-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

The short answer is: No, it shouldn't be like that. The needle should not keep moving forward after it penetrates the material. Your feed and needle movements are out of synch and need to be adjusted. That video link above does not work, by the way.

-

Three years ago I bought a small warehouse full of mostly heavy duty industrial sewing machine, about 30 cabinets worth of vintage parts, and about a dozen boxes full of original vintage documentation and sales literature. I've decided to simplify my life and change direction. That plan includes selling the entire remaining inventory wholesale for a firm $15,000. That calculates to an average of $100 per machine, with literally tons of free parts and documentation. Some machines are worth less than $100, but some machines a worth several $1,000. I'm NOT interested in selling individual machines or parts, it's all or nothing. The pictures are from 2016 when I bought the inventory. The entire inventory now lives in my 900 square foot garage on four industrial palette storage units, each measuring 4' wide x 8' long x 8' high, just so that you have an idea how much storage space you'll need to plan for. Count on needing at least 500 square feet of 10' tall warehouse space to house this inventory. Three of my four palette storage units will be for sale separately, in case you want some. Fair warning - it took me nearly a month to move the inventory to my location in 2016 - by myself. It should be a lot quicker this time around since I re-packaged most of the parts and broke down many of the tables to save storage space. Prepare to spend several days loading this stuff into a container or onto a really big truck by yourself. If you show up with a team of burly movers, it may go a lot quicker. Most of the big machines are on rolling plywood platforms or dollies and relatively easy to maneuver. I have a riding forklift that you're welcome to use (but only if you know how to use it.) You'll need to bring pallets or wooden crates (available very cheap locally near Monroe, Michigan.) My garage is in a residential neighborhood and I need to be mindful of my neighbors. If you are seriously interested send me a DM here on LW, email me directly at uwe@uwe.net or call me at +1 734-536-0901. I don't want to discuss details publicly or make the identity of the buyer known. I've updated the pictures PDF and inventory PDF to exclude the machines I sold in the past three years. The 150 machine count is approximate and likely on the conservative side. I live near Detroit, Michigan in the US. I'll be in Europe from May 8-31, just FYI. Here's the PDF with the pictures: Uwe-Inventory-Pictures-2016.pdf Here's a PDF with the inventory details:InventoryList2019.pdf I'm attaching a few pictures of the machine highlights.

-

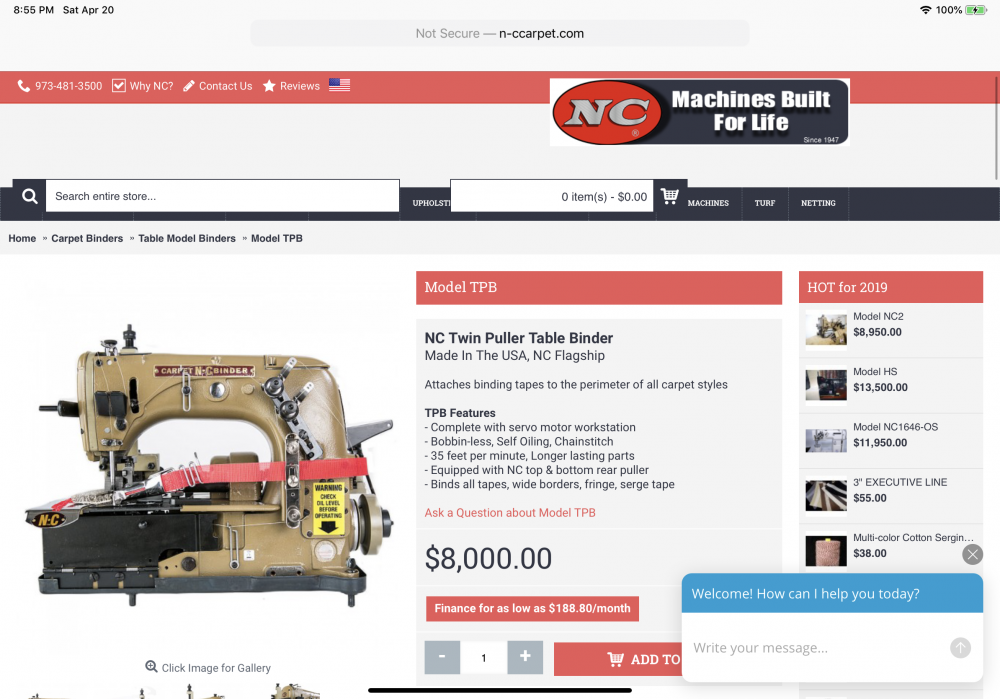

You’ll probably need a specialized carpet binding machine with built-in pullers. A simple walking foot isn’t going to pull a large rug through the machine. This Youtube video shows the type of machine you likely need: The machines made by N-C Carpet are not cheap http://www.n-ccarpet.com/index.php?route=product/product&path=600_1500&product_id=321

-

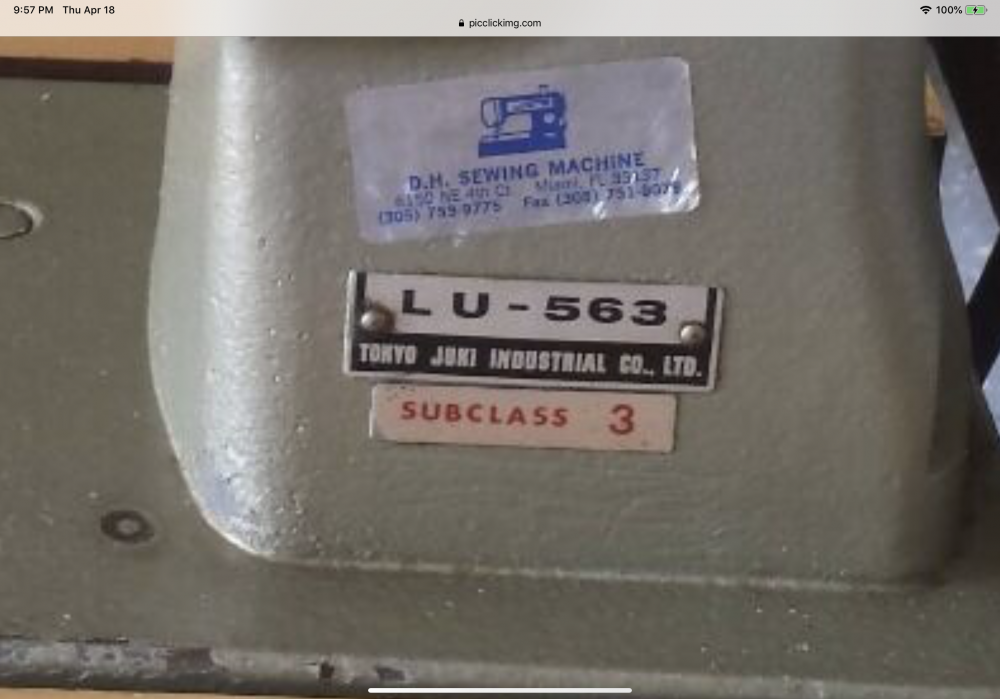

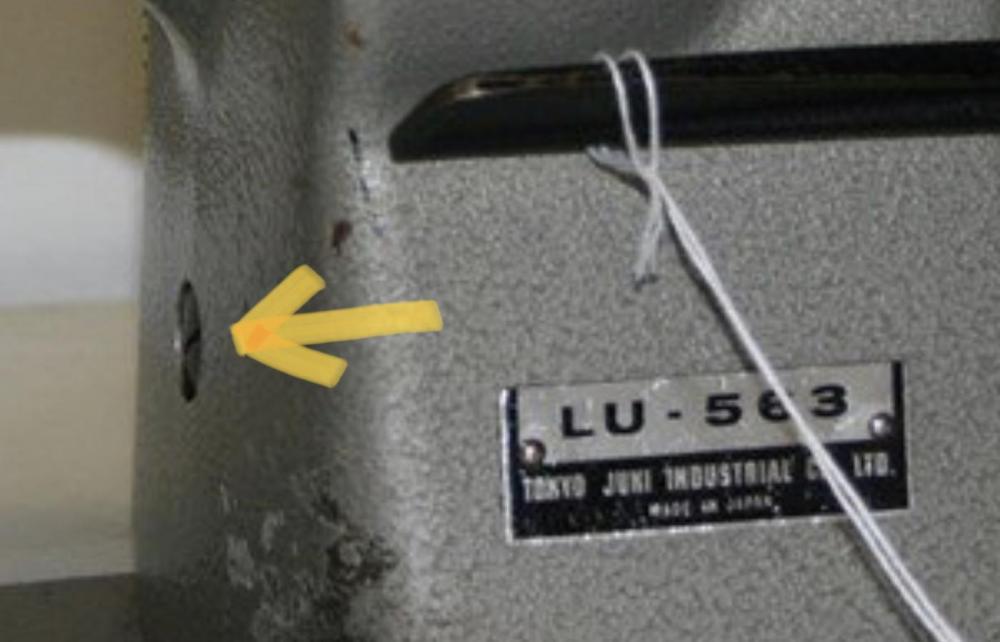

How can I tell if a machine is a 563 or 563-3?

Uwe replied to blackmad's topic in Leather Sewing Machines

The Juki LU-563 Subclass 3 machines normally have a separate little sticker just below the main ID plate. That little “Subclass 3” sticker can easily come off and get lost. In my book any Juki LU-563 without reverse is a Subclass 3. The standard Juki LU-563 also have a tell-tale reverse lever shaft attachment point visible on the left side of the riser. That detail is missing on your machine. So yours is a Subclass 3, as opposed to a regular LU-563 which just had the reverse lever removed. -

Flatbed table attachment for Adler 869?

Uwe replied to drunknpirate's topic in Leather Sewing Machines

Would you mind sharing the link to that website? These kind of reference to online resources work best if you make it a clickable link. Don't make dozens of people try and Google it when you already know the website address. -

Flatbed table attachment for Adler 869?

Uwe replied to drunknpirate's topic in Leather Sewing Machines

The only example I could find of a flatbed attachment for the Durkopp Adler 869 is sold by Sieck (http://www.sieck.de/en/machines/sewing-bags-and-leathergoods/arm-type-triple-transport/?produkt=7286) in Germany. They charge 200 Euro for that flatbed attachment. Here’s a picture from their website for the LW archives: The arm design of the DA 869 is very different from the vintage DA 69 and modern DA 669. The flatbed attachment I make for the vintage DA 69 won’t fit the DA 869. -

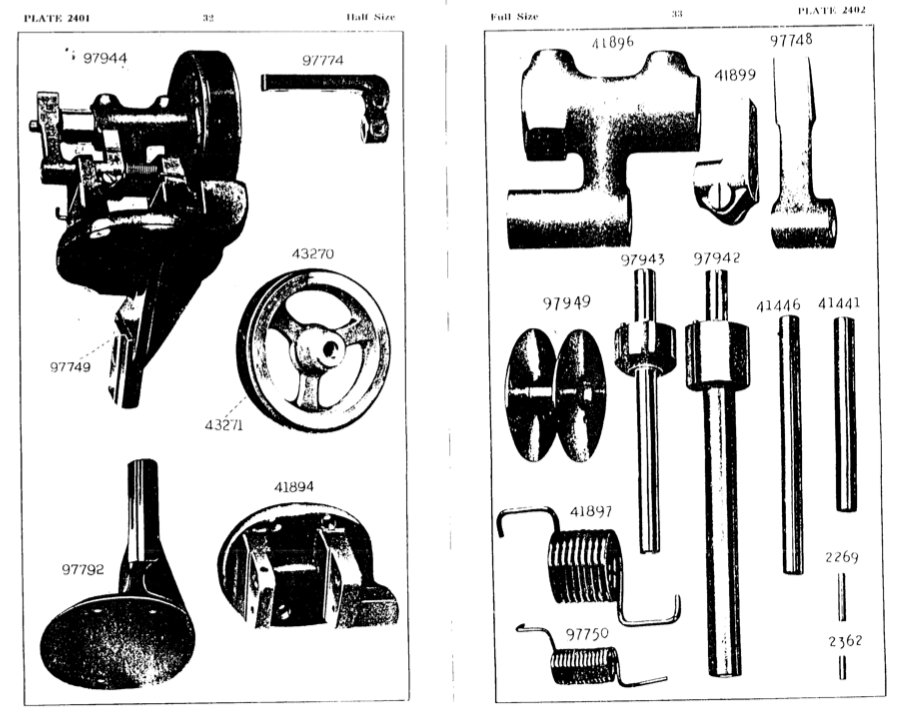

Are You Able to Identify this Simanco Part?

Uwe replied to Evo160K's topic in Leather Sewing Machines

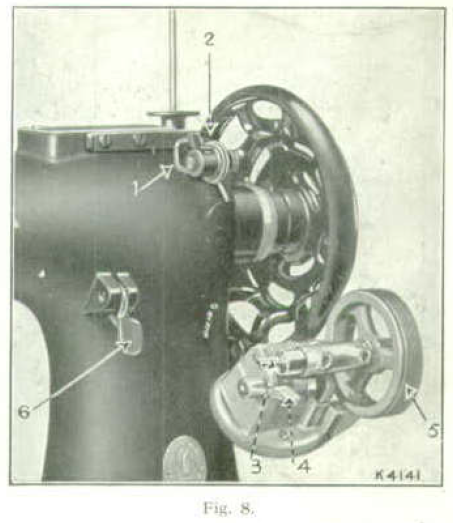

It's the bobbin winder from a Singer 132K. I can only make out the "41896" number in the pictures above, but it matches the parts diagram of the Singer 132K. Looks like yours is missing the rubber "tire" that should sit in the groove and provide friction against the handwheel. Here's the picture from the SInger 132K owner's manual (Singer 132K Manual.pdf) This page is from the Singer 132K parts list (132K6_10_12.pdf) -

205 Adler Clone Recommendation for Binding Work

Uwe replied to anvlts's topic in Leather Sewing Machines

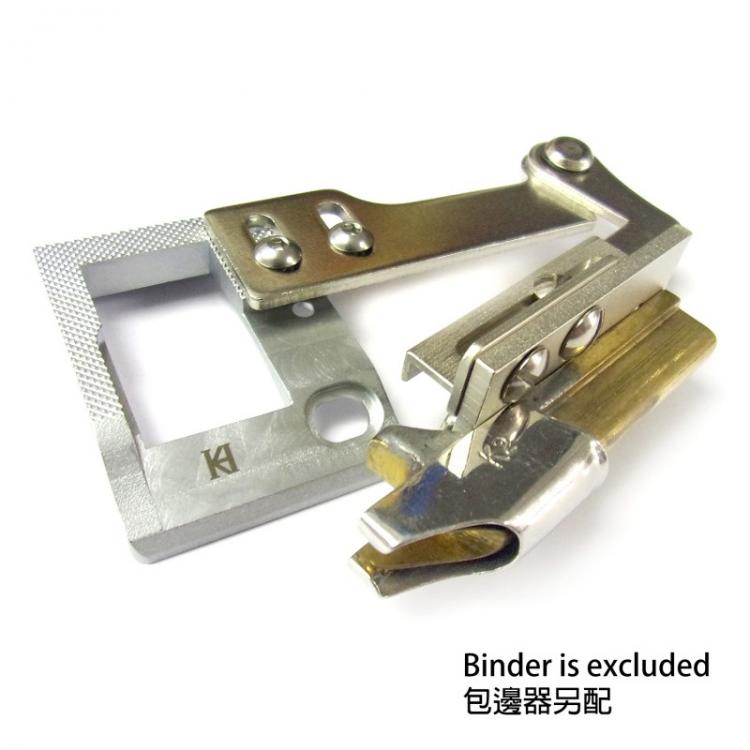

The Durkopp Adler 205-370 class of machines and clones are by far the best synchronized binding solution I've seen in that category of machines. The synchronized binding solutions for the Juki TSC-441 and clones look similar, but don't function the same way. I've not personally used the 205 clones sold by SewPro, Weaver, or Cowboy dealers. I would expect them to be of similar quality. The 205 clones I have lack the access hole in the arm needed for synchronized binding. The length of the arm on the 205 clone is an important consideration. The synchronized binder kit that Kwok Hing makes is designed for the standard 12" arm (DA 205-370). Some clone machines have longer arms (e.g. 205-420) and may not accept the KH synchronized binder kit. You can order KH parts for the DA 205 directly from their online store: http://www.khsew.com/index.php?route=product/search&search=205 You have to register to see pricing and place an order. The order confirmation email normally includes Paypal as a payment option. KH also released a fixed binder kit (KH205-FNP/FDB) recently, but I've not yet tried it. This kit should work with all 205 clones, regardless of arm length or access holes. Here's my installation video mentioned earlier, using an original Adler 205-370: Here's a video with a few binding samples: -

Pfaff 545 H4 Best Feet for veg tan leather?

Uwe replied to PWDrawhorn's topic in Leather Sewing Machines

I'd recommend trying standard Pfaff double-toe feet with a knurled outer foot (e.g. Kwok Hing part KP-1245W). I have some left in stock if you need it fast (KP1245W). If you have time, you can also order directly from Kwok Hing at http://khsew.com for less. The inner foot is perfectly smooth to begin with except for climbing teeth at the front. I doubt the knurled outer foot will leave major marks, but if it does, it's easy to turn it into to a smooth outer foot. I prefer using a pneumatic rotary sanding disc tool to make toothed feet perfectly smooth in about a minute or two. The bigger the footprint, the less likely it is to leave marks. Tiny footprints are not your friend when trying to avoid marking leather. Here's a picture of the underside of the KP1245W feet: -

You are talking about the needle guard. This is a part that can be bent slightly and carefully with a screw driver to adjust it. When bending the needle guard, make sure you don't use the hook tip as a lever point (it may break the tip of the hook!). Rotate the hook into a position so you can use the body casting as a lever point to push the needle guard plate in or out. The needle guard is supposed to barely touch the needle when the tip of hook is at the needle. The function of the needle guard is really to protect the hook. It prevents the needle from getting deflected towards the hook and causing the hook to strike the needle. It's best to upload videos to Youtube and share the link here in order to keep the video with the topic and so that others can see and learn from it too. I can do it for you if you don't know how. My email address is uwe@uwe.net I made a short video once that was an addendum to a hook timing video. It shows how the needle guard is supposed to barely touch (or "kiss") the needle. The same applies to the Pfaff 193 (and just about all other machines with a needle guard.)

-

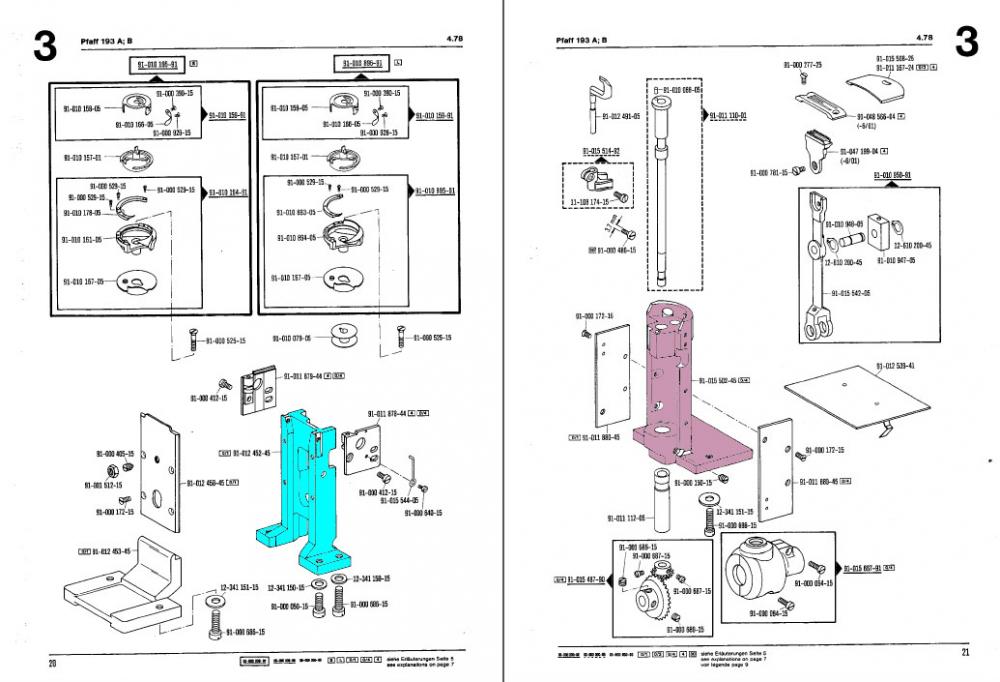

That picture upload did not work, sorry. It's a bit of a science to upload pictures in this form. Unless you pay-to-play, you have to downsize pictures before uploading. Either way, you can drag-and-drop or use the "choose files ..." link to upload pictures. The post on the Pfaff 193/593 (and many other post bed designs, I suspect) consists of two halves that can be moved independently. The left half of the post (blue in the picture below) is the feed dog carrier - it needs to stay aligned with the needle. The right half of the post (red) is the hook carrier. Either half can be moved independently of the other a small distance. This allows you to adjust the distance between hook and needle. The left side of the post needs to stay aligned with the needle, to make sure the needle is centered with the hole in the feed dog. In order to adjust the position of the hook relative and the needle, you have to move the RIGHT portion of the post. The post cover plates front and back have slotted holes or simply slide over the opposing part to allow relative position changes between the two halves of the post. In order to adjust the right half of the post, you'll also have to move the hook driving gears to make sure they stay nicely meshed. That's my theory, in any case. I have a Pfaff 593 but I've not yet adjusted hook-to-needle distance on it. If, as you say, it's really the bottom of the bobbin case that touches the needle, something totally different may be going on. Pictures are indeed required to have any chance of remote debugging. Here's a detail picture of my Pfaff 593 post. You can see that the front cover plate is really only attached to the left half of the post.

-

That may be true for a few particular models. Perhaps you misinterpreted something or somebody misspoke when you were there. Durkopp Adler has factories in several countries (Germany, Czech Republic, China, etc.) Only a select number of models are produced in Bielefeld nowadays, mostly high-end automated workstations for garment production. The Durkopp Adler 267 Traditional in particular is produced in China, I'm quite certain. The showroom in Bielefeld appears to have nearly every model Durkopp Adler (and Pfaff) currently makes on display, but not all those machines are built in Bielefeld. At least that was true when I was there in 2017.

-

Looking for a manual for my Adler 467 FA-373 G2HP

Uwe replied to 2bdana's topic in Leather Sewing Machines

You likely won't find a manual specific to just your model, but rather a general manual that covers a bunch of available options, including yours. The "G" means that it should have a wheel on top of the machine to adjust walking height (stroke) of the feet. The HP option means that it is capable of switching between two walking heights by means of a knee switch. Actuating the knee switch makes the machine use max foot walking height (to cross seams, etc.,) The default walking height is the one dialed in with the wheel on top of machine.On some machines, changing walking foot height also limits the maximum sewing speed. The Durkopp Adler 467 Service Manual (Durkopp-Adler-467-Service-Instructions.pdf ) covers various options, including your "G" and the "HP". Post some pictures of your machine including the type plate on the back, when you get a chance. -

Wanted to buy: Adler 30 or Singer 29K series sewing machines

Uwe replied to Willowfield's topic in Old/Sold

Love that acrylic handwheel @threepets! -

Wanted to buy: Adler 30 or Singer 29K series sewing machines

Uwe replied to Willowfield's topic in Old/Sold

I have a nice original Adler 30-1 and I'm game to meet up in Akron, OH about halfway to your ZIP. I'll send you some pictures later today. Regards, Uwe -

The folks a the Leather Machine Company who market the Cobra brand have some odd marketing policy not to make basic information available online. They want you to call them and talk their sales or support people. When you buy one of their machines new or used, you kind of buy into that philosophy. So give them a call - it's what they want.

-

I made a video on this topic using a Pfaff. The concept is the same for many other machines.

-

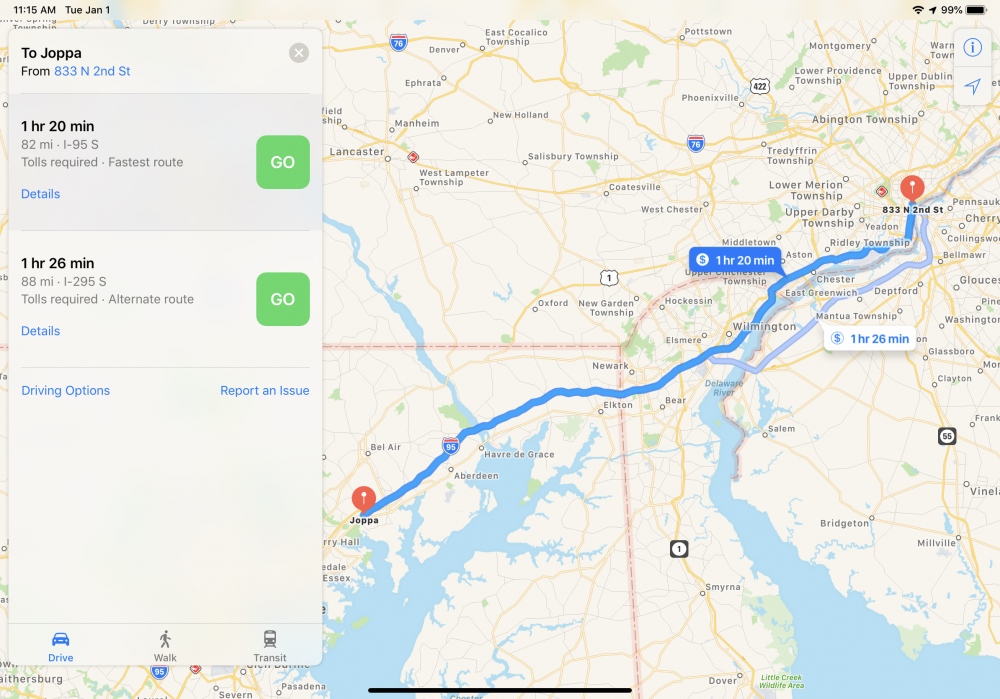

Keystone Sewing in Philadelphia is only about 85 miles from Joppa, MD. You can contact LW member @Gregg From Keystone Sewing to arrange a visit.

-

Pfaff 145 H3 for fabric - not leather - what is the difference?

Uwe replied to DanishMan's topic in Leather Sewing Machines

Very often the only difference between the leather and fabric versions of a machine are the feed dog, throat plate and presser feet. The leather versions will have smooth surfaces and the fabric version will have teeth or knurled surfaces on those parts. The parts are generally easy to swap out and you can turn most fabric machines into a leather machine by installing parts with smooth surfaces. -

Just some pictures of the original Consew 287 to preserve for posterity here on LW (which hopefully will live longer than that facebook post or facebook itself). It's a nice machine, really. Very likely made by Seiko, and probably worth the asking price.

-

Pfaff 545 - Tread Pickup Lever Lifting Product Up

Uwe replied to Kryptonite's topic in Leather Sewing Machines

We'll need that video or at the very least some close-up photos that show how the leather is lifted. It's just a wild goose chase otherwise. -

Suspended edge guide doesn’t fit right? What to do?

Uwe replied to myjtp's topic in Leather Sewing Machines

As mentioned earlier, a simple low-profile M5 screw like the one pictured below may be all you need. I order mine from Open Builds (https://openbuildspartstore.com/low-profile-screws-m5-10-pack/) Edit: I just now noticed that you're using the KB-267 adapter bracket. That bracket can be used in four different orientations to provide offset combinations of up/down and left/right. It looks like you have it in the up-left offset position. Try the down-left position instead. -

Sunstar km-380 cylinder arm machine

Uwe replied to davehorseblanket's topic in Leather Sewing Machines

I don't actually do much sewing beyond testing that a machine works as it should. I generally don't make products with sewing machines, I make products for sewing machines. I'm trying to sell most of my machines once I fix them up, except for a select few "keepers". The KM380 is actually a nice machine, but parts are getting nearly impossible to find. I eventually scored an OEM feed dog and an arm cover plate. Throat plates are positively impossible to get - I tried for over half a year. I ended up modifying a throat plate made for the Adler 69 to make it work on the KM380, just so I can make the machine functional. The modification was simple enough, grinding out the underside of the throat plate to make room for the swiveling feed arm to also move up and down. In my mind, the downsides of the slim arm full motion feed dog machines has nothing to do with the function. The full motion feed dog is definitely a plus in my mind, save for certain binding applications as mentioned in earlier posts. The main problem I see is that these slim arm full feed dog motion machines are so rare that nobody bothers to make parts for them (unless they're current OEM production models.) -

So which Consew model did you find comparable to the Durkopp Adler 669?