-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

One way to look at it is you take the total amount you paid for the thirty machines at the auction, divide that amount by 30, and - voilà - that is exactly what these machines were worth to you. A great starting point. Double that amount if you want to make a 100% profit.

-

They're worth whatever somebody is willing to pay. Transportation cost can be significant, too, with these behemoths. Auction items can be tricky to value because you have zero history on them - they were either "working when removed from factory," or they were beyond-repair parts machines they kept around to scavenge parts from as needed, or something in between. We actually have a member from Campbell Randall on the forum (user name: CampbellRandall) . He (or she) may be able to tell you (privately, perhaps) how much they offer for machines they take in to be refurbished, and how much they cost in perfect working condition after having been refurbished by them. The value of yours will lie somewhere in between, likely towards the bottom end of the range. It shouldn't be too much of a secret, really, the fellow who runs the Landis operation gave me useful ballpark value figures for the Landis 16 I recently acquired.

-

Fomax KDD 848H - what original is this machine based on?

Uwe replied to Uwe's topic in Leather Sewing Machines

I had come across the SewMaq twin of my mystery machine in a previous picture search. Unfortunately it also suffers from a total lack of manuals or parts diagrams. At least the sales flyer offers some basic specs of the machines. Thanks for all of your input! I've decided to tell the guy who owns the FOMAX mystery machine that he's out of luck, at least outside of Spain. -

Fomax KDD 848H - what original is this machine based on?

Uwe replied to Uwe's topic in Leather Sewing Machines

This machine clearly calls for the ten-foot-pole in my repair tool chest that I use NOT to touch certain machines with. -

Consew 225 (twins of the SInger 111W155) are great starter machines, both for learning how to sew with industrial machines and how to maintain/adjust them. Parts are readily available and cheap, should you need them. A new servo motor may be a worthwhile investment right upfront. I have a few videos on YouTube about this class of machines, including a hook adjustment video wich may be useful if you end up buying the machine:

-

Doing a Google search like "site:leatherworker.net Pfaff 145" will bring up previous discussions about a particular machine model or class (like Pfaff 145/545/1245), like the one listed below. Pfaff in general are high quality machines, with comparatively expensive, but generally available parts. General previous discussions about using Flatbed vs. cylinder arm machines for various flat vs three dimensional projects apply. The Pfaff 145 should do well with flat projects like upholstery and belts, but stiff bags my present a challenge.

-

Wrap a fabric tape measure around both of the timing pulley/cog wheels, just like the timing belt would run. Measure the overall length, how far the teeth are apart, and how wide the cog wheels are. That will tell you just about all there is know about a timing belt.

-

The middle Letter (G,A,W, etc.) usually indicates in which factory the machine was produced : http://www.sewalot.com/dating_singer_sewing_machine_by_serial_number.htm Some Singer manuals will give a brief description of the various subclasses.

-

Advanced Sewing Technologies Corp. is one of the big boys in used sewing machines supplies. They publish a monthly inventory spreadsheet, which currently shows one Singer 211A157AA, plus several other needle feed machines with reverse that may be suitable candidates. You can contact them for a quote of a specific model you're interested in and they send you a price and a picture of the machine.

-

Gave up on the antique Singer; bought refurbed Juki!

Uwe replied to horselady21's topic in Leather Sewing Machines

I'm glad you got it figured out. Feel free to call me directly if you run into trouble with that machine! -

Pictures always help identifying machines, parts, or variants thereof. Post some detailed close-up pictures of your SV machine, including the underside and all the bits you mentioned in your initial post.

-

I looked at a customer's Fomax KDD 848H machine today that needs repair (broken stitch dial mechanism). The machine was imported from Spain. I have a feeling the Fomax is a copy of some other major brand model but I'm striking out on Google and my other usual research sources. Does anybody recognise this design and/or know of a source for a parts diagram? It has a distinctive stitch dial detail:

-

Thanks Eric. I totally get that for a large operation like yours there are different considerations and decision criteria in play, compared to a craft person with one or two machines in the shop. In a factory the question usually is "which machine is the best option for this particular sewing operation?" For a crafter, the question usually is "How can I adjust this one versatile machine I have to do this particular sewing operation well?" I have a strong feeling that a compound feed sewing machine is perfectly capable of producing non-puckered seams on waxed canvas, given the right thread, presser feet, and adjustments. I also strongly suspect that thread tension top+bottom plays a big role in puckering or lack thereof, contrary to statements made earlier in the thread. Waxed canvas has been on my to-try list for a while. I just got a sample book of waxed canvas from Carr Textile and I'm going to order a few yards to experiment with.

-

Perhaps I'm missing something but I'm not following the logic on why a needle feed machine would cause less puckering than a compound (top+bottom+needle) feed machine. Can somebody elaborate on why and how a compound feed would cause more puckering? The only thing I can come up with is that a needle feed machine may not move the material 100% of the way, but only, say, 95% due to the needle flexing a little as it's pulling the material forward. That slightly shortened material movement may alleviate puckering. A properly adjusted compound feed machine will move the material 100% of the way (which is the point of that design).

-

It may be the generator that turns 120V AC into 240V 3-Phase AC to drive the motor. Weird, interesting, and potentially dangerous. Personally, I'd take some pictures to document it, remove it all and install a modern servo motor.

-

This machine is sold.

-

-

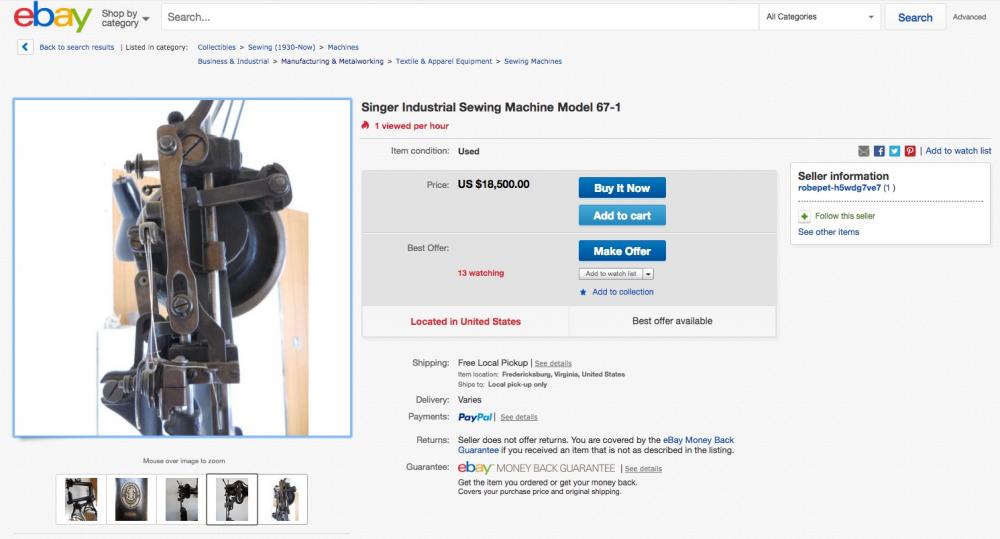

Fun and EXPENSIVE! Quite the monster, but the owner may be optimistic about its value. The Ebay listing may disappear without notice, so here's a few screen shots to preserve it for posterity:

-

Eric posted a detailed case study of this machine some time ago: Value of a machine is exactly whatever somebody is willing to pay for it. Actual sold listings on ebay range from $400-$500, so that's one reference point. The machine you're looking at may be worth more, less, or it may be a boat anchor candidate.

-

Ouch. One golden rule of sewing machine maintenance is to never loosen a screw unless you know exactly what it does, especially on machines you depend on for production work. Project machines are a different story. Not sure how you "fixed" the timing if you don't have a manual. Some of your statements sent a cold shiver down my spine. You need to get hold of the proper service/adjustment manual for your machine and go through the steps in sequence to get things back in working order. Toledo Bob apparently has a PDF version of the manual, according to another forum post. Neal of Neal's Saddlery may also be able to provide documentation since he's the official U.S. importer for Cowboy sewing machines. Why they don't just make the manuals available online is beyond me. While you're waiting for proper documentation, spend some time to figure out how to post images and short youtube video snippets, which are essential for remote, internet-based support.

- 2 replies

-

- cowboy 227

- cowboy 227r

-

(and 3 more)

Tagged with:

-

Where on this planet you live makes difference as to what's available and supported. Search the Leatherworker.net forums for models you're considering (e.g. google"site:leatherworker.net pfaff 335") Chances are good that almost any machine you're considering has already been discussed and compared at length. Among my current personal favorites in the medium duty cylinder arm arena are the Juki LS-341/LS-1341 class of machines (and their well-done clones like TechSew 2750, SewPro 1341, etc.) These machines have some of the most versatile feature set, big bobbins, large needle and thread range, without the limitations that come with a super-thin arm design like the Pfaff 335 or Adler 69 class machines (which are as good as it gets in the thin-arm designs). A good, used original will cost about the same as a new clone. Make sure manuals and wear parts are available/affordable before you buy (does a new hook cost $35 or $450?) Your budget and access to local service will be a factor in what makes the most sense. Be prepared to learn and do basic maintenance yourself. Shipping a machine around for simple adjustments is no fun.

-

Holding the top thread as you pull up the bobbin thread, and when you start sewing may help a great deal. Open the bobbin cover, turn the wheel by hand and observe what exactly is happening when you pull up the bobbin thread or start sewing. Don't just step on the pedal and wait for it to jam up. If the safety clutch pops, clear the thread jam and reset the clutch as shown in the video below.

-

It seems that a combination of high foot lift, high sewing speed and very thin material may cause some apparent banging of the presser foot against the feed dog. In general, the faster you intend to sew the lower the foot lift should be, otherwise physics gets in the way. Your Consew 226R is probably a close enough relative to a Juki LU-563 that my adjustment video might be useful to you, at least to figure how to change certain settings:

-

The motor in the mock-up picture is actually a stepper motor that I had used in another project. I used it for the mock-up because it's similar in size and weight to modular servo motor setups like the Consew CMS1000, which I had used on the Adler 69 setup shown earlier in the thread. Here's the project I used the stepper motor in:

-

I don't have any any first-hand experience using the machines, but they did have a fairly big display with a dozen or so machines on display at the recent TechProcess sewing technology trade show in Atlanta. Only a handful of aftermarket/clone manufacturers had displays there. They have their act (and website) more together than some other players in the field. The Zoje post beds are listed here: http://www.zoje-america.com/Post_Bed/index.html The clone that is most closely related (as in identical twin) to the Durkopp Adler post-bed machines is the Global LP2970. It rolls off the same production line at the Minerva factory in the Czech Republic as the authentic Durkopp Adler machines, but lacks some bells and whistles of the DA machines. DA apparently bought the Minerva factory from Global and they have some co-production and product-sharing arrangement. The killer post-bed machine that I personally NEED but will never be able to afford (likely over $10K) is the reinforced version of the DA M-Type H868. This machine is so rare, the staff at the DA stand in Atlanta didn't know what I was talking about when I asked for more info on the machine.