-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

A few Fun recent projects

garypl replied to Crispin's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Looks like AR-15 mag holders to me... Gary -

I have paint that is a year old and it works just fine, but several years maybe not the same. I think the worst that will happen is the paint will thicken or harden in the bottle. For that price I would buy a bottle with the oldest expiration date and see how it works. That being said, a little edge paint goes a really long way for a hobbyist. I have a 1 liter bottle that seems to be barely used up after 8 months. I have been giving samples to my leatherworking friends because of concerns over aging. I have been buying 125 ml bottles and they will be used up before they expire. Gary

-

There are good videos on YouTube about timing the Consew 206RB - just search for Consew 206RB in YouTube Gary

-

I spent 8 hours today cleaning oiling, and adjusting my 206RB-4. It was quite a learning experience and I am happy to report that it sews beautifully! It is so quiet and stitches look good using size 16 LR needle and 69 thread top and bottom. See picture below (brown thread - 6 oz bridle and 2 oz goat) I overstitched by turning the workpiece 180 degrees. Only problem I have is I cannot adjust the reverse stitch to match the forward stitch - reverse stitch length is smaller. I tried to adjust the length by moving the feed regulator rod (item 35 in Consew 206RB Feed Regulator parts manual) but I could not get it to move to increase regulate the stitch length. Can anyone offer advice as to how to adjust the stitch regulator? Some of the other adjustments were hard to do at first, until I broke loose stuck parts that must have never been touched before. Maybe the feed regulator rod is stuck, but I didn’t want to force it. For $180 I will be happy even if I never get reverse stitches correct! Gary

-

My first shot at carving and tooling...UGH!

garypl replied to StarcrossedReed's topic in Figure Carving

Looks pretty good for your first effort - I like the original version before you dyed it better! Keep on practicing! Gary -

I agree with going for an electric machine, but if you want a Boss, there is one for sale on Craigslist - here is the link: https://atlanta.craigslist.org/atl/tls/d/leather-sewing-machine/6651491765.html Asking $750 - located on the SC / GA border in Elberton Gary

-

Money Clip Wallet

garypl replied to Bob Blea's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks for the info Bob - I have one of the LW swivel knives and I like it a lot! Gary- 10 replies

-

Someone else snatched up the table and motor today before I could get away to meet the seller:) Oh well, I saved a long drive and the trouble of then reselling the parts, so I am not too disappointed!

-

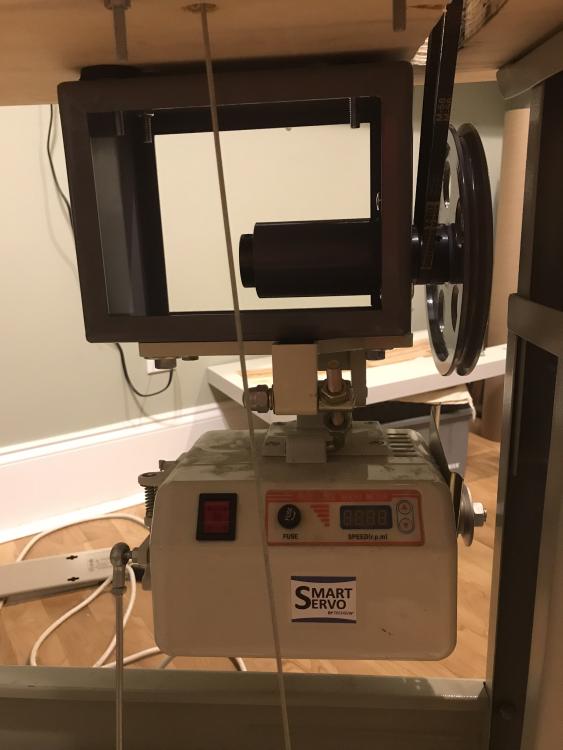

I have this type speed reducer and it costs more than the type shown above by Don, but it is easier to install and doesn’t require you to cut a larger slot in the table. Simply mount the speed reducer where the servo motor was mounted, then bolt the motor underneath the reducer. You will need another vee belt @32-33” to connect the speed reducer and motor. Call Bob at Toledo Sewing and he will fix you up. Gary

-

Okay, you all convinced me - I will pick up the new table this weekend and use it for something! This machine collecting is becoming habit forming! Gary

-

Thanks Floyd - I have another opportunity to buy a table with servo motor, light, thread holder and other accessories - everything but the head - for @$150. The servo motor is not a smart servo - it has the speed control Knob. Anyone have thoughts about this for resale or use if I find a good machine head? Gary

-

Thanks JJN - I just finished cleaning and oiling it and everything glides so smoothly when turning the handwheel. Just have to get the timing right because the presser and needle feet are out of sync. When the needle is down the needle and center needle foot are moving forward instead of backward.

-

Money Clip Wallet

garypl replied to Bob Blea's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Bob - I like the wallet - very nice! I also like that awl - what kind is it? Gary- 10 replies

-

Thanks Uwe - I figured it was worth it I will take a look inside and see if I can find any other identifying marks. Just got it home and won't have a chance to look closely for a day or two. Thanks Ferg! From what I could find, I thought it could be a 205 or 206RB. I will download some manuals and see f I can figure this out. I bought it as a project machine! Gary

-

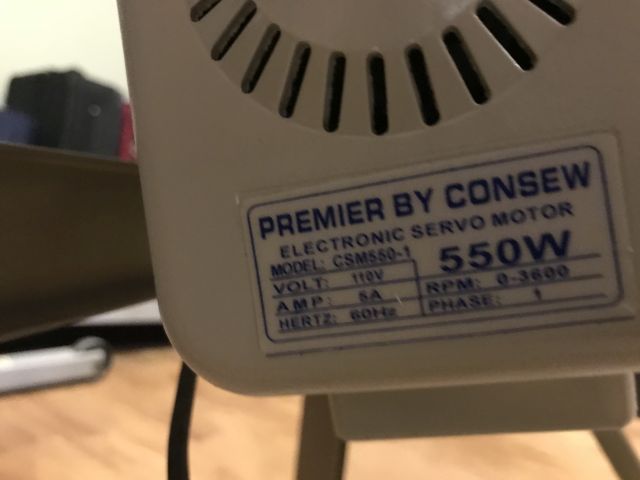

I picked up a used Consew machine today for $180. It included head, table, speed reducer, servo motor, old clutch motor that was replaced by servo, thread and other accessories. It runs but timing is off (I guess) the feed mechanism doesn't advance the material, just shifts back and forth. I am not sure of the model - could not find a model number anywhere, but here are some pictures - maybe someone can help identify it. The hook is in the front (vertical). I figure the speed reducer and servo motor were worth the price I paid. Both seem to be in fine working condition. Thanks for any information. Gary

-

Holster and Gun Belt

garypl replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Ryan, that’s a beautiful rig you made! Did you sew the belt and then trim to size? Almost looks like the cartridge loops are a separate piece of leather, but I can’t imagine sewing such a thin strip along the top edge. Nice work! Gary- 41 replies

-

Very nice work! Gary

-

Hi Thom, Welcome to the forum and thanks for your service! Sounds like you found a great resource in your local sewing machine repairman! It can be difficult to find a good repair shop nearby, especially one that wants to work with you to help get you started. Post some pics of your work and let us know what materials you are using - always something to be learned on this forum. Gary

-

I really don’t know anything about saddles, but I think you did a beautiful job on it! Gary

- 26 replies

-

Hydro/ vacuum formed knife sheath

garypl replied to ComputerDoctor's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I agree with Chrisash - first thing I noticed was the leather formed around the handle bump as a potential barrier to drawing the knife. I use a small vacuum bag from my kitchen for small items and I place a smooth piece of wood behind the leather to prevent the cross hatch pattern from the vacuum bag from imprinting on the leather. The bags have the cross hatch only on one side to pull the vacuum. Gary -

Patterning the old way when the CAD is just too hard

garypl replied to RockyAussie's topic in How Do I Do That?

Brian, that finished bag looks great and I am in awe of your talents, both in pattern making and crafting ability! Looking forward to seeing more about this project and thanks for posting! Gary- 40 replies

-

- crocodile cross body bag

- pattern making

-

(and 1 more)

Tagged with:

-

Happy Birthday Johanna and thanks for all you do to support this great forum! Gary

-

That’s a very nice looking belt and should last a long time! Gary