils back into it. If you want it to smell nice some cocoa butter also.

-

Good job Yin! I like the style, the font etc. If I might nit pick slightly, firstly I think some aspects could be shorter and secondly, if you are aiming at beginners, they won't understand terms like "casing solution", hell I don't understand what "casing solution" is, I thought it was just water but then I'm not a tooler. One last point, a genuine question, does the painters tape stick to damp leather? Or maybe put it on before casing? I've never seen blue painters tape over here in the UK. I'm not a tooler but I know your work and I will be following. I'm sure I'll learn lots.

-

Sorry no but where I do my workshop is very much that way inclined and almost everyone is involved in Cosplay, Larp, medieval, traditional archery etc. I'll ask and get back to you.

-

HaHa! These are mostly gun holster guys. You'd be better off looking in the Cosplay or Larp forums.

-

Some of my bags

toxo replied to angelhc's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Welcome Angel. Looks like you're doing OK. It's good you're trying different styles, just need a bit more practice. A couple of points - A really hairy strap never looks good a rub down with almost anything will improve it. When you're punching holes, always try to look down the line. That's important! If you punch crossways you can't see if a hole steps out of line and it only takes one stitch out of line to stick out like a sore thumb. Good work. -

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Here you go Adam. https://www.artisanleather.co.uk/swing-bag-clasp-small.html Tony See (Dieselpunkro) does sell the complete hardware kit for a lot of his patterns so you don't have to buy 100 rivets or 10 buckles etc. I should stress I have no connection with Tony See but I do like his setup. He makes it really easy for even complete beginners to turn out some nice stuff and if you ever have a problem he'll usually reply to a text within the hour. He also has a great sense of humour. My favourite line on one of his videos, - he sighs and shakes his head, sucks his teeth and says "The zipper, we gotta do the zipper". -

This is a bit like what we call a mattock over here. like a pick axe but with blades instead of points.

-

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

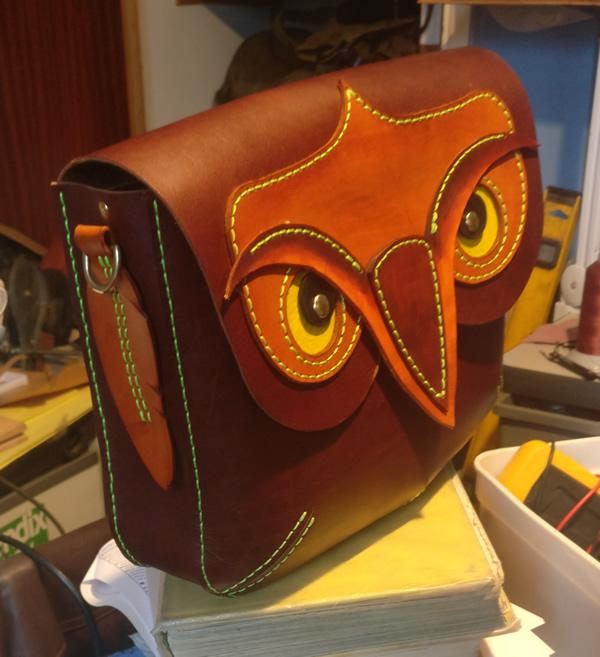

You guys gotta stop it! I promise you if I can do it, you can do it. Go here and join up. This is the link to Tony See's (DieselpunkRo) Facebook page. It's a whole army of beginners who are making lots of amazing stuff. https://www.facebook.com/groups/dieselpunkro As Frodo has already said, every one of his designs/patterns come with complete instructions including a step by step video. He's just started giving away one pattern every week for cheap. I think this week is the Owl Bag for less than a dollar. I made this some time ago. Doesn't have to be bags. Look here for all sorts from Hats to armour. https://www.leather-patterns.com/ -

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

On the blue one the front wraps around the gusset. The brown one marries alongside the gusset. -

Great job! I love a project with a practical purpose. Well done.

-

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks again guys. @PastorBob It's about 7x6x3 inches. Here's another I finished this week. And the front can go both ways. Some like this look. -

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks guys. @RockyAussie She asked for an extra long strap cos she's tall and big chested, (I've never seen her) so she can shorten it to suit. Also the full buckles that I have stick out more underneath so I went with the flat one with a keeper. One of my pet hates also, flappy straps. -

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks @Tequila and @AdamDavis The dye job was an experiment. The trick is to use one of those sponges with lots of big odd shaped holes. In my local shop they call em art or craft sponges. Start out leaving lots of gaps, once it's covered you can't uncover it and you can always do more later. Remember that dye usually dries lighter and on each subsequent series of dabs any colour that's gone over twice or three times is gonna be darker than the first coat. I use a hair dryer between each colour and stand back to decide what colour to do next. Two coats of Resolene or similar will protect it and have it shining like a mirror. Good luck and don't forget to show us the results. -

My latest cross body bag/purse.

toxo replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

And there's Frodo!