-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

You're gonna tell us what was wrong and how you fixed it, right?

-

The presser bar of the 45K5 does look like it would also accept regular presser feet with the flat mount point at the bottom of the presser bar. The roller foot appears to just clamp to the round portion of the presser bar above the flat mount point - at least that's what the pictures seem to indicate. Sometimes the different subclasses have only very minor differences with only very few parts swapped out.

-

Page 20 of the Pfaff 1245 manual has a dimensioned CAD drawing for the table cutouts, which is a reasonable starting point as well (alas, they tell you every dimension EXCEPT the actual main cutout size!) ba_1245_05-12_e.pdf

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

Singer 45k - clutch motor or treadle sewing machine

Uwe replied to Buster2008's topic in Leather Sewing Machines

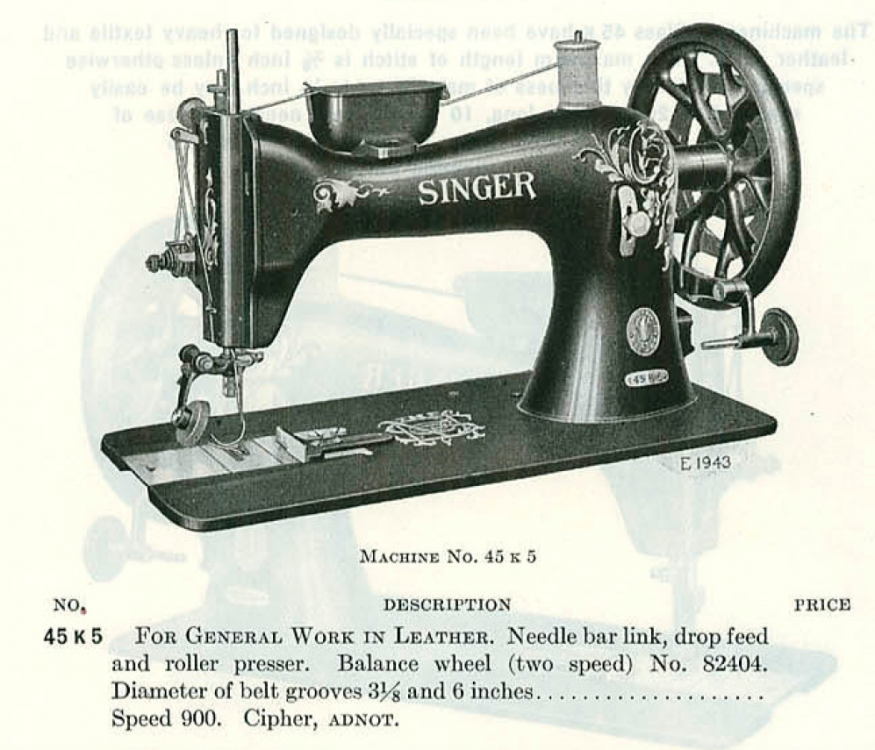

The Singer 45K came in both flatbed and cylinder arm versions. Lots of subclasses were made over time (Description of Singer 45K sublasses). Make sure the ones you're considering will fit your needs. Reading the Singer 45K manual (Flatbed) or Singer 45K manual (Cylinder Arm) ahead of time will help understand what you're getting yourself into. -

Looks like the 45K5 was designed for roller feet which may be pricey (there's one on Ebay right now for $117 : http://r.ebay.com/AMAUJB ) I've not tried to install other feet on a 45K so I can't comment on that. I do know that 45K hooks are readily available from various sources, including me http://r.ebay.com/WCsheT

-

What you end up getting for the machine depends on a lot of factors (condition, accessories, location, shipping cost, market - is there a buyer ready, able, and willing at all?) Sometimes a perfectly good machine will not sell because everybody who wants one already has one. People who buy machines intended for resale generally pay much less than what you could potentially get from an end user. Another LW member managed to sell a pristine, like-new Durkopp Adler 204-64 a few years back for just over $2K, it appears. If you want more than $700 for yours, you'll have to step up your photography game. Blurry pictures do not help your case for getting top dollar for your machine.

-

31-15 Roller Foot Conversion--parts don't add up!

Uwe replied to oxeyenyc's topic in Leather Sewing Machines

The Singer 31-15 was not really designed to accommodate any roller feet, it seems. At least the parts manual for the Singer 31-15 doesn't show any roller feet options. Sometimes you get lucky and a part designed for another machine fits and actually works. I'm guessing that your big roller foot ends up being much taller than a regular foot, and the standard presser bar does not have enough of an adjustment range to accommodate the big roller foot. You may be out of luck making the big roller foot work with your existing presser bar, even though you can mount the roller foot. Perhaps that is also why the original roller foot you bought came with a special presser bar to make it work. -

In my experience hauling a top-heavy sewing machine in a trailer is a bad idea. If the machine is not tied down inside the trailer it's a VERY bad idea. You're lucky the whole thing wasn't upside down when you got home after driving two hours.

-

An original Durkopp Adler 204 in good (as in "nice") condition both mechanically and cosmetically wouldn't leave Garden City for under $1500, but that's just me. Of course some people's definition of "good" is just few screws away from "for parts only". A picture or two sure would help a lot in determining potential value.

-

Some screw has probably worked itself loose over the past five months of regular use. Something is now slightly out of place and occasionally catching something else. You have to find out what it is and put it back in place and tighten it down. "Muscling through" is almost never a good idea if it's the machine itself that's causing the hang-up, as opposed to the material. Disconnect the motor belt and turn it over by hand (don't reconnect the motor until you have this figured out.) It's the only way in my experience to really feel the machine and find tight spots. When you find a tight spot or a hang-up, wiggle the handwheel while looking at every moving part to see if anything is out of place. There will likely be rub marks or scratches evident as well. Remove covers to see what's going on. Remove throat plate, take out the hook and see if it still happens. That'll take considerable time, but MUCH less time than shipping it off to Gregg to have him do essentially the same thing, or repair something once something actually breaks.

-

Having a dealer close-by who's personable, knowledgable and motivated is a big deal and worth a LOT all by itself. If you get good vibes from them, then the machine you're considering may be a perfect fit with great support. I personally really like the Juki LS-341 and LS-1341 class of machines and a well-done clone or re-badge is the prudent choice for many crafters. The same-factory-different-label cooperation between OEM and secondary custom branding is somewhat rare in the sewing machine world but it does happen. The Durkopp Adler and Global brands are one example. DA makes post bed machines at the Minerva plant in the Czech Republic. DA bought the Minerva plant from Global and made some cooperation agreement. All the machines come off the same assembly line, but the higher-end machines with more bells and buttons get the DA logo, the basic machines get the Global logo. Juki does operate factories in both Japan and China to my knowledge and who knows what goes on behind closed doors during the night shift.

-

What is this old German cyclinder machine a clone of?

Uwe replied to alexitbe's topic in Leather Sewing Machines

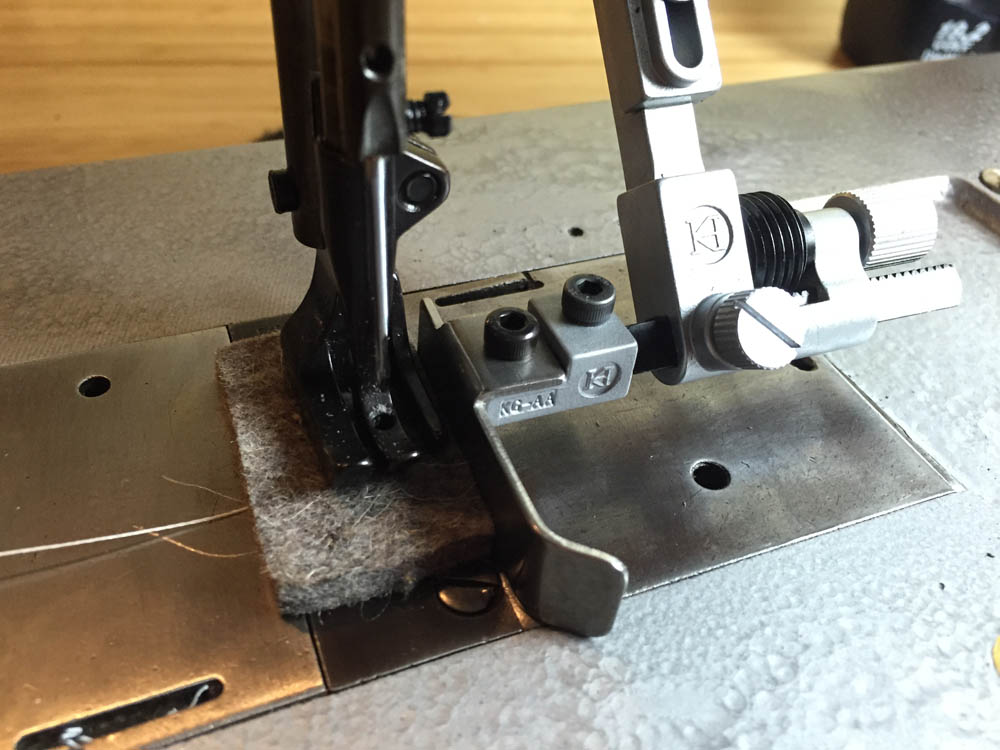

It appears to be a Köhler 17-61 based on the info and pictures on this web page: http://www.naehmaschinenverzeichnis.de/verzeichnis-der-naehmaschinen/altenburg-köhler-textima/ The machine does have an optional walking foot mechanism that can be engaged and disengaged. That shaft across the back is there for that reason. Installing the walking foot and moving the screw indicated in the picture from the lower to upper position enables the walking foot. The walking foot installs on the front presser bar, but sits behind the needle. It's an unusual design and finding these specialty presser feet may be hard or impossible. Unless your machine comes with a box full of parts and feet, it may not be a practical candidate. Here's a picture with the optional walking foot installed: -

I had a similar thing happen to my Adler 205-370 about a month ago, just a few octaves lower. Two days before I was to deliver a custom binding workstation I had built around the Adler, it developed a low-pitched groan when I turned it over by hand very slowly. Something was rubbing that shouldn't be rubbing and it was unacceptable. After oiling everything I could think of and a dozen more places with no improvement, I started disassembling things to see if the groan would stop at some point - it didn't. The machine was in pieces and so was I. The following day, in a last-ditch effort, I took the hand-wheel off and, by golly, the groan was gone! It was so well oiled that I could easily turn it over by grabbing the shaft itself. It turns out the needle position sensor mount was the root cause. I had added a washer because the screw that came with the adapter was a tiny bit too long. Alas, the washer pushed against the hand wheel instead of the shaft. The groan started days later when I went over all the screws one more time to make sure everything was nice and tight before delivery. This last tightening pushed the handwheel towards the housing and started to rub and groan. I changed the screw for the adapter, got rid of the washer and all's been well ever since. So the basic approach recommended above - to oil everything and then start removing things - is a good, methodical approach.

-

Anyone heard of this brand of sewing machines?

Uwe replied to kubacik's topic in Leather Sewing Machines

For local support and agents, you need to take a close look at Minerva Boskovice (http://www.minerva-boskovice.com/), right in your back yard. They produce for Durkopp Adler and Global. Seriously high-quality stuff. -

Anyone heard of this brand of sewing machines?

Uwe replied to kubacik's topic in Leather Sewing Machines

I've come across the Strima website on a few occasions. They seem to have a good web presence and have a serious business going including their own house-brand TEXI. They're located in Poland, which is probably within day-trip distance from where you are. Shipping sewing machines is always risky. Sieck (http://www.sieck.de/) in Bayreuth, Germany may actually be closer to you - they also have nice used and new gear, including used original Pfaff 335 for 1500 Euro (http://www.sieck.de/maschinen/naehmaschinen-taschen-lederwaren-herstellung/armnaehmaschinen-dreifach-transport/details/7283/). -

There are very few true Juki LS-1341 clones out there, actually. Most clones are based on the older Juki LS-341 design, the predecessor to the 1341. The info on the Kobe House brand's Japan Sewing Machine & Supply Co. website is a bit sparse. Do you have any pictures of your Kobe 1341 clone?

-

The clones sometimes need considerable setup and tweaking out of the box to make them cooperate. Usually the dealer does that. If you're doing it yourself, here's the engineering manual for the Juki 134x series to help with that task: http://semsi.com.mx/Manuales/JUKI/LS-1340&42-7EM01_e.pdf

-

pfaff 545 hinge Will Pfaff 1245 hinge blocks fit a 545

Uwe replied to clintooo's topic in Leather Sewing Machines

Those Pfaffs are very nice machines. I have a Pfaff 545 H4 N10 version that I'm working on. I just ordered a new hook for it, but it hasn't arrived yet. I usually go on a manual hunt whenever I start working on a machine. I came across a 1979 edition of the Pfaff 145/545 manual in english and with nice quality pictures. It has some inconsistent page sizes, but overall the quality is quite nice. I ran OCR on it to enable text searching and uploaded it here: http://docs.uwe.net/Pfaff-145-545.pdf The 118-page parts manual for the Pfaff 145/545 hints at the complexity of this class and many subclasses of this machine: http://docs.uwe.net/Pfaff-145-545-Parts.pdf By the way, the administrators of this site can attach files to posts that exceed the normal upload limits. The Pfaff 545 needle bar (part# 91-710650-92) is available aftermarket for around $18: http://www.ebay.com/itm/NEEDLE-BAR-PART-91-710650-92-fits-PFAFF-335-WALKING-FOOT-/290918359686 Not sure how well they work, but it may be worth a try. -

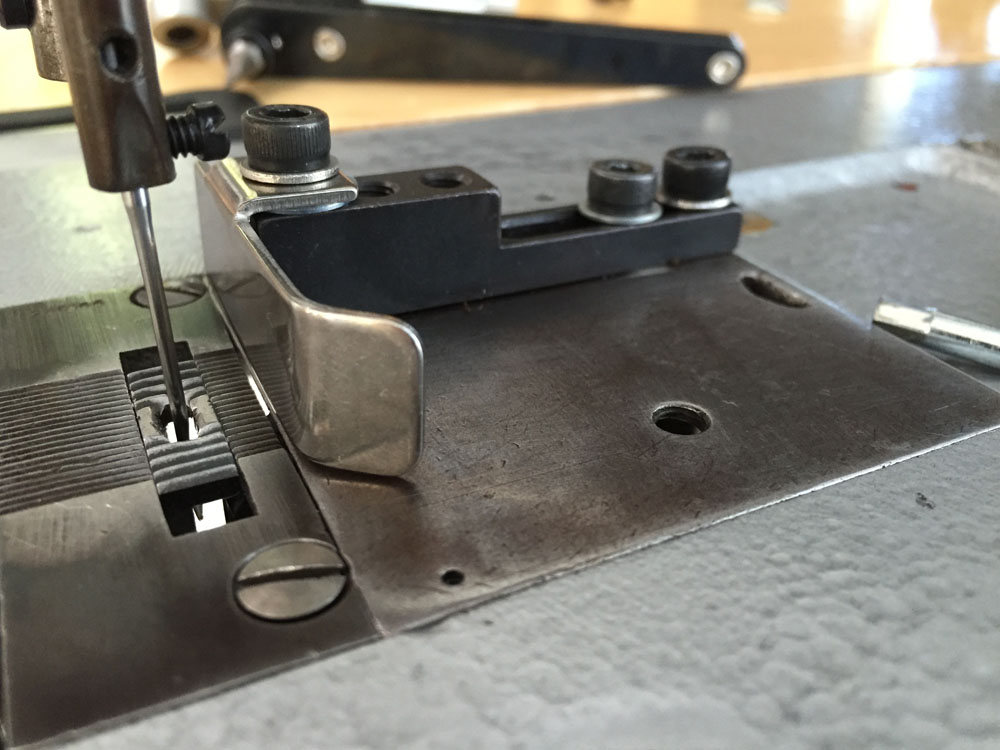

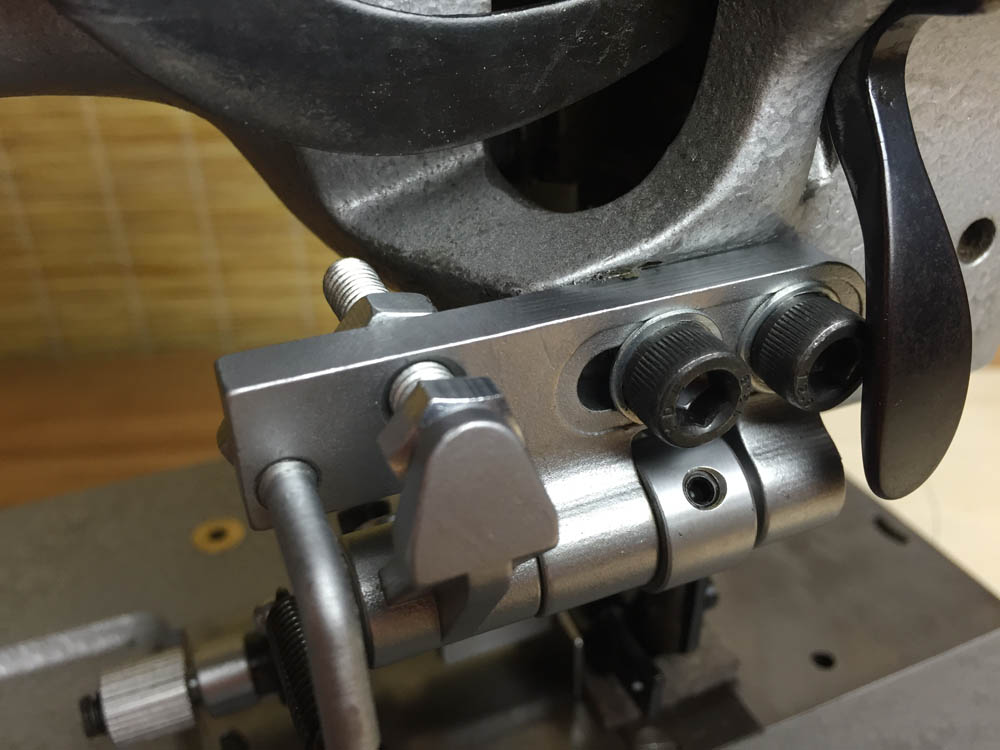

I installed a similar type guide (KG-867 by Kwok Hing) on my Consew 225 a while ago. Your installation with the offset bracket definitely has more range to the right. Mine also needs mounting screws with lower profile heads. The straight guide that comes with your set is really a zipper guide, but I'm sure it'll work fine for other applications. I sell the updated Kwok Hing version of the guide (KG-867) for $70 on my Ebay store. I recently ordered a few things from Kunpeng to check out their quality. I also cobbled together a straight edge guide mounted to the right slide plate from Kwok Hing parts I had lying around. This approach is handy if you have multiple slide plates that you can quickly swap out.

-

Singer 31-15 (What is this bracket for?...)

Uwe replied to danicarby's topic in Leather Sewing Machines

Beautiful work on restoring that machine and table! Very interesting and informative blog post on the restoration project! -

Inconsistent tension- knots visible alternate top/bottom

Uwe replied to PigeonTreeCrafting's topic in Leather Sewing Machines

One other possibility is that your foot pressure is a little too light. Your sample shows no foot pressure marks at the top at all - very pretty and usually what people want. Alas, the material must be held down by the presser feet while the knot gets pulled up into the material. Any small variation in leather density may cause trouble if the foot pressure is too light. The material may lift up as the thread take-up lever is trying to pull the knot up into the material and the knot stays at the bottom. The bobbin thread also goes slack a little bit as the material comes down again. The next stitch will have loose bobbin thread, causing the next knot to get pulled to the top on that stitch. At least that's how the sewing machine in my head works Your stitch samples shows this kind of knot pattern like ---v^v---- (where "-" means middle, "v" means bottom, "^" means top). Watch the material as you sew to see if lifts up occasionally. -

Inconsistent tension- knots visible alternate top/bottom

Uwe replied to PigeonTreeCrafting's topic in Leather Sewing Machines

All the other stitches look really nice though! I'd check the basics first, like proper threading and timing. Thread needs to come off the spool vertically, no at an angle to avoid snags. Make sure you can manually pull top and bottom thread very smoothly, without any snags. A poorly wound bobbin may cause uneven knots. Perhaps the thread comes off the spool in jerky fashion for some reason. Some spools are sticky or wound weirdly and cause snags. On a test piece with fingers far away from the needle, sew a stretch watching the thread path instead of needle area. Try some pre-wound bobbins if you can get your hands on some, just to compare to your self-wound bobbins. Listen for any weird noises when the offending knots happen. If something interferes occasionally with the smooth movements of the machine, odd things start happening. Does this happen when you stop/start the machine? -

Perhaps Seiko needs to be mentioned in that conversation. Seiko manufactured the Consew 206RB1/2/3/4/5 machines for Consew. Consew does not actually manufacture anything of their own to my knowledge, they just sell things others make with their label on it. Consew started sourcing the RB-5 from a manufacturer in China at some point. When exactly that was may only be known by people who signed a non-disclosure agreement. If you want to make sure you get a Consew 206RB-5 machine made by Seiko in Japan, buy a Seiko STH-8BLD-3 instead (But I'm not even sure that statement is 100% accurate). The Seiko STH-8BLD-3 I have definitely states "Made in Japan" on the sticker. If you want to make sure you get a Consew 206RB-5 machine made in China, buy one that was made within the last five years or so, to be on the safe side.

-

Most people do correlate origin with quality, especially if China is involved. It's unlikely that Plasmaguy wants to make sure he's buying a machine made in China and avoid the ones made in Japan. Look at the tags and stickers, if it's made in Japan it will likely say so. If it's may in China it may also say so, or more likely not say anything about country of manufacture.

-

The Tacsew T111-155 has an oil sump and an oil pumping system. There should be some way to regulate how much oil is being pumped to the top. Perhaps you can dial back the oil flow until things are lubricated properly but not spewing oil. I'm still puzzled why Tacsew would name a machine 111-155, as if to purposely confuse scores of people and make them think the machine has anything in common with the Singer 111W155. Even Cory got tripped up on his Tacsew 111-155 blog post with nice pictures of the oil pump system.